Column full-section partition plate type stirrup-free fiber reinforced concrete mixed frame joint

A technology of reinforced concrete columns and joints, which is applied in the field of joints of reinforced concrete column-steel beam hybrid frame structures, which can solve the problems of difficult plastic deformation in welding affected areas, narrow space for concrete pouring and vibration, and warping deformation of end plates out of plane To achieve the effect of improving the applicability and implementability, reducing the difficulty of concrete pouring, and preventing the column end from being damaged under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

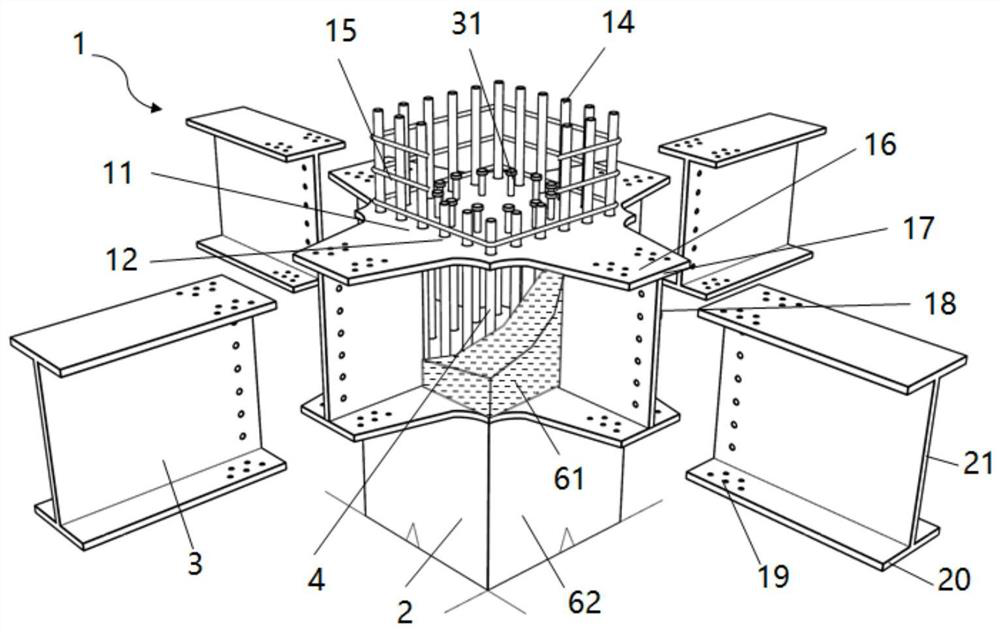

[0042] Such as figure 1 As shown, the hybrid frame node 4 of this embodiment is the node where the reinforced concrete column 2 and the steel beam 3 are connected to each other in the hybrid frame structure system 1;

[0043] The gusset plate 11 is composed of two upper and lower steel plates. In order to avoid local stress concentration to cause pressure damage at the end of the node column, at the same time ensure that the connection between the left and right steel beam flanges 20 has sufficient strength and rigidity, and at the same time facilitate the integrated prefabrication of the node 4 and the reinforced concrete column 2 , the horizontal gusset plate 11 in the form of a full-section partition of the column is adopted; in order to reduce the construction difficulty of the node 4 and ensure the accuracy of the reinforcement, the gusset plate 11 is provided with round holes 12 corresponding to the upper and lower sides, and the longitudinal steel bars 14 of the column ...

