Beneficiating method of diaspore type bauxite

A beneficiation method and bauxite technology, which can be used in flotation, solid separation, etc., and can solve problems such as single

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

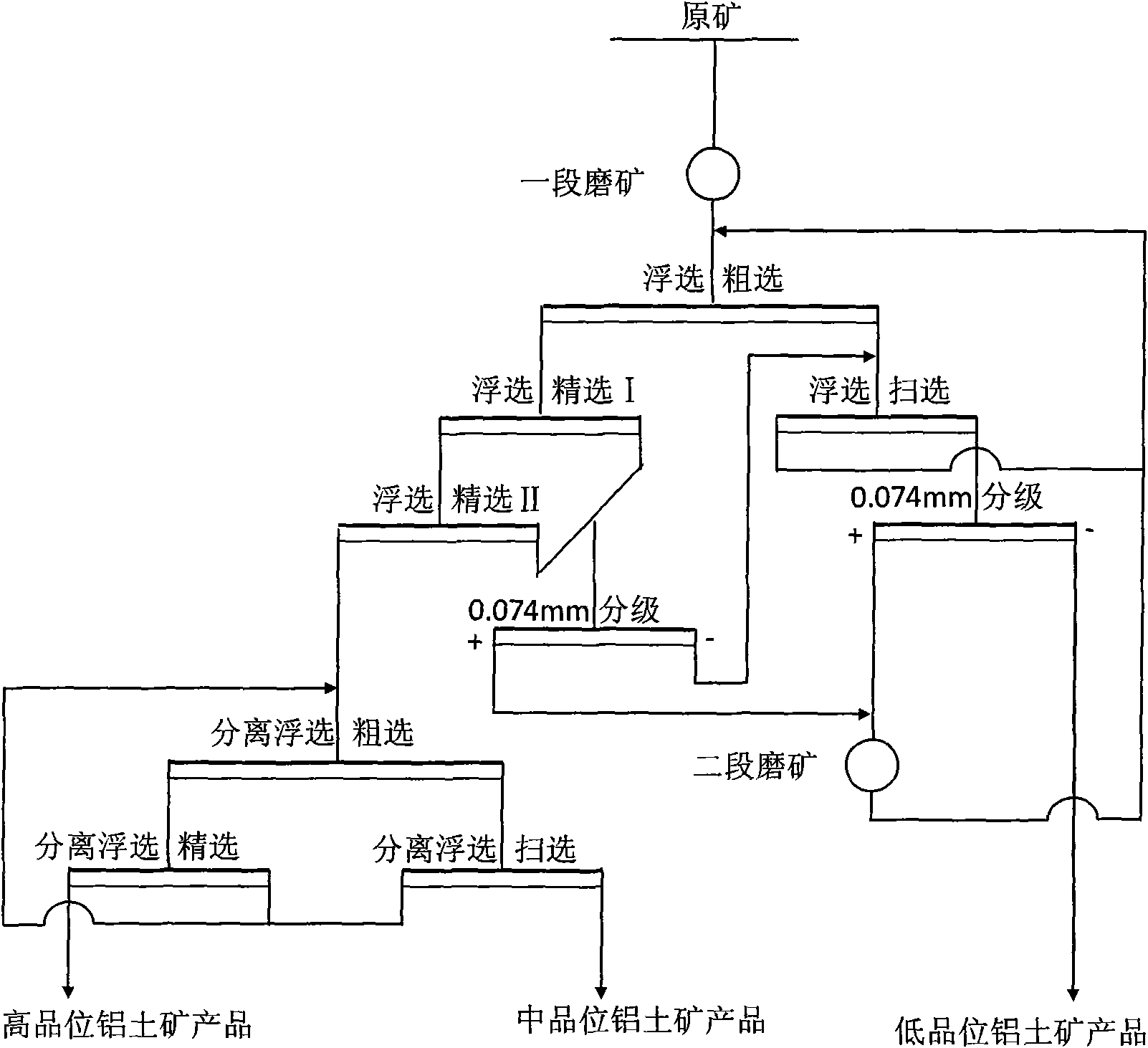

Method used

Image

Examples

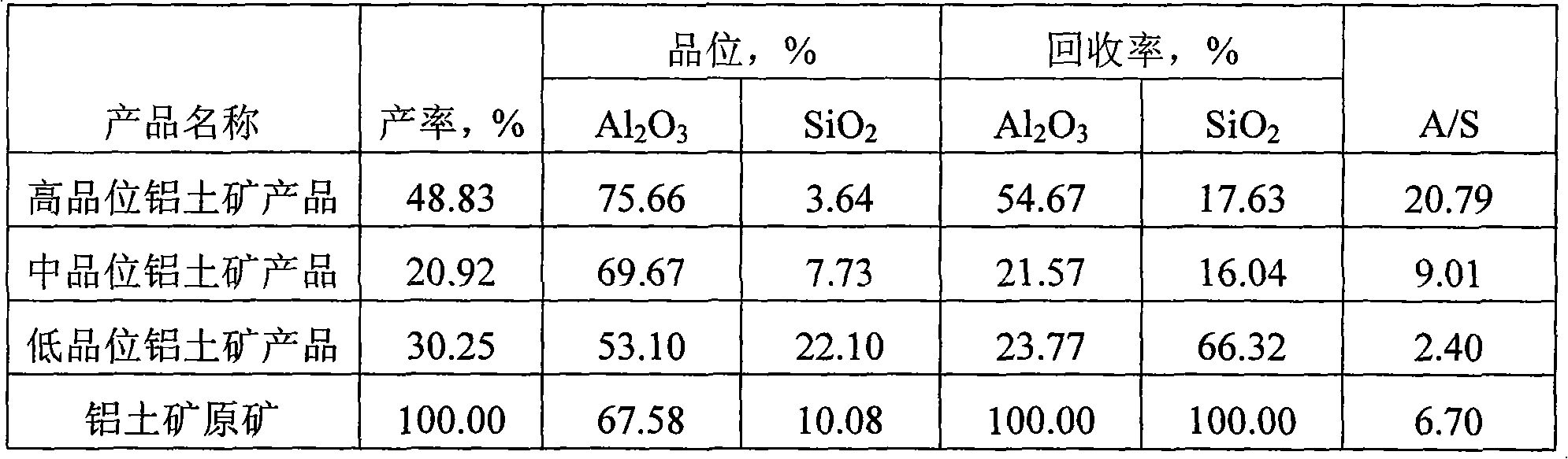

Embodiment 1

[0046] Bauxite raw ore Al 2 o 3 67.58%, SiO 2 10.08%, aluminum silicon ratio 6.70. The beneficiation and separation process includes grinding the first stage of the raw ore with a particle size of -0.074mm to account for 55%. The reagent system used in the flotation roughing is: sodium carbonate dispersant 6000g / t, fatty acid collector 500g / t, flotation time 4 minutes; the reagent system for roughing underflow sweeping is: fatty acid collector 100g / t, and the flotation time is 4 minutes; the underflow of sweeping is wet sieved with a 0.074mm sieve, and the product under the sieve is low-aluminum products; Blank selection, underflow concentration using 0.074mm sieve wet sieve, the under-sieve product enters the sweeping operation, and the above-sieve product of the two classifications is combined for regrinding (grinding fineness is -0.043mm particle size accounts for 85%) and the product and sweeping The foams are merged into the roughing operation; the foams that have been...

