Method for mineral dressing and silicon removal of bauxite

A bauxite and desiliconization technology, which is applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of difficult filtration of ore dressing products, long flotation process flow, fine particle size of flotation feed, etc., to achieve Increase economic and social benefits, good process technology and economic indicators, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

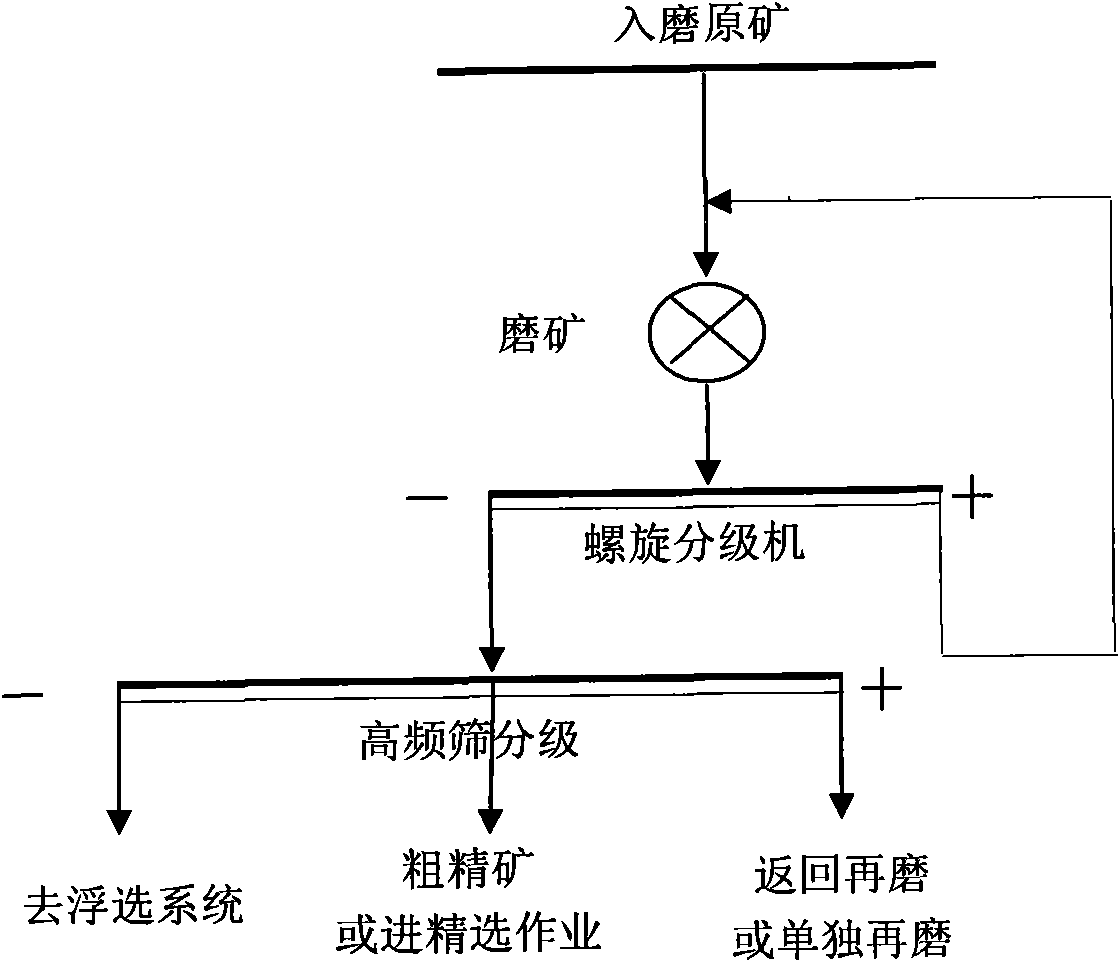

[0021] Taking Henan bauxite as the test sample, the raw ore Al 2 o 3 60.15%, SiO 2 11.76%, and the aluminum-silicon ratio is 5.11. See attached process flow chart figure 1 , the specific process of desiliconization is as follows:

[0022] Low-grade bauxite in Henan is ground in a Φ1500×1500 ball mill with a processing capacity of 2t / h. After being classified by a spiral classifier, the sand is turned and returned to the mill for regrinding. The overflow enters the double-layer high-frequency vibrating screen for classification. , after classification by high-frequency vibrating screen, three products are obtained, the coarse particles of +0.3mm are returned to the mill for regrinding, the intermediate particles of +0.1mm~-0.3mm are used as coarse concentrates, and the fine particles of -0.1mm enter the flotation system, the materials entering the flotation system go through a rough-fine closed-circuit flotation process to obtain concentrate 1 and tailings. The results o...

