A kind of acid-resistant petroleum fracturing proppant and its manufacturing method

A fracturing proppant and manufacturing method technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of general acid resistance, unsuitable for complex topography and landform areas, influence of acid resistance, etc. Achieve the effect of improving acid resistance, accelerating the time of crystal phase reaction, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

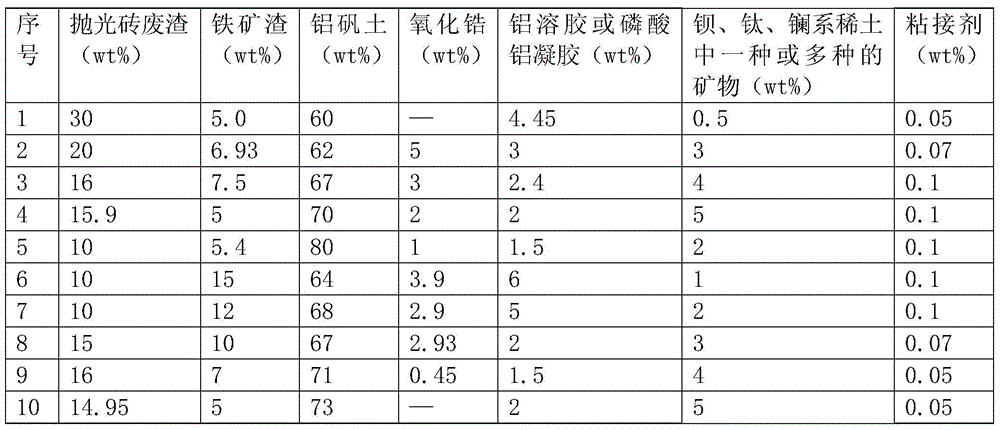

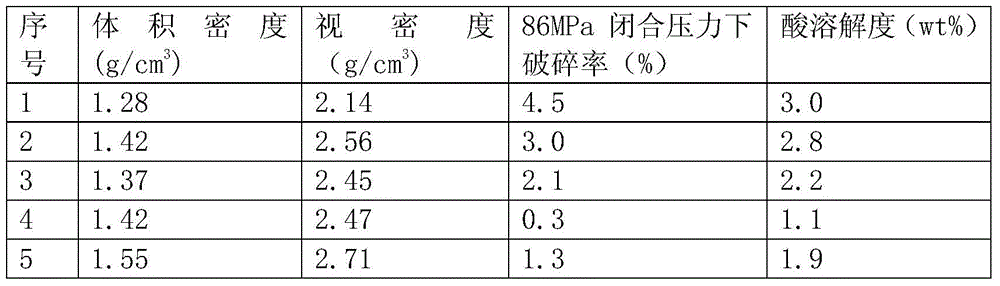

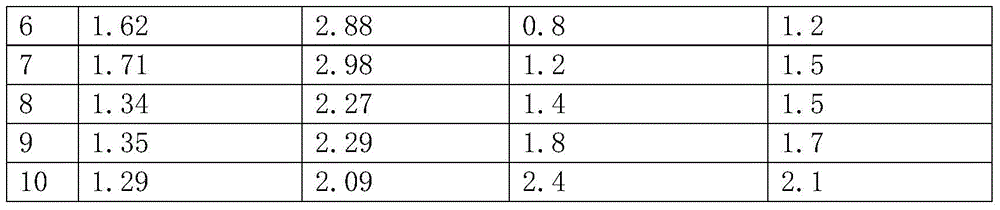

[0036] With reference to Table 1, Table 1 is the formulation table of Examples 1-10.

[0037] Table 1

[0038]

[0039] Weigh the raw materials according to the formula components given in Table 1, and then add 40% to 70% of the dry weight of water for ball milling to make a slurry with a fineness of 350 to 600 mesh. Preferably, a small amount of solution can be added Glue, which can make the slurry have better fluidity; then the slurry is spray-dried and then rolled and granulated by a granulator to make granular powder; then the granular powder is dried and sieved, A granular powder with a particle size of ΦΦ20 mesh to 60 mesh (850 to 250 μm) is obtained. Select a φ2.5×45m rotary kiln, and calcinate at 1100°C to 1180°C for 1-3 hours (the calcining time increases with the content of bauxite in the formula, for example, the calcining time of Example 1 is 1 hour, and the calcining time of Example 1 is 1 hour. The calcination time of 4 and 9 is 2.5 hours, and the calcinatio...

Embodiment 11-12

[0049] In addition, in order to improve the flow conductivity and acid resistance of the prepared acid-resistant petroleum fracturing proppant, the present invention also provides Example 11 and Example 12.

[0050] Select the acid-resistant petroleum fracturing proppant particles prepared in the above Example 3, and use a 20-ton ball mill to charge 40 to 45 tons of material for self-grinding and polishing (self-grinding and polishing does not add ball milling media such as ball milling balls, and uses the material itself for polishing. Grinding) for 3 to 4 hours, after the ball is out, sieve and remove the throwing debris below 60 meshes, and then wrap the polished particles with a resin layer. Specifically, use a drum mixer to grind the polished particle powder. Spray the atomized resin during the disturbance, and keep the temperature in the drum mixer within the range of 80-100°C through the hot air source at the other end. Wherein the resin selected in embodiment 11 is phe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com