A Pillarless Segmental Caving Method for Dividing an Ore Block Along the Orebody Strike

A segmented caving method and no bottom pillar technology, which is applied in mine/tunnel ventilation, ground mining, mining equipment, etc., can solve the problems of early capital investment impact, occupying time cost, etc., and achieve shortening of production time and investment, mining The effect of less quasi-works and improving the ore mining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

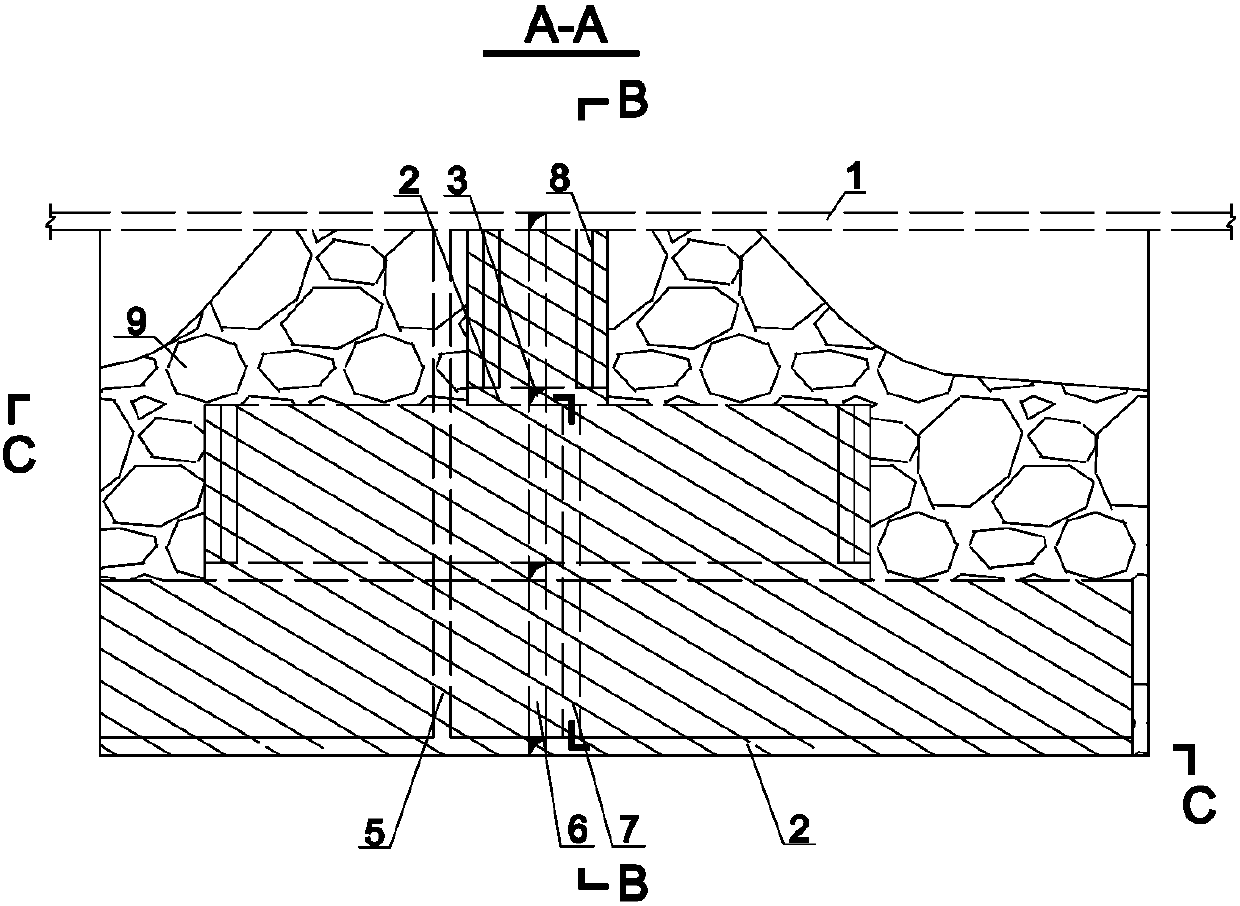

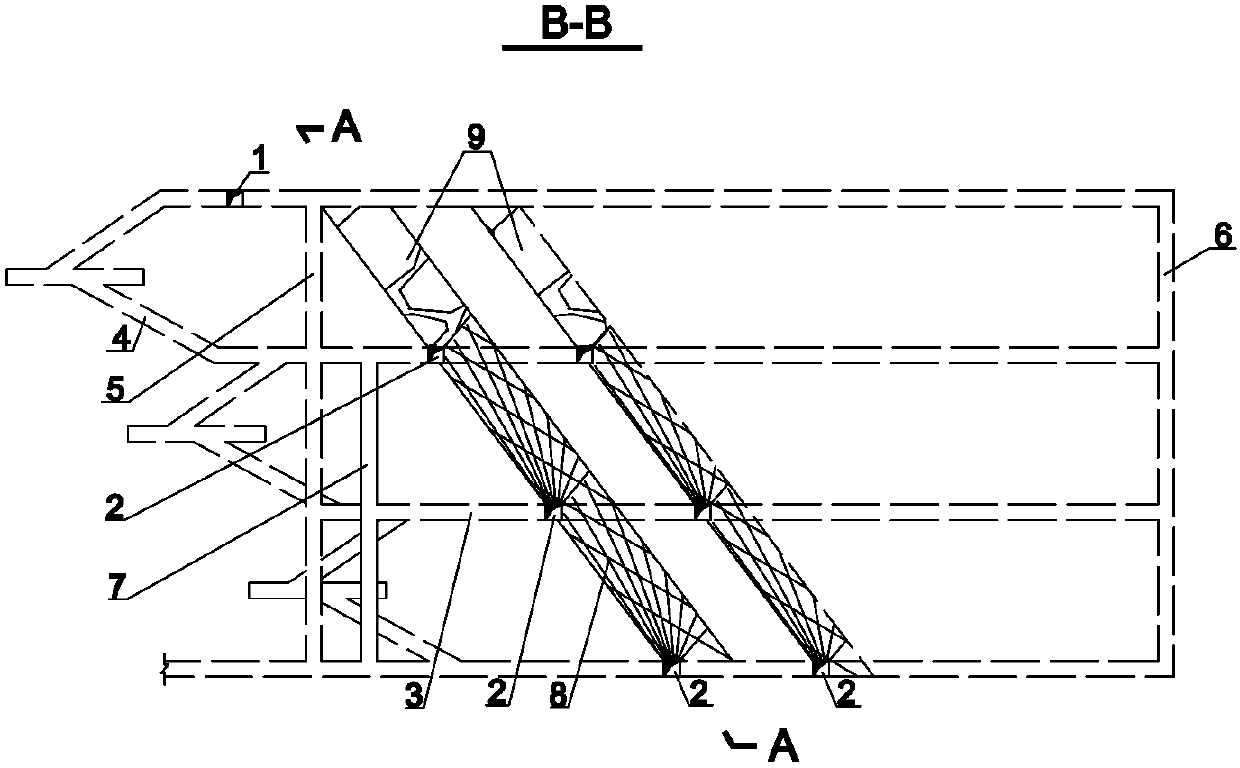

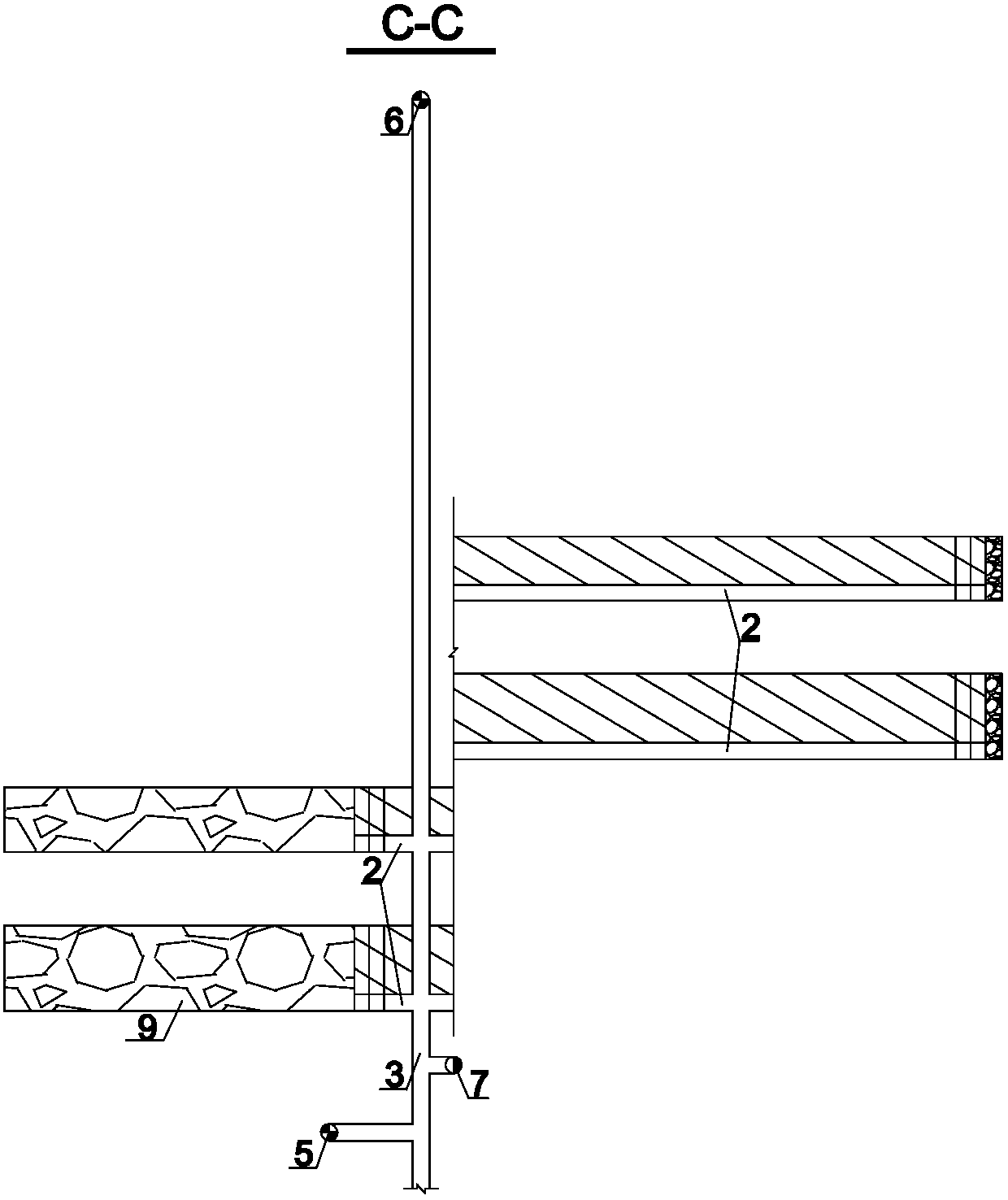

[0021] Such as Figure 1-3 Shown, a kind of non-bottom column segmental caving method that divides an ore block along the ore body strike of the present invention is characterized in that comprising the following steps:

[0022] Step 1: Divide the ore blocks along the ore body trend. The length of the ore body is the length of the ore body. The road 2 is excavated to both ends respectively; the development system and the mining system include the air return roadway 1, the air return patio 6 in the mining area, the shaft 7 in the mining area, the ramp 4 in the mining area and the air intake patio 5 in the mining area;

[0023] Step 2: The mining sequence of the ore block is from top to bottom, and the segment mining sequence is from both ends to the middle;

[0024] Step 3: Use rock drilling equipment to construct the upward fan-shaped blast hole 8 in the route 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com