Patents

Literature

34results about How to "Reduce the difficulty of pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

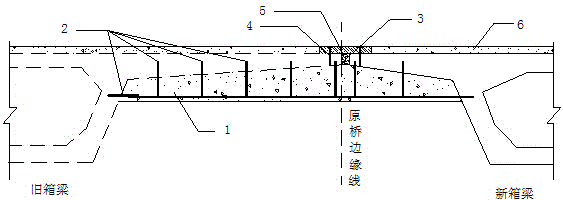

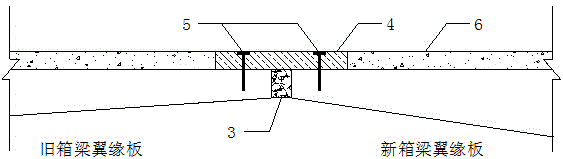

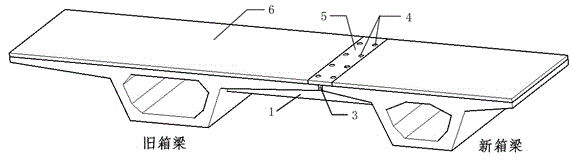

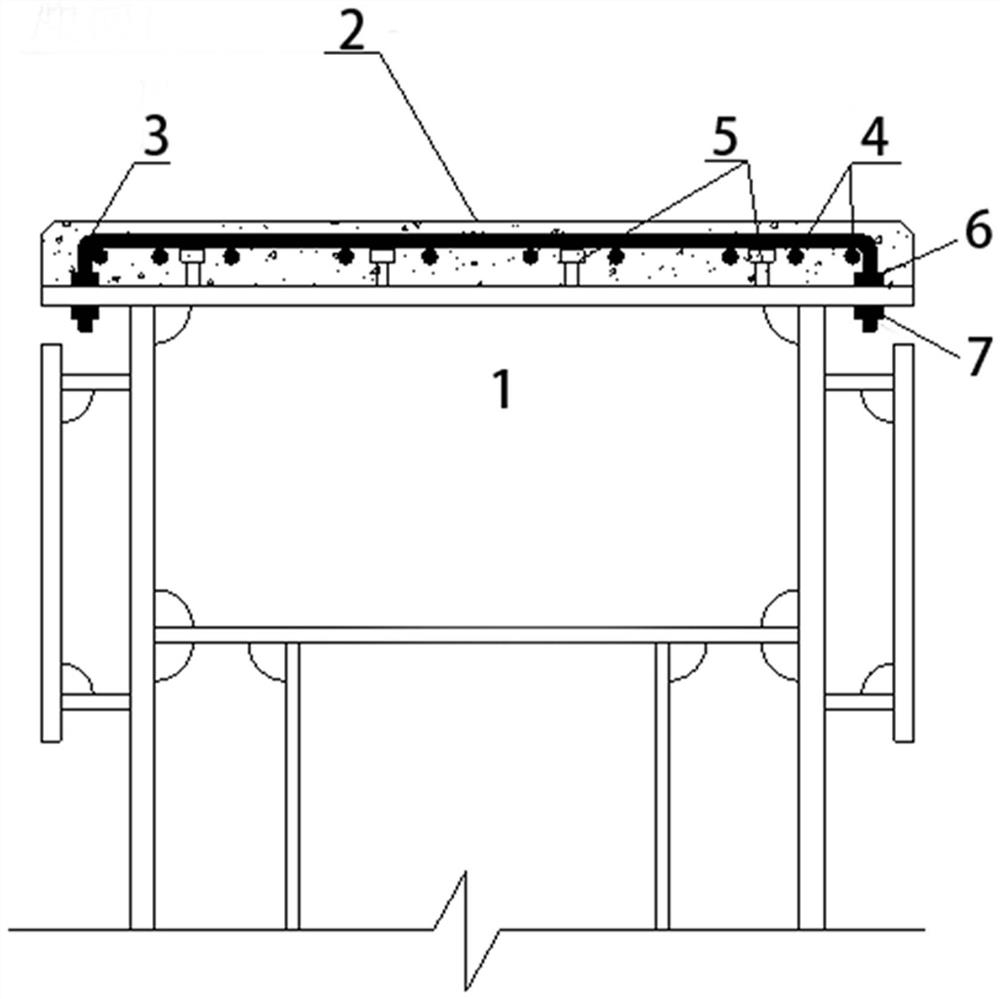

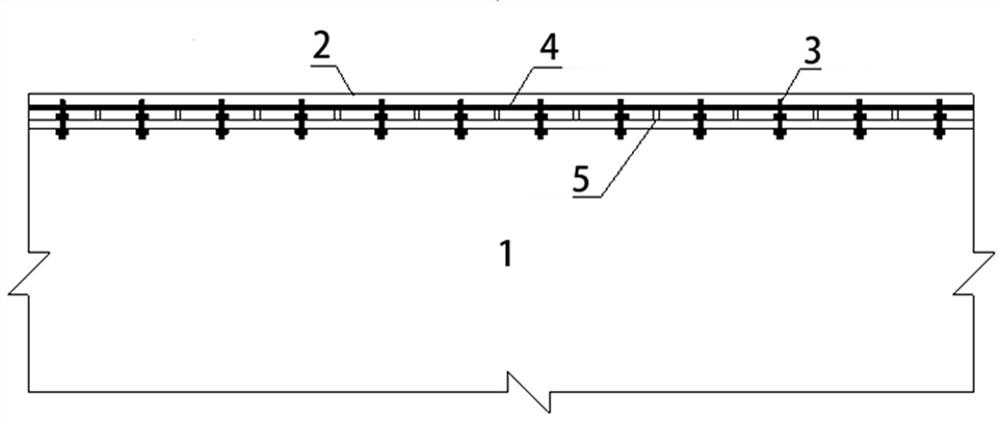

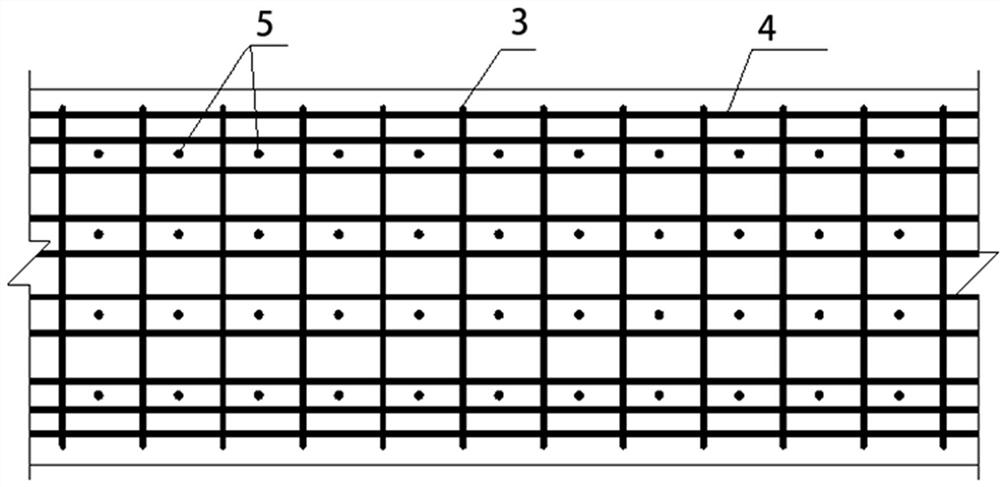

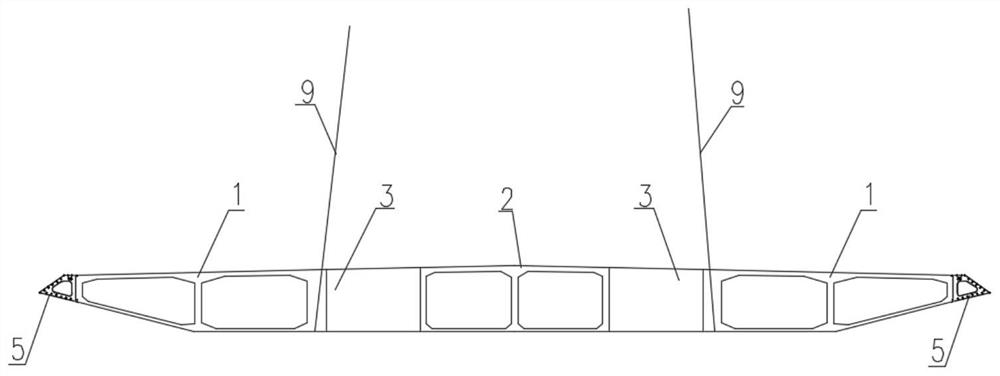

Transversely-widening splicing structure of three-dimensional prestress concrete continuous box girder bridge

InactiveCN104631348AAvoid the difficulty of horizontal reinforcementSolve the lack of resistanceBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a transversely-widening splicing structure of a three-dimensional prestress concrete continuous box girder bridge. While flange plates of a new box girder and an old box girder are kept separated, the new box girder and the old box girder are connected by adding transverse reinforcing ribs which are longitudinally arranged at intervals. The whole transversely-widening splicing structure comprises the old box girder, the new box girder, the transverse splicing reinforcing ribs, longitudinal splicing seams, rubber belts, anchoring bolts and bridge surface laying layer, wherein the rubber belts, the anchoring bolts and the bridge surface laying layer are arranged on the longitudinal splicing seams. The transversely-widening splicing structure is characterized in that the transverse splicing reinforcing ribs are arranged between webs of the new box girder and the old box girder at certain intervals so that a new main beam and an old main beam can be connected together; meanwhile, the flange plates of the new box girder and the old box girder are separated, and the plate type rubber belts are laid on the separation seams. The plate type rubber belts are fixed to the flange plates through the bolts, and the top faces of the rubber belts are flush with the bridge surface laying layer. By means of the transverse splicing method, the defect that three-dimensional prestress concrete box girder flange plates can not be removed is overcome, the problem caused when the ribs are transversely planted at the ends of the flange plates is solved, and the purpose of transverse splicing of the three-dimensional prestress concrete continuous box girder bridge is well achieved.

