Bauxite surface preprocessing-reverse floatation desiliconizing method

A surface pretreatment and reverse flotation desiliconization technology, which is applied in flotation, solid separation, etc., can solve the problems of small difference in the number of active sites between aluminum and silicon, poor process indicators, and incomplete dissociation, etc. Achieve the effect of reducing mechanical inclusions of coarse particles, reducing pollution effects, and short equilibrium time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A certain ore sample in Gongyi, Henan was taken as the test ore sample, and its chemical composition is shown in Table 1.

[0026] Table 1 Chemical composition of a certain ore sample in Gongyi, Henan

[0027] chemical composition

al 2 o 3

SiO 2

Fe 2 o 3

TiO 2

K 2 o

Na 2 o

CaO

A / S

Content %

64.05

11.21

4.88

2.53

0.77

0.14

0.79

5.71

[0028] The specific process is as follows:

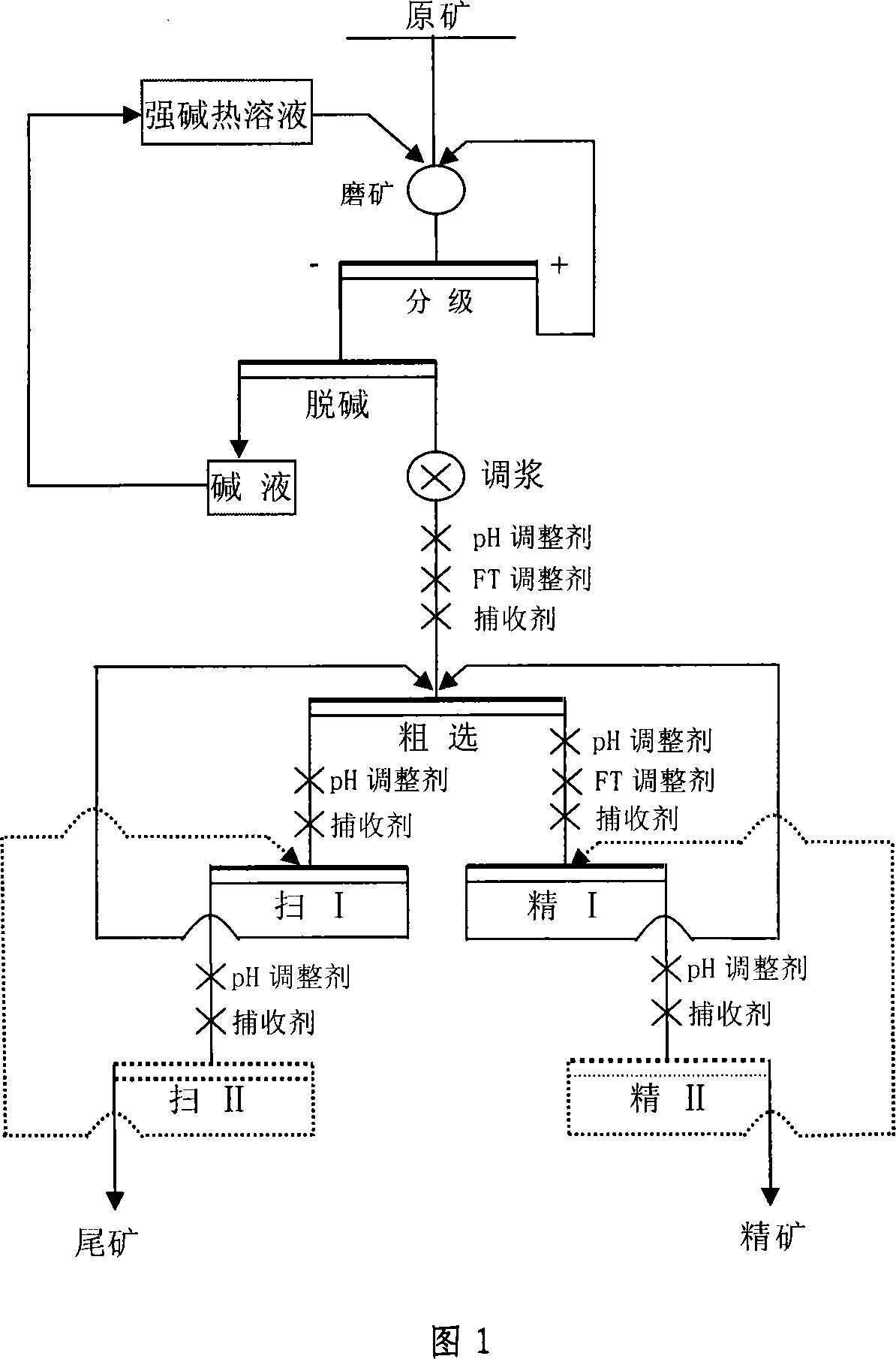

[0029] Carry out reverse flotation desiliconization according to the method of the present invention, flow process is shown in accompanying drawing 1, ore is broken to-3mm, takes by weighing 500 grams of ore and 300ml [OH - ] NaOH solution with a concentration of 100mol / l is added to the wet ball mill, the temperature of the lye is 50°C, and the fineness is -0.074mm, accounting for 75%. Slurry with water, add sulfuric acid solution to adjust the pH value, pH ≈ 6.0, then add 300...

