Method for producing aluminium oxide and by-product silicon by low-temperature alkali digestion of low-grade bauxite

A technology for low-grade bauxite and alumina, applied in chemical instruments and methods, preparation of alkali metal aluminate/alumina/hydroxide, aluminum silicate, etc., can solve the problem of low recovery rate of aluminum concentrate, separation The selection process is difficult to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

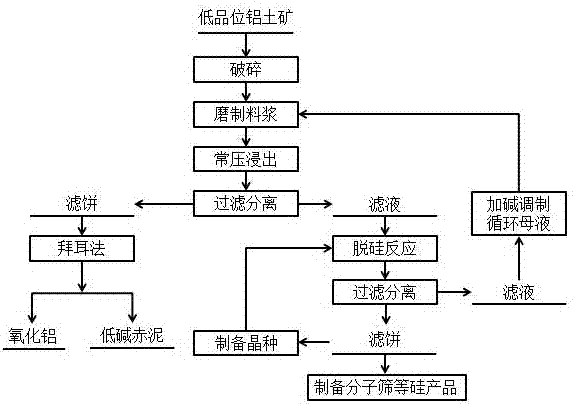

Image

Examples

Embodiment 1

[0018] Shanxi low-grade diaspore type bauxite is used, the main chemical composition is Al 2 o 3 55%, SiO 2 20%, the others are impurities, and its aluminum-silicon ratio is 2.75;

[0019] Crush the low-grade bauxite to 2~5mm, then mix the ore powder with the circulating mother liquor to prepare the raw material slurry, the liquid-solid ratio is 6, and grind it in a ball mill until the particle size is -0.074mm, accounting for more than 60%;

[0020] The raw material pulp is subjected to a dissolution reaction at 80°C in a reaction kettle for a reaction time of 2 hours. After the reaction is completed, it is filtered and separated, and the obtained filter residue is high-grade bauxite, and the filtrate is a solution containing sodium aluminosilicate;

[0021] The high-grade bauxite obtained by filtration is dissolved by the Bayer process to produce alumina and low-alkali red mud;

[0022] Add the sodium aluminosilicate solution obtained by filtration to hydrated sodium al...

Embodiment 2

[0025] Shanxi low-grade diaspore type bauxite is used, the main chemical composition is Al 2 o 3 63%, SiO 2 13%, the others are impurities, and its aluminum-silicon ratio is 4.8;

[0026] Crush the low-grade bauxite to 2~5mm, then mix the ore powder with the circulating mother liquor to prepare the raw material slurry with a liquid-solid ratio of 8, and grind it in a ball mill until the particle size is -0.074mm, accounting for more than 60%;

[0027] The raw material slurry is dissolved in a reaction kettle at 70°C for 1 hour. After the reaction, it is filtered and separated to obtain a high-grade bauxite residue, and the filtrate is a solution containing sodium aluminosilicate;

[0028] The high-grade bauxite obtained by filtration is dissolved by the Bayer process to produce alumina and low-alkali red mud;

[0029] Add sodium aluminosilicate hydrated sodium aluminosilicate solution obtained by filtration for desiliconization reaction, so that aluminum oxide, silicon ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com