Owner:SOUTHEAST UNIV

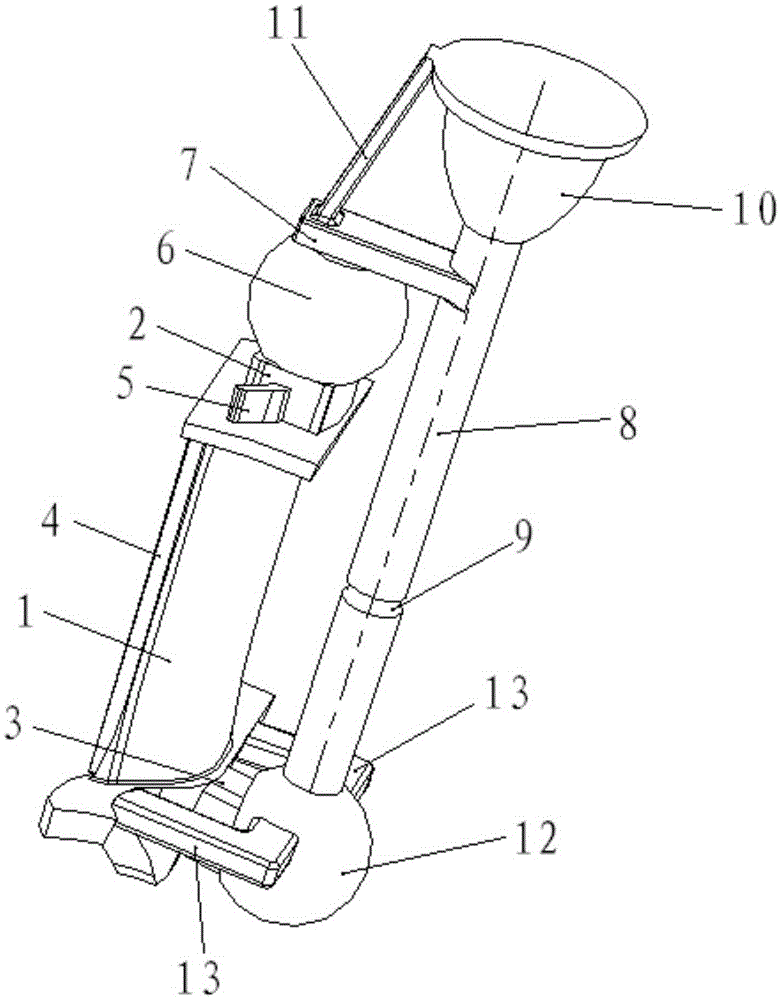

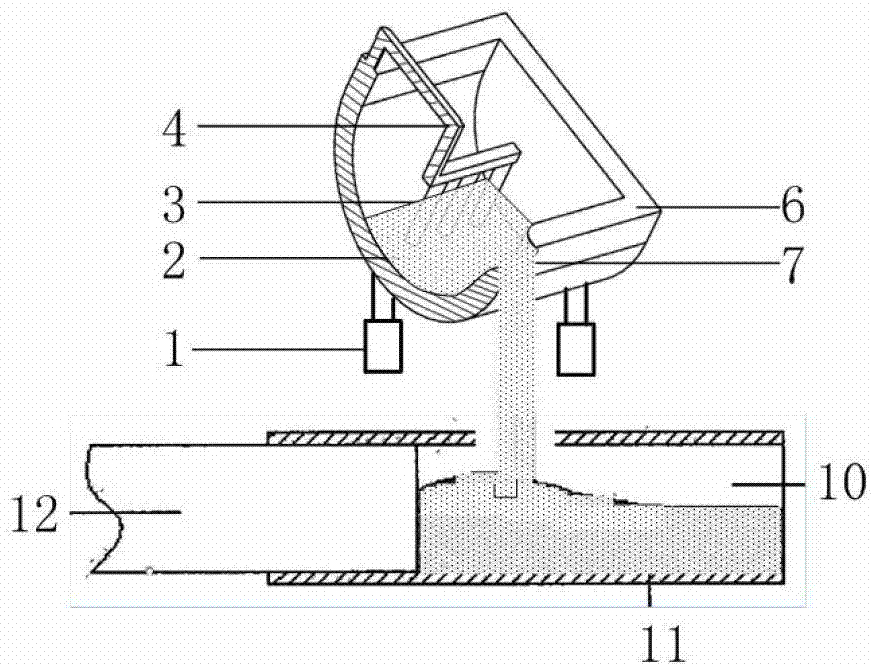

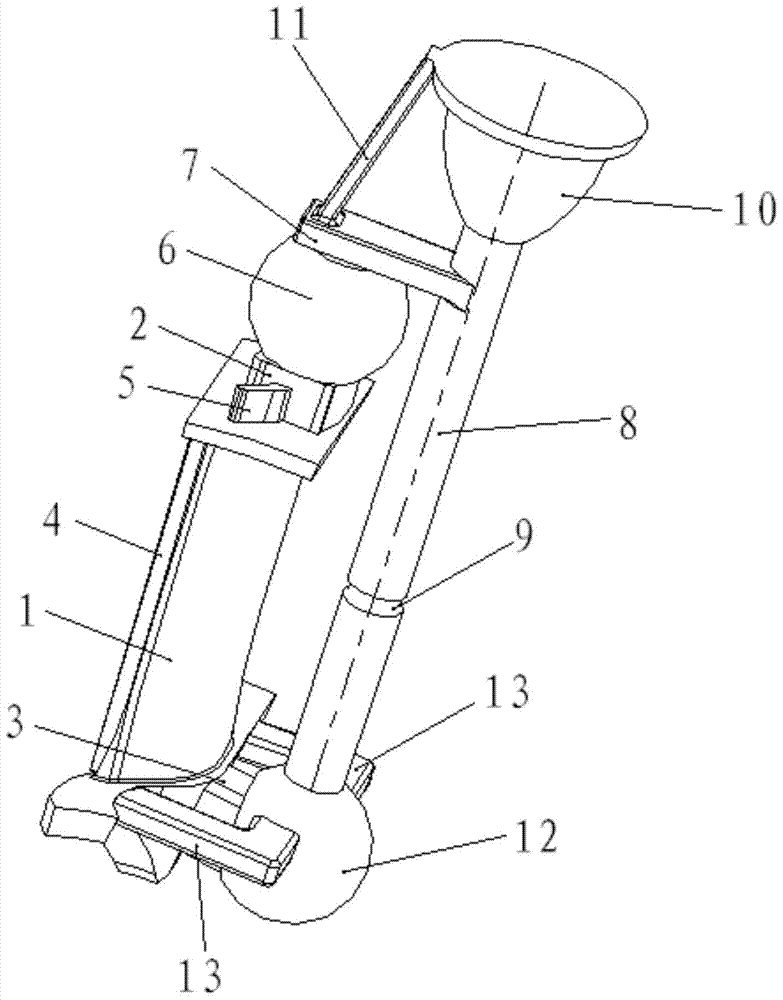

Wax mold of large-size hollow shrouded blade casting pouring system and manufacturing method of wax mold

The invention provides a wax mold of a large-size hollow shrouded blade casting pouring system and a manufacturing method of the wax mold. The wax mold comprises a casting wax mold and a runner wax mold; a core is arranged in the casting wax mold; a shroud inner gate is formed in the top of the casting wax mold, while a tenon inner gate is formed in the bottom of the casting wax mold; the runner wax mold comprises a first spherical riser of which the bottom is bonded to the top of the shroud inner gate and the top is connected to one end of a first horizontal runner; the other end of the first horizontal runner is connected to a straight runner; the top of the straight runner is bonded to a gate cup, while the bottom of the straight runner is connected to a second spherical riser; the second spherical riser is bonded to the tenon inner gate; the second spherical riser is connected to one end of a second horizontal runner, and the other end of the second horizontal runner is connected to the casting wax mold. According to the wax mold of the large-size hollow shrouded blade casting pouring system, the spherical risers and the corresponding runners are designed reasonably, such that smooth filling and effective feeding to a casting can be realized and the stress can be reduced; hence, the wax mold is applicable to produce large-size, hollow shrouded and complex-structure blades; the pouring difficulty can be reduced, such defects as core breakage, looseness and cracks of the casting can be avoided, and the product qualification rate can be increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

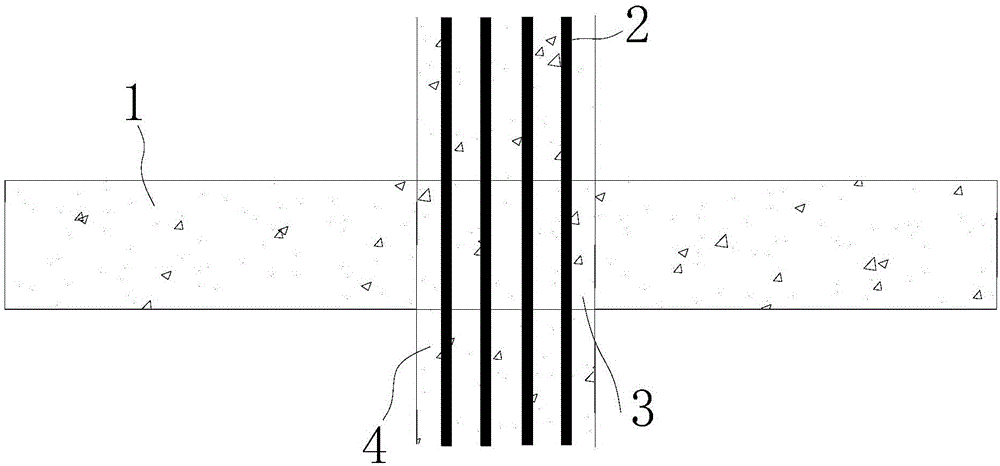

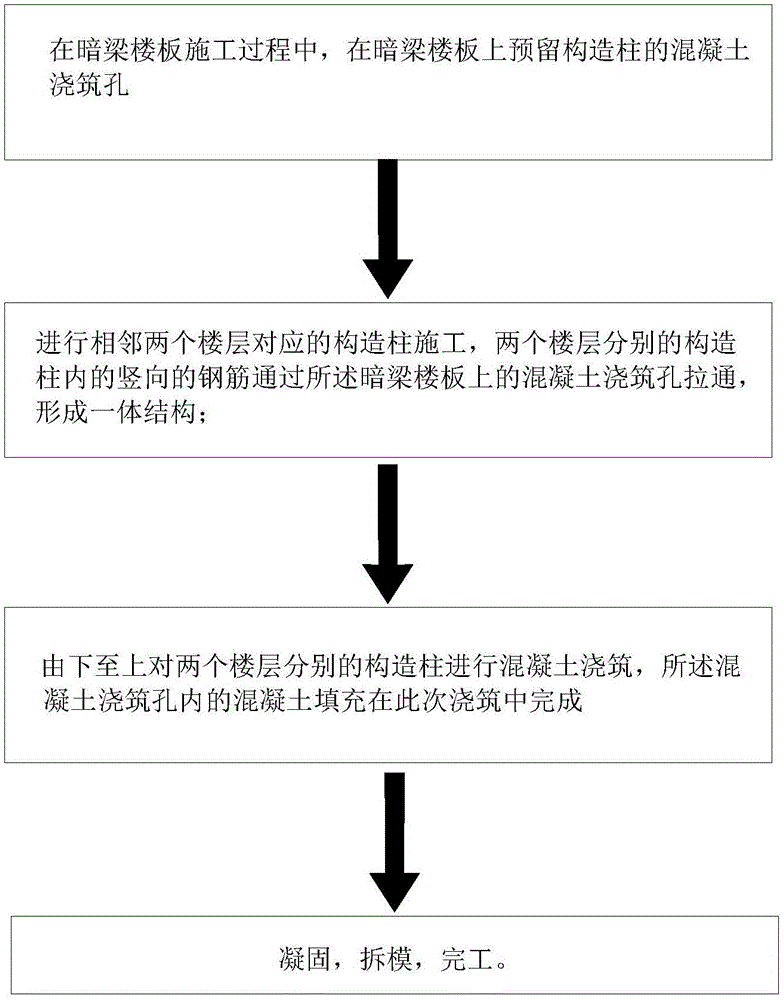

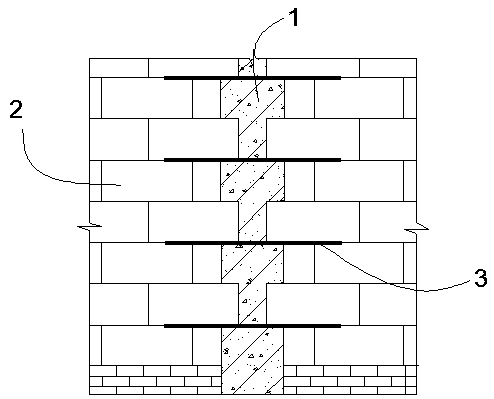

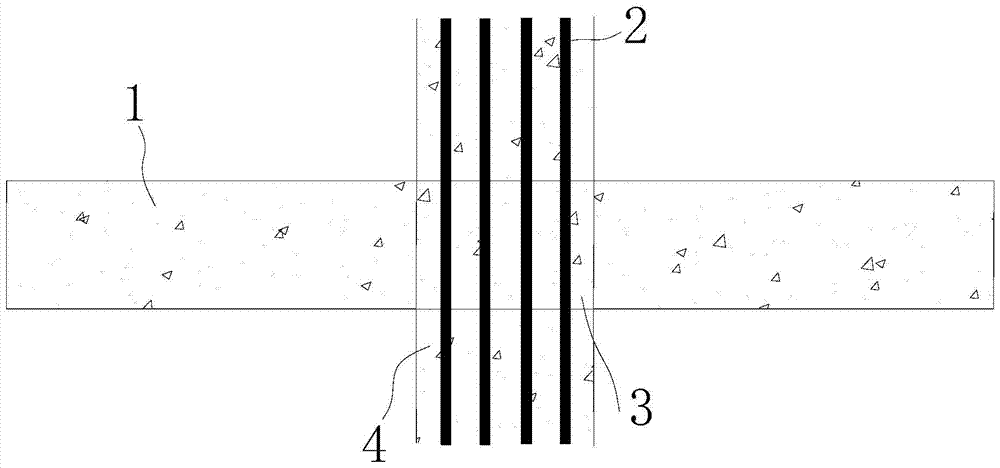

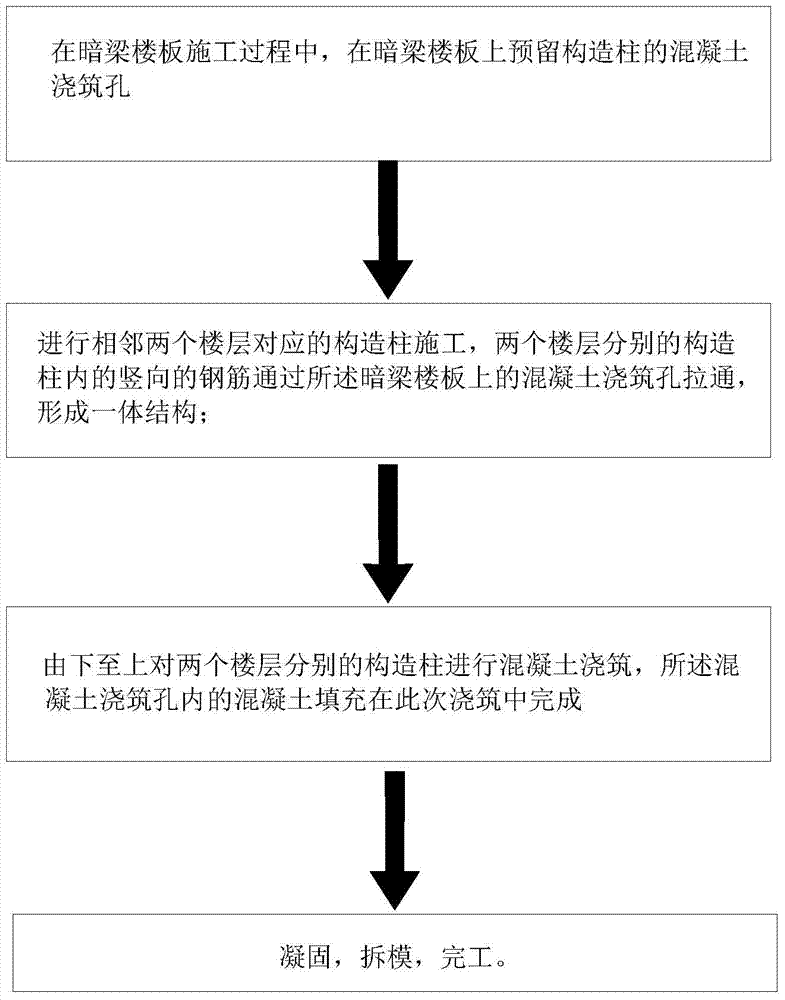

Hidden beam floor constructional column structure and construction method thereof

ActiveCN105155669AAvoid displacementFirmly connectedBuilding material handlingFloor slabArchitectural engineering

The invention relates to the field of constructional column construction, in particular to a hidden beam floor constructional column structure and a construction method thereof. The constructional column structure comprises a steel reinforcement cage and a column-shaped structure, wherein a plurality of rebars are vertically arranged in the steel reinforcement cage, and the upper end lower ends of the rebars are connected with hidden beam floors; the column-shaped structure is formed by pouring of concrete; the rebars are arranged in the column-shaped structure in a penetration manner, and the upper and lower ends of the column-shaped structure are connected with the floors; the constructional column penetrates through two adjacent storeys, and rebars in separate constructional columns of the two storeys are integrally connected; and the column-shaped structure are arranged around the rebars at a junction part of the two storeys. The application of the invention aims to provide the floor constructional column structure which has the advantages that rebars are saved; the constructional column structure can be firmly connected with a main body; rebar displacement is avoided; pouring difficulty is reduced; and the cost is lowered. Meanwhile, the relevant construction method is also provided.

