Concentrating and dry stacking method of iron tailing slurry

A technology for iron tailings and dry stacking is applied in the field of mine safety to achieve the effects of improving dehydration efficiency, reducing power consumption and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

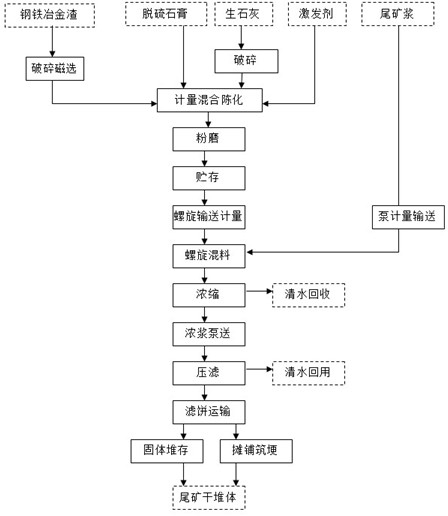

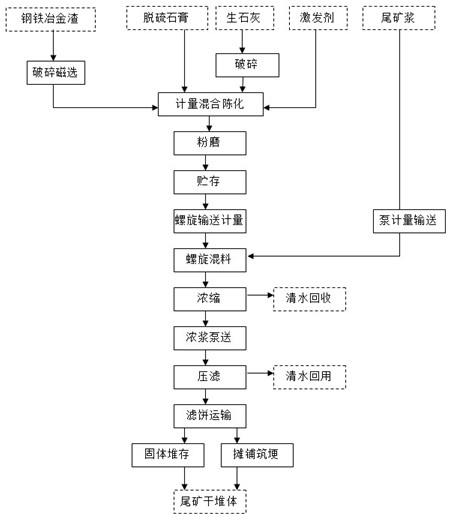

[0024] Embodiment 1: as figure 1 As shown, the specific steps of the iron tailings slurry concentration and dry stacking method are as follows:

[0025] (1) Preparation of composite admixture: Iron and steel metallurgical slag, chemical waste gypsum and quicklime are the main components

[0026] The carrier made of raw materials and the activator composed of aluminum sulfate, ferric chloride, and polyferric aluminum sulfate are mixed and configured at a weight ratio of 100:0.6, and then the mixture is dried, crushed, and dry-milled to pass 0.08 ㎜ sieve to the powder with a balance of less than 5% is the composite admixture; (the composition of the carrier is 70wt% of iron and steel metallurgical slag, 15wt% of chemical waste gypsum, and 15wt% of quicklime, and the iron and steel metallurgical slag is a mixture of steel slag and blast furnace water slag , the weight ratio is steel slag:blast furnace water slag=1:0.5. The composition of the activator is 20wt% aluminum sulfate,...

Embodiment 2

[0030] Embodiment 2: as figure 1 As shown, the specific steps of the iron tailings slurry concentration and dry stacking method are as follows:

[0031] (1) Preparation of composite admixture: Iron and steel metallurgical slag, chemical waste gypsum and quicklime are the main components

[0032] The carrier made of raw materials and the activator composed of aluminum sulfate, ferric chloride, and polyferric aluminum sulfate are mixed and configured at a weight ratio of 100:3, and then the mixture is dried, crushed, and dry-milled to pass 0.08 ㎜ sieve to the powder with a balance of less than 5% is the composite admixture; (the composition of the carrier is 75wt% of iron and steel metallurgical slag, 12wt% of chemical waste gypsum, and 13wt% of quicklime, and the iron and steel metallurgical slag is a mixture of steel slag and blast furnace water slag , and its weight ratio is steel slag:blast furnace water slag=1:1. The composition of the activator is 30wt% aluminum sulfate,...

Embodiment 3

[0036] Embodiment 3: as figure 1 As shown, the specific steps of the iron tailings slurry concentration and dry stacking method are as follows:

[0037] (1) Preparation of composite admixture: Iron and steel metallurgical slag, chemical waste gypsum and quicklime are the main components

[0038] The carrier made of raw materials and the activator composed of aluminum sulfate, ferric chloride, and polyferric aluminum sulfate are mixed according to a weight ratio of 100: 5.0, and then the mixture is dried, crushed, and dry-milled to pass 0.08 ㎜ sieve to the powder with a balance of less than 5% is the composite admixture; (the composition of the carrier is 80wt% iron and steel metallurgical slag, 10wt% chemical waste gypsum, 10wt% quicklime, and the iron and steel metallurgical slag is a mixture of steel slag and blast furnace water slag , and its weight ratio is steel slag: blast furnace water slag=1: 2.0. The composition of the activator is aluminum sulfate 40wt%, ferric chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com