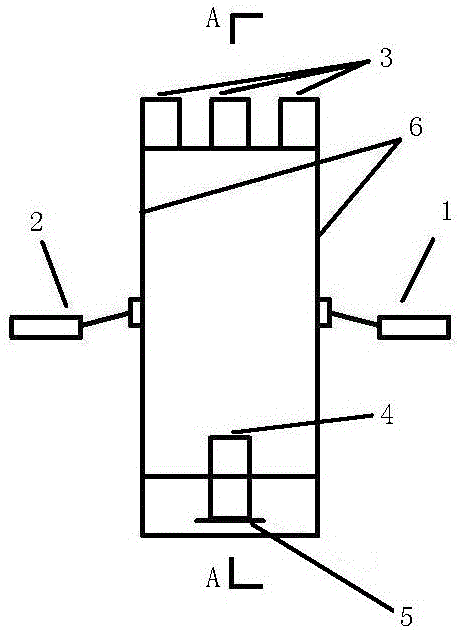

Suspension Composite Live Electric Separator and Its Electric Separator Method

A composite electrification and electric separator technology, applied in chemical instruments and methods, electrostatic effect separation, solid separation, etc., can solve the problems of poor separation effect, particle agglomeration, environmental pollution, etc., and achieve good separation effect and concentrate. The effect of high grade and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

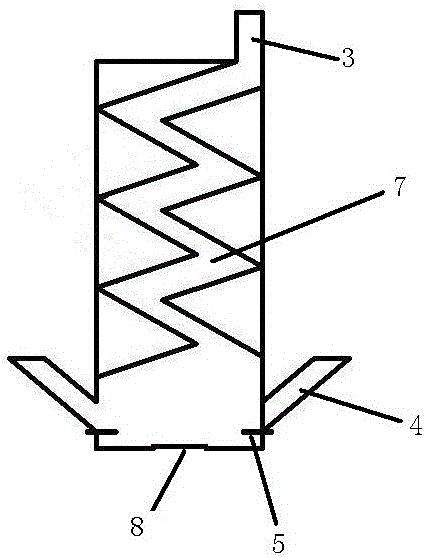

Embodiment 1

[0033] A molybdenum-copper mine in Inner Mongolia, the useful mineral is MoS 2 and CuFeS 2 Associated sulfide minerals and FeS 2 , The gangue minerals are mainly quartz and feldspar, the raw ore Mo grade is 0.12%, and the Cu grade is 0.09%. The ore particle size is -0.2mm accounting for 90%, -0.074mm accounting for 65%, and the moisture content is less than 0.5%. Sorting conditions: the distance between the two high-voltage electrode plates is 500mm, the voltage between the high-voltage electrode plates is 150kV, the voltage of the metal charged rod is 100kV, and the wind speed of the suspended air inlet of the electric separator is 12m / s. Material concentration 0.5kg / m 3 The friction channel is made of stainless steel plate, the friction channel is Z-shaped channel, and the above-mentioned electric separator and electric separation method are used to separate and obtain two kinds of products, medium ore and tailings, wherein the medium ore yield is 10.27%, and the Mo grade ...

Embodiment 2

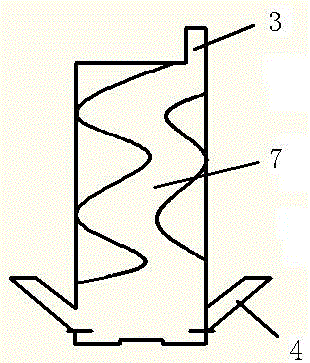

[0035] A vanadium-titanium magnetite in Panzhihua, tailings TiO after weak magnetic separation 2 Grade 2.51%, S grade 1.13%, particle size -0.2mm accounts for 80%, -0.074mm accounts for 50%, moisture is less than 0.5%, useful minerals are mainly ilmenite and rutile densely symbiotic with ilmenite, and some pyrite. The gangue minerals are mainly silicate minerals such as feldspar, ordinary pyroxene, titanite and titanite. Sorting conditions: the distance between the two high-voltage electrode plates is 50mm, the voltage between the high-voltage electrode plates is 30kV; the wind speed of the suspended air inlet in the sorting area is 0.7m / s, and the concentration of the material is 0.2kg / m 3The friction channel is made of quartz plate, and the friction channel is a clapboard-type channel, and the above-mentioned electric separator and the electric separation method are used to separate and obtain three kinds of products of sulfur medium ore, titanium medium ore and tailings, w...

Embodiment 3

[0037] With the titanium middle ore in embodiment 2, TiO 2 Grade 21.54%, carry out the re-selection of the electric separation method once, the separation conditions: the distance between the two high-voltage electrode plates is 900mm, the voltage between the high-voltage electrode plates is 280kV, the voltage of the metal charged rod is 180kV, and the electric The wind speed of the suspended air inlet of the selection machine is 27m / s, and the concentration of the material is 0.9kg / m 3 ; The friction channel is made of rubber plate, and the friction channel is an S-shaped channel. Use the above-mentioned electric separator and electric separation method to separate and obtain titanium concentrate and titanium tailings two products, titanium concentrate TiO 2 The grade is 47.17%, the yield is 34.11%, and the recovery rate is 74.7%. The tailings TiO2 grade is 8.27%, the yield is 65.89%, and the recovery rate is 25.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com