Dewatering process screening fine ore of alumyte

A technology of bauxite and flotation concentrate, applied in the direction of separation methods, chemical instruments and methods, aluminum compounds, etc., can solve the problems of poor filtration performance and weak dehydration performance, and achieve settlement and filtration performance and filter cake Moisture improvement, reduction of production energy consumption and beneficiation costs, and the effect of increasing the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

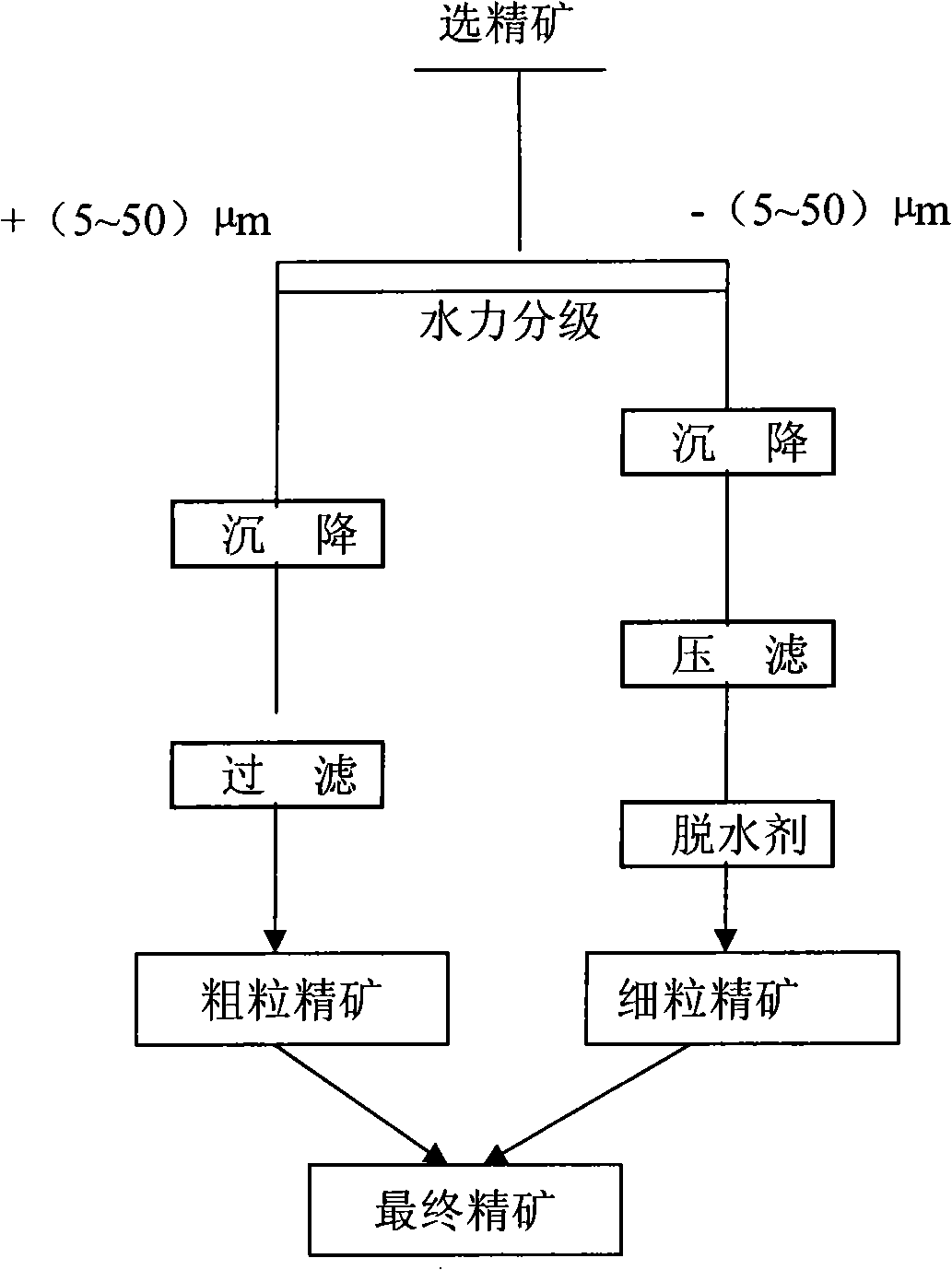

[0015] The bauxite concentrate with a concentration of 10% is classified under the action of a hydrocyclone, and the classification limit is 5 μm; +5 μm particles first enter the thickener, and the concentration is increased to 70% at a pH value of 7.2 Afterwards, the ceramic filter is used for filtration, and the filtration capacity is from 210kg / m before classification. 2 .h increased to 348kg / m 2 .h, filter cake moisture 11.9%; -5μm fine particles are raised to 45% by sedimentation method under the condition of pH value 6.2, and then treated by pressure filtration and adding dehydrating agent, the water content is 19.8%.

Embodiment 2

[0017] The bauxite concentrate with a concentration of 10% is classified under the action of a hydrocyclone, and the classification limit is 10 μm; +10 μm particles first enter the thickener, and the concentration is increased to 70% under the condition of a pH value of 7.6 Afterwards, the ceramic filter is used for filtration, and the filtration capacity is from 210kg / m before classification. 2 .h increased to 452kg / m 2 .h, filter cake moisture 10.6%; -10μm fine particles are raised to 49% by sedimentation method under the condition of pH value 6.5, and then treated by pressure filtration and adding dehydrating agent, the water content is 17.6%.

Embodiment 3

[0019] The bauxite concentrate with a concentration of 10% is classified under the action of a spiral classifier, and the classification limit is 25 μm; +25 μm particles first enter the thickener, and the concentration is increased to 71% under the condition of pH value 7.2 Ceramic filter is used for filtration, and the filtration capacity is from 210kg / m before classification. 2 .h increased to 764kg / m 2 .h, filter cake moisture 9.5%; -25μm fine particles are raised to 52% by sedimentation method under the condition of pH value 6.4, and then treated by pressure filtration and adding dehydrating agent, the moisture content is 16.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com