Owner:CHENGDU NO 4 CONSTR ENG

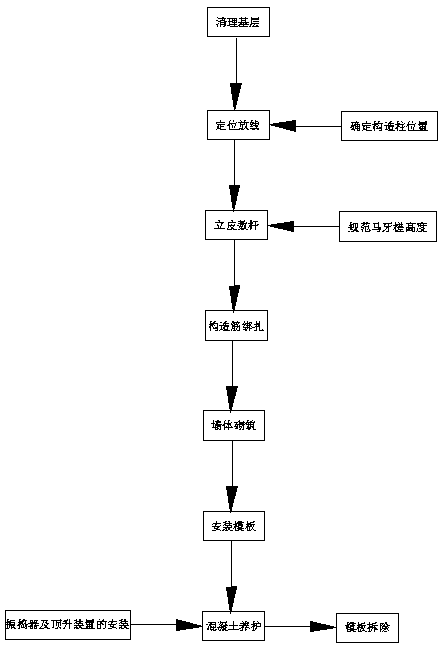

Construction method of constructing column

InactiveCN110230394AEnsure safetyEasy to installForms/shuttering/falseworksBuilding material handlingRebarUltimate tensile strength

The invention discloses a construction method of a constructing column. The construction method of a constructing column comprises the following steps that 1, pre-laying treatment is carried out; 2, wall construction is carried out; specifically, a wall is constructed at the position of the indwelling constructing column to construct a stubble shape, a reinforcing bar is placed in a horizontal joint of a brickwork of the wall, and then after the wall construction is completed, the reinforcing bar is rotated to enable a hole to be formed in the horizontal slit, then the reinforcing bar is takenout, in the wall construction process, a hole forming method is used for moving up layer by layer to complete the pre-installing of a screw hole; 3, the constructing column is constructed; and 4, a constructing column template is removed, the pouring strength of the constructing column reaches 50% after the pouring, and the constructing column template is demolded. The construction method of theconstructing column is simple in construction operation and reliable in quality, and is suitable for the construction of various brick-concrete structure masonry and lightweight wall. The constructingcolumn has good forming quality and high rigor, and solves the problem of the quality defect of traditional concrete pouring.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

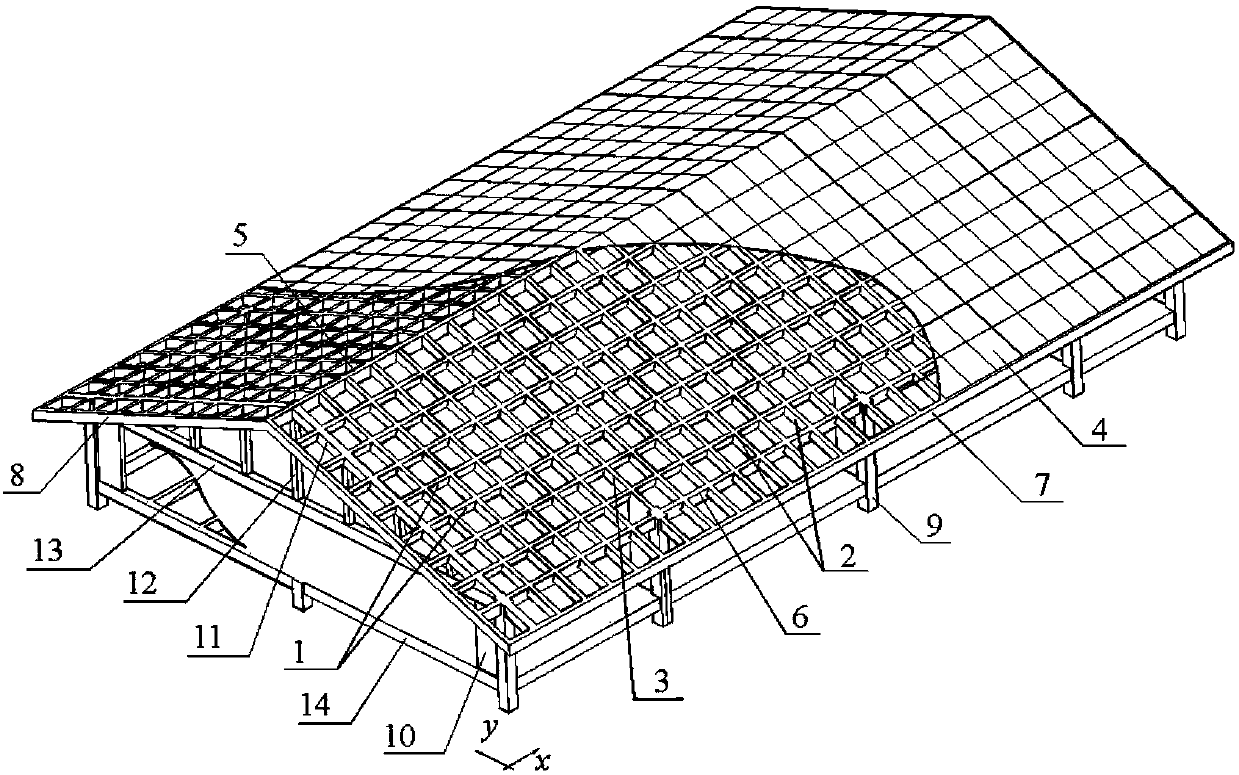

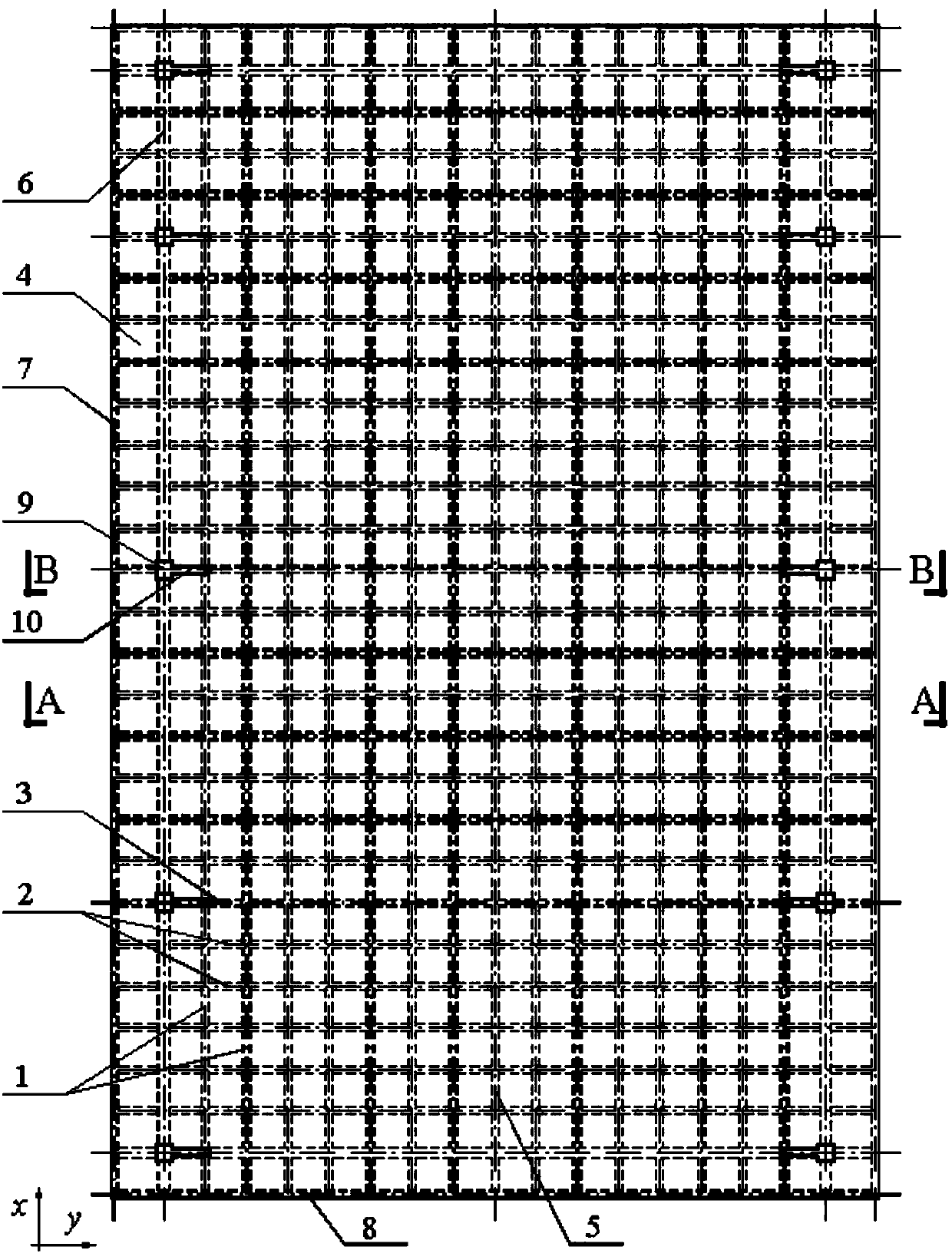

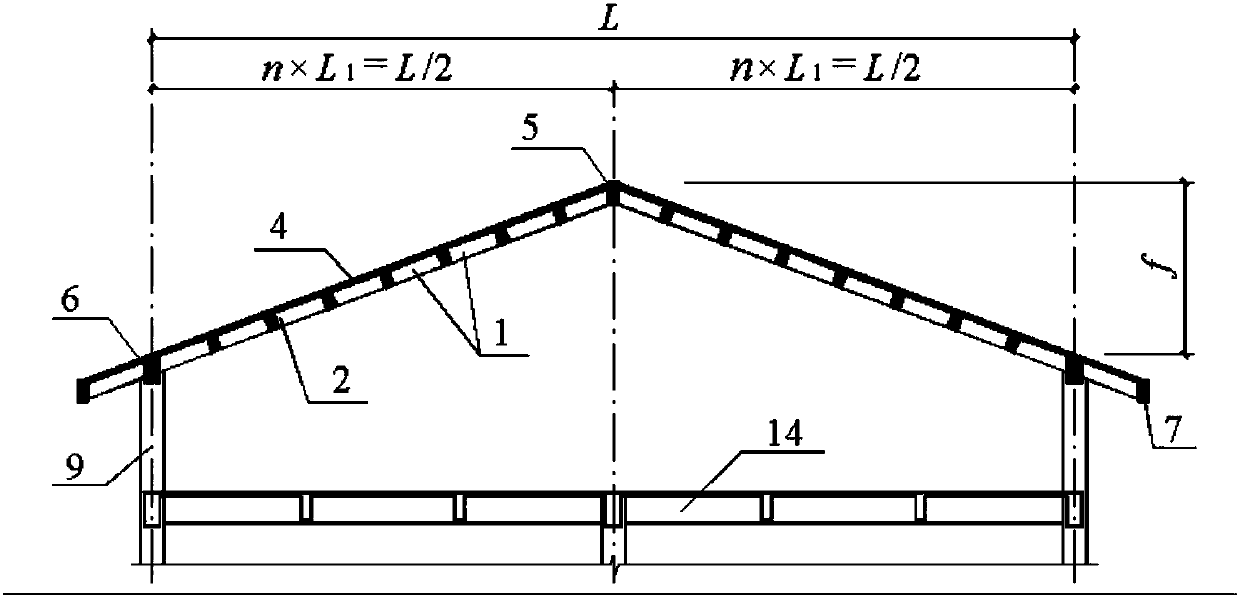

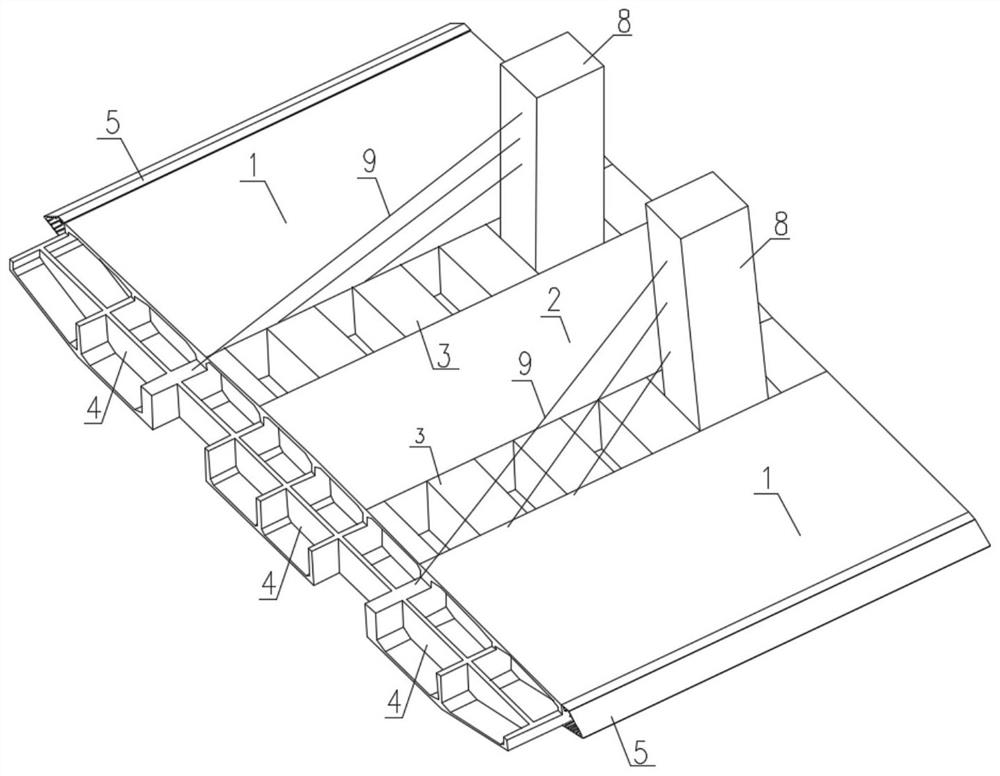

Fabricated longspan concrete double-slope net shell roof framework and manufacturing method thereof

PendingCN107916740AGood space performanceMeet styling needsBuilding roofsBuilding material handlingFalseworkArchitectural engineering

The invention discloses a fabricated longspan concrete double-slope net shell roof framework and a manufacturing method thereof. The framework is formed by obliquely placed multi-ribbed slabs converged at a ridge beam, the two ends are supported on gable end partitions, slope bases supported on longitudinal frame beams vertically intersected with anti-pushing frameworks, and no supporting frame isinstalled under the ridge beam. The gable end partitions are triangle vierendeel trusses composed of upper chords, lower chords and vertical web members, the anti-pushing frameworks are composed of framework columns and short-leg shears supported under lower part floor beams. The framework manufacture adopts a fabricated method, roof boards and ribs are prefabricated and all-round scaffolds, prefabricated parts are connected into an entirety through cast-in-place of connecting blocks and pouring of the boards and the ribs connecting concrete, the use ratio of the large space under the roof isimproved, the problem of flowing during the cast-in-place of obliquely placed concrete in a large area is overcame, the template consumption is reduced, and the construction period is shortened.

