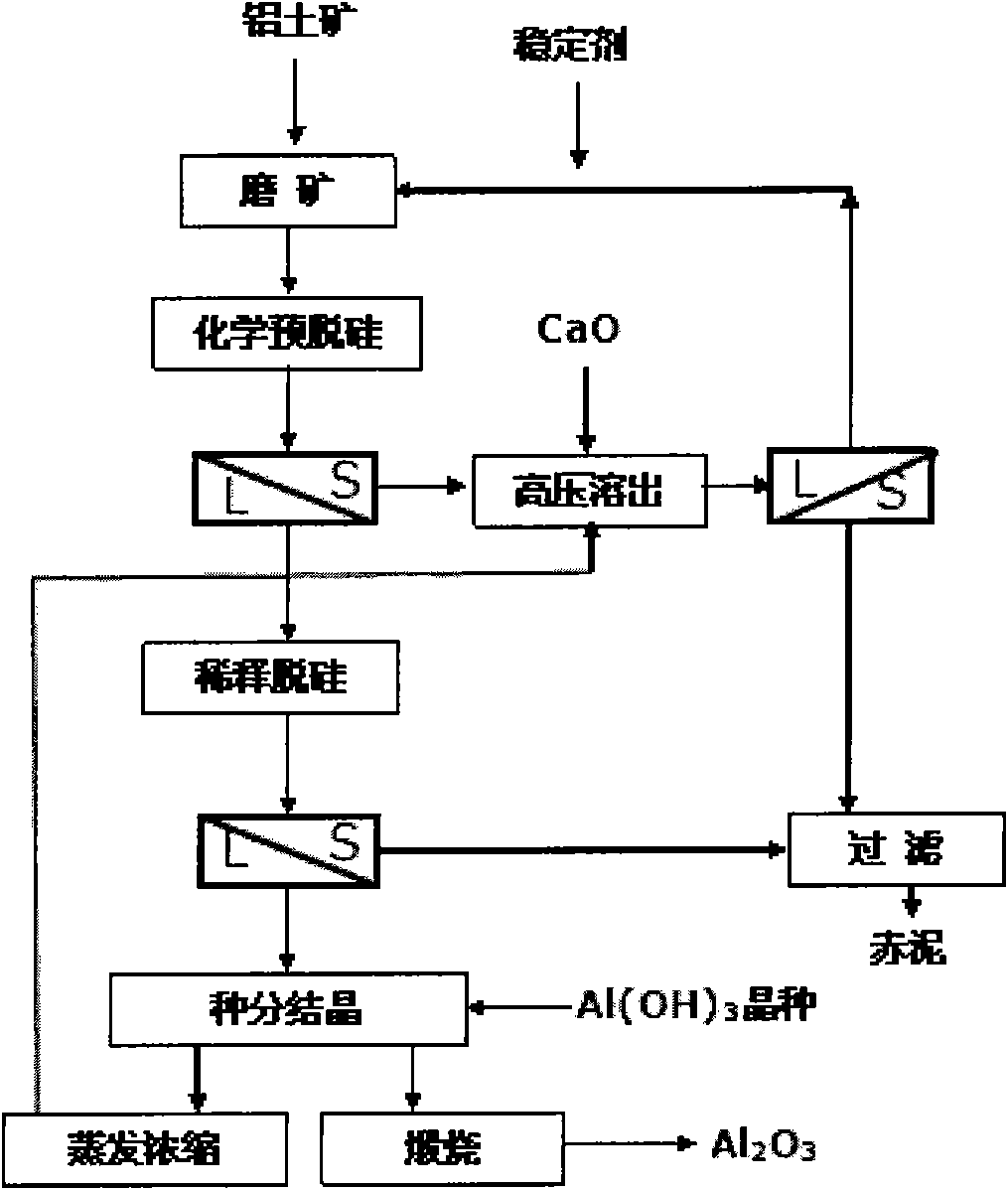

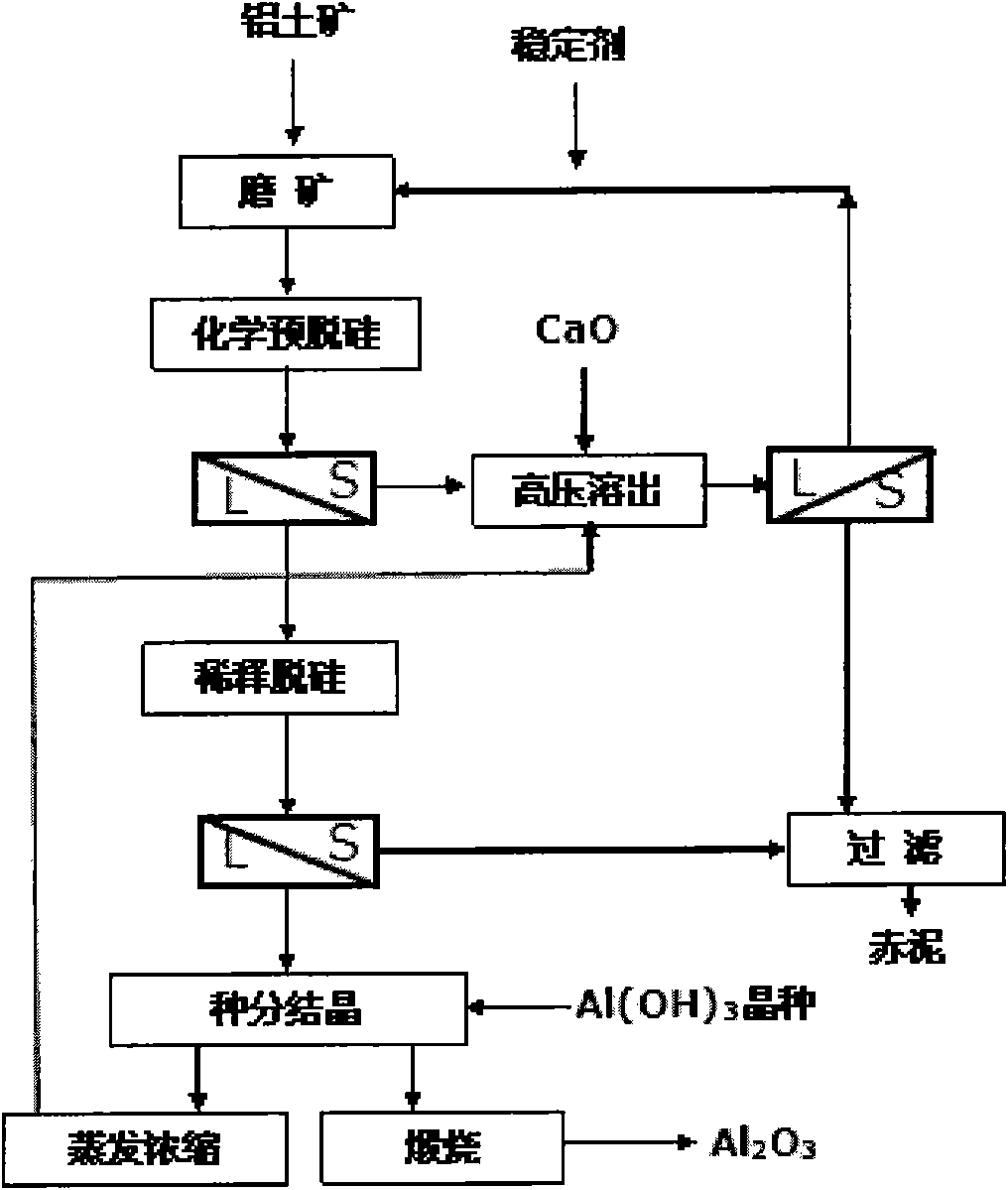

Method for modifying Bayer process, processing low-grade diaspore bauxite and producing alumina

A bauxite, low-grade technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve problems such as unfavorable operation, complicated process, low alumina recovery rate, etc., and achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

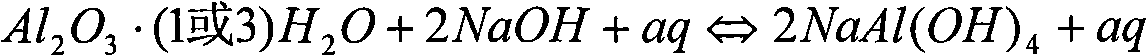

Method used

Image

Examples

Embodiment 1

[0037] A low-grade diaspore-type bauxite (produced in Jinjiang, see Table 1 for ingredients) was ground and sieved to obtain mineral powder, in which mineral powder with a particle size of less than 0.074mm accounted for 80%, and dissolved in silica Add 100 g of ore powder obtained after grinding and sieving into the container to make low-grade diaspore bauxite and sodium aluminate solution containing stabilizer (by NaOH and Al(OH) 3 Add water to prepare sodium aluminate solution) 500ml and mix, wherein, the concentration of stabilizer in the sodium aluminate solution containing stabilizer (dipotassium hydrogen phosphate) is 0.1g / L, NaOH concentration is 400g / L, Al 2 o 3 The concentration is 300g / L; the leaching temperature is 130°C. In the silica dissolving container, the sodium aluminate solution soaks the diaspore bauxite for 6 to 8 hours, and the sodium aluminate solution dissolves 65wt% of the silicon dioxide in the diaspore bauxite And it is stable in the slurry, and t...

Embodiment 2

[0048] A low-grade diaspore-type bauxite (sourced from Sanmenxia Cayman Aluminum Co., Ltd., whose composition is shown in Table 2) was ground and sieved to obtain mineral powder, of which the mineral powder with a particle size of less than 0.074mm accounted for 80%. Add 