Insulation board provided with two layers of mesh fabric

A thermal insulation board, double-layer technology, applied in the direction of thermal insulation, building components, construction, etc., can solve the problems of easy collapse, poor shear resistance and low strength of thermal insulation boards, and avoid cracking, slump phenomenon, dispersion shrinkage, etc. Effects of pressure and insulation stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

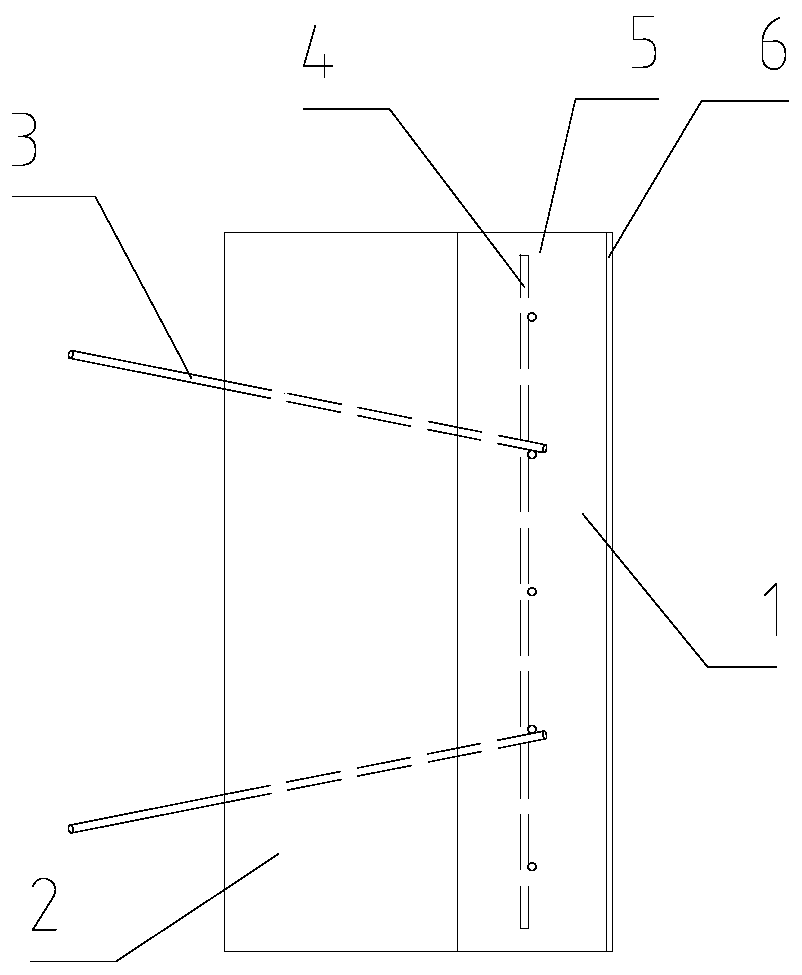

[0036] Such as Figure 1-3 The insulation board with a single-layer grid cloth structure is shown, with an insulation layer, a concrete layer on one side of the insulation layer, and a steel wire mesh support frame running through the interior of the insulation layer and the concrete layer. The steel wire mesh support frame includes horizontal support steel wires and Longitudinal support steel wires, horizontal support steel wires and longitudinal support steel wires are interlacedly connected, and the wire mesh support frame is also provided with abdominal wires, one end of the abdominal wires is overlapped with horizontal support steel wires or longitudinal support steel wires, and the interlaced horizontal support steel wires and longitudinal support steel wires are located at Inside the concrete layer, the other end of the abdominal wire passes through the insulation layer and leaks outside the insulation layer. The outer abdominal wires are arranged at an angle with the o...

