Non-returning type intermittent iron remover

A kind of iron remover, intermittent type technology, applied in the field of non-returning type intermittent iron remover, can solve the problems of long time consumption of returning ore slurry, great influence, no product output, etc., so as to increase the time of ore extraction and reduce Chemical cost, effect of reducing mechanical inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

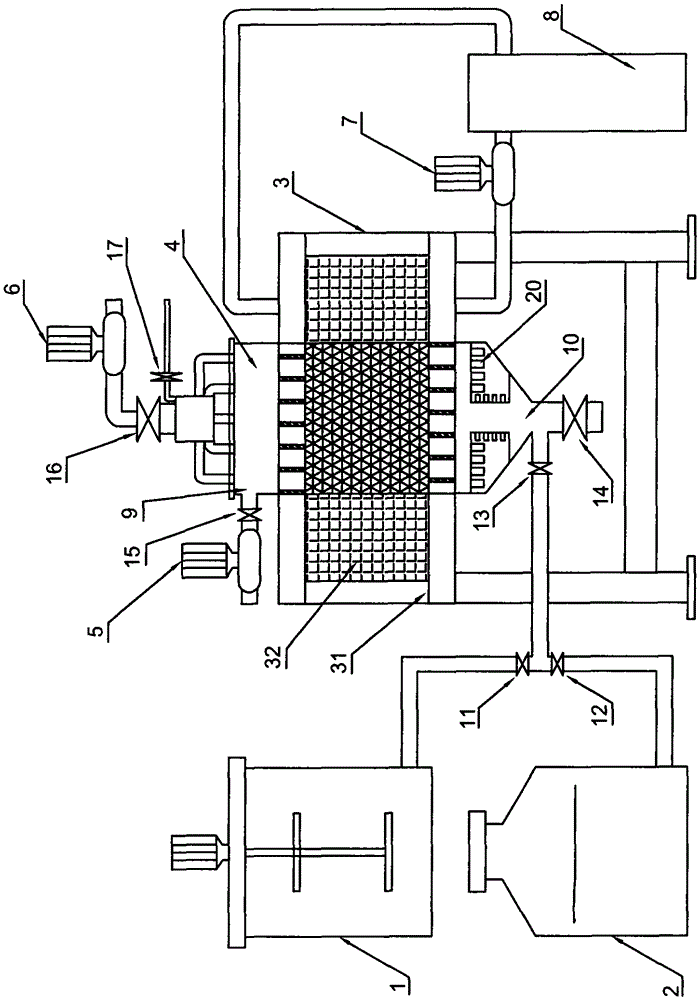

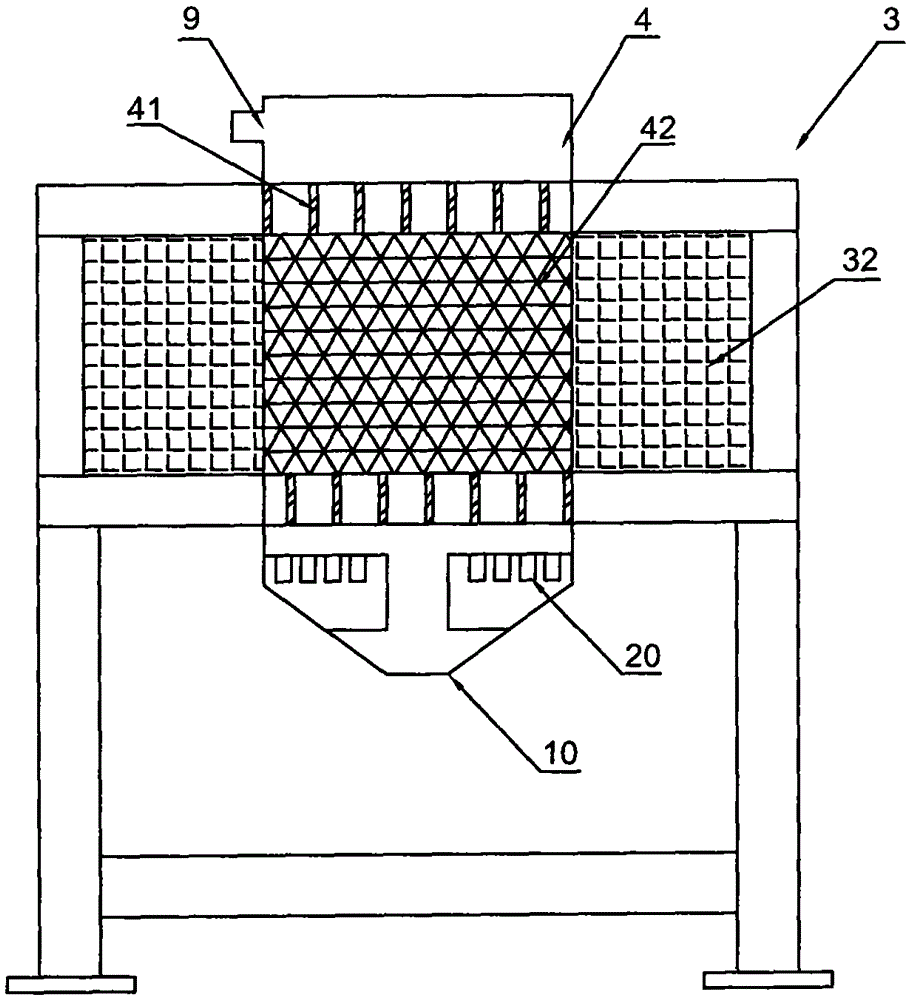

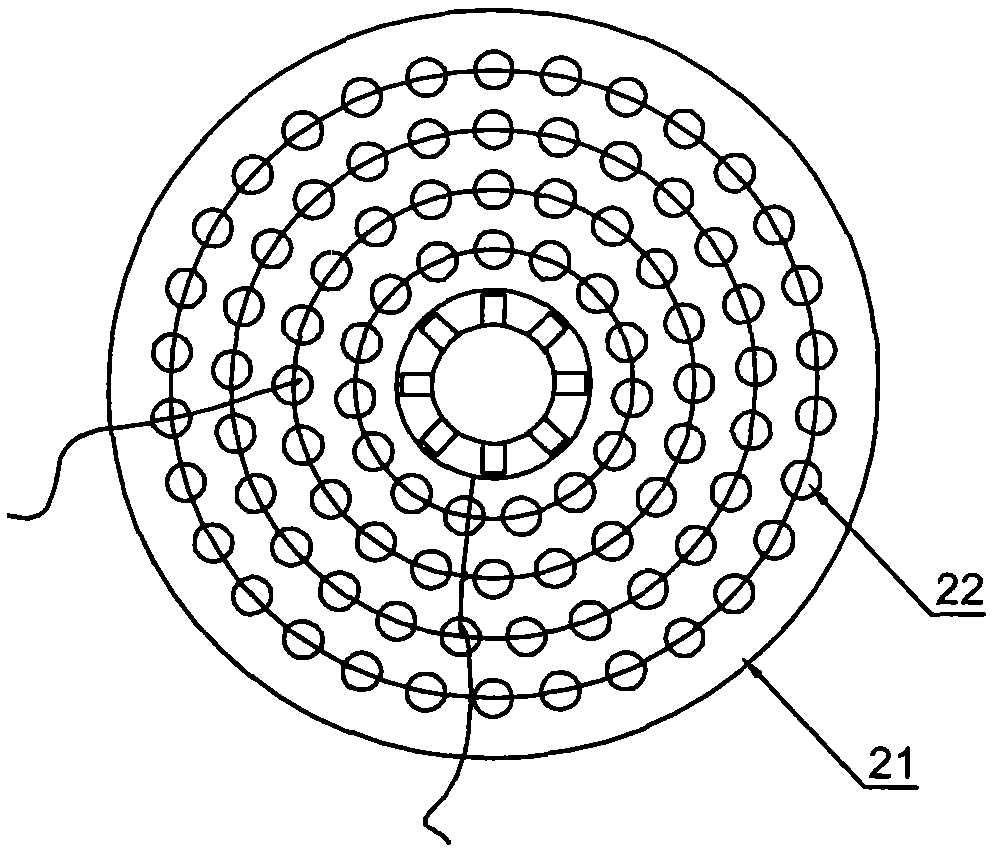

[0016] refer to figure 1 , figure 2 , non-returning type intermittent iron remover, including the iron remover body 3, the iron remover body 3 includes a frame 31 and a working cavity 4 arranged on the frame 31, and a winding is arranged outside the working cavity 4 The coil 32, the working chamber 4 is provided with a magnetically conductive pole plate 41 and a magnetic gathering medium 42, and an upper port 9 and a lower port 10 are respectively arranged on the upper and lower parts of the working chamber 4, and there are a slurry outlet pipe and an upper port 9 connection, a slurry valve 15 and a slurry pump 5 are sequentially provided at the port of the slurry outlet, and the lower port 10 is connected with a pipeline and an iron discharge pipe, and a pipeline valve 13 and an iron discharge valve are respectively provided on the pipeline and the iron discharge pipe 14. The other end of the pipeline is connected with a slurry inlet pipe and a water inlet pipe respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com