Method for extracting alumina from high silicon bauxite

A high-silica bauxite and alumina technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve problems such as the deterioration of alumina economic effects, and achieve effective decomposition, low alkali circulation, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

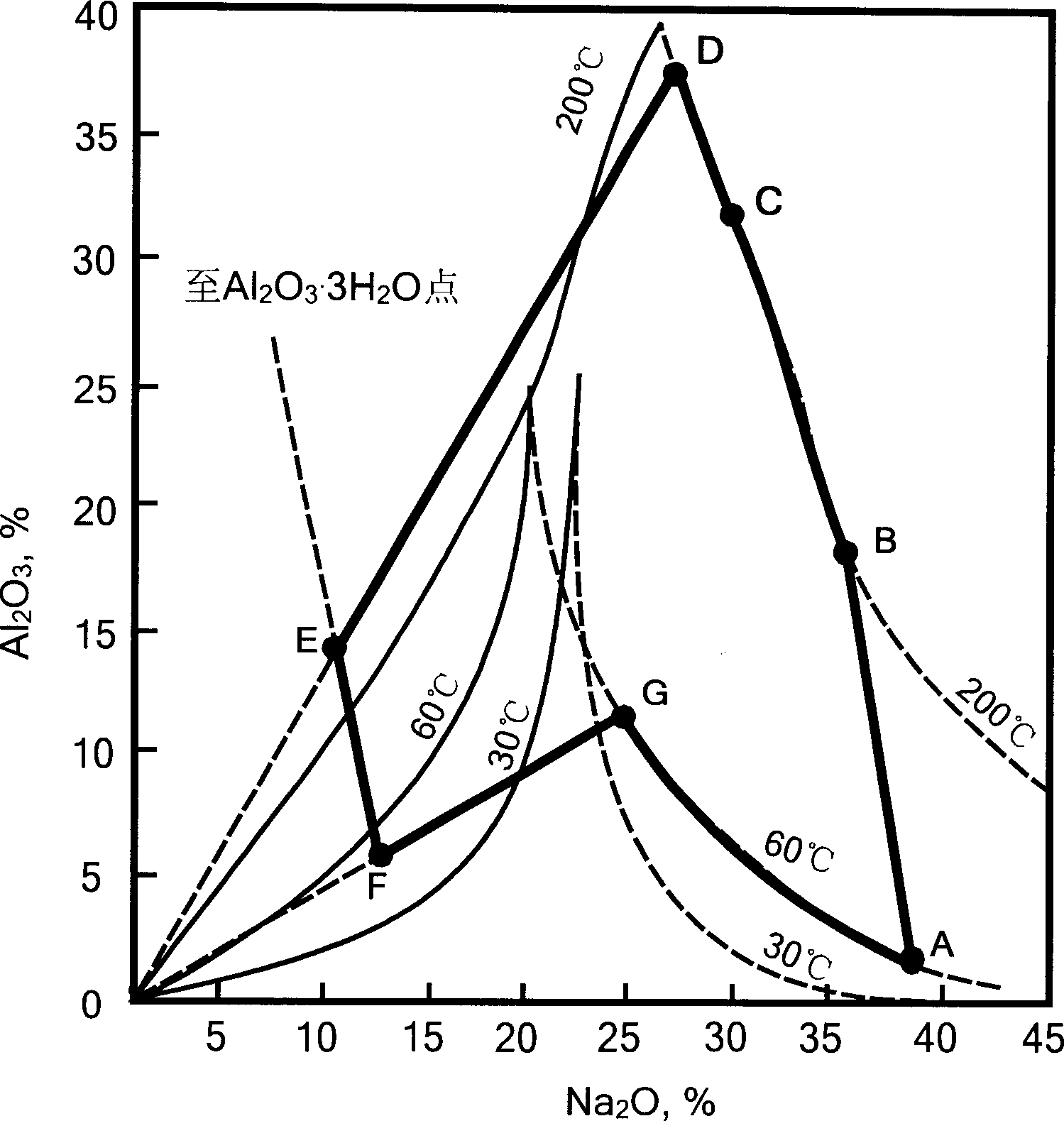

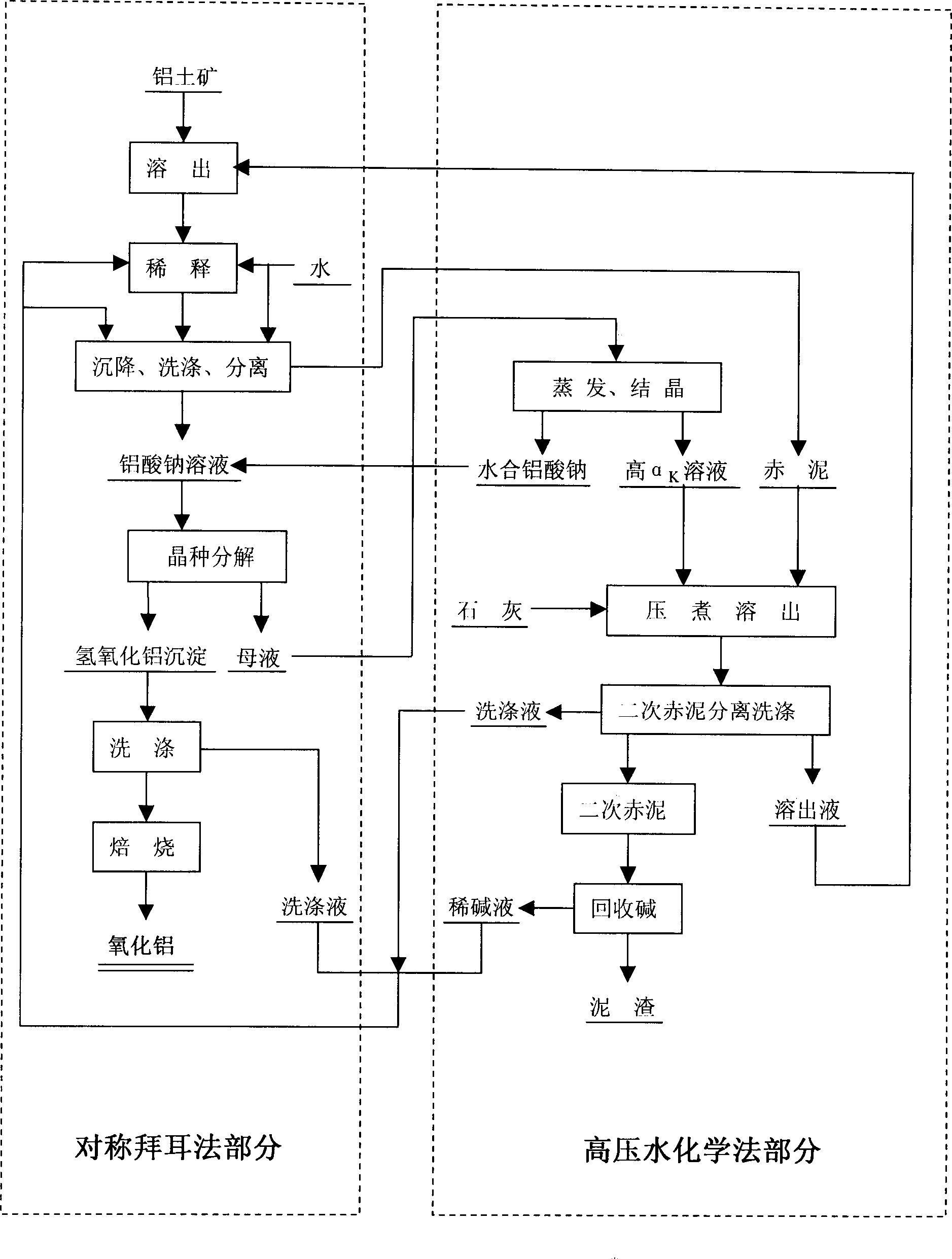

Method used

Image

Examples

Embodiment 1

[0022] Example 1. Bauxite containing Al 2 o 3 66.85%, SiO 2 8.01%, Fe 2 o 3 6.10%, CaO 0.80%, TiO 2 3.30%, burning reduction 13.97%, the main aluminum-containing mineral component is diaspore.

[0023] Add NaOH 93g in the stripping reactor, NaOH 2 O·Al 2 o 3 2.5H 2 O 27g, water 95ml, made into a simulated high-pressure water chemical eluate. Treat 100g of bauxite and add 4g of CaO. Discharge after elution at 175-186°C for 60 minutes. After the red mud was filtered, washed and dried, it was analyzed that Al 2 o 3 16.56%, SiO 2 13.06%, equivalent to a relative dissolution rate of 96.35%.