Owner:GUIZHOU UNIV

Prefabricated sewage intercepting box culvert and construction method thereof

InactiveCN108360402ASimple structureImprove construction efficiencyGround-workRear quarterWater leakage

The invention relates to a prefabricated sewage intercepting box culvert and a construction method thereof. The prefabricated sewage intercepting box culvert comprises prefabricated sewage intercepting box culvert sections, a cast-in-place cushion layer, cast-in-place bearing platforms and a cast-in-place bottom plate, wherein each sewage intercepting box culvert section comprises a top plate andside plates which form an n shape together; hoisting rings are arranged on the sewage intercepting box culvert sections; the bearing platforms and the bottom plate are positioned on the cushion layer;the bottom plate is sandwiched between the bearing platforms and is integrally cast with the bearing platforms; grooves are arranged on the top surfaces of the bearing platforms; the bottom ends of the side plates are inserted into and supported in the grooves; the grooves are filled with slight expansion fine aggregate concrete; the adjacent sewage intercepting box culvert sections are connectedby the end surfaces of the top plates and the side plates; a water-swellable waterstop strip is attached to the connection part; and the connection part is filled with the slight expansion fine aggregate concrete. The prefabricated sewage intercepting box culvert is simple in structure, high in construction efficiency, not difficult in casting and good in sealing effect, and can avoid the problemof water leakage.

Owner:CHINA FIRST METALLURGICAL GROUP

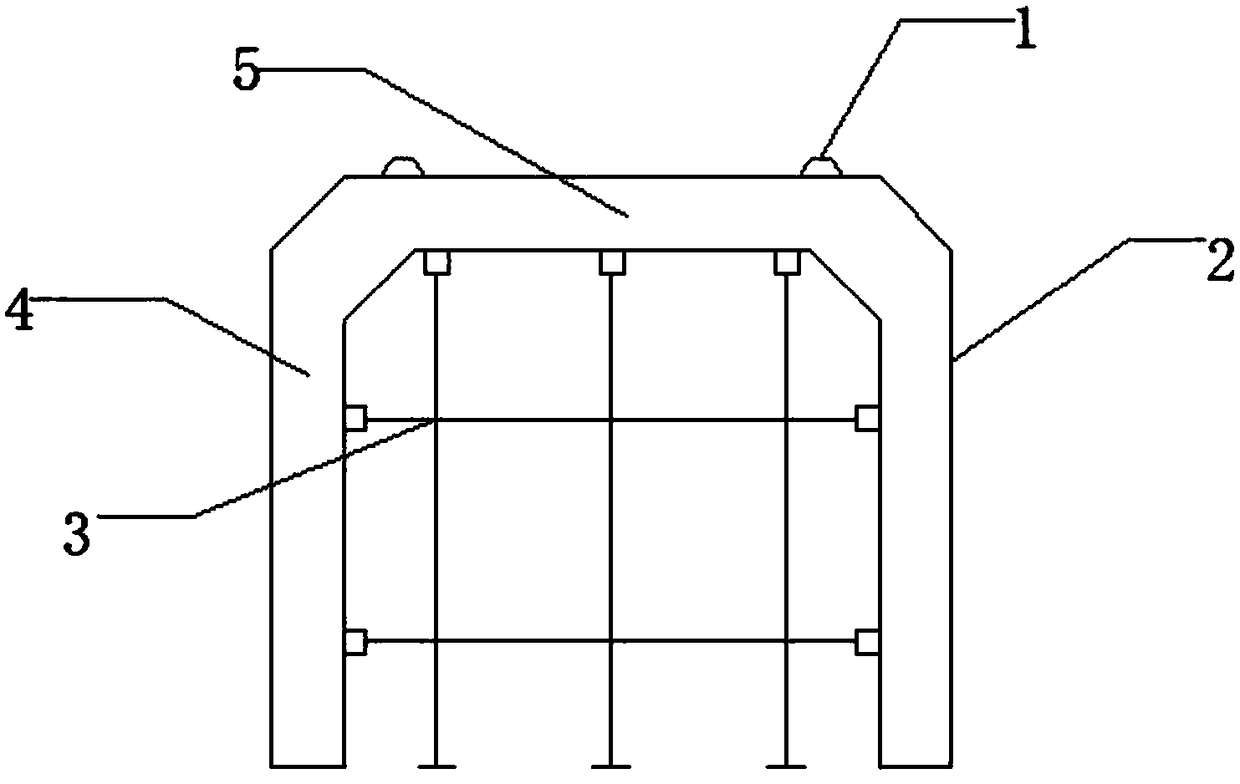

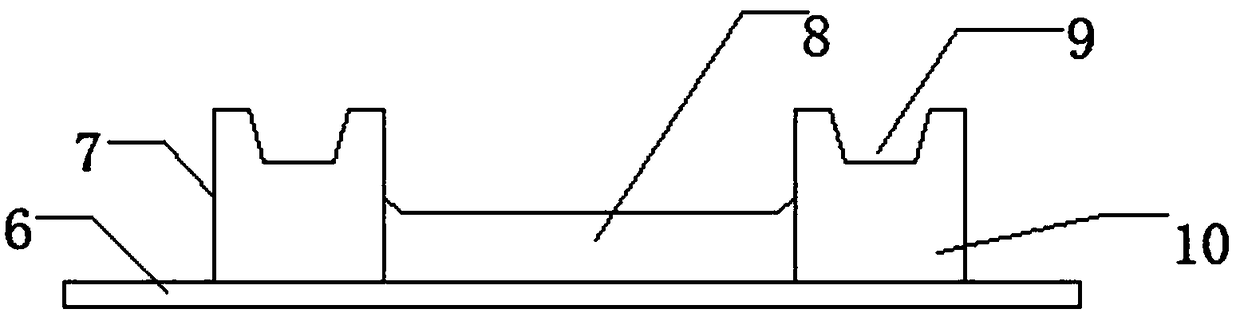

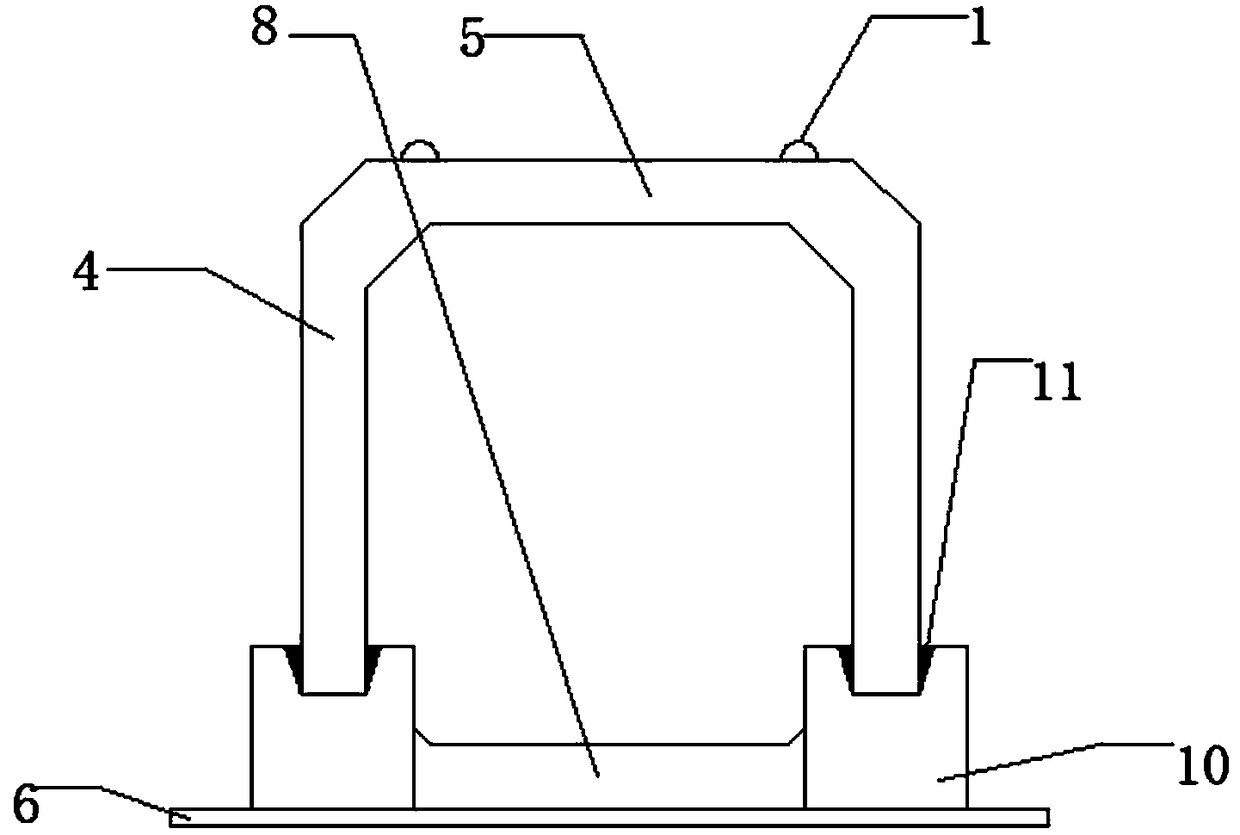

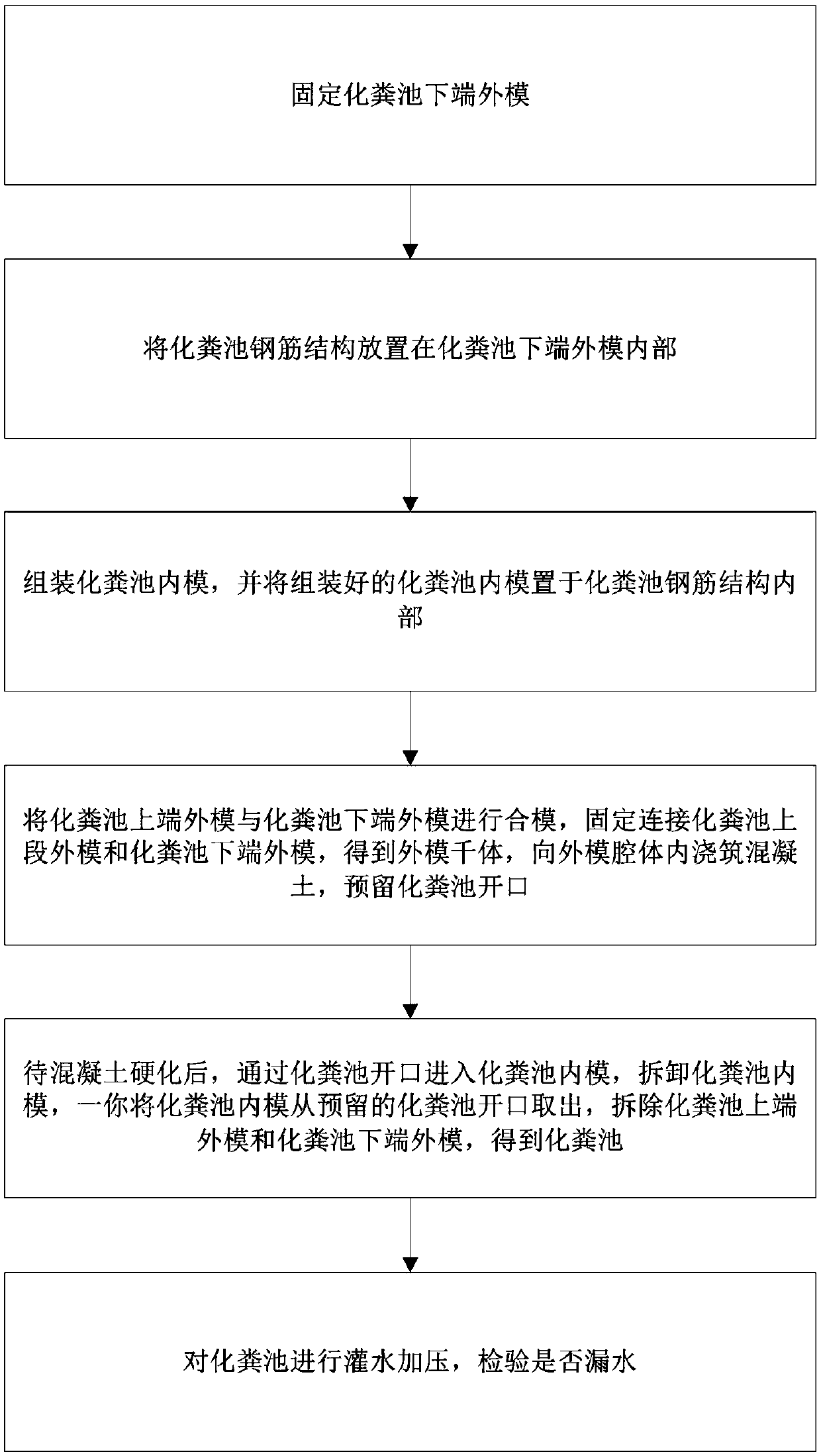

Integral molding method of septic tank

InactiveCN109534638AHigh degree of continuous internal structureHigh mechanical strengthBiological sludge treatmentWater leakageReinforced concrete

