Driven gear heat treatment method

A heat treatment method and driven gear technology, which is applied in the field of heat treatment of 18Cr2Ni4WA parts, can solve the problems of unmachinable parts of the cavity, influence of the surface of the cavity area, carburization of the cavity area, etc., and achieve high production efficiency, low cost, and improved viscosity. knot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

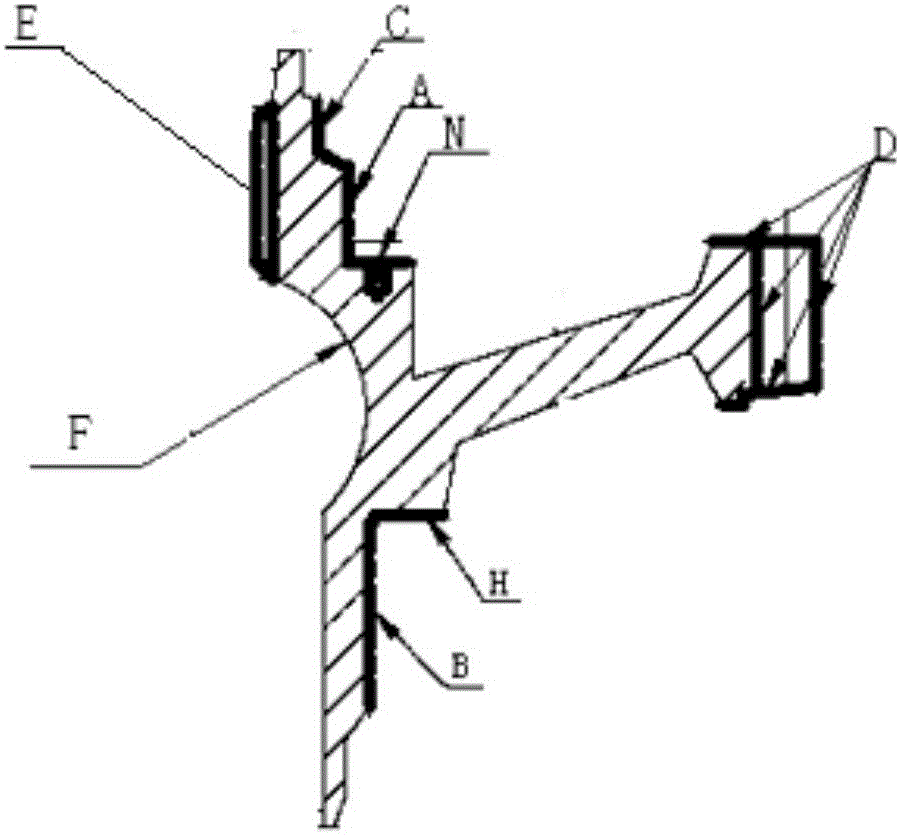

[0021] The heat treatment method for the driven gear of this embodiment is to mechanically process the driven gear after quenching and tempering treatment to remove the surface oxide scale; to carry out copper plating treatment on the surface of the driven gear workpiece to ensure that the surface of the part is completely covered with a copper plating protective film; The driving gear is machined to remove the copper-plated protective film attached to the surface of the A, B, C, D, H, N areas and the inner spline E area, which is convenient for subsequent carburizing. Place the driven gear workpiece in a sealed well-type carburizing furnace, drop kerosene as a carburizing agent, keep the temperature at 900°C±10°C, keep it warm for 5 hours, and cool it in air after it comes out of the furnace, and carry out carburizing treatment on the driven gear to obtain The depth of the carburized layer on the surface of the workpiece to be carburized is 0.8-0.9mm; the driven gear workpiece...

Embodiment 2

[0023] The heat treatment method for the driven gear of this embodiment is to mechanically process the driven gear after quenching and tempering treatment to remove the surface oxide scale; to carry out copper plating treatment on the surface of the driven gear workpiece to ensure that the surface of the part is completely covered with a copper plating protective film; The driving gear is machined to remove the copper-plated protective film attached to the surface of the A, B, C, D, H, N areas and the inner spline E area, which is convenient for subsequent carburizing. Place the driven gear workpiece in a sealed well-type carburizing furnace, pass through acetone (other embodiments can also be alcohol, ethanol, ether, etc.) The driven gear is carburized, and the depth of the carburized layer on the surface of the carburized area of the obtained workpiece is 0.9-1.0mm; the driven gear workpiece is tempered at a high temperature at 650°C±10°C, kept for 6 hours, and cooled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com