Method and device for removing coal ash, and oil, phenols and ammonia from coal chemical industry wastewater

A technology for the removal of coal chemical wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. To improve the utilization rate, avoid the decline of the dephenolization efficiency, and reduce the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

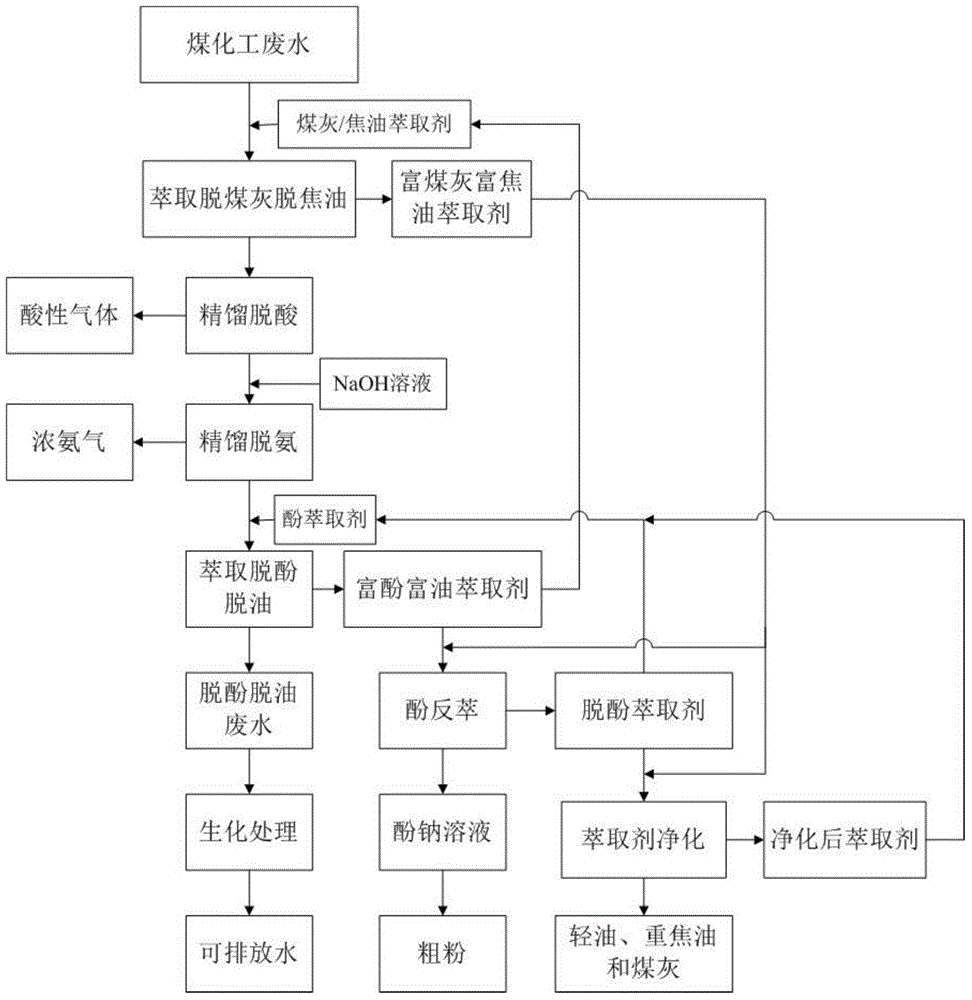

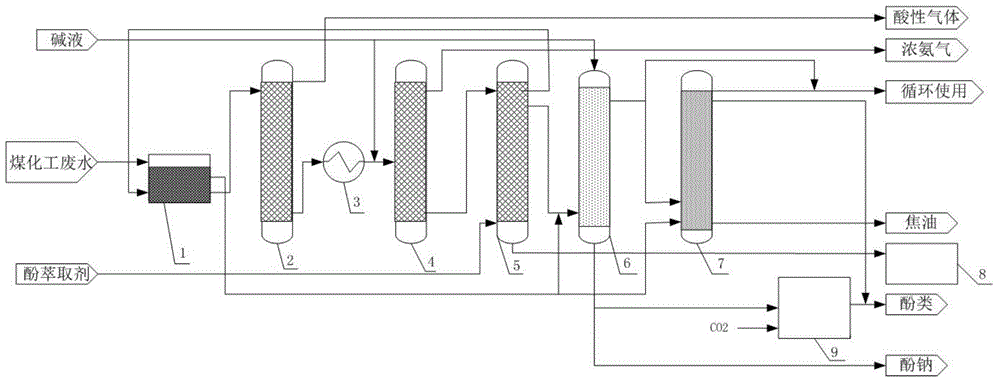

[0127] use figure 2 The removal device shown is used for the removal of coal ash and oleaminophenol in coal chemical wastewater. The composition of the raw coal chemical industry wastewater is shown in Table 1. The water quality of the raw material coal chemical wastewater is reddish brown, the pH value is 8.9, the water temperature is 62°C, and the BOD 5 / COD Cr The value is 0.22, and the flow rate is 102 tons / hour.

[0128] Table 1: Properties of Raw Coal Chemical Wastewater

[0129]

[0130]

[0131] The removal process of coal ash and oleaminophenol in the raw coal chemical industry wastewater is:

[0132] The coal chemical industry wastewater flows through the mixing and clarification tank and then enters the extraction reactor 1 to remove coal ash, tar, coke powder and a small amount of phenol. The ratio of the coal ash / tar extractant to the coal chemical industry wastewater is 1:5, and the reaction temperature is 50 ℃; the waste water after the extraction rea...

Embodiment 2

[0143] use figure 2 The removal device shown in Table 1 removes coal ash and oleaginous phenol in the raw material coal chemical industry waste water described in Table 1, and the removal process is:

[0144] The raw coal chemical industry wastewater flows through the mixing and clarification tank and then enters the extraction reactor 1 to remove coal ash, tar, coke powder and a small amount of phenol. The ratio of the coal ash / tar extractant to the coal chemical industry wastewater is 1:4, and the reaction temperature 40°C; the waste water after the extraction reactor 1 is deacidified by the deacidification rectification tower 2, the top temperature of the deacidification rectification tower 2 is 60°C, and the temperature of the tower bottom is 110°C; Add 50% sodium hydroxide solution to the waste water and then flow into the deamination rectification tower 4 for deammonization treatment; the waste water discharged from the deamination rectification tower 4 enters the pheno...

Embodiment 3

[0148] use figure 2 The removal device shown in Table 1 removes coal ash and oleaginous phenol in the raw material coal chemical industry waste water described in Table 1, and the removal process is:

[0149] The raw coal chemical industry wastewater flows through the mixing and clarification tank and then enters the extraction reactor 1 to remove coal ash, tar, coke powder and a small amount of phenol. The ratio of the coal ash / tar extractant to the coal chemical industry wastewater is 1:4, and the reaction temperature 30°C; the waste water after the extraction reactor 1 is deacidified by the deacidification rectification tower 2, the top temperature of the deacidification rectification tower 2 is 30°C, and the temperature of the tower bottom is 90°C; Add 30% sodium hydroxide solution to the waste water and then flow into the deamination rectification tower 4 for deammonization treatment; the waste water discharged from the deamination rectification tower 4 enters the phenol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com