The invention provides an integral molding method of a septic tank. The septic tank comprises a septic tank lower end external mold, a septic tank upper end external mold, a septic tank internal moldand a septic tank reinforcing bar structure. The method comprises the specific molding steps of fixing the septic tank lower end external mold, placing the septic tank reinforcing bar structure insidethe septic tank lower end external mold, assembling the septic tank internal mold, placing the assembled septic tank internal mold inside the septic tank reinforcing bar structure, closing and fixedly connecting the septic tank upper end external mold and the septic tank lower end external mold so as to obtain an external mold cavity, pouring concrete into the external mold cavity, reserving a septic tank opening, disassembling the septic tank internal mold from the septic tank opening after the concrete is hardened, taking out the septic tank internal mold through the septic tank opening, and then, disassembling the septic tank upper end external mold and the septic tank lower end external mold, thereby obtaining the septic tank. The molding method provided by the invention is simple, the condition that reinforced concrete structured septic tanks suffer from slits and water leakage can be avoided, and the mechanical strength and use effect of the overall septic tank are improved.

Owner:漯河俊展环保科技有限公司

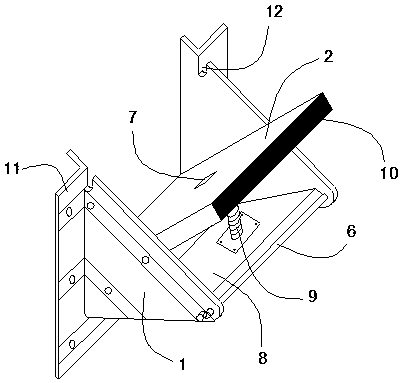

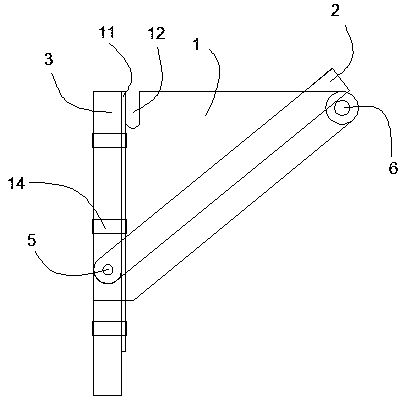

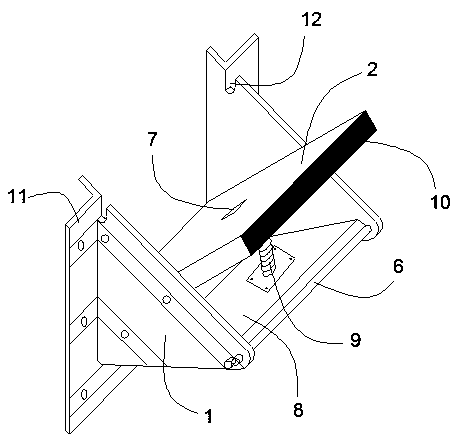

Construction method for pouring constructional column concrete

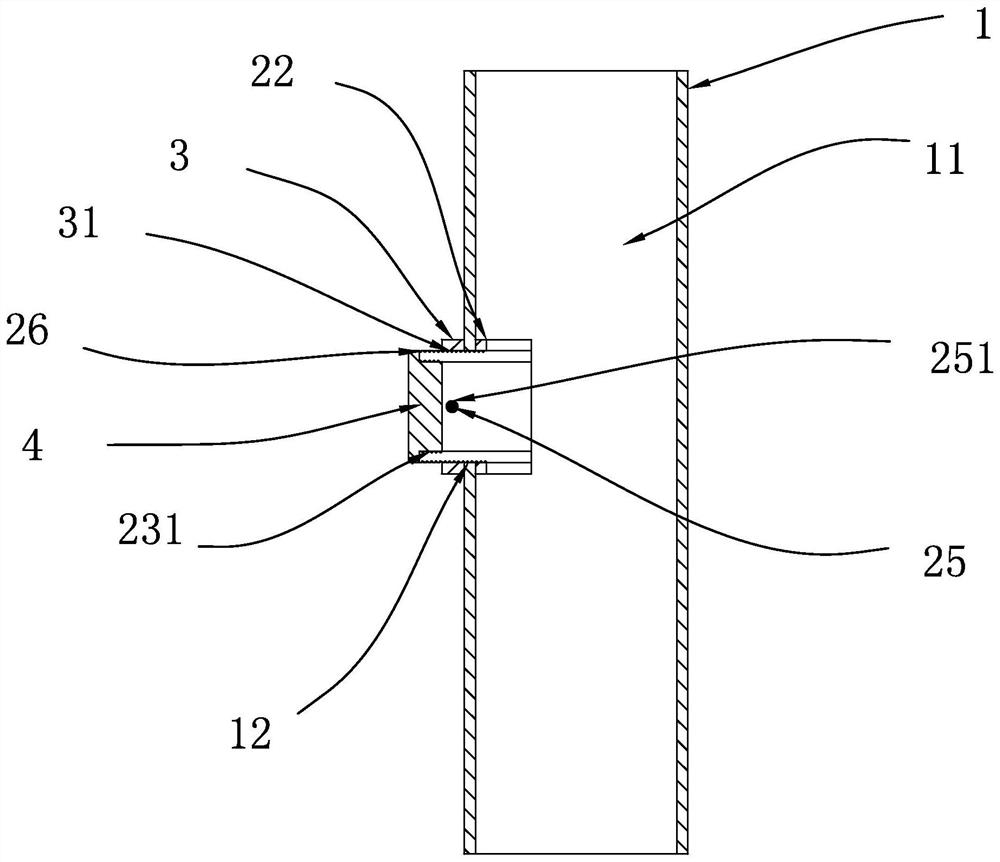

InactiveCN110145121AReduce the difficulty of pouringSimple structureForms/shuttering/falseworksBuilding material handlingBrickHoneycomb

The invention discloses a construction method for pouring constructional column concrete. The construction method is characterized by comprising the following steps that 1, a switchable pouring structure is prepared; 2, treatment before pouring is carried out, particularly, water is sprayed to wet a horsetooth-cut brick wall and a constructional column template at a constructional column construction position; 3, stone-removing cement mortar with the same material as the constructional column concrete is injected into the pouring bottom surface; 4, pouring treatment is carried out, particularly, concrete is poured onto a movable plate, the concrete is poured into the structural column through the movable plate, and simultaneously a movable plate vibrator is started to enable the concrete to be quickly poured and vibrated while pouring; and 5, concrete is poured and vibrated to be compact, particularly, each time concrete with a certain height is poured, vibrating is carried out once, so that the concrete is compact, and the operation is not stopped until pouring of the whole structural column is finished. Since the horsetooth-cut brick wall and the constructional column template are sprinkled with water, the phenomenon that the cast concrete slurry is adsorbed by the brick wall masonry to cause the stones to be blocked in the columns so as to generate the uncompacted phenomenaof honeycombs, hemp surfaces and the like is avoided.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

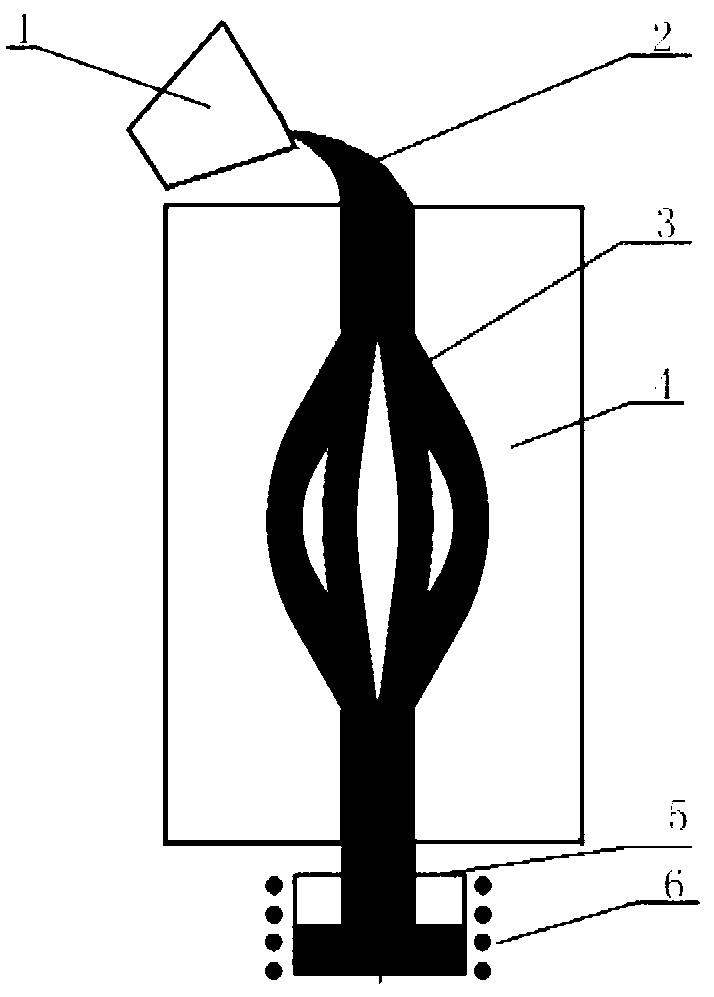

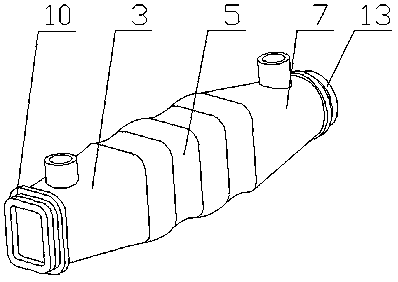

Shunt converging pouring gate preparation semisolid slurry and rheoforming device

The invention discloses a shunt converging pouring gate preparation semisolid slurry and rheoforming device, and belongs to the technical field of semisolid metal processing. The shunt converging pouring gate preparation semisolid slurry and rheoforming device is composed of a pouring cup, a metal melting body, a shunt converging pouring gate, a graphite plate, cooling and heating elements, a preparation crucible, a temperature controller, a heater, a pressure die casting machine and a pressing chamber, an injection plunger, a squeezing casting machine and a pressing chamber, an injection plunger, a casting machine, a lower die and an upper die. According to the shunt converging pouring gate manufacturing semisolid slurry and rheoforming device, the shunt converging channel is use for achieving the cooling and stirring of the alloy melting body to promote nucleation and prepare the semisolid slurry, and the prepared semisolid slurry, the pressure die casting machine, and the squeezing machine and the casting machine are combined to carry out rheoforming. The shunt converging pouring gate manufacturing semisolid slurry and eheoforming device is simple in structure, less in investment, low in production cost, stable and reliable in continuous manufacturing working, and very suitable for manufacturing and forming production of the semisolid metal slurry and blank.