[0024] Add NaOH 100g to the dissolution reactor, NaOH 2 O·Al 2 o 3 2.5H 2 10g of O and 100ml of water were used to prepare a simulated solution (equivalent to the solution obtained by separating the crystallization of sodium aluminate hydrate after evaporation of the mother liquor). Then add 16g of CaO, treat the red mud obtained above at 260-270°C for 60 minutes, and ...

Embodiment 2

[0025] Example 2. Bauxite containing Al 2 o 3 45.61%, SiO 2 12.10%, Fe 2 o 3 44.83%, CaO 2.78%, TiO 2 2.71%, burning reduction 10.90%, the main aluminum-containing mineral composition is diaspore, and also contains part of diaspore.

[0026] Add NaOH 93g in the stripping reactor, NaOH 2 O·Al 2 o 3 2.5H 2 O 30g, water 90ml, dubbed into a simulated high-pressure water chemical eluate. Treat 100g of bauxite and add 10g of CaO. Discharge after 75 minutes of dissolution at 150-175°C. After the red mud was filtered, washed and dried, it was analyzed that Al 2 o 3 13.81%, SiO 2 13.06%, equivalent to a relative dissolution rate of 97.95%.

[0027] Add NaOH 100g to the dissolution reactor, NaOH 2 O·Al 2 o 3 2.5H 2O 10g, water 90ml, dubbed into a simulated solution (equivalent to the solution obtained by separating the crystallization of sodium aluminate hydrate after evaporation of the mother liquor). Then add 20g of CaO, treat the red mud obtained above at 275...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com