Embodiment 2

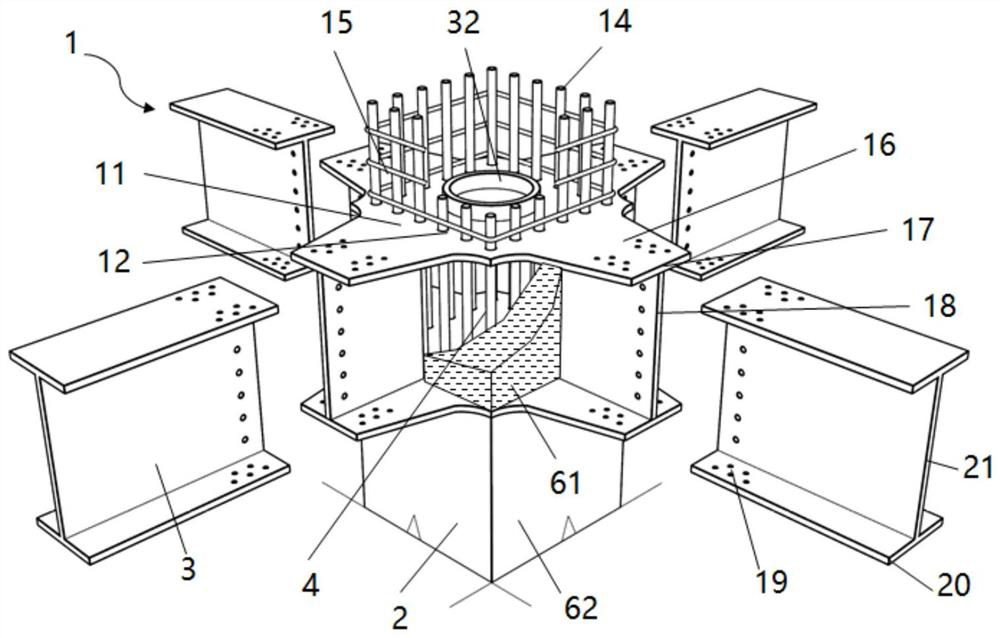

[0047] Such as figure 2 As shown, it is the same as in Example 1, the column is in the form of a full-section partition, no stirrups are provided in the core area of the joint, and fiber reinforced concrete 61 is used.

[0048] The difference from Example 1 is that in order to prevent the concrete in the round hole 12 where the column longitudinal steel bar 14 is pierced from not being filled and compacted, resulting in relatively large relative sliding between the reinforced concrete column 2-horizontal gusset plate 11-concrete 61 in the node core area The displacement affects the seismic performance of the node 4, and the vertical circular steel pipe protrusions 32 are welded on the outer side or inner and outer sides of the upper and lower gusset plates 11 to form a horizontal shear key and effectively reduce the sliding deformation. The rest of the structure is similar to Example 1.

Embodiment 3

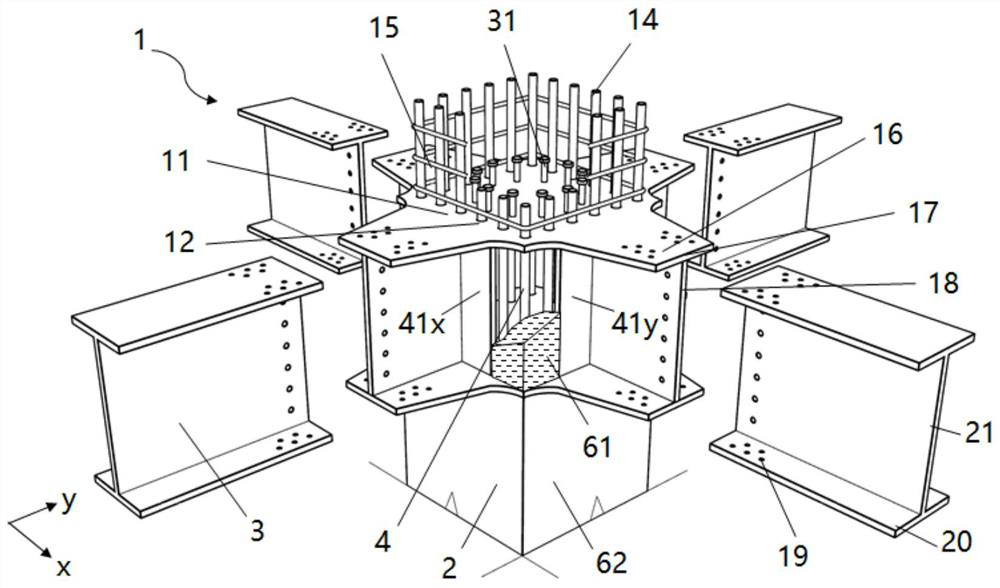

[0050] Such as image 3 As shown, it is the same as in Example 1, the column is in the form of a full-section diaphragm, no stirrups are set in the core area of the joint, fiber reinforced concrete 61 is used, and vertical studs 31 shear keys are installed on the outer sides of the upper and lower joint plates.

[0051] The difference from Example 1 is that although the shear strength of fiber reinforced concrete 61 is higher than that of ordinary concrete, when the amount of fiber per unit volume exceeds a certain level, the shear strength of fiber reinforced concrete 61 will no longer increase. Therefore, when the shear force acting on the joint is large and the shear strength provided by the fiber-reinforced concrete 61 in the joint is insufficient, it is necessary to add steel to provide shear resistance. The purpose of the present invention is to omit the stirrups and simplify the construction process of the joints. Therefore, the addition of stirrups or the addition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com