Owner:UNIV OF SCI & TECH BEIJING

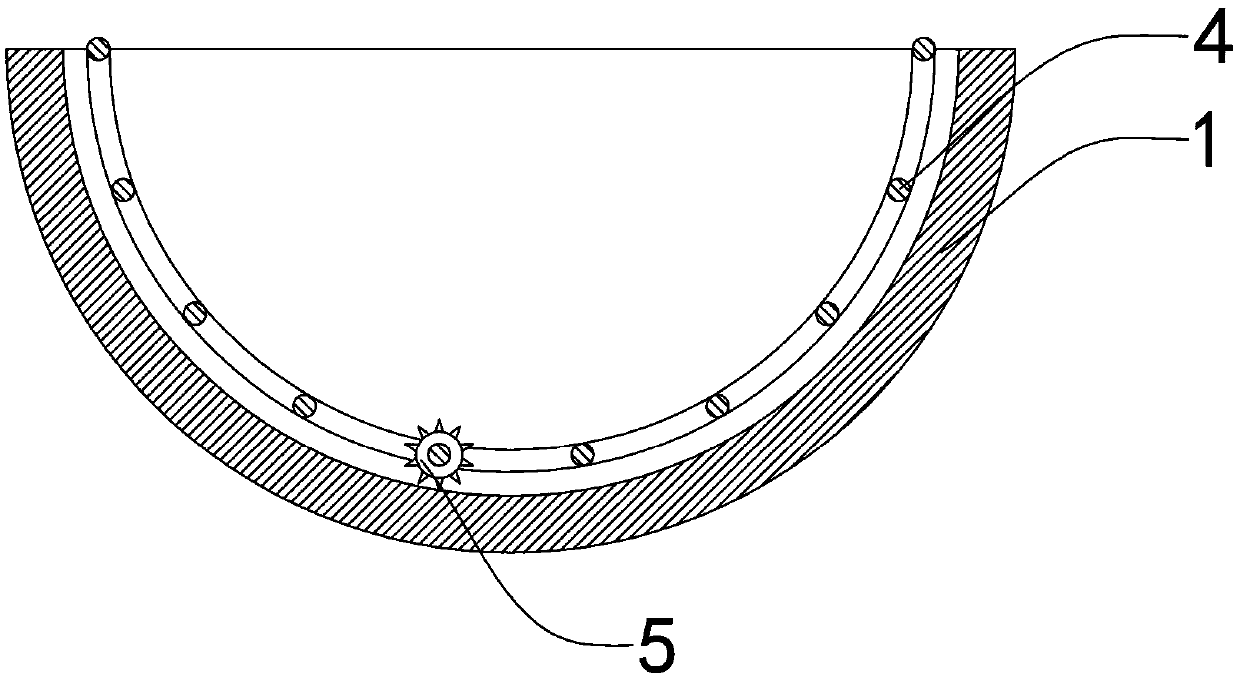

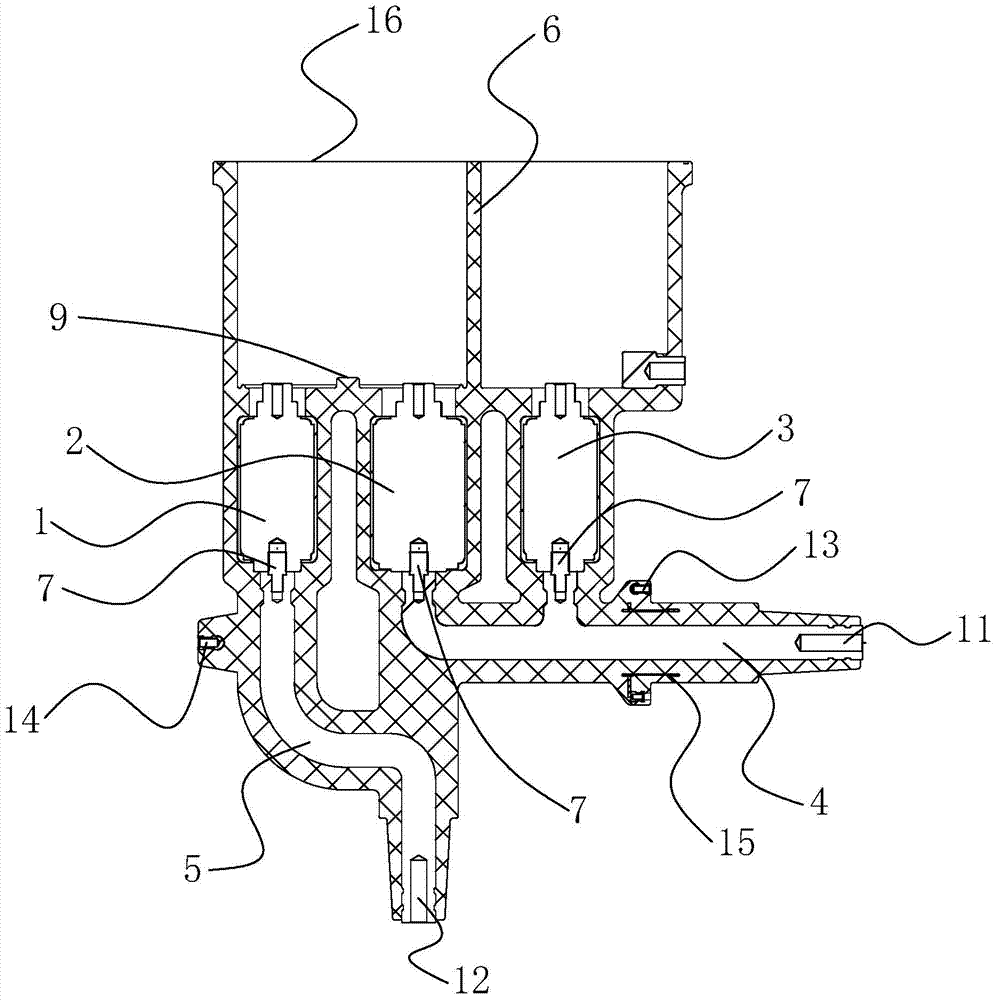

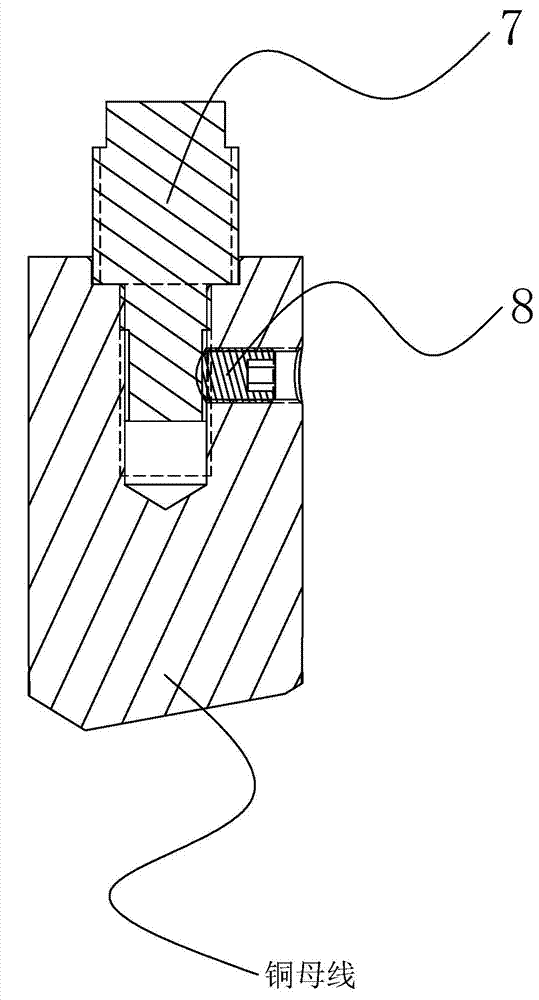

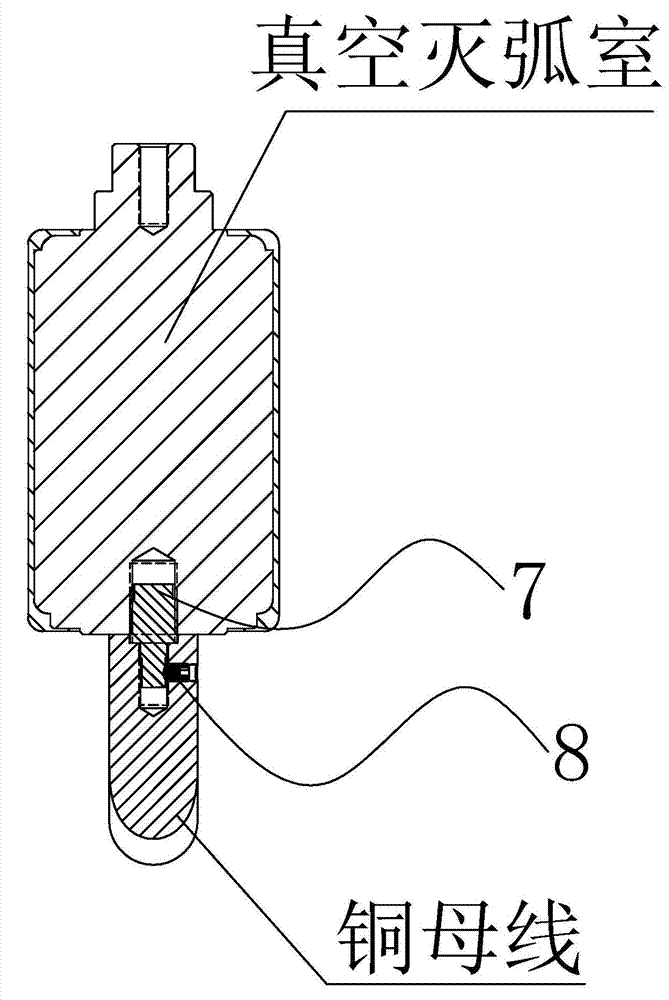

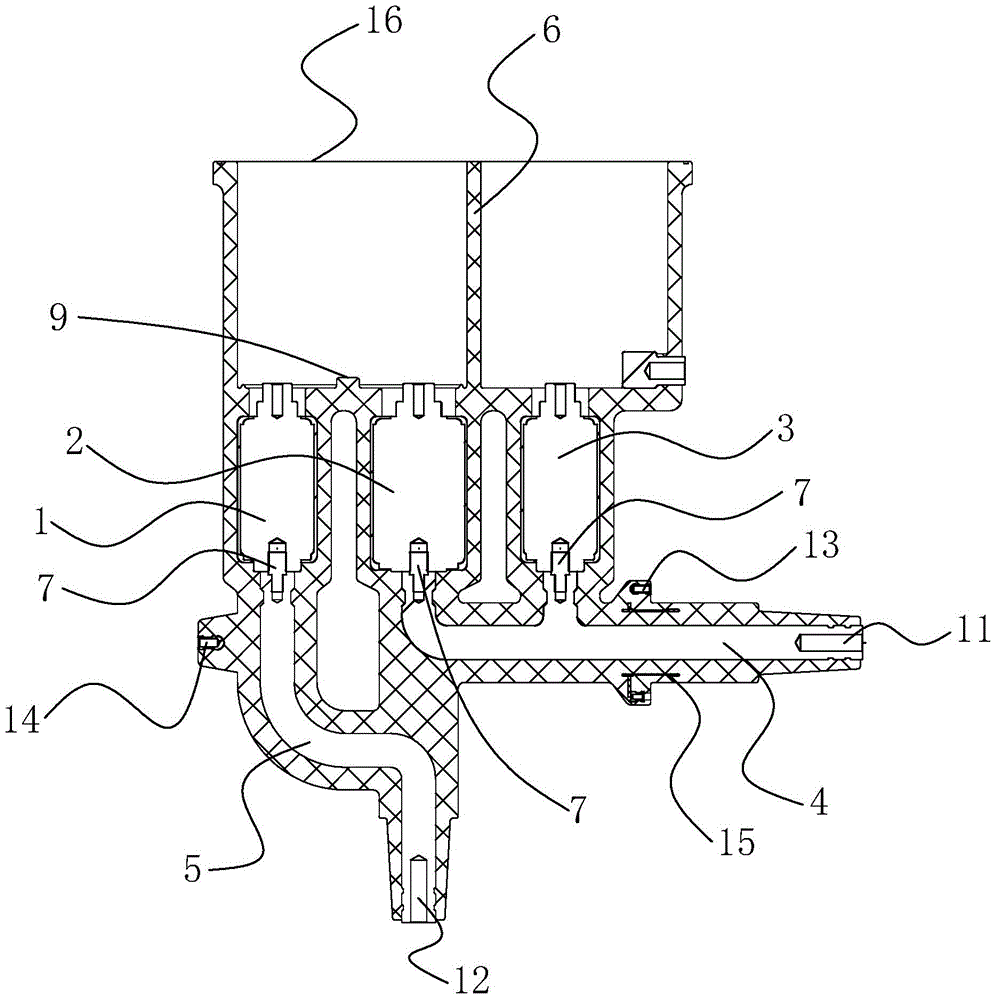

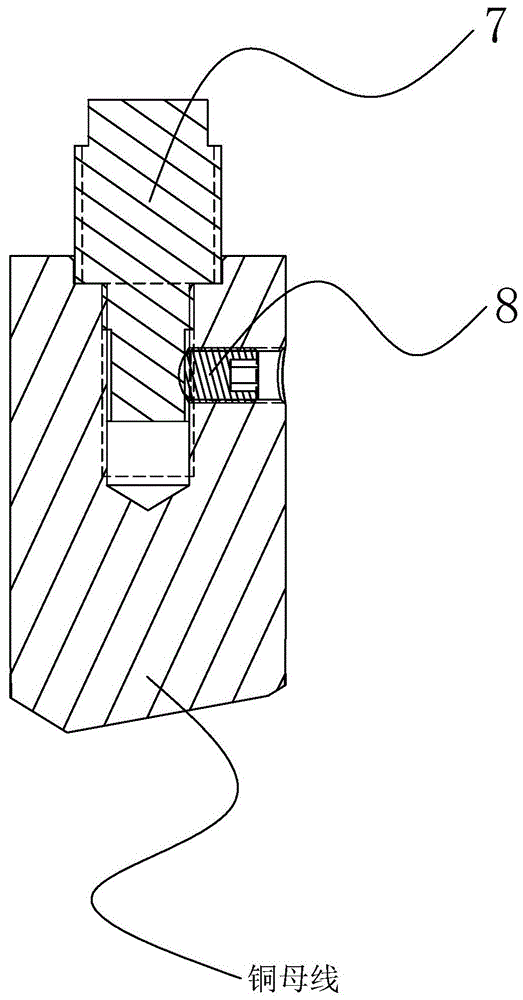

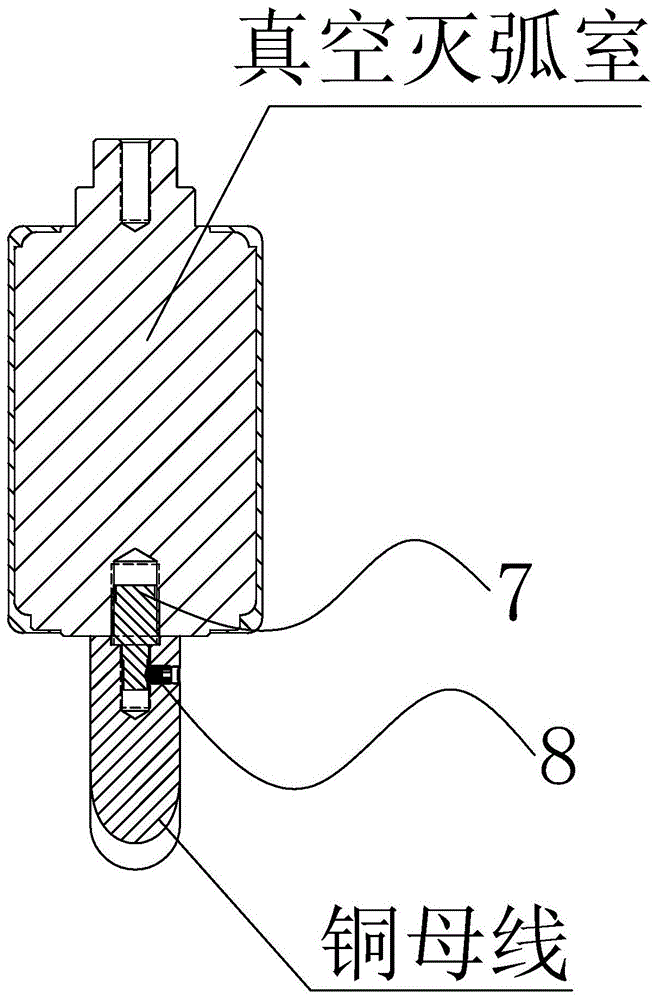

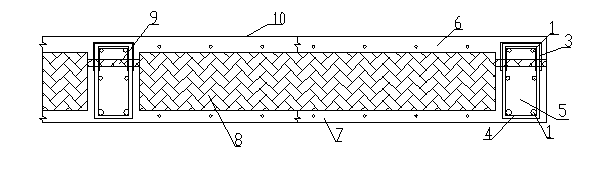

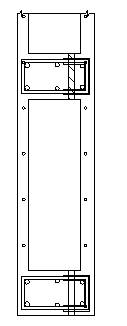

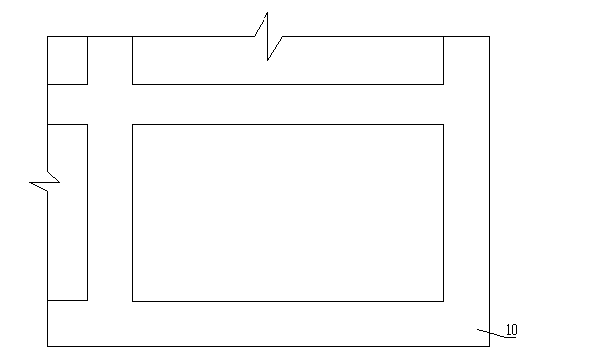

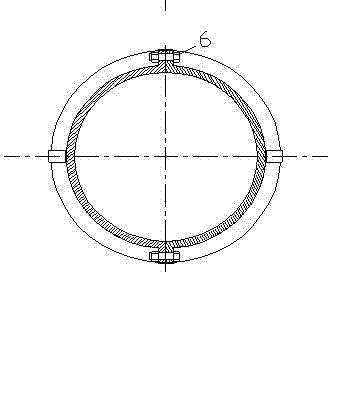

Solid-sealed polar pole of vacuum breaker

ActiveCN104124099AAvoid mutual contraction effectsImprove pouring qualityHigh-tension/heavy-dress switchesAir-break switchesEpoxyCopper

The invention discloses a solid-sealed polar pole of a vacuum breaker. The solid-sealed polar pole of the vacuum breaker comprises a vacuum arc extinguishing chamber I, a vacuum arc extinguishing chamber II and a vacuum arc extinguishing chamber III which are sequentially and horizontally arranged. The three vacuum arc extinguishing chambers are vertically mounted, and the upper end of every vacuum arc extinguishing chamber is a movable end; the lower ends of the vacuum arc extinguishing chamber II and the vacuum arc extinguishing chamber