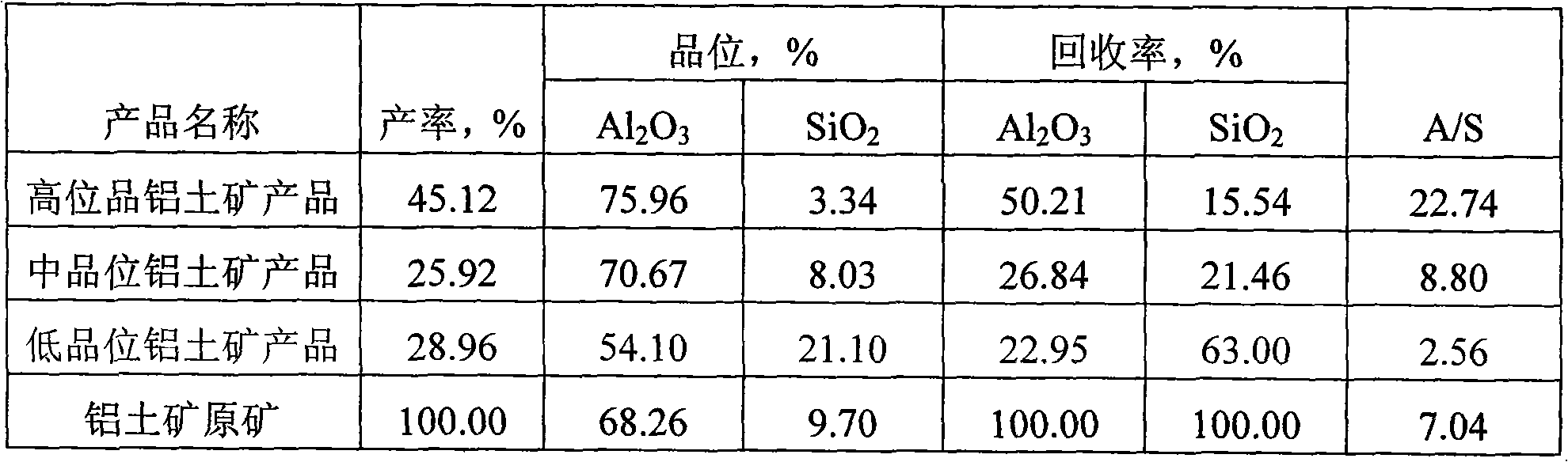

Embodiment 2

[0050] Bauxite raw ore Al 2 o 3 68.20%, SiO 2 9.70%, aluminum silicon ratio 7.04. Grinding fineness of the first stage of raw ore -0.074mm particle size accounts for 60%. The reagent system used in the flotation roughing is: sodium carbonate dispersant 5000g / t, fatty acid collector 600g / t, flotation time 4 minutes; roughing underflow The agent system for sweeping is: fatty acid collector 100g / t, flotation time 4 minutes; the underflow of sweeping is wet sieved with a 0.074mm sieve, and the products under the sieve are low-aluminum products; Wet sieve with 0.074mm sieve, the under-sieve product enters the sweeping operation, and the above-sieve product of the two classifications is combined for regrinding (grinding fineness is -0.043mm particle size accounts for 95%) and the product is combined with the sweeping foam to enter the roughing operation ;Twice-selected foam undergoes one roughing, one refining, and one sweeping to realize the separation of high-aluminum products ...

Embodiment 3

[0054] Bauxite is the test ore sample, raw ore Al 2 o 3 67.55%, SiO 2 10.61%, aluminum silicon ratio 6.37.

[0055] Grinding fineness of the first stage of raw ore -0.074mm particle size accounts for 65%. The reagent system used in flotation roughing is: sodium carbonate dispersant 5000g / t, fatty acid collector 600g / t, flotation time 4 minutes; roughing underflow The agent system for sweeping is: fatty acid collector 150g / t, flotation time 4 minutes; the sweeping underflow is wet sieved with a 0.074mm sieve, and the products under the sieve are low-aluminum products; Wet sieve with 0.074mm sieve, the under-sieve product enters the sweeping operation, and the above-sieve product of the two classifications is combined for regrinding (grinding fineness is -0.043mm particle size accounts for 90%) and the product is combined with the sweeping foam to enter the roughing operation ;Twice-selected foam undergoes one roughing, one refining, and one sweeping to realize the separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com