A permanent beam formwork, a concrete structural member and a manufacturing method for a reinforced embedded buckle connection

A manufacturing method and permanent technology, applied to truss structures, bridge parts, bridges, etc., to achieve simple manufacturing procedures, ensure shear strength, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the technical solution provided by the present invention will be further described below in conjunction with the accompanying drawings. This implementation example is an illustration of the present invention, rather than limiting the present invention.

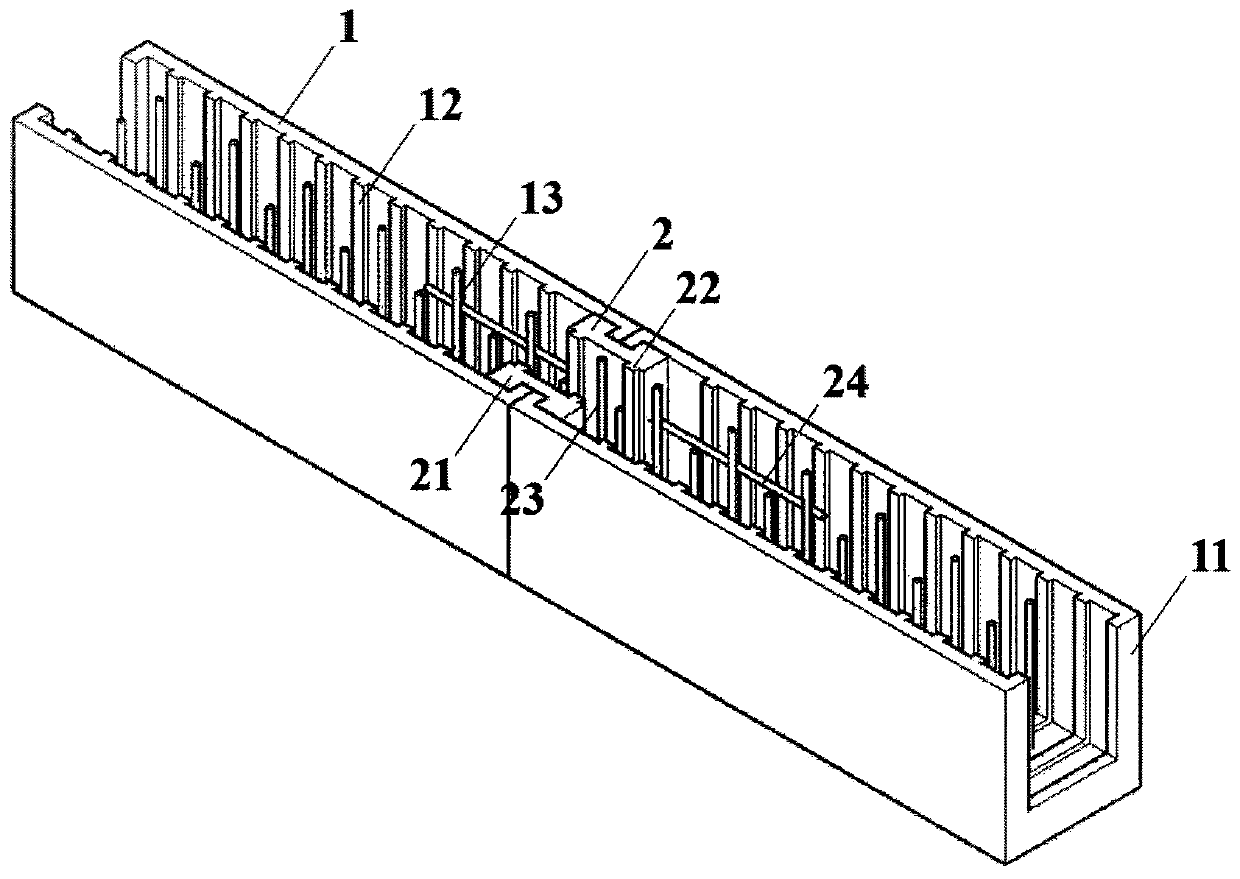

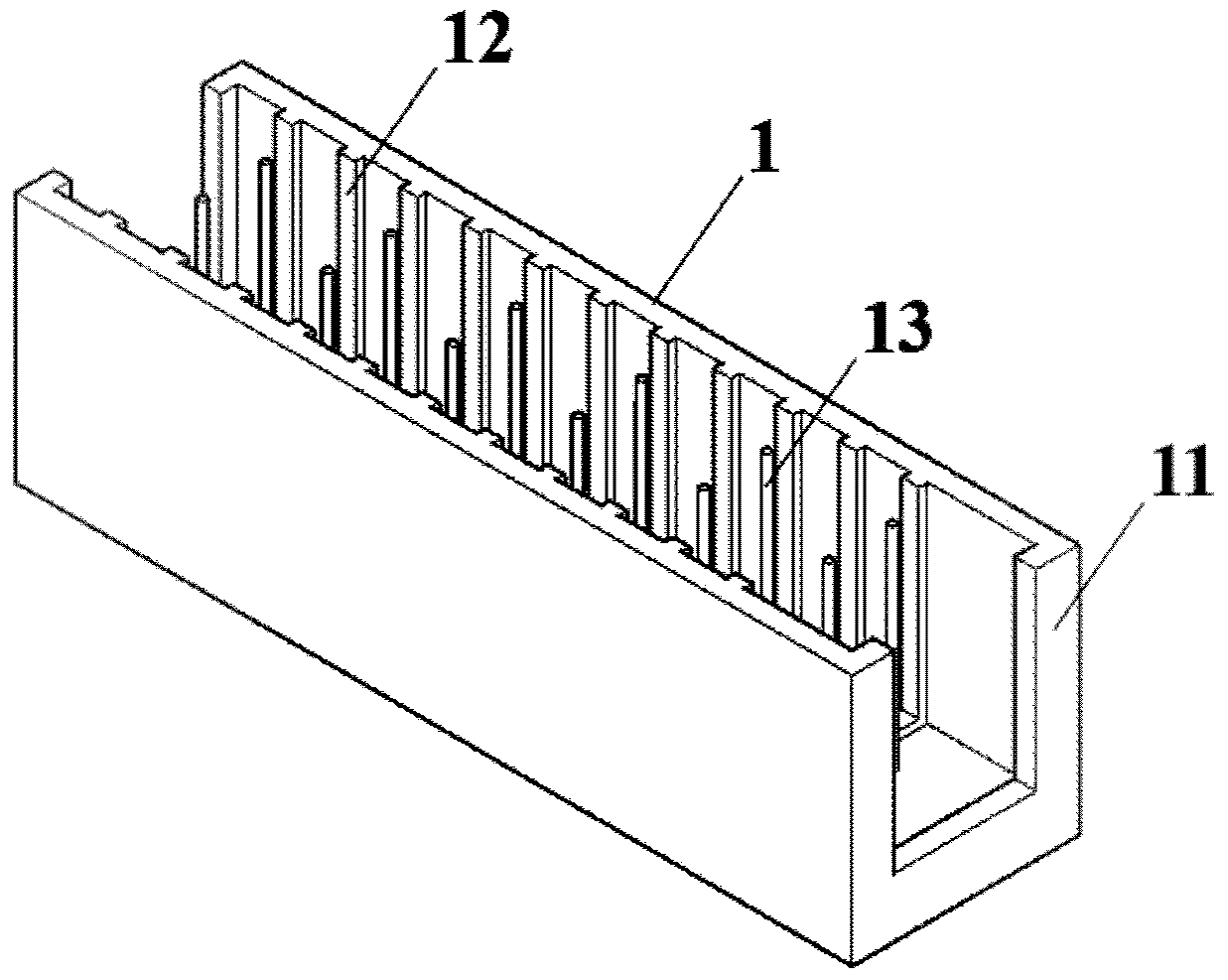

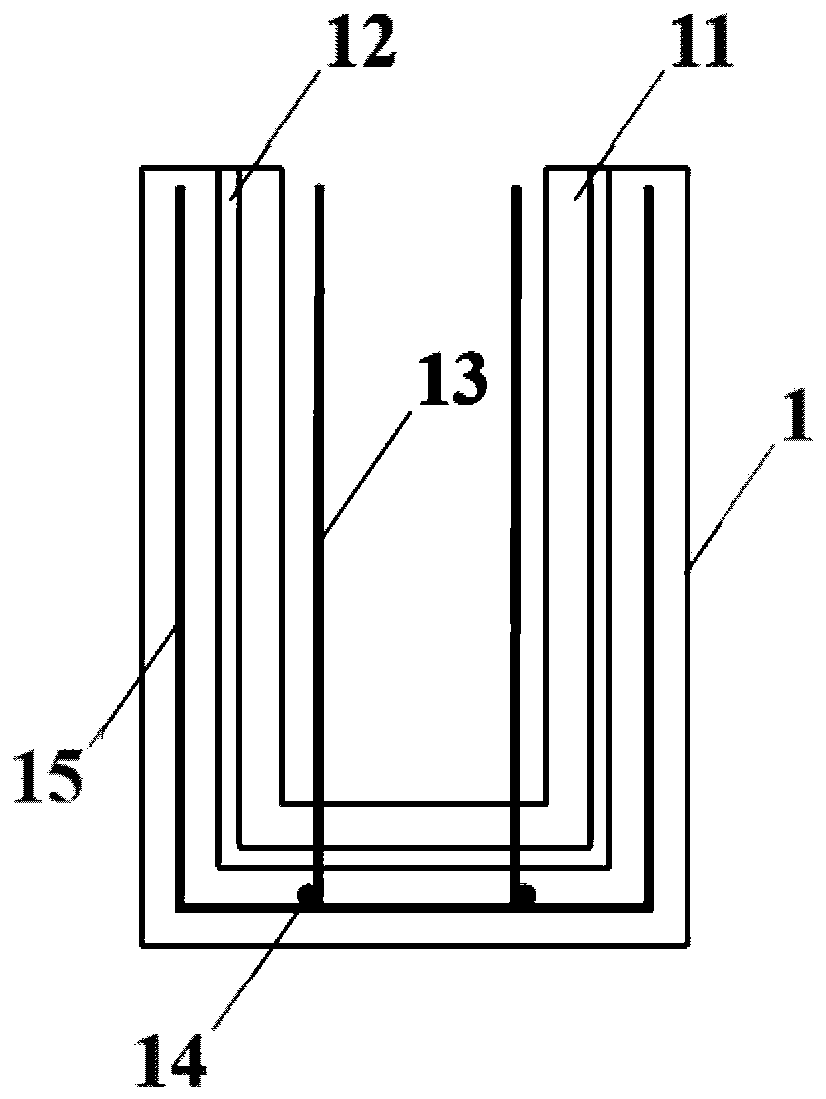

[0023] Referring to the accompanying drawings, a permanent beam formwork with reinforcement type embedded buckle connection provided by the present invention is composed of a panel 1 and a connector 2; the panel 1 has a first connection part, and the connector 2 has a second connection part, the second connecting part can be buckled with the first connecting part of the two panels after splicing, and the connecting piece 2 is on the side of the pouring interface of the two panels after splicing and is connected to the side of the two panels 1 The first connection parts overlap each other, the first connection part of the panel 1 is provided with a groove 11 for fastening, and the second con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com