III are connected with a copper bus bar I, and the lower end of the vacuum arc extinguishing chamber I is connected with a copper bus bar II; the movable ends of the vacuum arc extinguishing chamber I and the vacuum arc extinguishing chamber II are mounted inside the same cavity through separation of an epoxy baffle, and the movable end of the vacuum arc extinguishing chamber III is arranged inside a independent cavity through separation; a mounting surface is arranged above the epoxy baffle. The solid-sealed polar pole of the vacuum breaker is easy to mould by casting, avoids the problems existing in the prior art such as concealed cracks, cracking, local amplification, low strength and radiating difficulty and fully meets requirements on power supply.

Owner:ZHUHAI XJ ELECTRIC +1

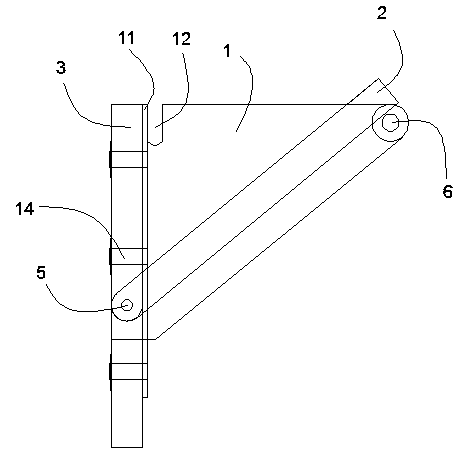

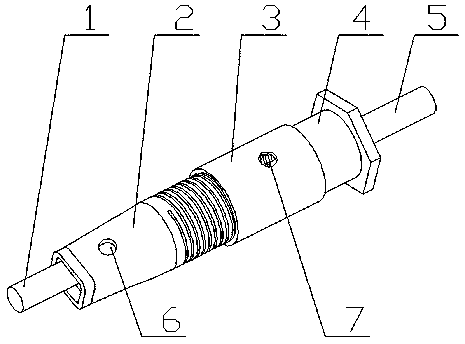

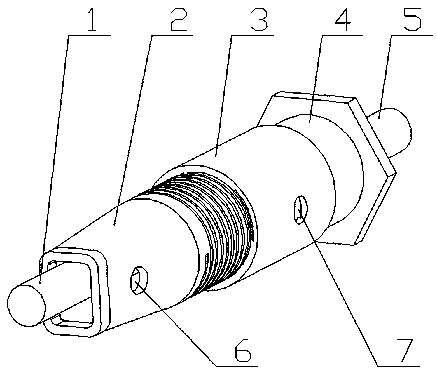

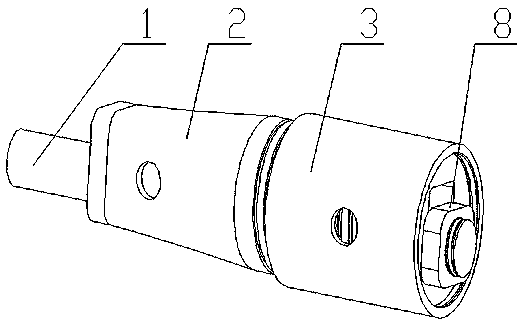

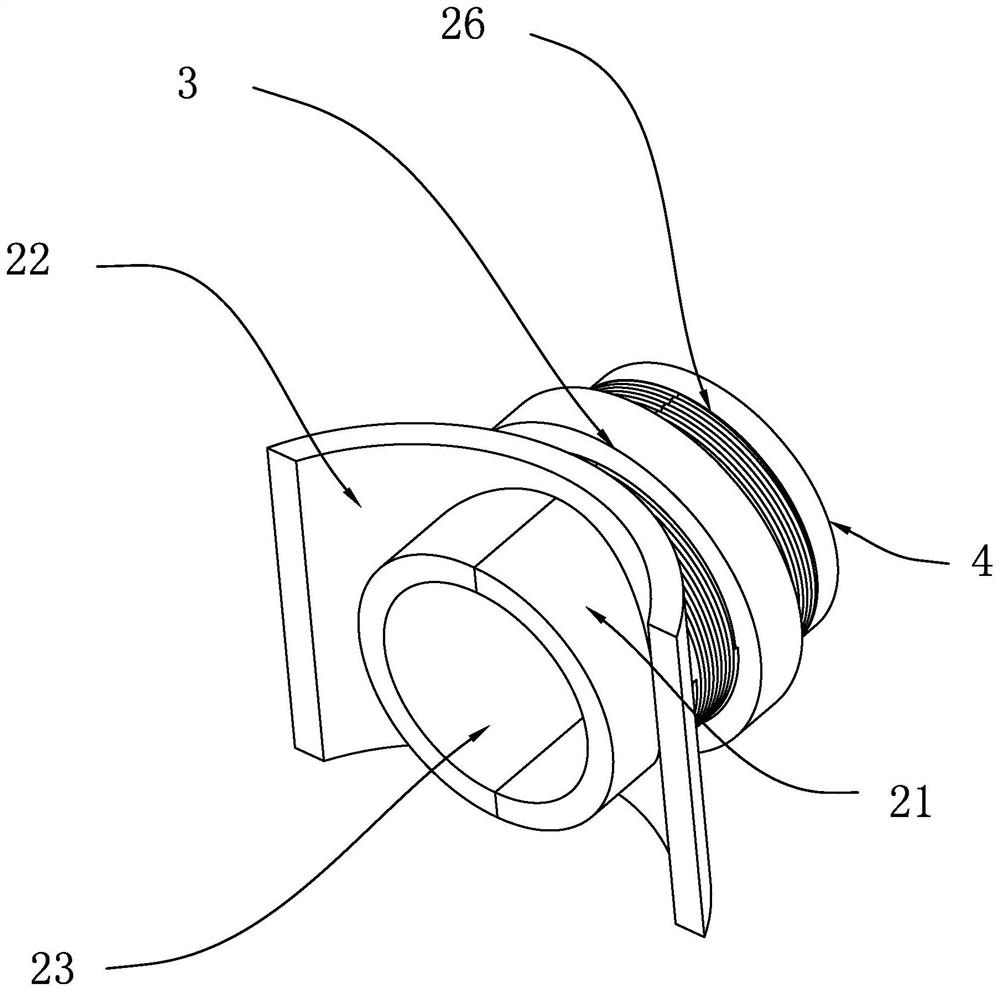

Switchable pouring port structure

PendingCN110158959AReduce the difficulty of pouringImprove pouring qualityAuxillary members of forms/shuttering/falseworksBuilding material handlingArchitectural engineering