100g of ore powder obtained after grinding and sieving into the silica dissolution container, and make low-grade diaspore bauxite and sodium aluminate solution containing stabilizer (by NaOH and Al(OH) 3 Add water to prepare sodium aluminate solution) 500ml and mix, wherein, the concentration of stabilizer in the sodium aluminate solution containing stabilizer (aminotrimethylene phosphonic acid) is 0.1g / L, NaOH concentration is 400g / L, Al 2 o 3 The concentration is 300g / L; the leaching temperature is 90°C. In the silica dissolving container, the sodium aluminate solution soaks the diaspore type bauxite for 6-8 hours, and the sodium aluminate solution dissolves 72wt% of the silicon dioxide in the diaspore type...

Embodiment 3

[0059] Grind and sieve low-grade diaspore-type bauxite in a certain place in Guizhou (see Table 3 for composition) to obtain mineral powder, wherein the mineral powder with a particle size of less than 0.074mm accounts for 80%, and put it into the silica dissolution container Add 100g of ore powder obtained after grinding and sieving to make low-grade diaspore bauxite and sodium aluminate solution containing stabilizer (by NaOH and Al(OH) 3 Add water to prepare sodium aluminate solution) 500ml and mix, wherein, the concentration of stabilizer in the sodium aluminate solution containing stabilizer (sodium ethylenediamine tetramethylene phosphonate) is 0.1g / L, and the concentration of NaOH is 400g / L , Al 2 o 3 The concentration is 300g / L; the leaching temperature is 90°C. In the silica dissolving container, the sodium aluminate solution soaks the diaspore bauxite for 6 to 8 hours, and the sodium aluminate solution dissolves 78wt% of the silicon dioxide in the diaspore bauxite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com