Hydraulic sorting device

A technology of hydraulic separation and container, which is applied in the field of separation equipment and hydraulic separation device, can solve the problems of loss of a large number of fine-grained diaspore minerals, reducing the removal efficiency of fine-grained silicate minerals, etc. Achieve the effect of high concentrate aluminum-silicon ratio, reduce mechanical inclusions, and improve recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

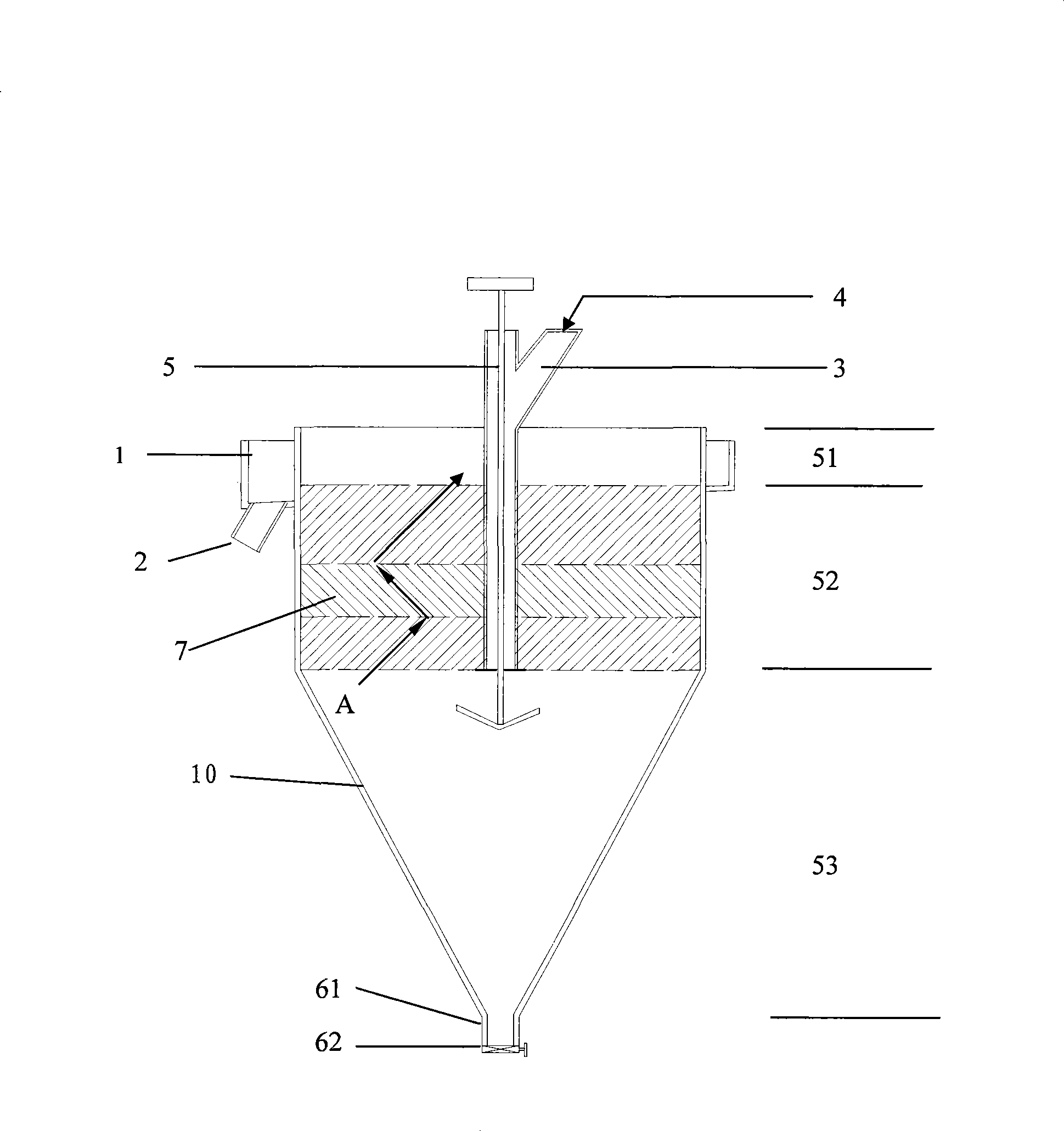

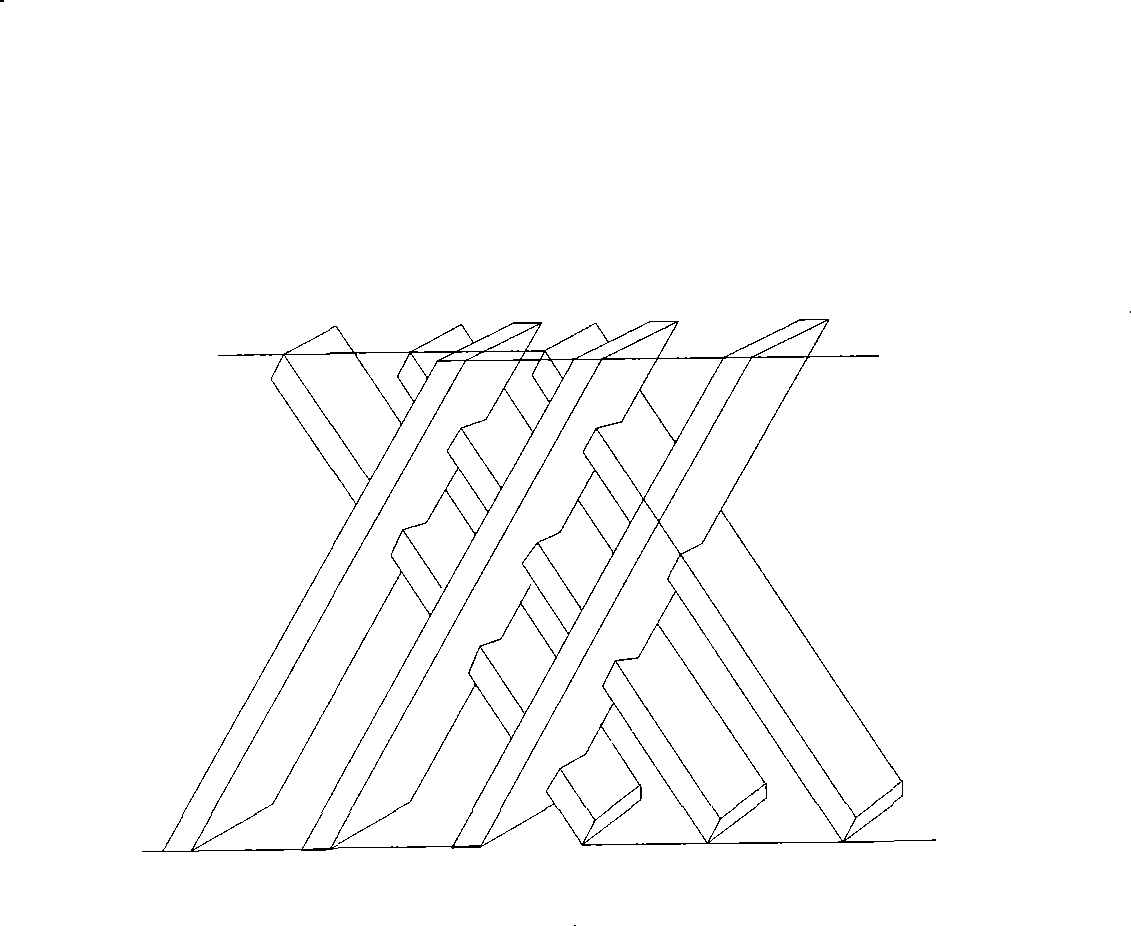

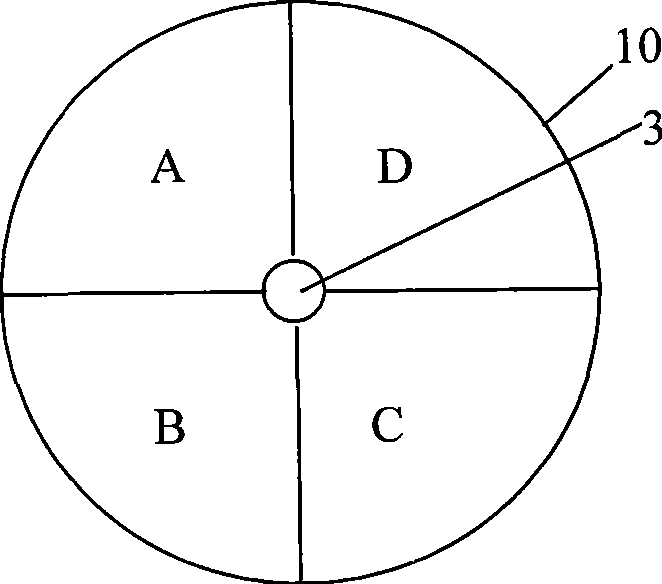

[0022] Hydraulic separation device of the present invention sees figure 1 , the present invention includes a container 10, the upper part of the container 10 is a cylinder, and the bottom is a cone. The top of the container 10 is provided with an overflow weir 1 , and the bottom of the overflow weir 1 is provided with a slime outlet 2 . A central feeding cylinder 3 is installed at the central axis of the container 10 , the lower end of the central feeding cylinder 3 is flush with the lower end of the cylinder of the container 10 , and an ore slurry inlet 4 is provided on the top of the central feeding cylinder 3 . The bottom of the cone of the container 10 is equipped with a grit sink 61 and a concentrate discharge valve 62, whose function is to adjust the flow rate of the rising water by adjusting the flow rate of the concentrate slurry, thereby adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com