A Segmented Empty Field Method for Structures without Columns and Bottoms

A technology of bottom structure and open-field method, which is applied in ground mining, earth square drilling, underground mining, etc., and can solve the difficulty of recovering the ore volume of the stud and bottom structure, the impact of ore recovery and early capital investment, and the waste of high-grade ore and other problems, to achieve the effect of shortening the production time, saving ore pillars, and reducing the amount of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

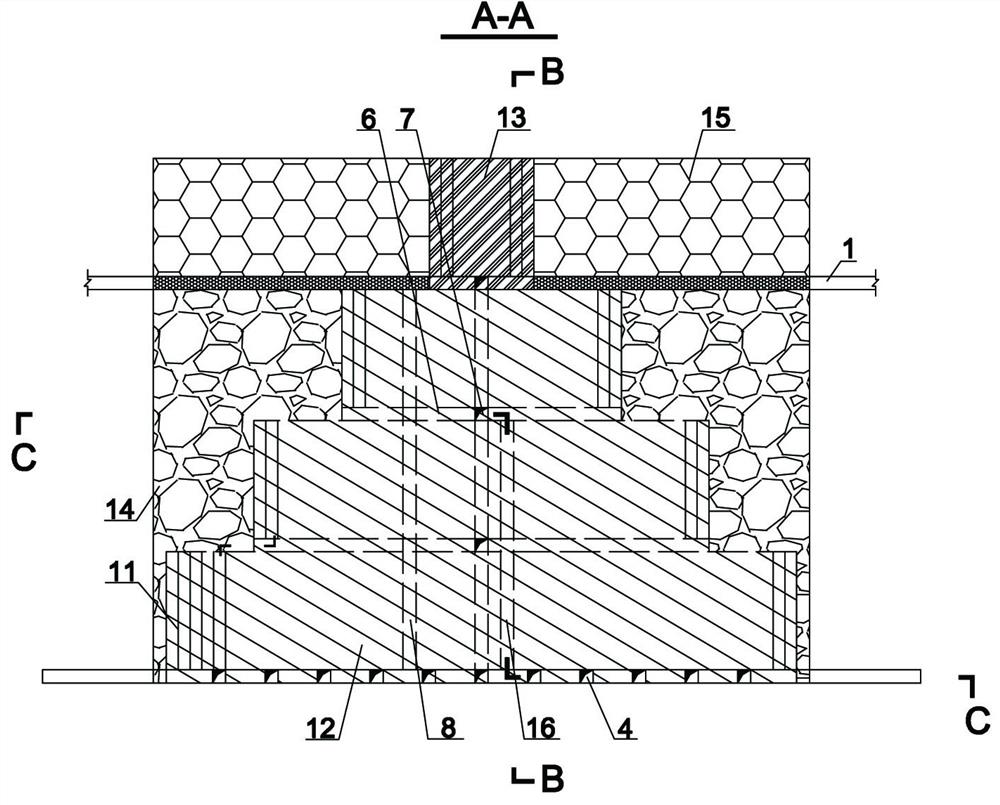

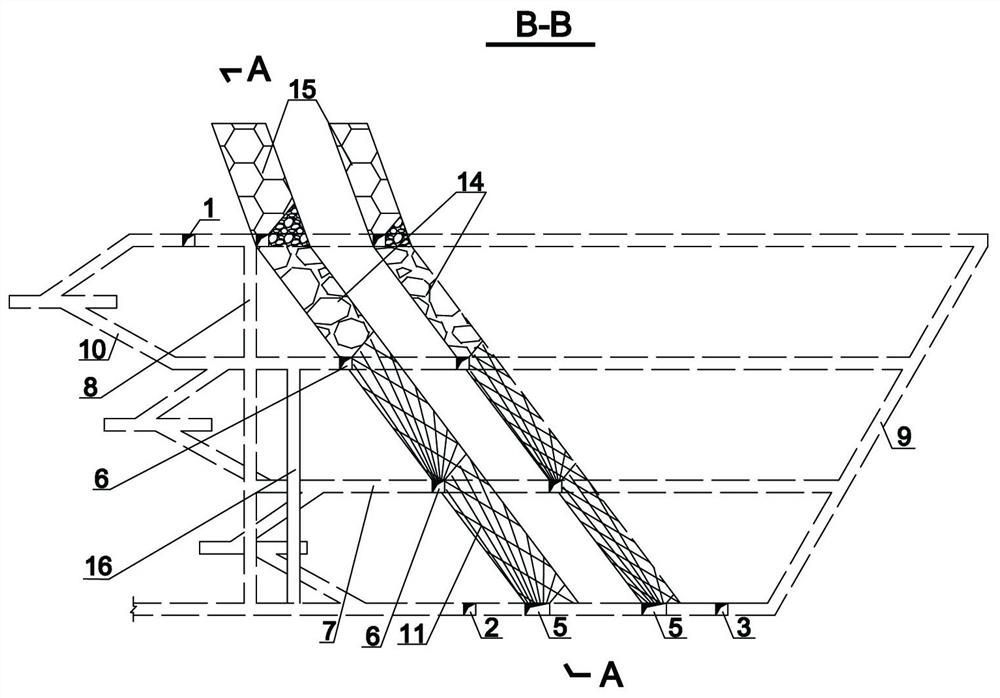

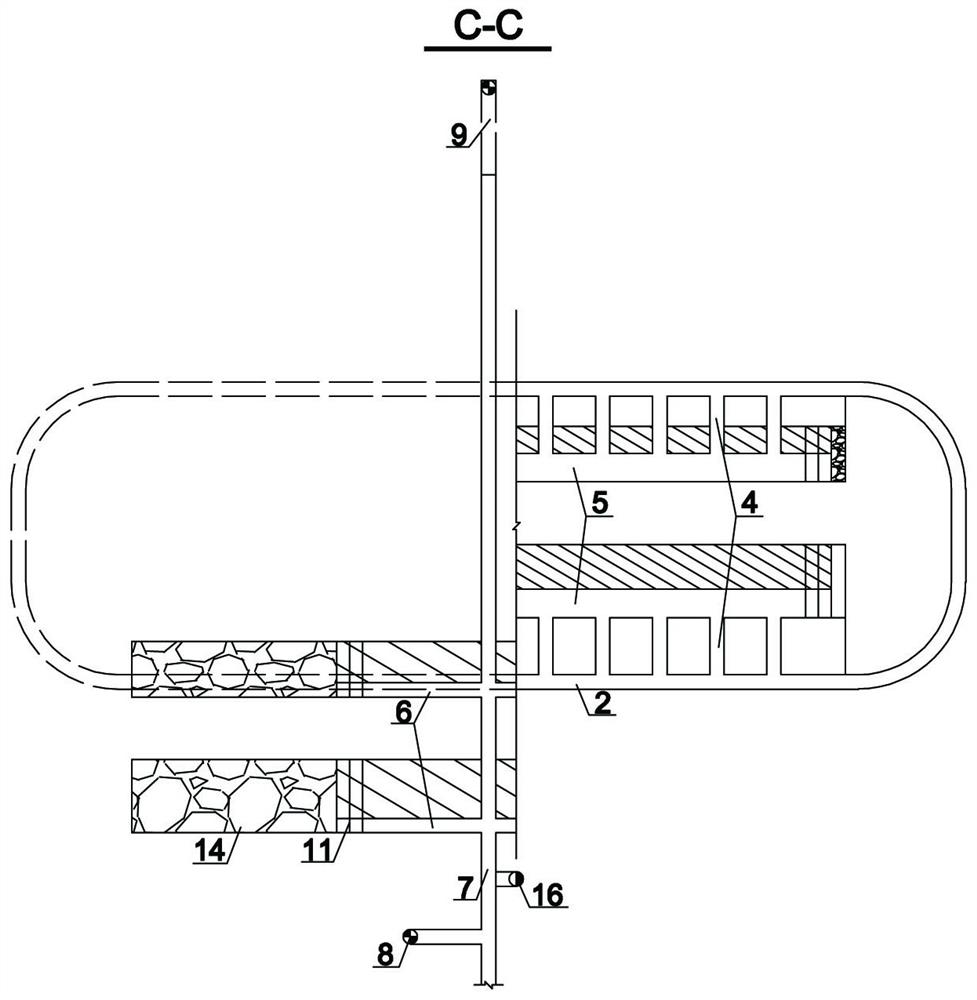

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as Figure 1-3 As shown, a segmented empty field method without a bottom structure of a column without a column of the present invention is characterized in that it comprises the following steps:

[0023] Step 1: Divide the ore block along the trend of ore body 12. The length of the ore block is the length of the ore body. 1. Dig the footwall ore outlet connecting road 2 at the bottom of the ore block, dig the upper wall ore outlet connecting road 3 at the top, and then dig the segmented rock drilling roadway 6 to both ends in the ore body 12, and dig out the ore at the bottom of the ore block. Lane 4 and Ladi Lane 5;

[0024] Step 2: The mining sequence of the ore block is from top to bottom, and the segment mining sequence is from both ends to the middle;

[0025] Step 3: Form a 0m~30m thick rock cover layer 15 on the top of the ore block before mining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com