Construction method of prefabricated underground diaphragm wall

A technology of underground diaphragm wall and construction method, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of water leakage at joints, difficult control of construction effect, time-consuming and labor-intensive construction, etc., to ensure shear strength. , The effect of enhancing the waterproof effect and improving the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The construction method of the prefabricated underground diaphragm wall of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] First, the structure of the prefabricated underground continuous wall in the present invention will be described.

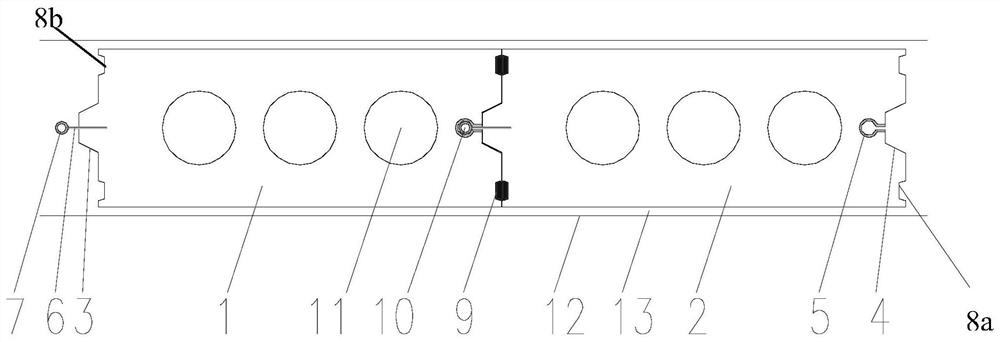

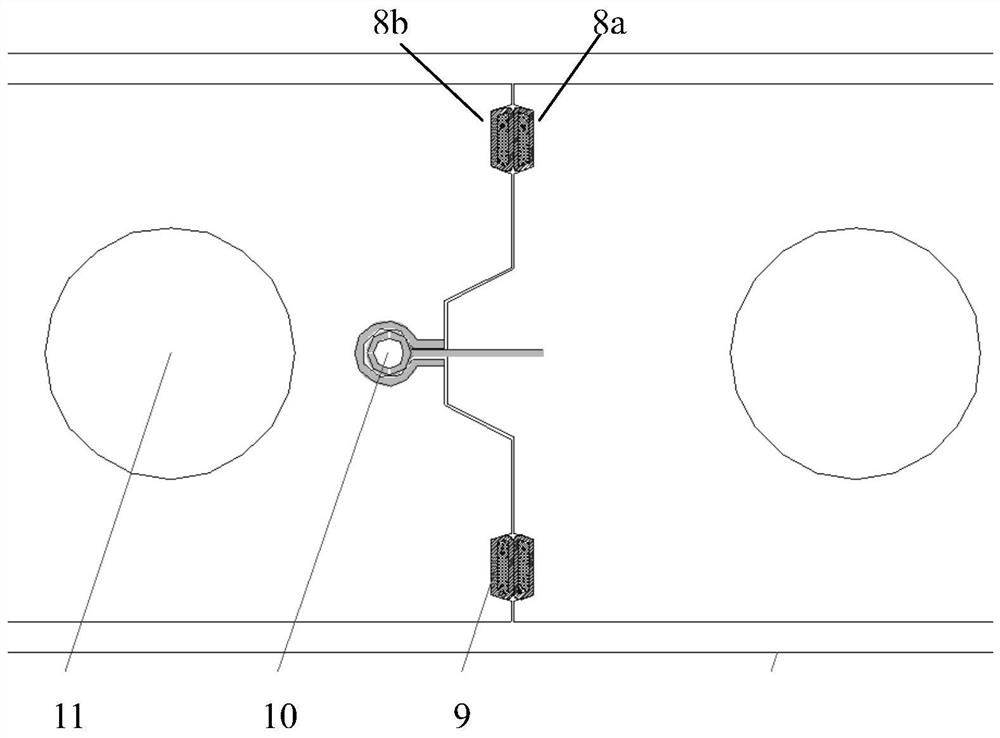

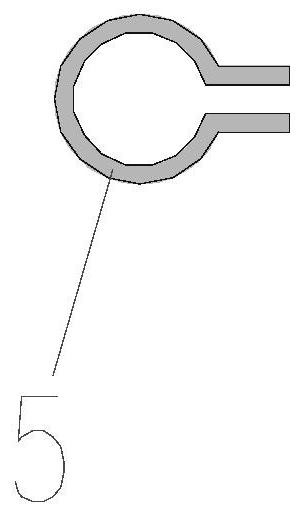

[0042] Such as Figure 1 to Figure 9 As shown, the prefabricated underground continuous wall includes a plurality of prefabricated wall units that are connected end to end and have the same structure, and a first groove 4 and a second groove 4 are formed on one side connecting surface of each wall unit. Two grooves 8a, a tenon 3 and a third groove 8b are formed on the connecting surface of the other side of the wall unit, and the shapes of the tenons 3 and the first groove 4 are adapted. As shown in the figure, for two adjacent wall units 1 and 2, the tenon 3 of unit 2 is embedded in the first groove 4 of unit 1, the second groove 8a of unit 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com