Parallel floatation process of desilionization for bauxite

A bauxite and desiliconization technology, applied in flotation, process efficiency improvement, solid separation, etc., can solve the problems of accelerating the tailings and concentrate settlement process, etc., to reduce organic content, increase production capacity and return water utilization The effect of efficient and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

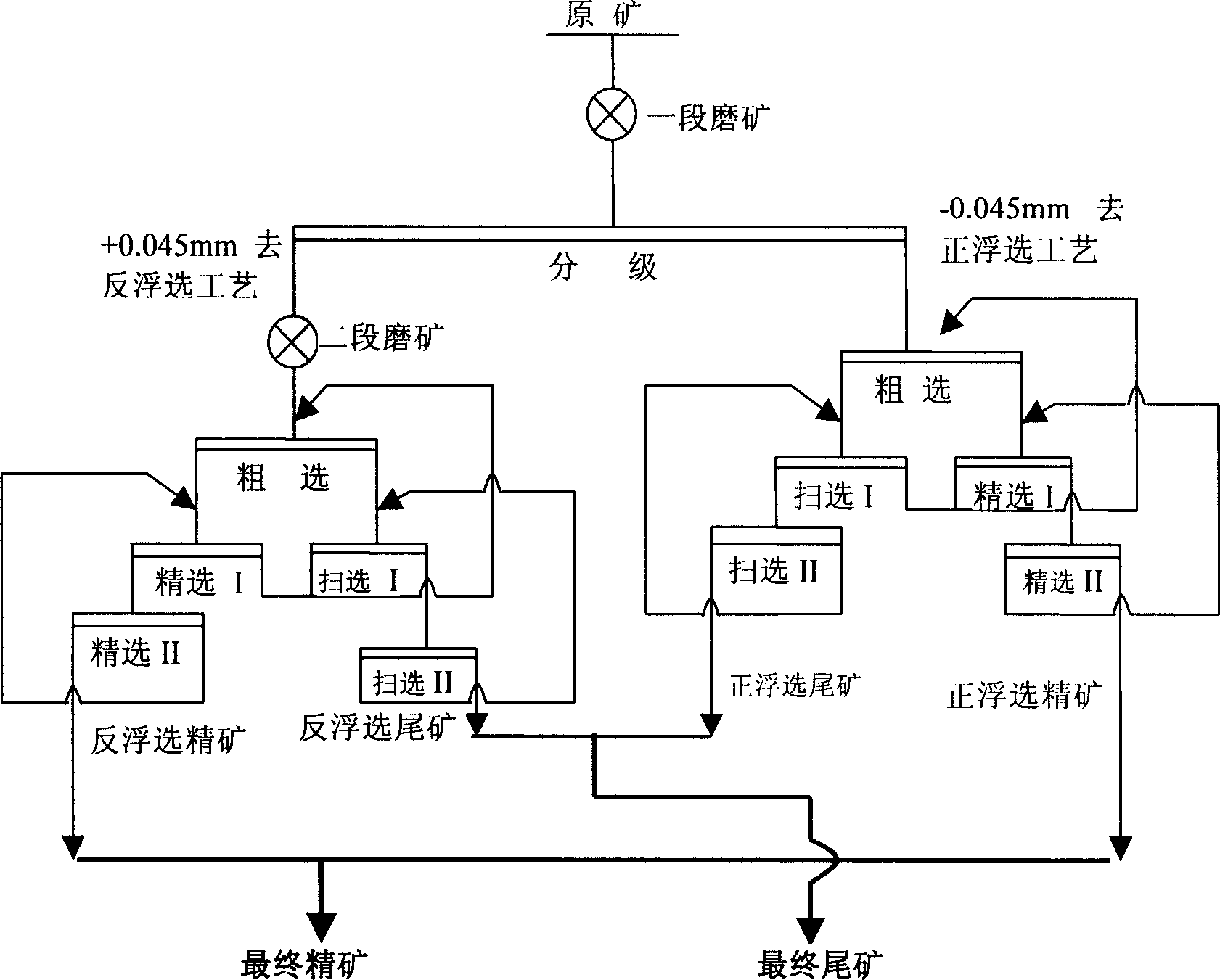

[0020] Taking the low-grade bauxite in Gongyi, Henan as the test sample, the raw ore Al 2 o 3 60.93%, SiO 2 14.88%, the ratio of aluminum to silicon is 4.09, the principle process flow chart adopted is shown in figure 1 , the specific process of beneficiation and desiliconization is as follows:

[0021] a) Grinding and grading: use a mill to grind bauxite, the grinding fineness is -0.074mm, accounting for 80%, the overflow concentration is 38%, and the grinding products are classified by a 0.045mm high-frequency vibrating screen to obtain Coarse and fine grade products;

[0022] b) Flotation desiliconization: The fine-grained products that are classified are adjusted to a pH value of 9.5 with sodium carbonate, and the regulator sodium hexametaphosphate 60g / t, oleic acid, hydroxamic acid, naphthenic acid collector 700g / t t, after stirring for 5 minutes, enter the flotation operation. After adopting the process of first roughing, second finishing and second sweeping, the foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com