Construction method of HDPE film for road embankment seepage prevention

A construction method and road technology, applied in the directions of roads, roads, buildings, etc., can solve the problems of HDPE anti-seepage membrane damage, etc., and achieve the effect of reducing damage, ensuring reliability, and ensuring anti-seepage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

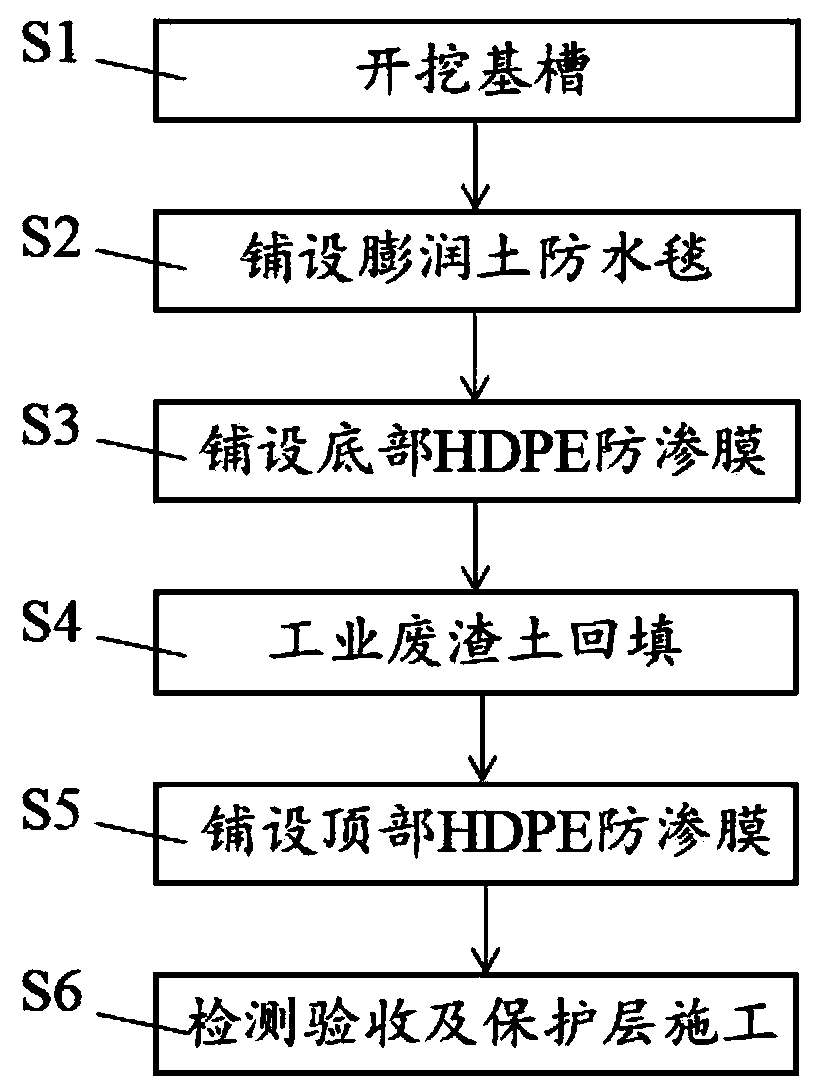

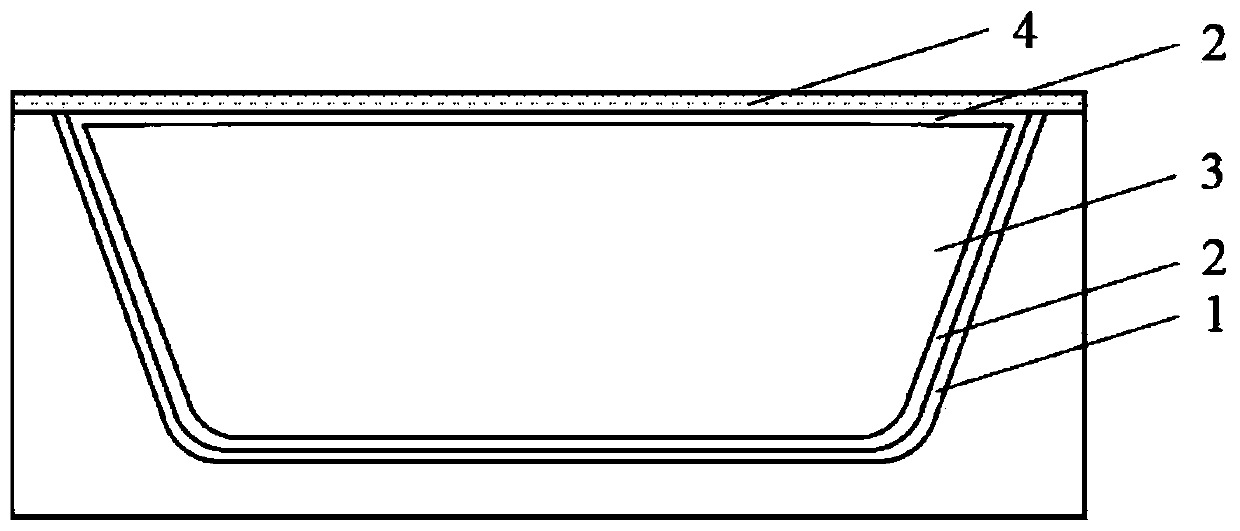

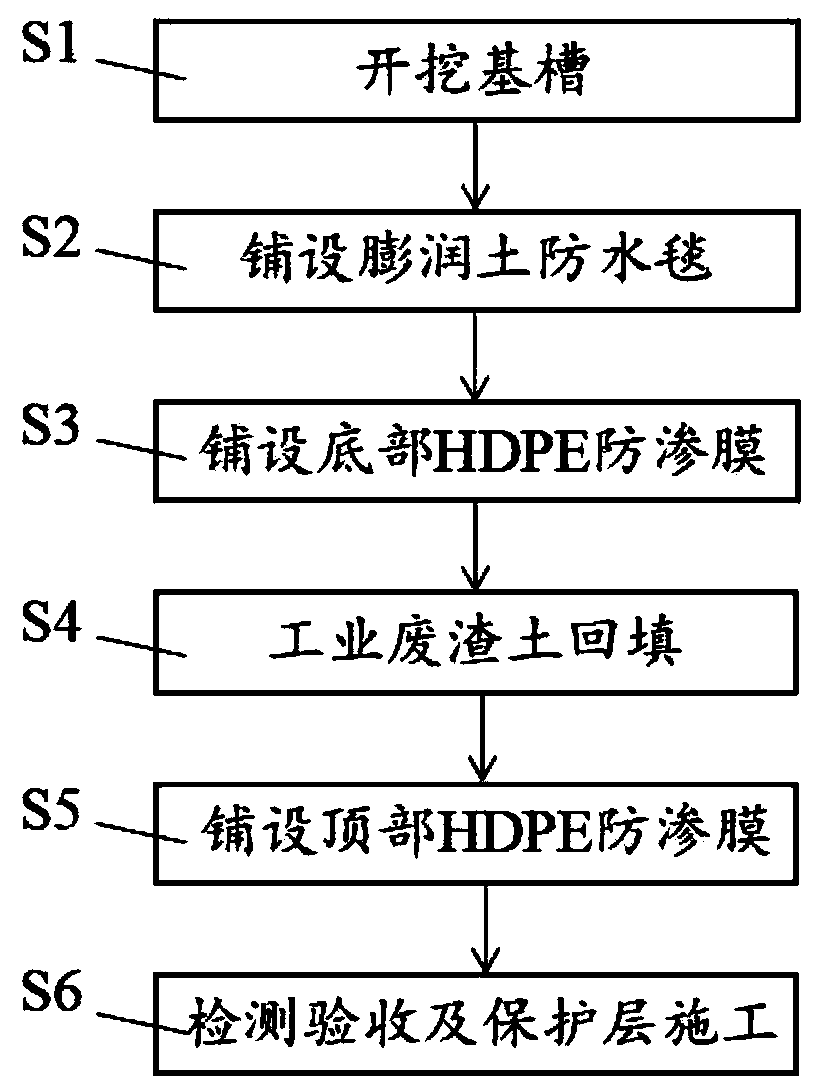

[0031] Reference manual attached figure 1 and figure 2 , present embodiment provides a kind of HDPE film is used for the construction method of anti-seepage of road embankment, comprises the following steps:

[0032] S1. Excavation of foundation trench: set up a groove within the scope of the road land, the cross section of the groove is an isosceles trapezoidal structure, the surface of the groove is solid and flat, and the corners are smooth. Specifically, the foundation groove should meet the requirements of no cracks, no obvious sharp protrusions, no water seepage, water collection, organic residues and harmful substances that may cause environmental pollution; the radius of the arc at the corner of the foundation groove is not less than 50cm.

[0033] S2. Laying bentonite waterproof blanket: laying a layer of bentonite waterproof blanket 1 on the base groove by direct overlapping, specifically, the overlapping width is 15cm.

[0034] S3. Lay the bottom HDPE anti-seepag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com