Hydrogel 3D printing internal environment control device and method

A 3D printing and control device technology, applied in manufacturing auxiliary devices, processing environment adjustment, additive processing, etc., can solve problems affecting the quality of printed products, deformation of printed structures, dehydration of hydrogel structures, etc., and achieve internal environmental control Stable and efficient, reducing deformation and shrinkage, and reducing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

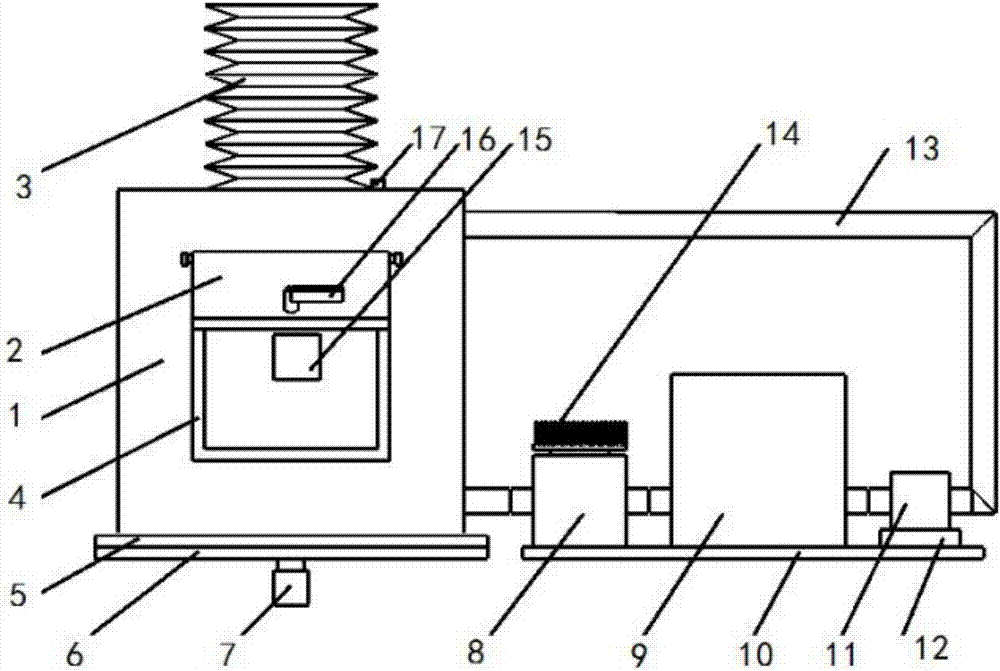

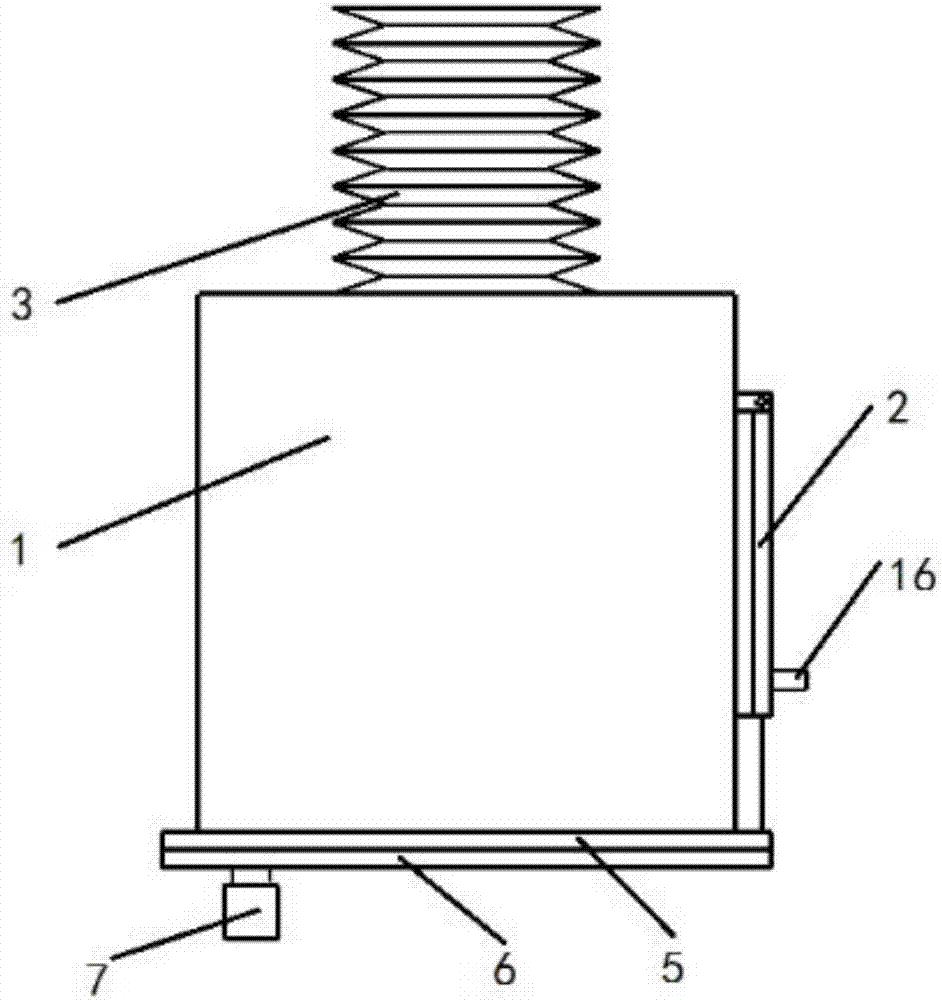

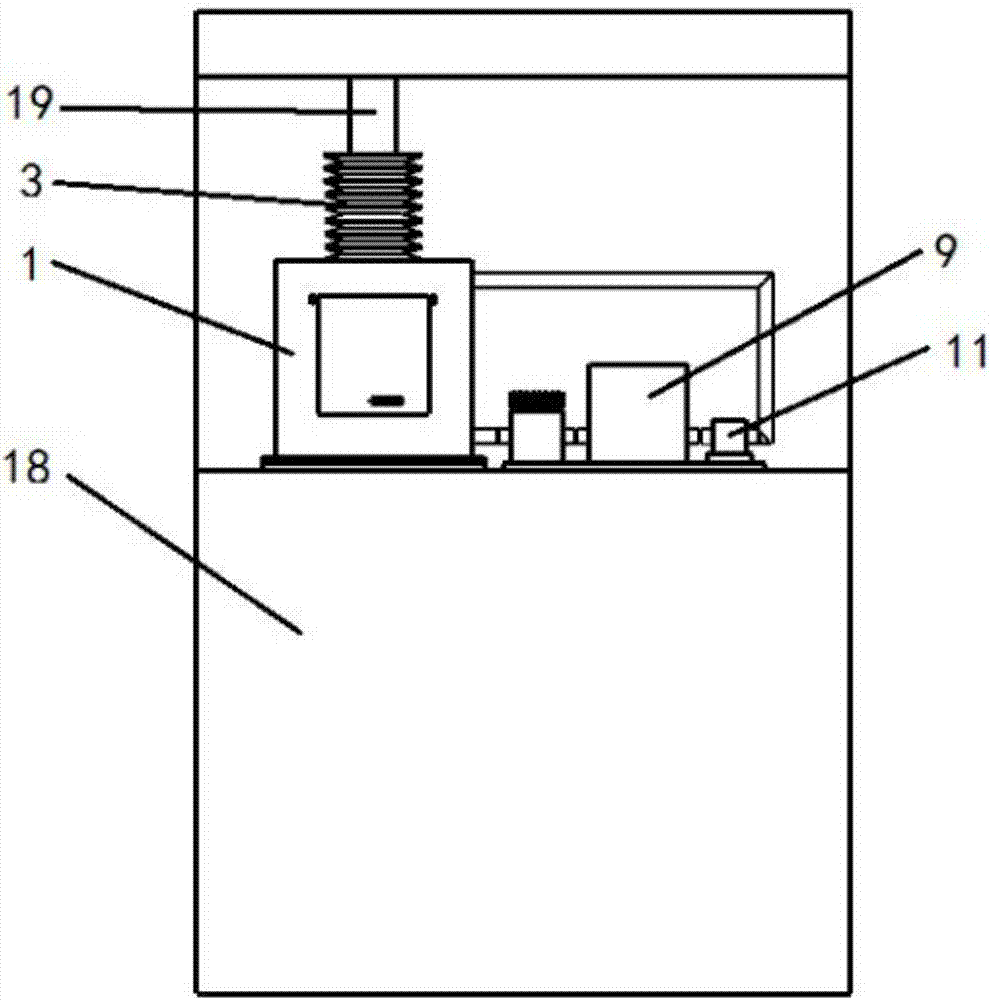

[0026] Such as Figures 1 to 3 shown. The invention discloses a hydrogel 3D printing internal environment control device, which includes a heat insulating glass shell 1, the heat insulating glass shell 1 is bonded to a connecting substrate 5 at the bottom, and the connecting substrate 5 is then co-installed with a printer liquid tank substrate 6. The top of the heat-insulating glass shell 1 is sealed and socketed with the cantilever guide rod 19 of the lifting system of the hydrogel 3D printer 18 through the sealing rubber cover 3; the temperature and humidity sensor 15 is installed on the inner rear wall of the heat-insulating glass shell 1;

[0027] There are upper and lower ventilation holes on the right side wall of the heat-insulating glass shell 1, and the upper ventilation hole is connected to the air pump 11, the ultrasonic humidification generator 9 and the thermoelectric semiconductor square copper tube 8 in turn through the copper tube 13 coated with heat-insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com