Embodiment 2

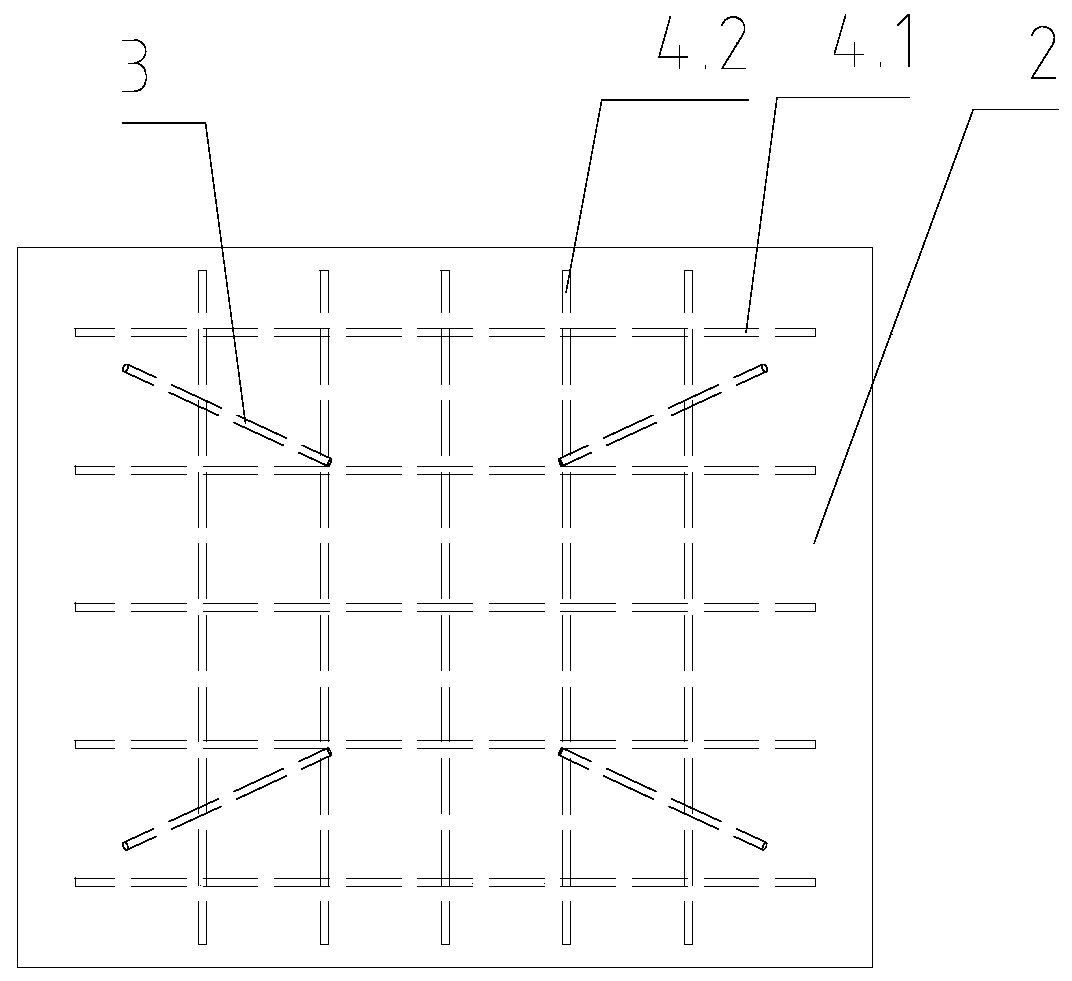

[0038] Such as Figure 4-6 As described above, a double-layer mesh insulation board is provided with an insulation layer 2, a concrete layer 1 is arranged on one side of the insulation layer 2, a steel wire mesh support frame 4 is arranged inside the concrete layer 1, and two layers are arranged in parallel in the concrete layer 1. Mesh cloth, the mesh cloth is made of alkali-resistant glass fiber mesh, which improves the mechanical strength of the insulation board, ensures the continuity of the resistance of the facing layer, disperses the shrinkage pressure and heat preservation stress of the surface layer, avoids stress concentration, and can effectively resist the natural environment. Surface cracking caused by temperature, humidity changes and accidental impact. The wire mesh support frame 4 is provided with a belly wire 3, which is made of galvanized iron wire or stainless steel wire. Layer 2 exterior.