Embodiment 2

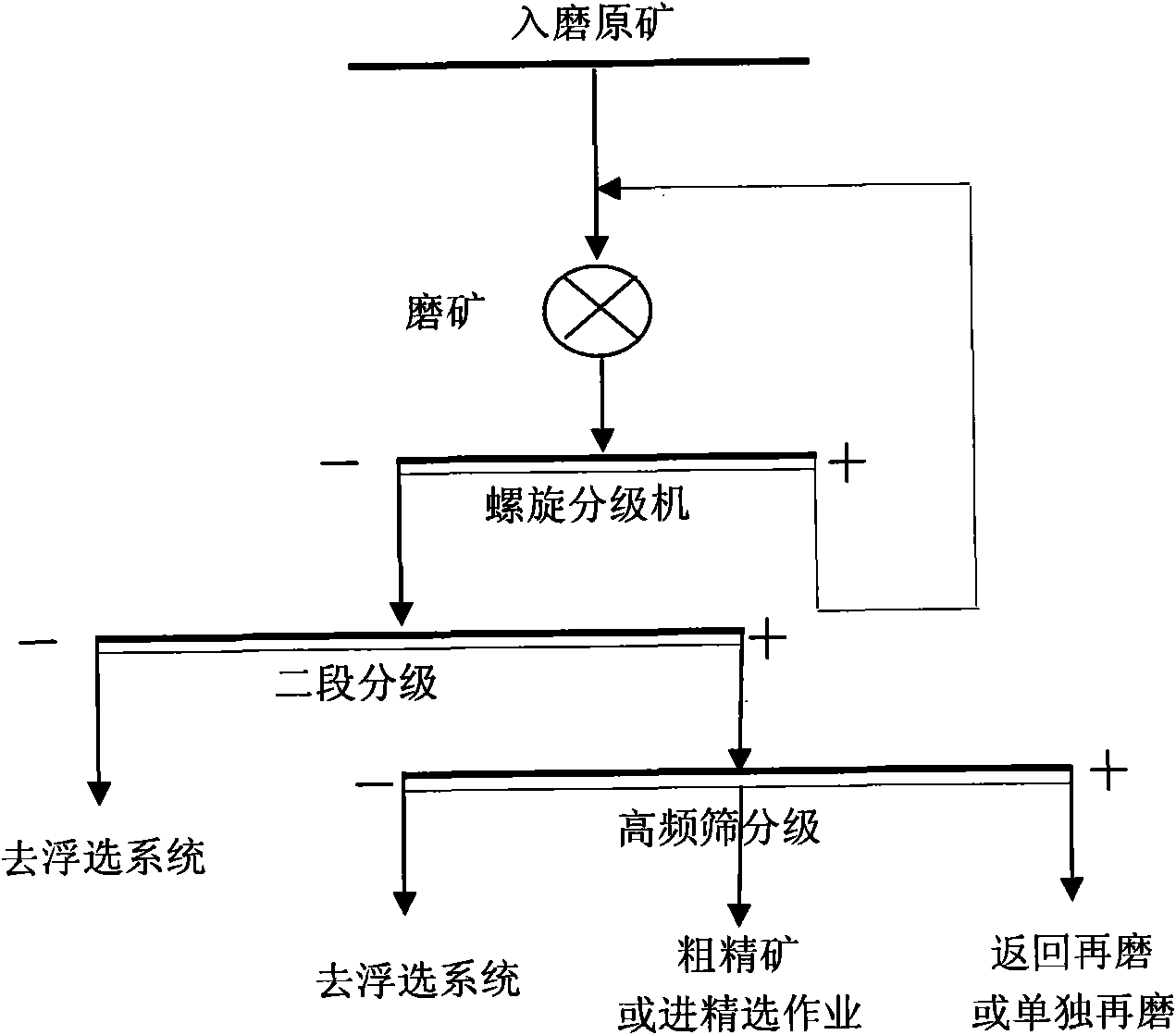

[0028] Taking a foreign bauxite as the test sample, the raw ore Al 2 o 3 66.30%, SiO 2 10.68%, and the aluminum-silicon ratio is 6.21. See attached process flow chart figure 2 , the specific process of desiliconization is as follows:

[0029] Foreign bauxite is ground in a ball mill with a processing capacity of 3t / h. After being classified by a spiral classifier, the sand is turned and returned to the mill for regrinding. The overflow enters the double-layer high-frequency vibrating screen for classification, and the high-frequency vibrating screen After grading, three products are obtained. The coarse particles of +0.25mm are returned to the mill for regrinding, the intermediate particles of +0.075mm~-0.25mm are directly entered into the selection link of the flotation system for flotation desiliconization, and the fine particles of -0.075mm are The particles enter the flotation system and undergo a rough-fine closed-circuit flotation process to obtain concentrate and...

