Low-melting-point lead-free solder alloy

A technology of lead-free solder alloy and low melting point. It is applied in the field of solder and low melting point lead-free solder alloy. It can solve the problems of increased cost, less bismuth, and failure to meet temperature requirements, etc., to refine the alloy structure, improve gloss, and improve The effect of brazeability and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

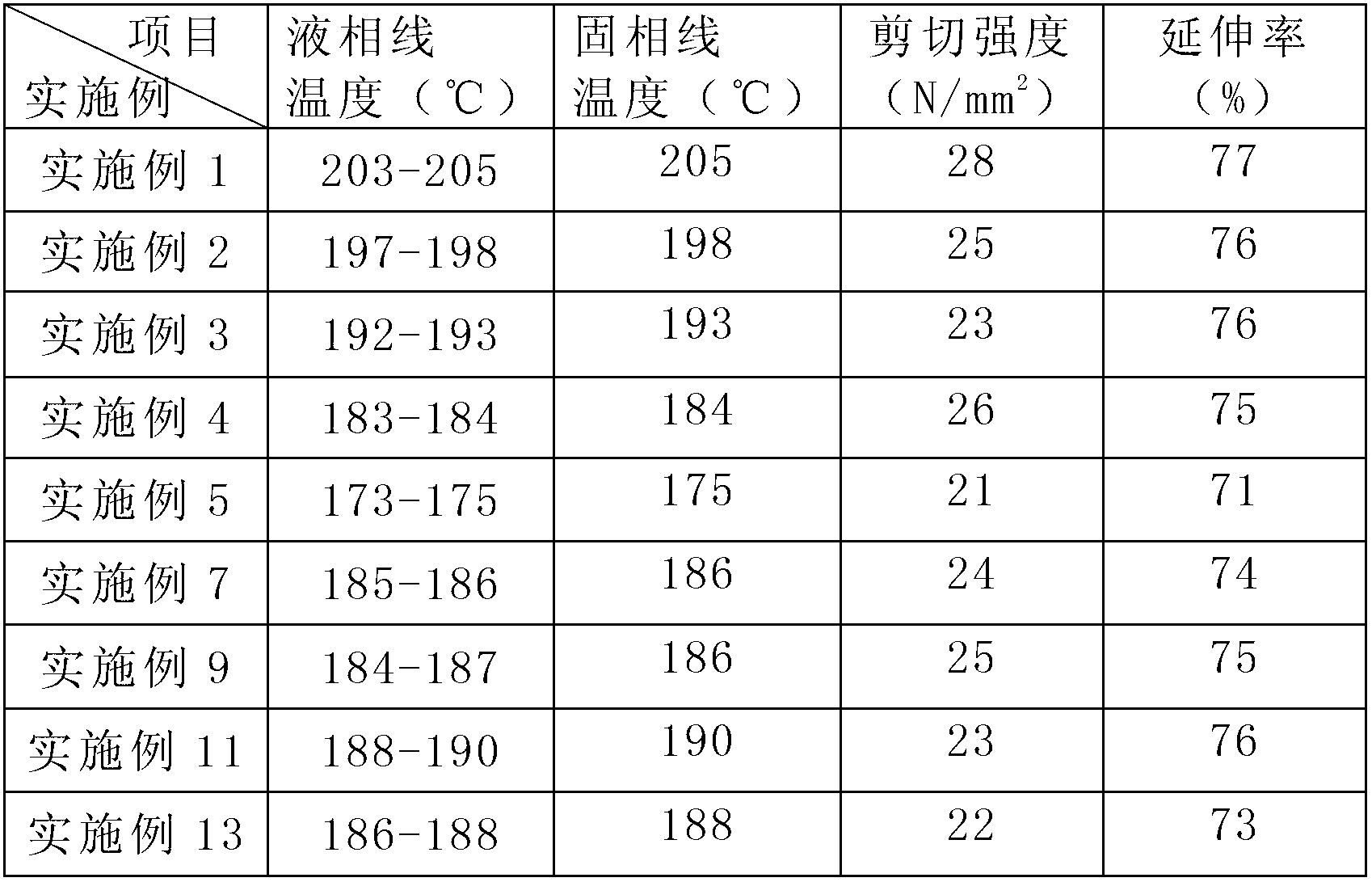

Examples

Embodiment 1

[0026] A low melting point lead-free solder alloy, the lead-free solder alloy contains the weight percent of the following components:

[0027] Bi: 10%; Ag: 2.8%; In: 0.5%; P: 0.005%; the balance is Sn, and unavoidable impurities may also be included.

[0028] The low melting point lead-free solder alloy in this embodiment is prepared by the following method:

[0029] Weigh the required raw materials according to the weight percentages of Bi, Ag, In, P and Sn in this example, add them to the furnace, and then heat up to 300°C to melt, then put them into a mixer and stir them for 40 minutes before casting Forming to obtain the low melting point lead-free solder alloy of the present invention.

Embodiment 2

[0031] A low melting point lead-free solder alloy, the lead-free solder alloy contains the weight percent of the following components:

[0032] Bi: 15%; Ag: 2.8%; In: 0.5%; P: 0.0052%; the balance is Sn, and unavoidable impurities may also be included.

[0033] The preparation method of the low-melting-point lead-free solder in this embodiment is the same as the method described in Embodiment 1, the only difference is that the weight percentages of the components of the lead-free solder alloy are weighed according to the proportions in this embodiment.

Embodiment 3

[0035] A low melting point lead-free solder alloy, the lead-free solder alloy contains the weight percent of the following components:

[0036] Bi: 20%; Ag: 2.5%; In: 0.8%; P: 0.0055%; the balance is Sn, and unavoidable impurities may also be included.

[0037] The preparation method of the low-melting-point lead-free solder in this embodiment is the same as the method described in Embodiment 1, the only difference is that the weight percentages of the components of the lead-free solder alloy are weighed according to the proportions in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com