Plywood used for bottom plate of container

A kind of technology of container floor and plywood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

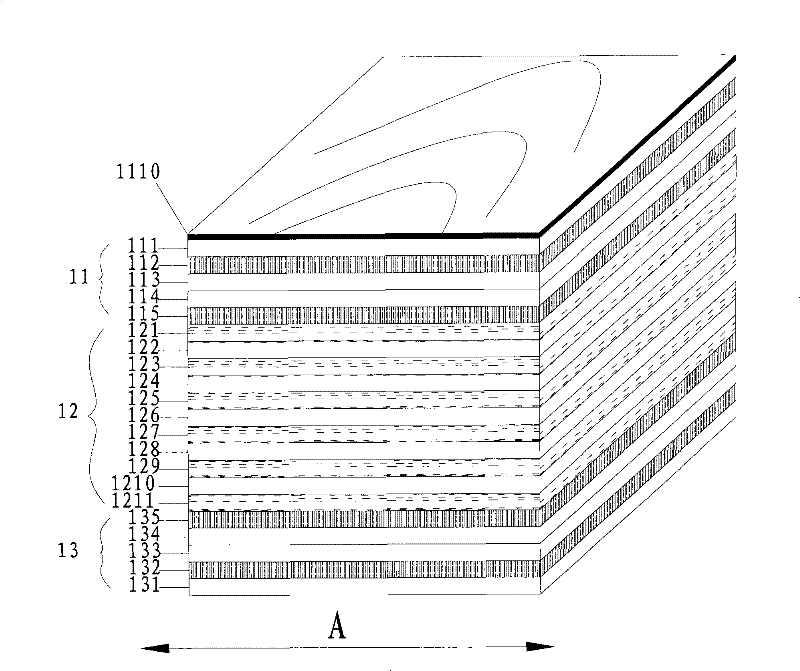

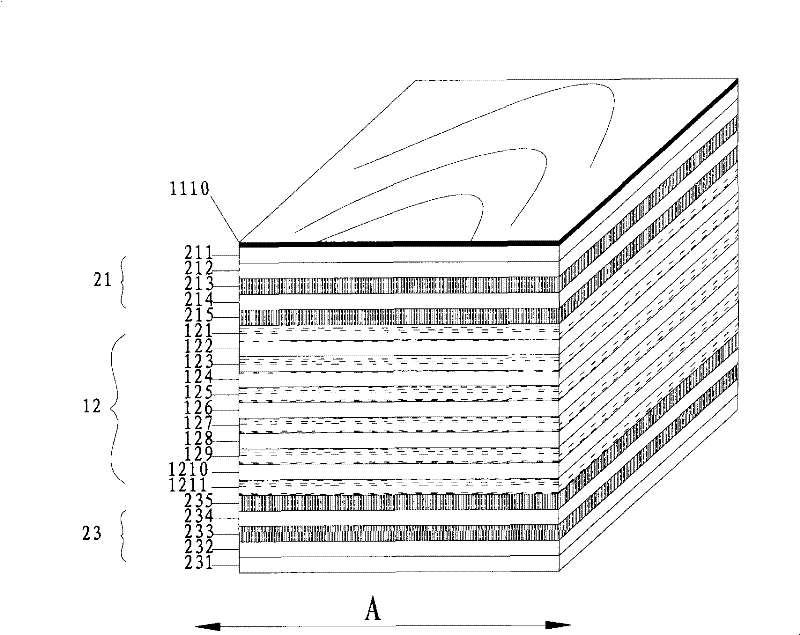

[0022] Such as figure 1 As shown, the container bottom plate of the present invention is composed of 21 layers of veneers, including an upper layer 11, a lower layer 13 and an intermediate layer 12 sandwiched between the upper and lower layers, and the upper layer is sequentially from outside to inside. Wooden veneer 111 along the grain, wood veneer 112 across the grain, two consecutive wood veneers along the grain 113, 114, and wood veneer 115 across the grain; the middle layer is 11 consecutive pieces of veneer along the grain 121- 1211, of which 121, 123, 125, 127, 129, and 1211 are bamboo curtain veneers along the grain, 122, 124, 126, 128, and 1210 are pine or eucalyptus wood veneers along the grain, and the bamboo curtain veneer and wood veneer are mutually Arranged in a staggered manner; the lower layer is sequentially arranged from outside to inside with the parallel grain wood veneer 131, the horizontal grain wood veneer 132, two consecutive parallel grain wood veneer...

Embodiment 2

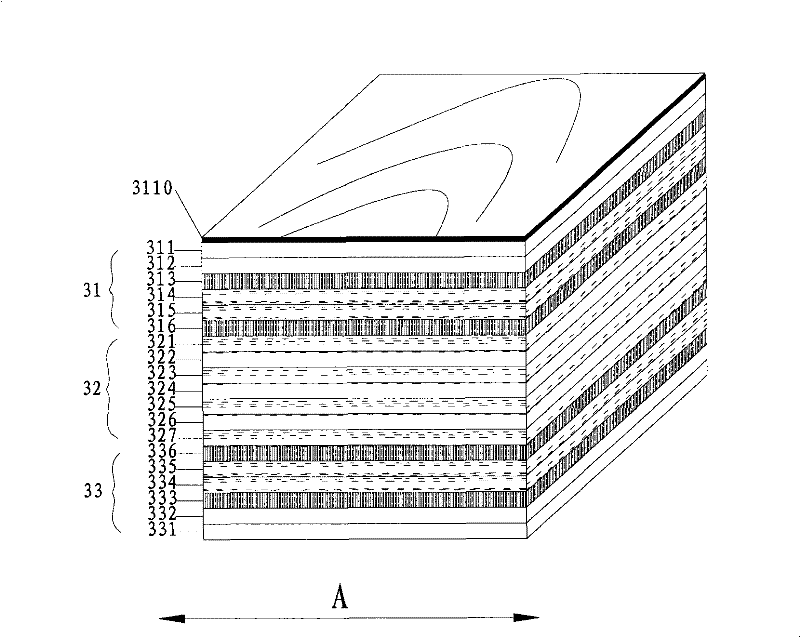

[0028] Such as image 3 As shown, the plywood for the container floor of the present invention is composed of 19 layers of veneers, including an upper layer 31, a lower layer 33, and an intermediate layer 32 sandwiched between the upper and lower layers. 311, 312 long-grained wood veneer, 313 horizontal-grained wood veneer, 2 consecutive long-grained long-medium boards 314, 315, and horizontal-grained wood veneer 316; the middle layer is 7 consecutive long-grained long medium boards laminated along the grain 321-327, wherein 321, 323, 325, and 327 are bamboo curtain long boards, 322, 324, and 326 are pine or eucalyptus long boards; the lower layer is two long boards 331 and 332 along the grain from outside to inside, Horizontal grain wood veneer 333, 2 consecutive long middle boards 334, 335 along the grain, horizontal grain wood veneer 336; the outermost veneers 311 and 331 of the upper and lower layers are clone veneers, 314, 315, 334 , 335 is the long medium board of bambo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com