Improved annular fuel element of supercritical water reactor and fuel component consisting of fuel element

A supercritical water reactor and fuel element technology, which is applied to fuel elements, greenhouse gas reduction, nuclear power generation, etc., can solve the problem that annular fuel elements cannot be applied to supercritical reactors, etc., and achieve the effect of increased geometric size and stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

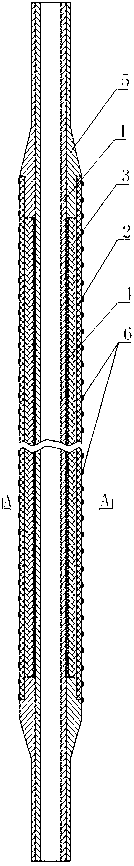

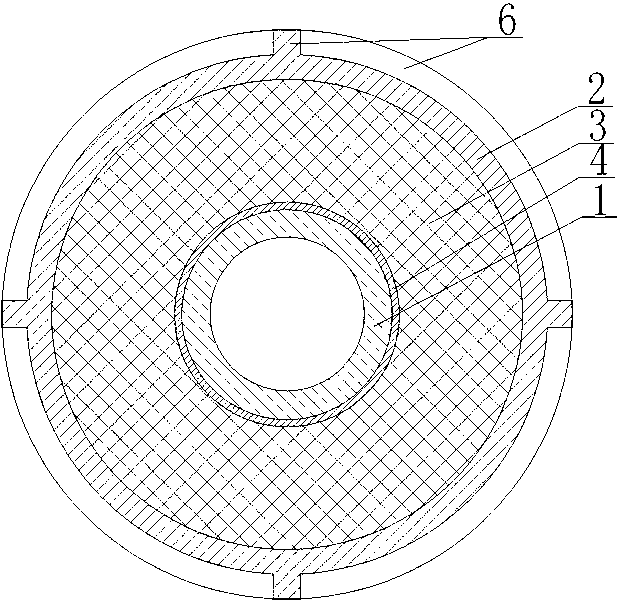

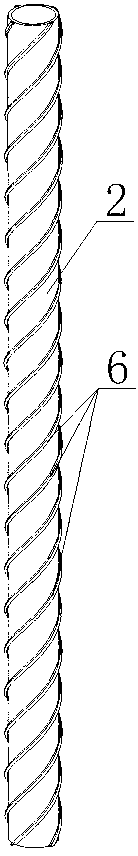

[0031] Such as Figures 1 to 3 As shown, the improved annular fuel element of the supercritical water reactor of the present invention includes an inner cladding 1 and an outer cladding 2 coaxially fitted with the inner cladding 1, and UO is filled between the inner cladding 1 and the outer cladding 2 2 Pellet Fuel 3, at UO 2 A layer of thermal insulation coating 4 is also arranged between the granular fuel 3 and the inner cladding 1; the outer diameter of the outer cladding 2 is 32.4mm, and the thickness of the inner cladding 1 and the outer cladding 2 is 0.57mm, UO 2 The thickness of the particulate fuel area is 2.5 mm, the thickness of the thermal insulation coating 4 is 0.16 mm, and the inner diameter of the inner cladding 1 is 24.8 mm. The outer shell 2 and the inner shell 1 are made of stainless steel 310S, and the thermal insulation coating 4 is made of zirconia.

[0032] The supercritical water reactor improved annular fuel assembly of the present invention includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com