Method for printing embossment microstructure with positioned color register

A printing method and microstructure technology, applied in printing, printing machines, printing of special varieties of printed matter, etc., can solve the problem of difficult pattern and precise positioning of ink printing, and achieve the effect of small deformation and shrinkage and accurate relative position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and the embodiments given in the accompanying drawings. The production technique of the present invention is easy to implement for those skilled in the art.

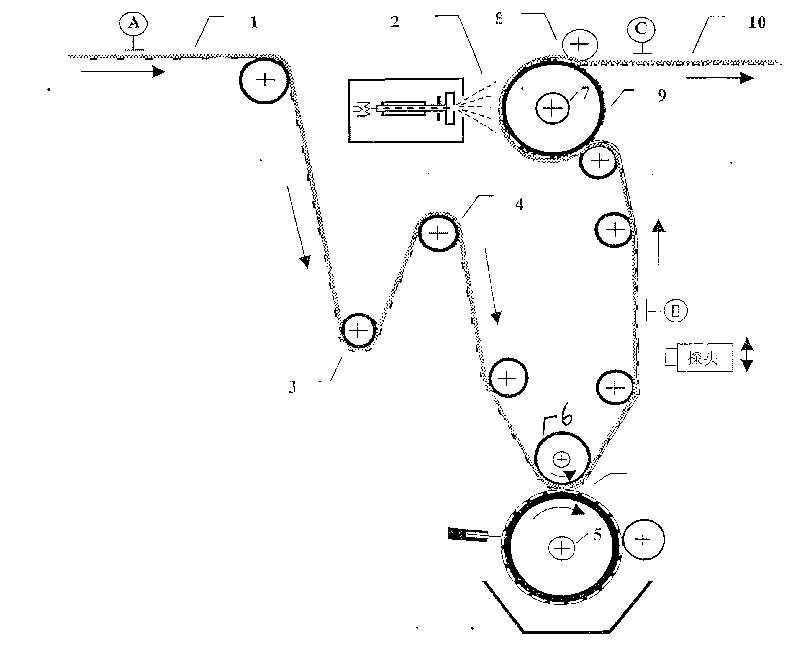

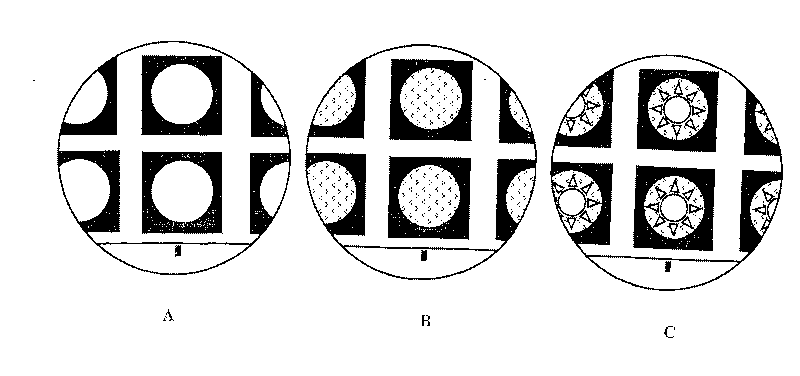

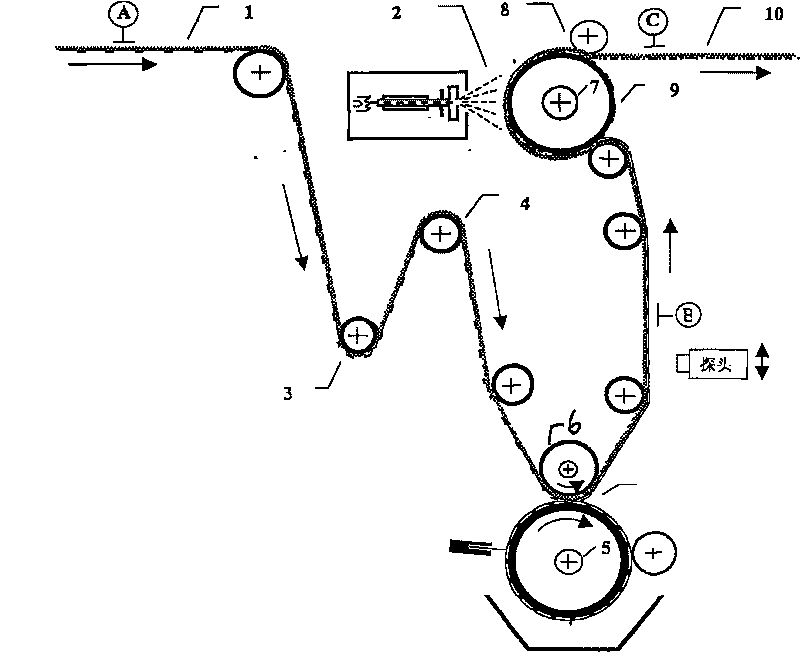

[0018] 1. The printing material is unwound through the deviation correction device and tension control, and first enters the ordinary ink printing unit, performs at least one single-color ordinary printing and obtains detectable tracking lines, cursors (or the edge of the first set of color images), see figure 1 1 place and figure 2 (A).

[0019] 2. Control the electronic axis 5 or floating roller 3 through photoelectric detection and PLC calculation to accurately apply the transfer printing ink to the required color register position through the gravure roller 6, and keep its viscosity without curing, see figure 2 (B).

[0020] 3. Through photoelectric detection and PLC central calculation, the electronic axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com