Embodiment 3

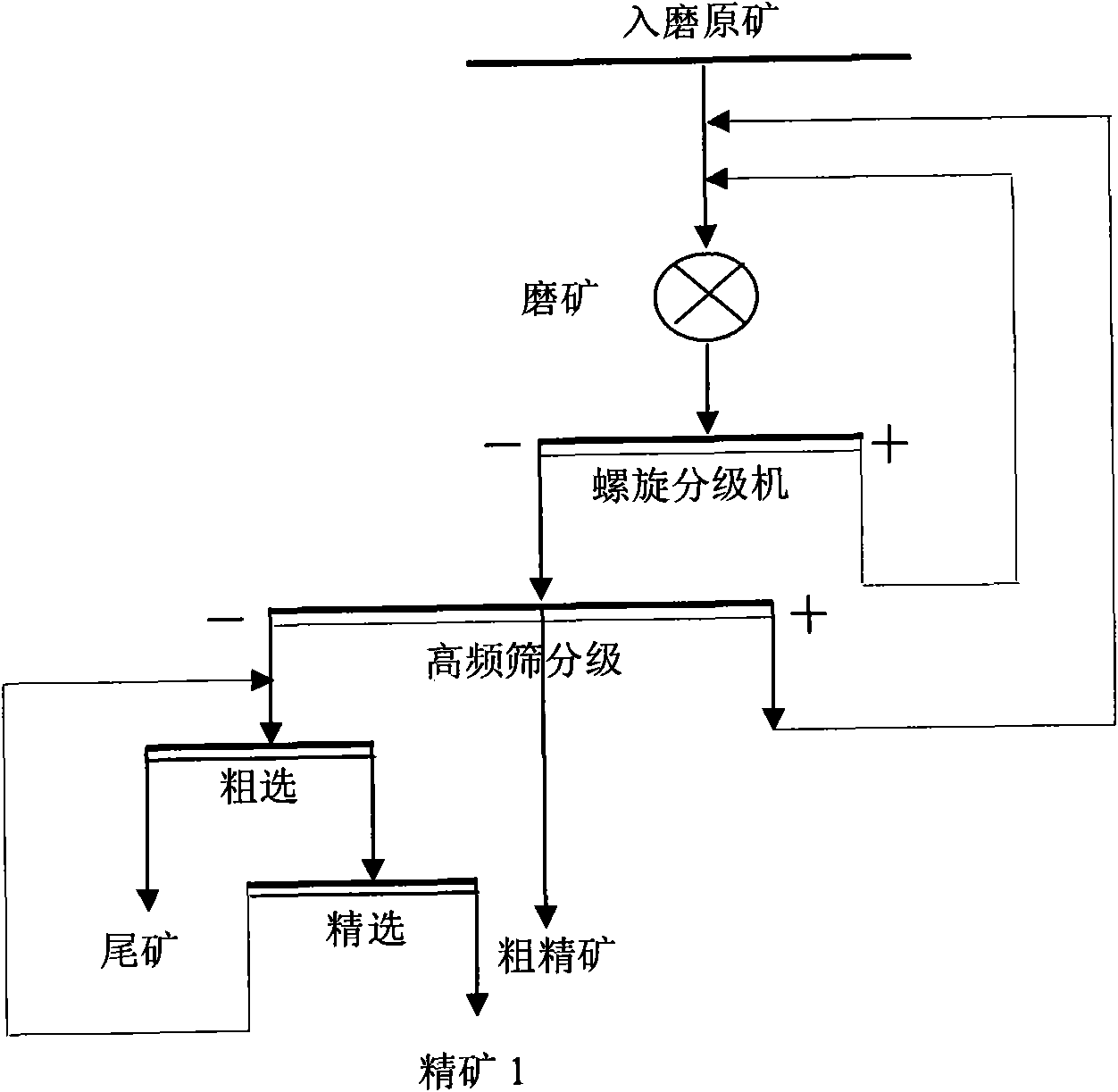

[0035] Taking Shanxi bauxite as the test sample, the raw ore Al 2 o 3 59.43%, SiO 2 12.26%, and the aluminum-silicon ratio is 4.85. See attached process flow chart image 3 , the specific process of desiliconization is as follows:

[0036] The low-grade bauxite in Henan is ground in a Φ2100×2700 ball mill with a processing capacity of 5t / h. After being classified by the first-stage spiral classifier, the sand is turned back to the mill for re-grinding, and the overflow enters the second-stage classifying cyclone for classification. ;The second-stage grading cyclone enters the double-layer high-frequency vibrating screen for classification, the coarse particles of +0.15mm return to the mill for regrinding, and the -0.037mm fine particles enter the flotation system together with the overflow of the second-stage grading cyclone. +0.037mm~-0.15mm intermediate size particles directly enter the flotation system for beneficiation and desiliconization; two products, concentrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com