Sludge return sedimentation pool improved from pipe chute sedimentation pool and improving method thereby

A technology of inclined tube sedimentation tank and sludge return, which is applied in the field of municipal engineering, can solve the problems of limited processing capacity and difficulty in improving the overall quality of effluent, and achieve the effects of improving coagulation efficiency, improving effluent effect, and strengthening physical flocculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

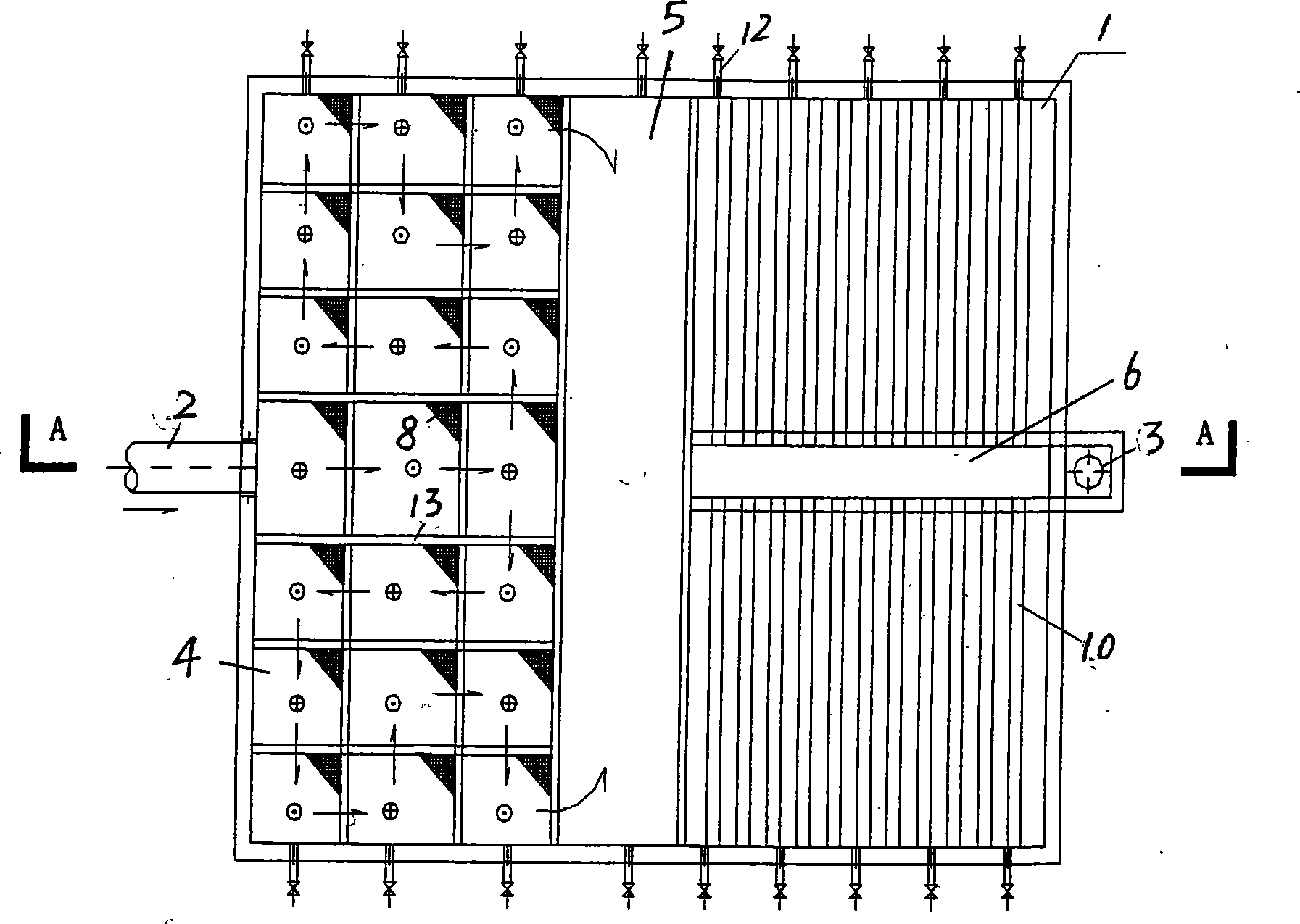

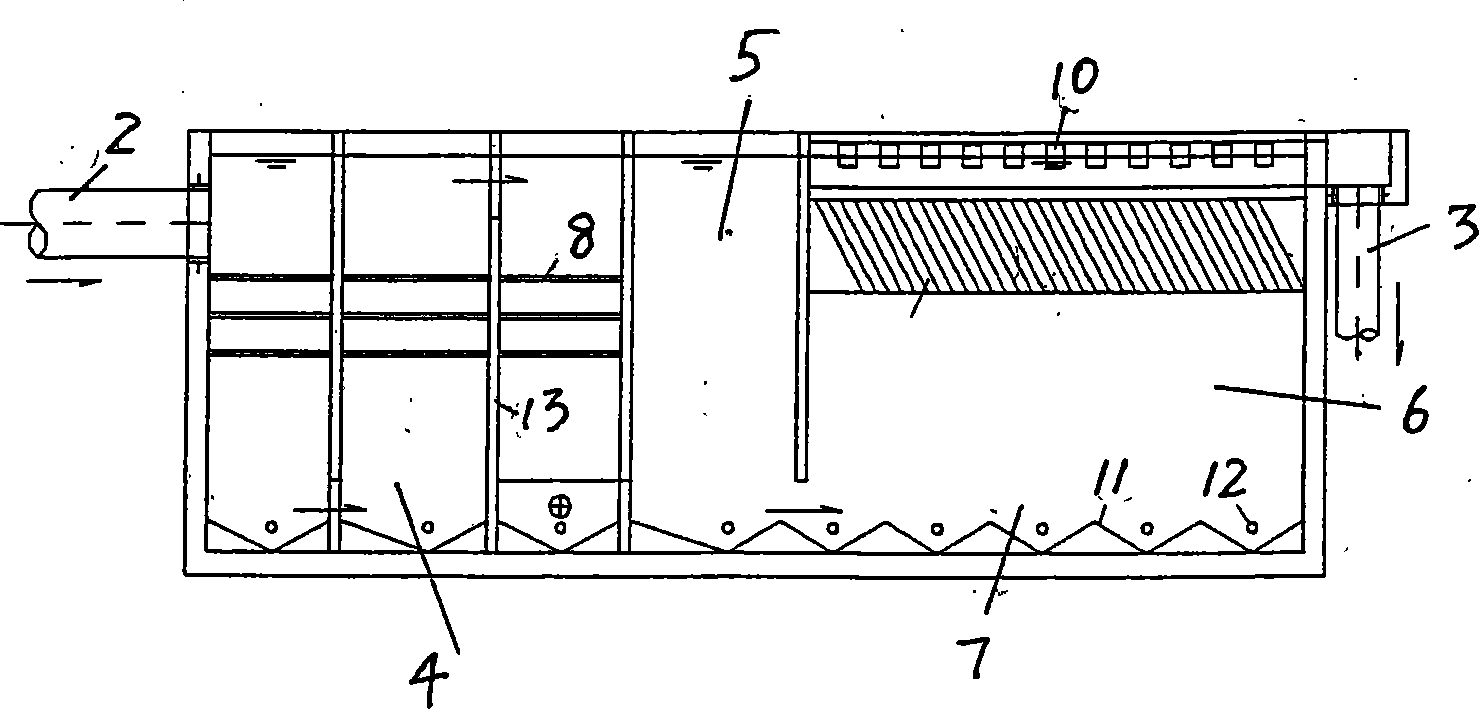

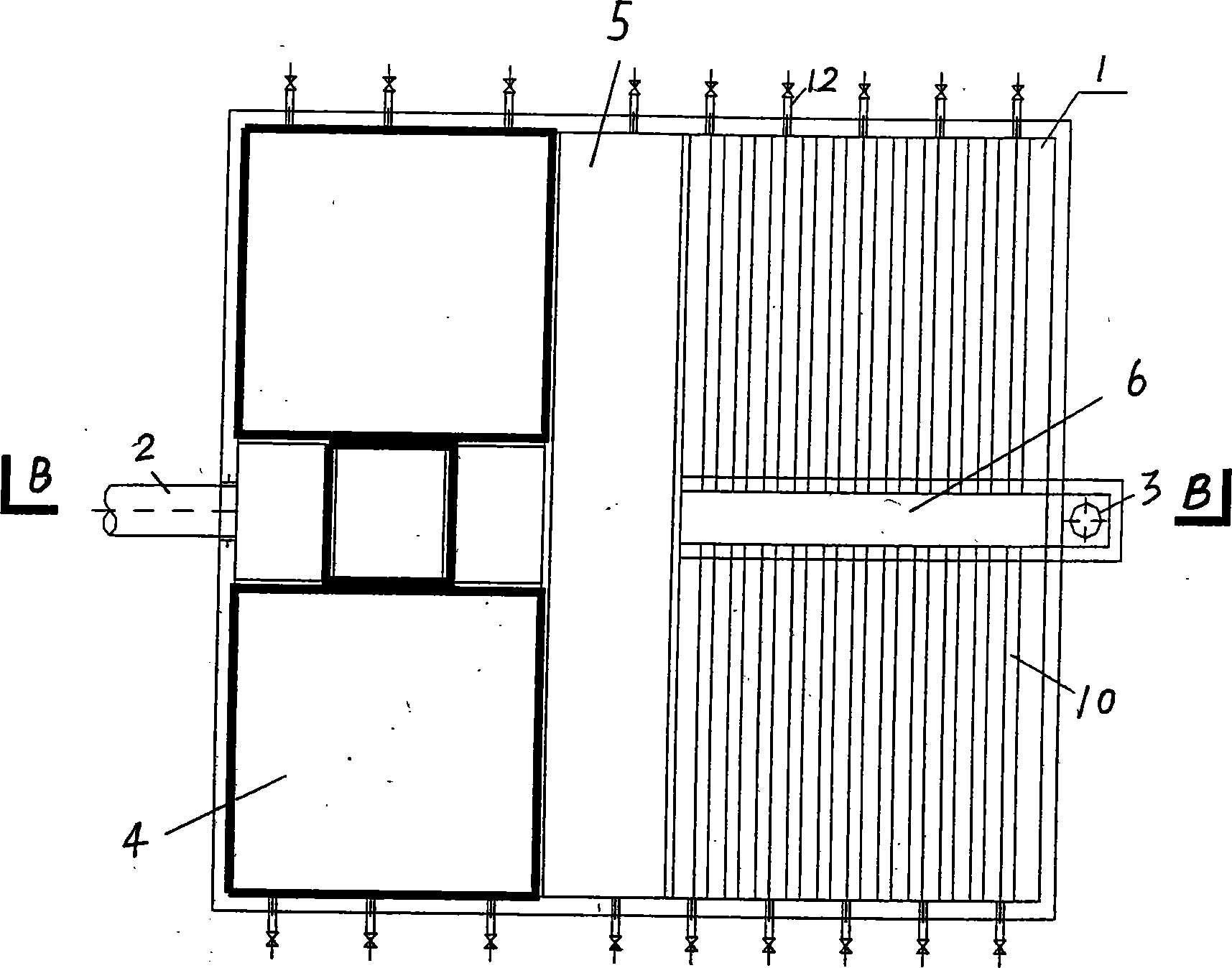

[0015] The invention is a sludge return sedimentation tank, which is obtained by transforming the traditional inclined tube sedimentation tank. Such as figure 1 with figure 2 As shown, the traditional inclined tube sedimentation tank includes a main tank body 1, which is provided with an inlet pipe 2 and an outlet pipe 3. The main tank body 1 is composed of an upper reaction zone 4, a transition zone 5, an inclined tube outlet zone 6 and a mud discharge zone. 7 components, the reaction area 4 is equipped with reaction facilities such as grid 8 and partition wall 13, the inclined pipe outlet area 6 is provided with plastic inclined pipe 9 and stainless steel outlet rectangular groove 10, and the mud discharge area 7 is equipped with a mud discharge bucket 11 and a mud discharge bucket 11 communicates with the mud discharge pipe 12, the mud discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com