Embodiment 2

[0036] The test sample is the same as Example 1.

[0037] The specific process is as follows:

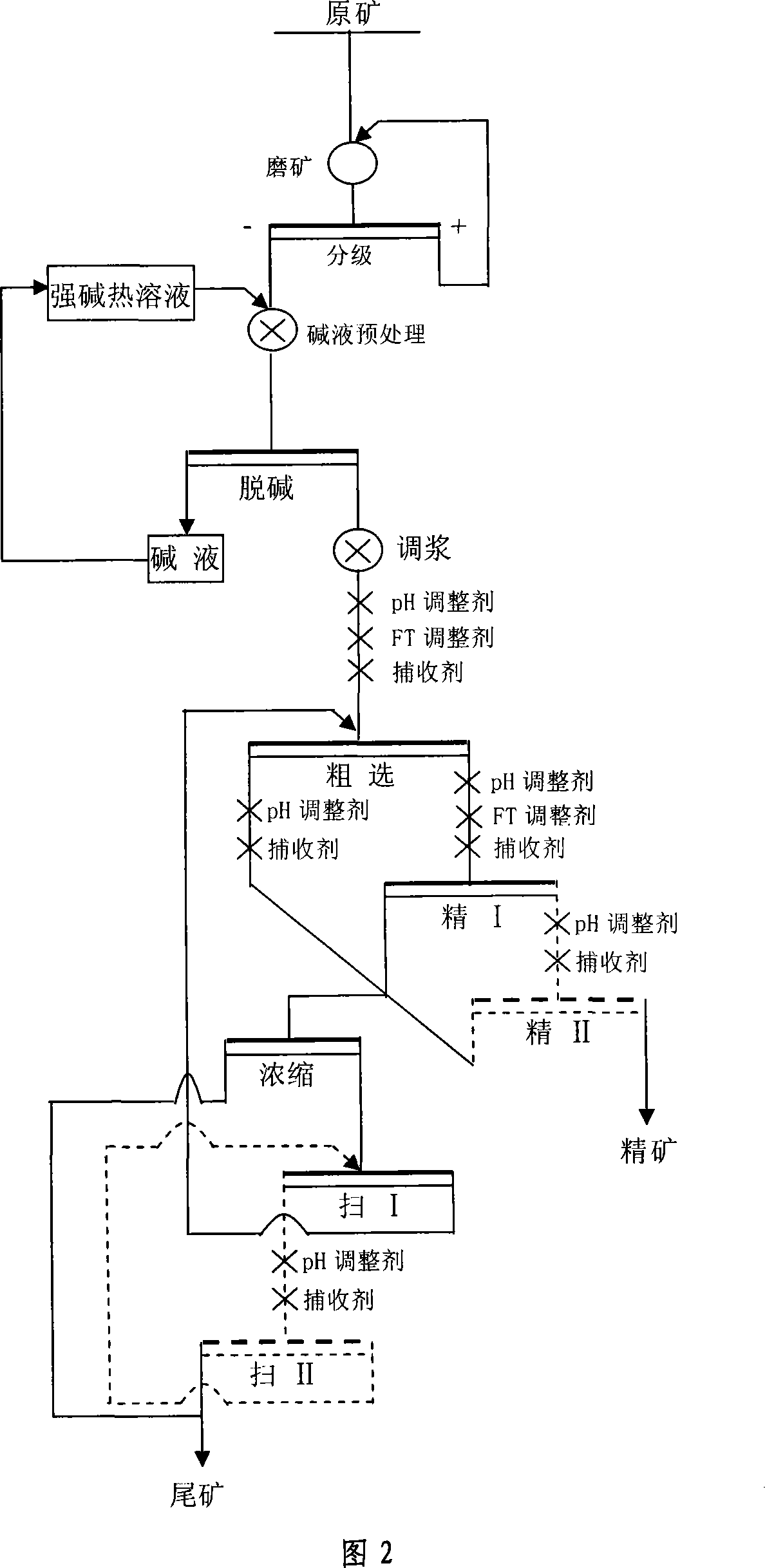

[0038] Carry out reverse flotation desiliconization according to the method of the present invention, flow chart is shown in accompanying drawing 2, ore is crushed to-3mm, weighs 500 grams of ore and joins in wet ball mill, grinds to fineness and is-0.074mm accounts for 75%, then adds [OH - ] The NaOH solution with a concentration of 85mol / l is used for surface treatment, the temperature of the lye is 64°C, and the treatment time is 30 minutes. The dealkalization is carried out by a hydrocyclone. pH ≈ 6.0, then add 250g / t of FT adjuster, 750g / t of collector, the ratio of the two components of collector is 1:1, after one roughing and two refining operations, roughing and refining Foam is selected for concentration, sand settling is carried out for two sweeps, sweep II foam is tailings, and sweep I bottom flow is returned to rough separation for separation. The flotation process indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com