Downstream collecting type magnetic medium, magnetic medium stack, intermittent magnetic separation equipment, vertical ring high gradient magnetic separator and magnetic beneficiation method

A high-gradient magnetic separator and magnetic medium technology, applied in the field of magnetic separator and magnetic ore dressing, magnetic medium, and magnetic medium stack, can solve the problems of the decline in the recovery rate of magnetic minerals, the difficulty in adjusting the feeding flow rate, and the inability to apply, etc. Improved recovery, elimination of mechanical inclusions, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

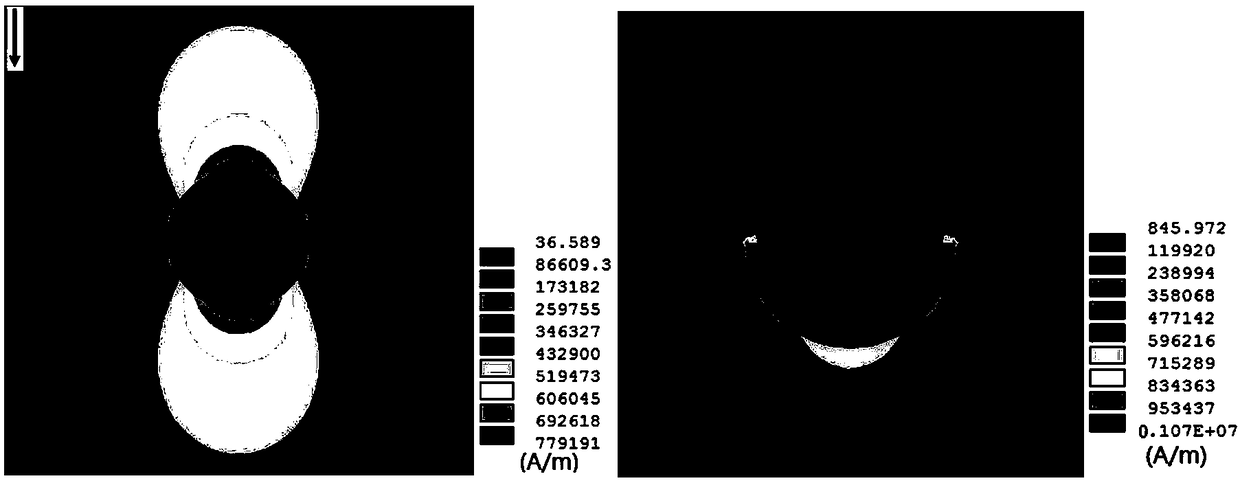

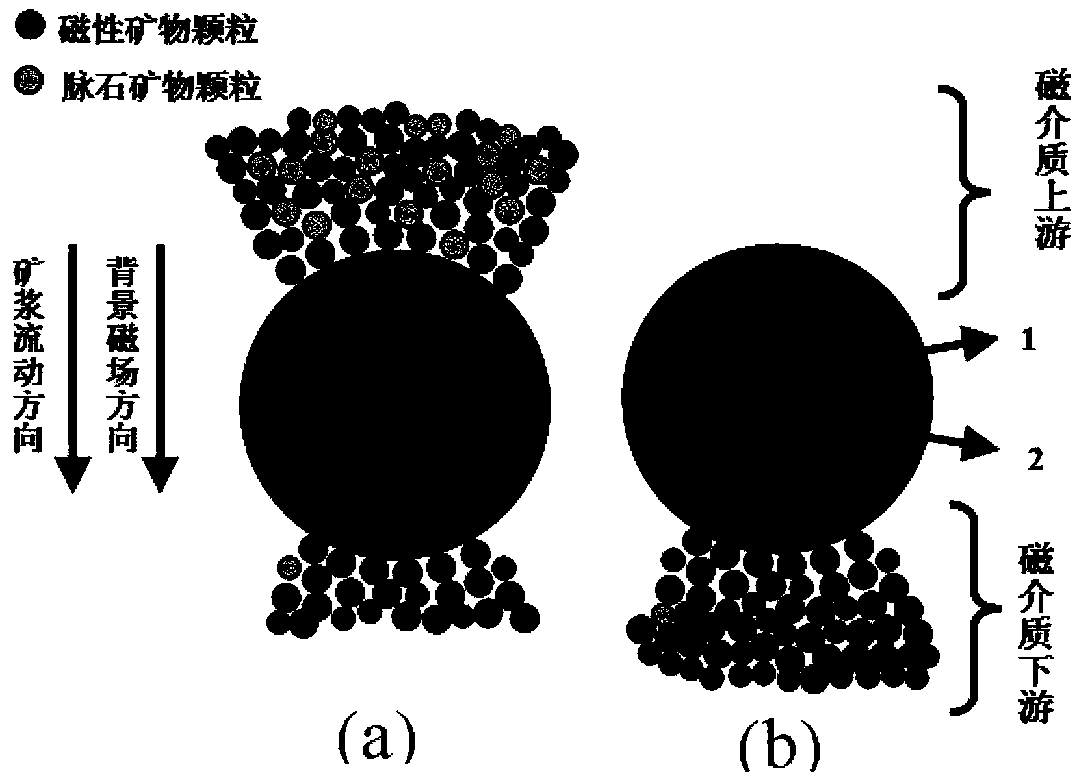

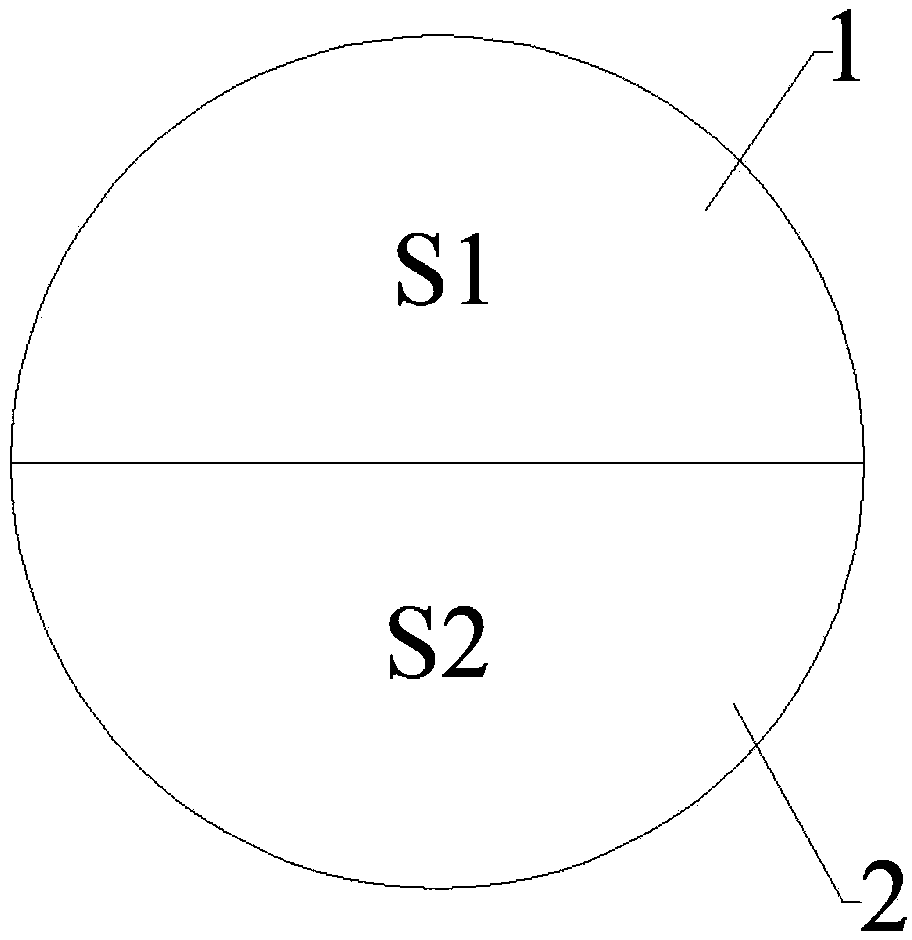

[0054] image 3 As shown, in the downstream collecting magnetic medium of this embodiment, the magnetic medium is sequentially provided with a non-magnetic part 1 and a magnetic part 2 along the flow direction of the pulp, and the non-magnetic part 1 and the magnetic part 2 are fixedly connected to each other. In this embodiment, the magnetic medium is cylindrical, and in the cross section of the magnetic medium, the areas of the non-magnetically permeable part 1 (area S1 ) and the magnetically permeable part 2 (area S2 ) are equal.

[0055] The magnetic medium stack of this embodiment includes a plurality of the above-mentioned magnetic mediums, and the magnetic mediums are arranged in parallel and at intervals. In this embodiment, the number of magnetic media can be changed according to actual needs.

[0056] Such as Figure 4 As shown, the present embodiment provides a kind of intermittent magnetic separation equipment, comprising a magnetic field generator 3 and a stack ...

Embodiment 2

[0069] In the downstream capture type magnetic medium in this embodiment, the shape and material of the non-magnetically conductive part 1 and the magnetically conductive part 2 can be the same as any magnetic medium in embodiment 1, the difference is that the magnetic medium is annular, such as Figure 17 shown.

[0070] Utilize the magnetic medium pile that the annular magnetic medium in the present embodiment obtains, intermittent magnetic separation equipment (such as Figure 18 Shown) and the structure of the vertical ring high gradient magnetic separator, the method utilizing its two magnetic separations are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com