Cement-based composite material blanket based on sandwich mesh cloth and preparation method of blanket

A composite material blanket and cement-based technology, applied in chemical instruments and methods, roofing with flexible materials, excavation, etc., can solve problems such as loss and loss, and lack of dry powder materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

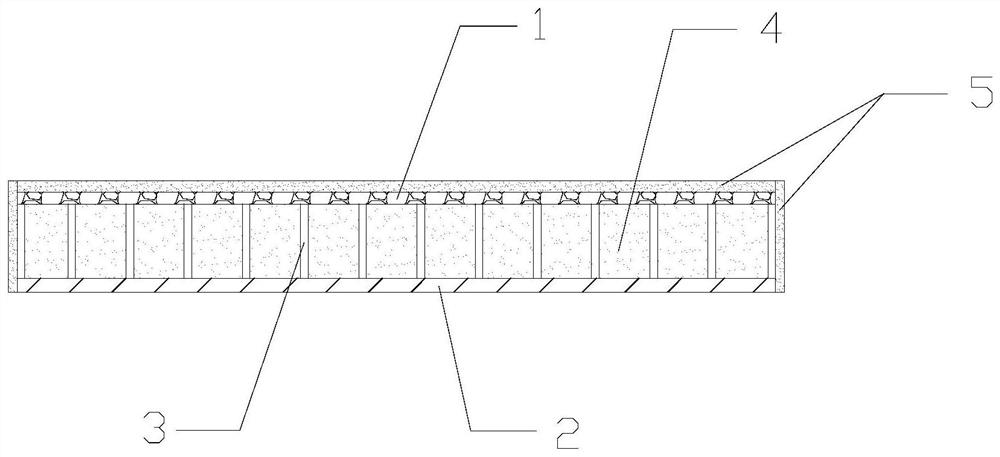

[0030] The dry powder material is made of cement and sand mixed in a ratio of 1:1, the cement includes 20% sulfoaluminate cement and 80% Portland cement, the sand is dry river sand, and the thickness of the sandwich mesh is 1cm , and its weight per square meter is 1.1kg, the mesh diameter / side length of the mesh surface layer is 1mm, the label of Portland cement is above 425#, and the river sand is dry fine sand with a mud content of less than 2 %, the mass proportion of fineness modulus below 2.2 is 70%, and the label of waterproof polymer cement is not less than 425#, and the mass proportion is 50%.

Embodiment 2

[0032] The dry powder material is made by mixing cement and sand in a ratio of 1:1. The cement includes 20% sulphoaluminate cement and 80% portland cement. The sand is the mesh diameter of the dry sea sand mesh surface layer. / The length of the side is 1mm-2mm, the thickness of the sandwich mesh is 2cm, and its weight per square meter is 1.2kg, the label of Portland cement is above 425#, and the sea sand is dry fine sand, and its mud content is less than 2%, the fineness modulus below 2.2 is 75%, the grade of waterproof polymer cement is not less than 425#, and the mass proportion is 55%.

Embodiment 3

[0034] The dry powder material is made of cement and sand mixed in a ratio of 1:1. The cement includes 20% sulfoaluminate cement and 80% Portland cement. The sand is a mixture of dry river sand and sea sand. The mesh diameter of the surface layer is 2mm, the thickness of the sandwich mesh is 3cm, the thickness of the sandwich mesh is 1cm, and its weight per square meter is 1.3kg, and the label of Portland cement is above 425#. , river sand and sea sand are dry fine sand, with a mud content of less than 2%, and those with a fineness modulus below 2.2 are 78%. The grade of waterproof polymer cement is not less than 425#, and the mass ratio is 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com