Bauxite column-type floatation method

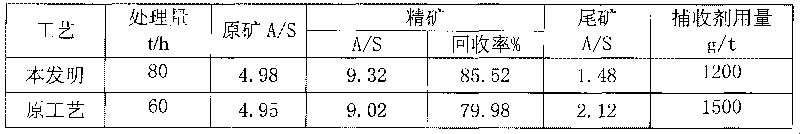

A bauxite and column technology, which is applied in the field of beneficiation and desiliconization of low-grade diaspore bauxite, can solve the problems of small processing capacity, difficult control, poor beneficiation index, etc. Reasonable and ensure the effect of tailings grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

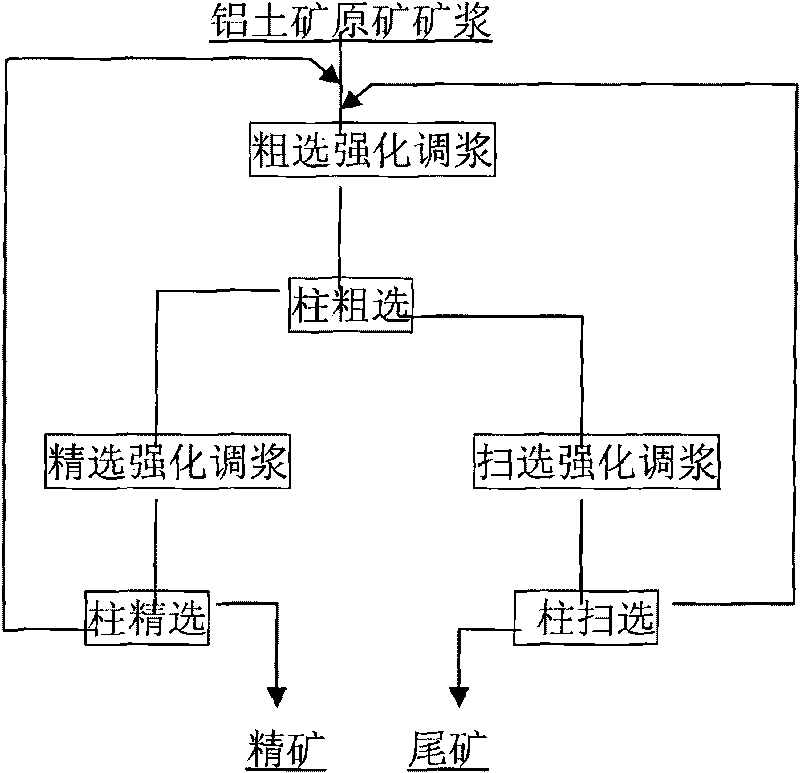

Method used

Image

Examples

Embodiment 1

[0031] Bauxite raw ore pulp A / S 3.0, grinding fineness 92%, PH 10.0, weight concentration 40%, regulator in the flotation process is water glass, collector is oxidized paraffin wax soap, tall oil at a ratio of 3:1 Proportional mix. When adding flotation reagents to the pulp of bauxite raw ore, the amount of regulator added is 120 g / ton of raw ore, and the amount of collector added is 1100 g / ton of raw ore. The flotation concentrate slurry overflowed from the rougher flotation column is added to the flotation agent for slurry adjustment. The amount of regulator added is 100 g / ton of raw ore, and the amount of collector added is 100 g / ton of raw ore. The tailings of the bottom flow of the coarse flotation flotation column are added with flotation reagents to adjust the slurry. The amount of regulator added is 40 g / ton of raw ore, and the amount of collector added is 100 g / ton of raw ore.

Embodiment 2

[0033] The bauxite raw ore pulp is A / S 4.0, the grinding fineness is 75%, the pH is 9.5, and the weight concentration is 20%. The regulator of the flotation process is polyphosphate, and the collector is fatty acid soap. When adding flotation agents to the pulp of bauxite raw ore, the amount of regulator added is 50 g / ton of raw ore, and the amount of collector added is 700 g / ton of raw ore. The flotation concentrate slurry overflowed from the rougher flotation column is then added to the flotation agent during the slurry adjustment process. The addition amount of the regulator is 0, and the addition amount of the collector is 50 g / ton of raw ore. The tailings of the rough flotation flotation column bottom flow are added with flotation reagents to adjust the slurry. The amount of regulator added is 10 g / ton of raw ore, and the amount of collector added is 50 g / ton of raw ore.

Embodiment 3

[0035] The bauxite raw ore pulp is A / S 5.0, the grinding fineness is 70%, the pH is 9.0, and the weight concentration is 30%. The regulator of the flotation process is polyphosphate, and the collector is modified fatty acid. When adding flotation agents to the pulp of bauxite raw ore, the amount of regulator added is 10 g / ton of raw ore, and the amount of collector added is 200 g / ton of raw ore. The flotation concentrate slurry overflowed from the rougher flotation column is added to the flotation agent for slurry adjustment. The amount of regulator added is 10 g / ton of raw ore, and the amount of collector added is 200 g / ton of raw ore. The tailings of the bottom flow of the rough flotation flotation column are added with flotation reagents during the slurry adjustment process. The additive amount of the regulator is 0, and the additive amount of the collector is 200 g / ton of raw ore.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com