Novel technology and device for Bayer process-based separation of iron in high-iron red mud

A Bayer process red mud, new process technology, applied in the improvement of process efficiency, chemical instruments and methods, magnetic separation and other directions, can solve the problems of weak industrial applicability, unsatisfactory effect, complex process, etc., to eliminate the impact and Accident hidden danger, reduction of related costs, and the effect of mature operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

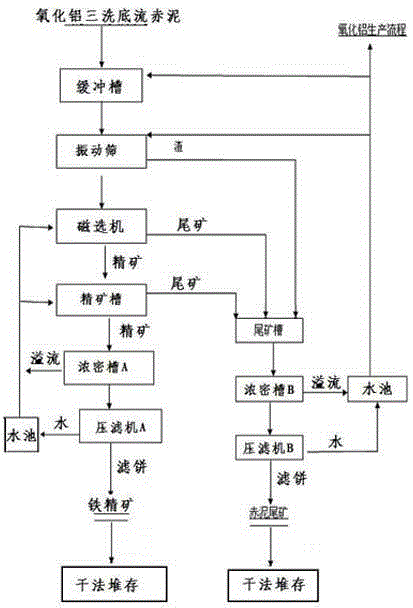

[0029] Such as figure 1 As shown, the high-speed rail Bayer process red mud high-efficiency iron separation device of the present invention includes a buffer tank, a vibrating screen, a magnetic separator, a concentrate tank, a tailing tank, a thick tank, and a filter press. The solid waste from alumina production is settled three times The outlet of the underflow red mud is connected with the buffer tank; the buffer tank is connected with the inlet of the vibrating screen, the outlet of the obtained vibrating screen is connected with the inlet of the magnetic separator, and the concentrate outlet of the magnetic separator is connected with the inlet of the thick tank A, The tailings outlet of the magnetic separator communicates with the inlet of the thick tank B; the outlet of the thick tank A communicates with the inlet of the filter press A; the outlet of the thick tank B communicates with the inlet of the filter press B.

[0030] The said magnetic separator is provided with on...

Embodiment 2

[0040] Such as figure 1 As shown, the high-speed rail Bayer process red mud high-efficiency iron separation device of the present invention includes a buffer tank, a vibrating screen, a magnetic separator, a concentrate tank, a tailing tank, a thick tank, and a filter press. The solid waste from alumina production is settled three times The outlet of the underflow red mud is connected with the buffer tank; the buffer tank is connected with the inlet of the vibrating screen, the outlet of the obtained vibrating screen is connected with the inlet of the magnetic separator, and the concentrate outlet of the magnetic separator is connected with the inlet of the thick tank A, The tailings outlet of the magnetic separator communicates with the inlet of the thick tank B; the outlet of the thick tank A communicates with the inlet of the filter press A; the outlet of the thick tank B communicates with the inlet of the filter press B.

[0041] The magnetic separator is Jones magnetic separa...

Embodiment 3

[0054] Such as figure 1 As shown, the high-speed rail Bayer process red mud high-efficiency iron separation device of the present invention includes a buffer tank, a vibrating screen, a magnetic separator, a concentrate tank, a tailing tank, a thick tank, and a filter press. The solid waste from alumina production is settled three times The outlet of the underflow red mud is connected with the buffer tank; the buffer tank is connected with the inlet of the vibrating screen, the outlet of the obtained vibrating screen is connected with the inlet of the magnetic separator, and the concentrate outlet of the magnetic separator is connected with the inlet of the thick tank A, The tailings outlet of the magnetic separator communicates with the inlet of the thick tank B; the outlet of the thick tank A communicates with the inlet of the filter press A; the outlet of the thick tank B communicates with the inlet of the filter press B.

[0055] The magnetic separator is Jones magnetic separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com