[0039] The alkali-resistant glass fiber mesh is pressed into the ...

Embodiment 3

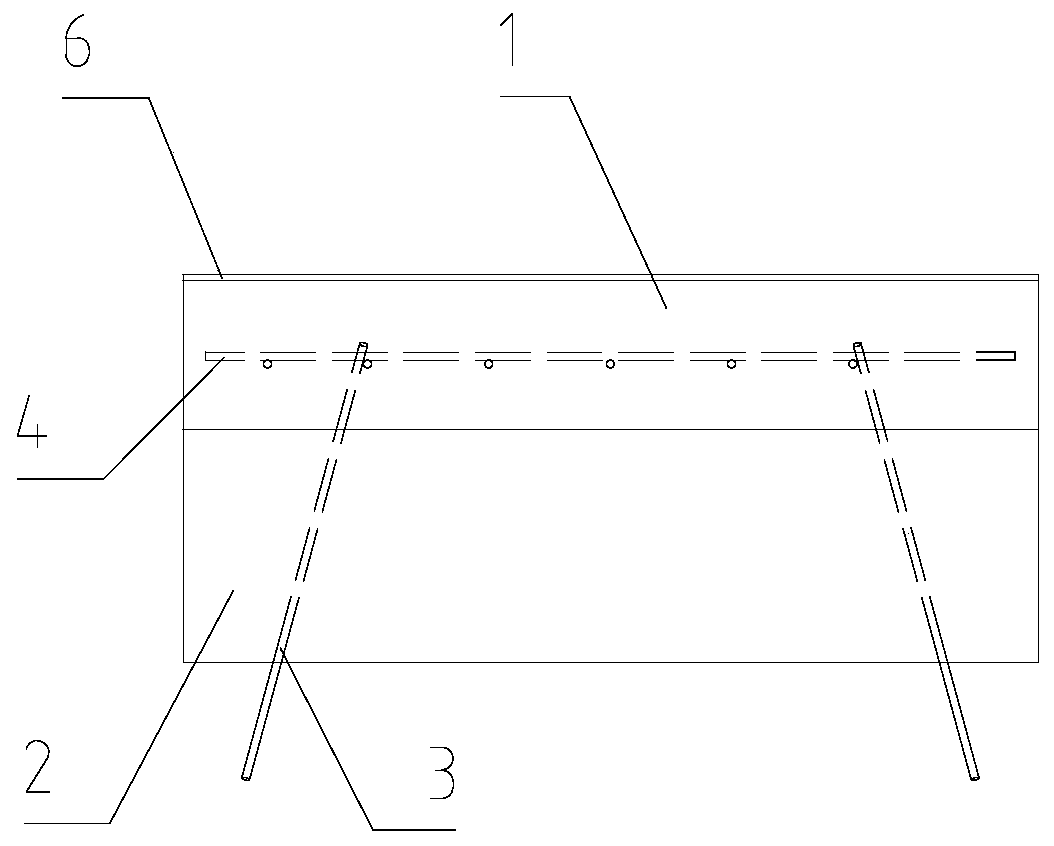

[0055] Figure 7-Figure 9 As another embodiment of the present invention, different from Embodiment 1, among the horizontal support steel wires 4.1 and longitudinal support steel wires 4.2 intertwined on the wire mesh support frame 4, the horizontal support steel wires 4.1 are bent up and down, and bent up and down When the distributed horizontal support wire 4.1 runs through the concrete layer 1 of the insulation board, the length of the horizontal support wire 4.1 bent up and down is lengthened, and the up and down bending design of the horizontal support wire 4.1 can evenly support the concrete layer 1 of the insulation board , so that the concrete layer 1 supporting the insulation board receives a uniform support force, so that the load-carrying capacity of the insulation board is enhanced, that is to say, when the horizontal support steel wire 4.1 bent and distributed up and down runs through the concrete layer 1 of the insulation board, the improvement The technical prob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com