Owner:CHINA METALLURGICAL CONSTR ENG GRP

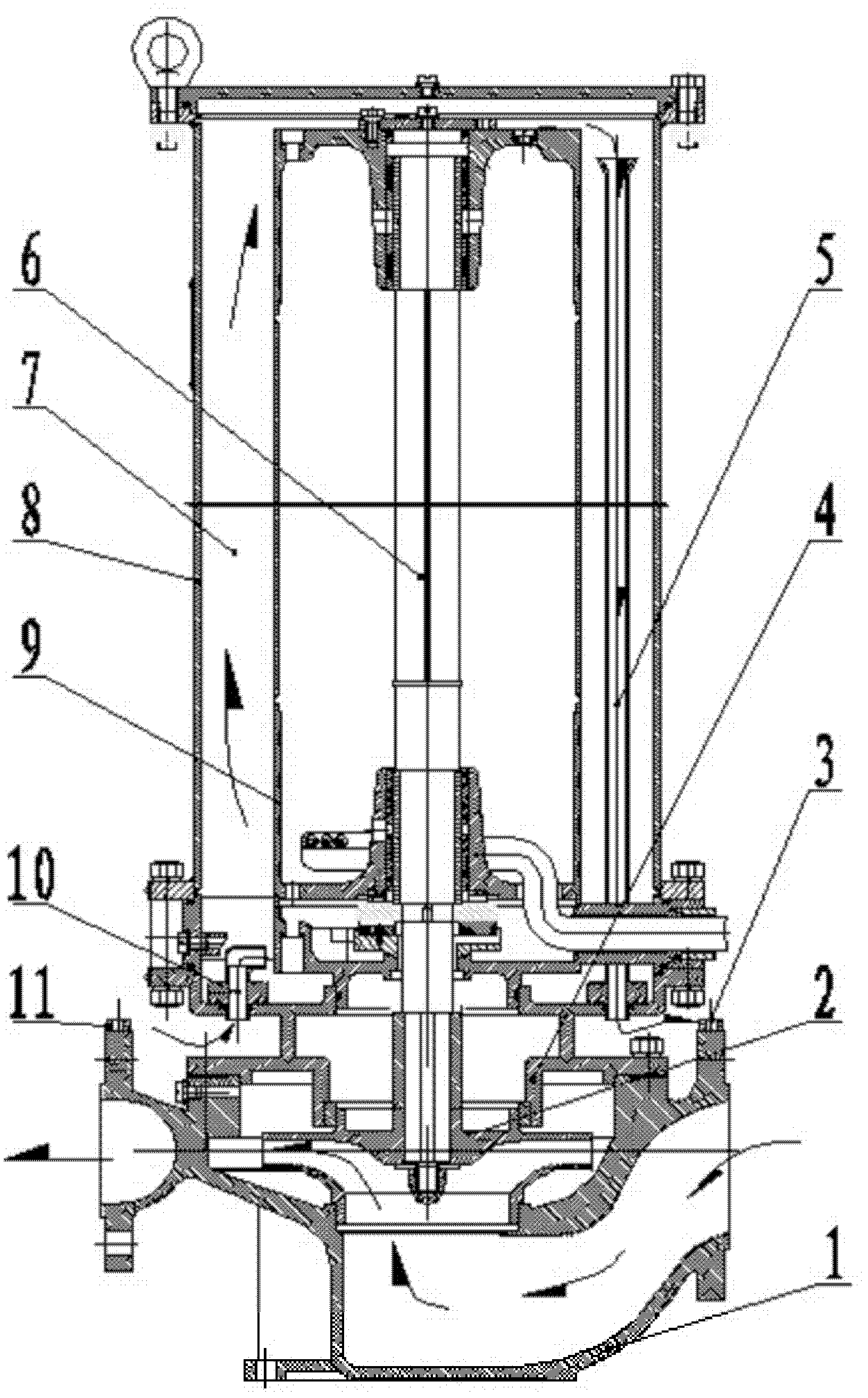

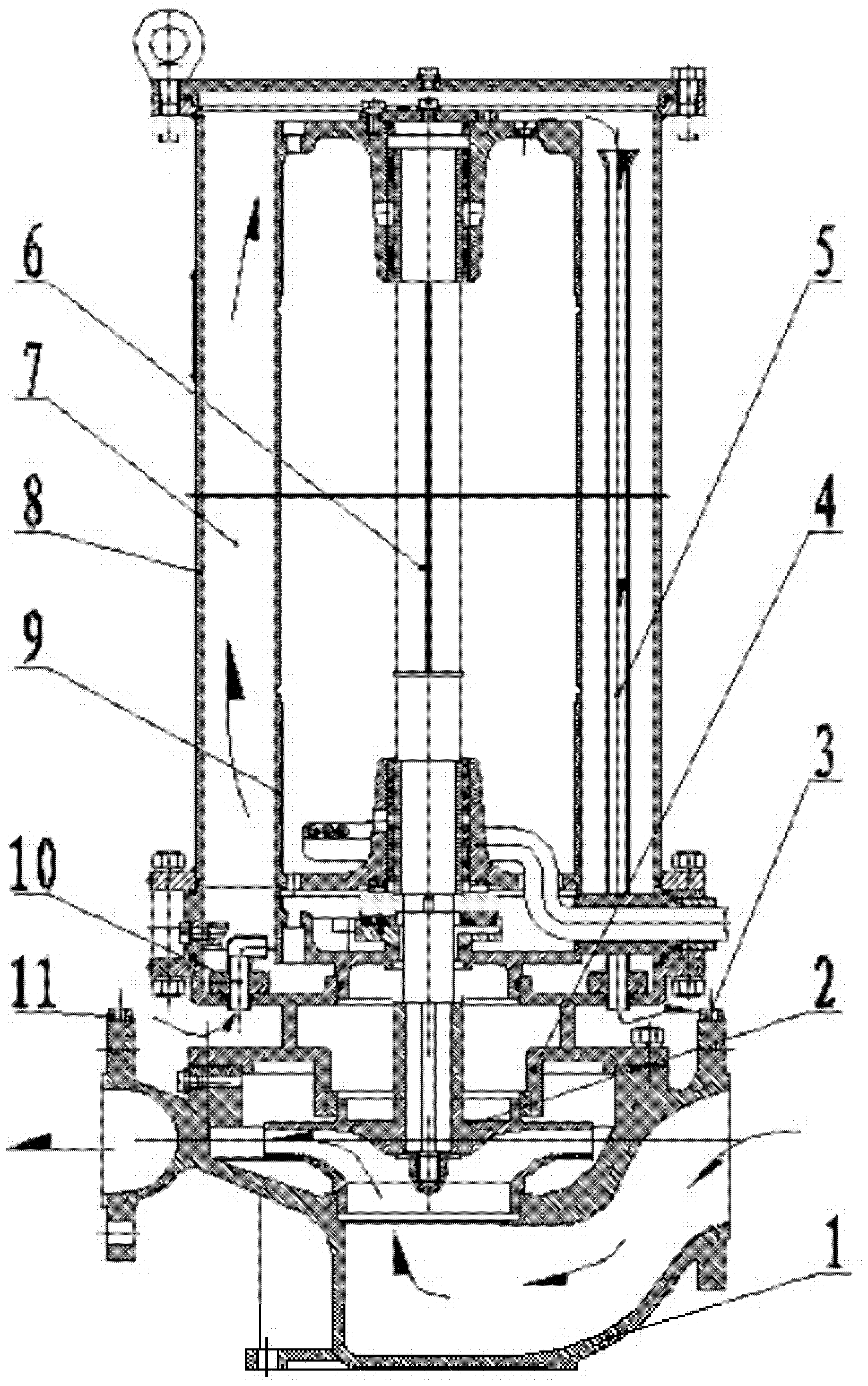

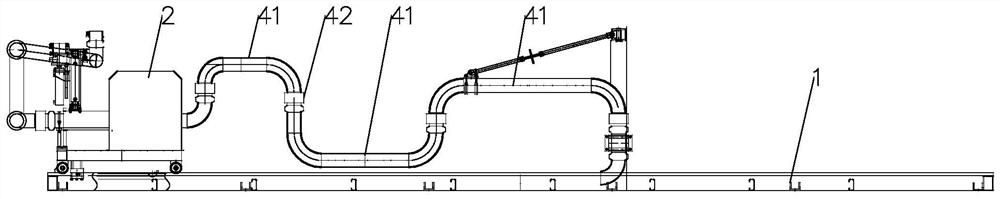

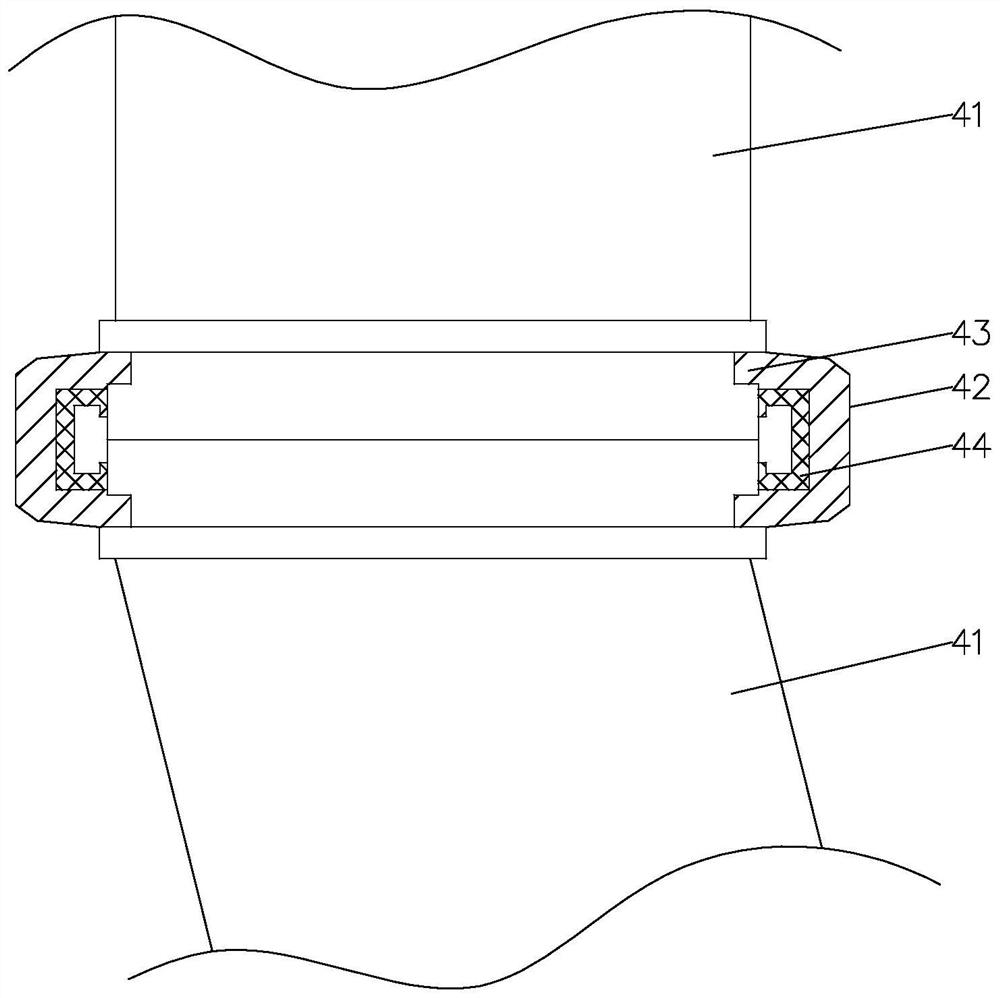

An amphibious vertical centrifugal pump unit

InactiveCN102278316ACutting costsReduce the difficulty of pouringPump componentsPump installationsWater flowEngineering

The invention provides an amphibious vertical centrifugal pump unit. The centrifugal pump (1) is connected with a heat exchange housing (8) and a submersible motor (9) through a connecting casting (4), and the heat exchange housing (8) and the motor Between (9) is a heat exchange chamber (7), the cooling circulation waterway beginning (11) on the centrifugal pump (1) is connected with the water inlet pipe (10) of the cooling circulation waterway, the water inlet pipe (10), the heat exchange chamber (7), the cooling circulation water return pipe (5) and the cooling circulation water end (3) are connected in sequence. The submersible motor (9) drives the centrifugal pump (1) to work, most of the water is conveyed along the main pipeline of the centrifugal pump (1), and a small part of the water is sent to the beginning of the cooling circulation waterway (11), and the water flows through the water inlet pipe (10), The heat exchange chamber (7) and the return pipe (5) then enter the end of the cooling circulation waterway (3) and merge with the main pipe.

Owner:SICHUAN RES & DESIGN INST OF AGRI MACHINERY

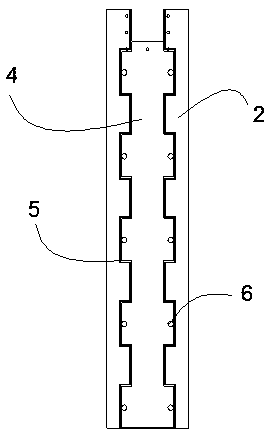

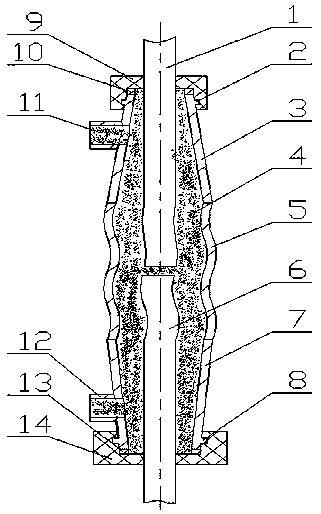

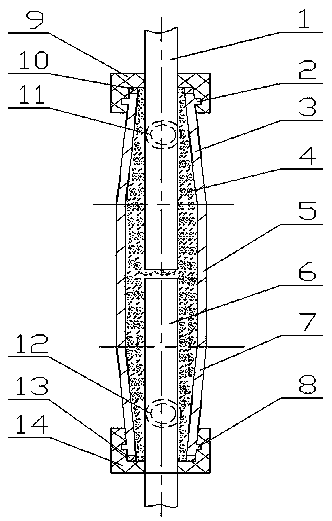

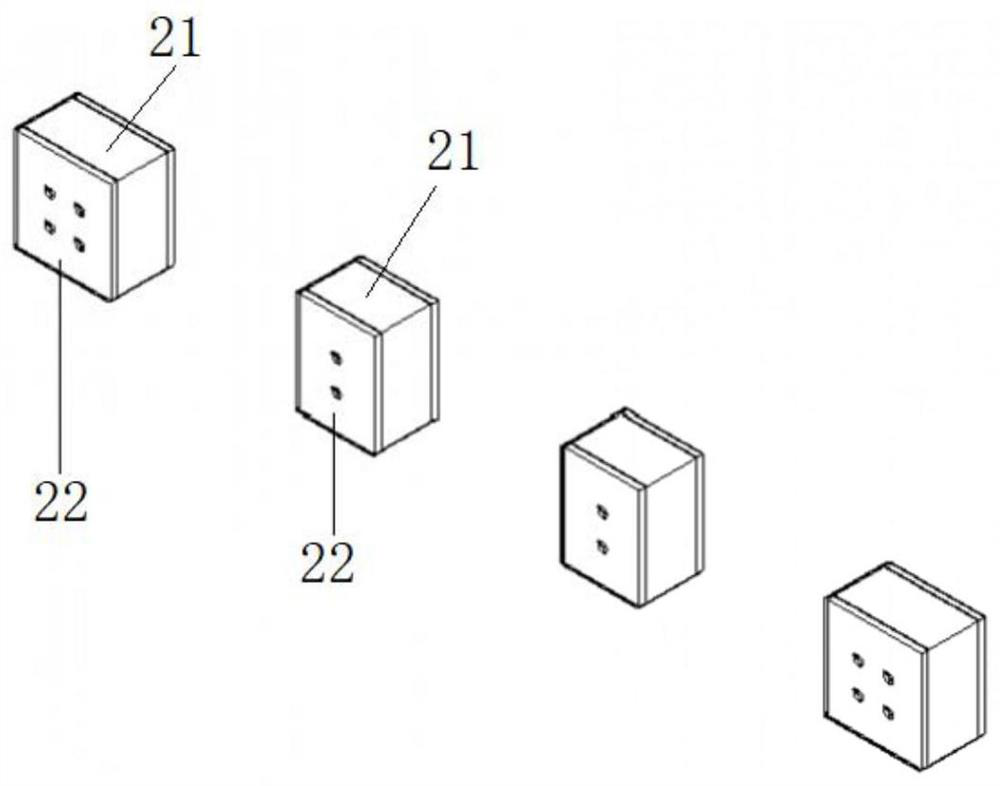

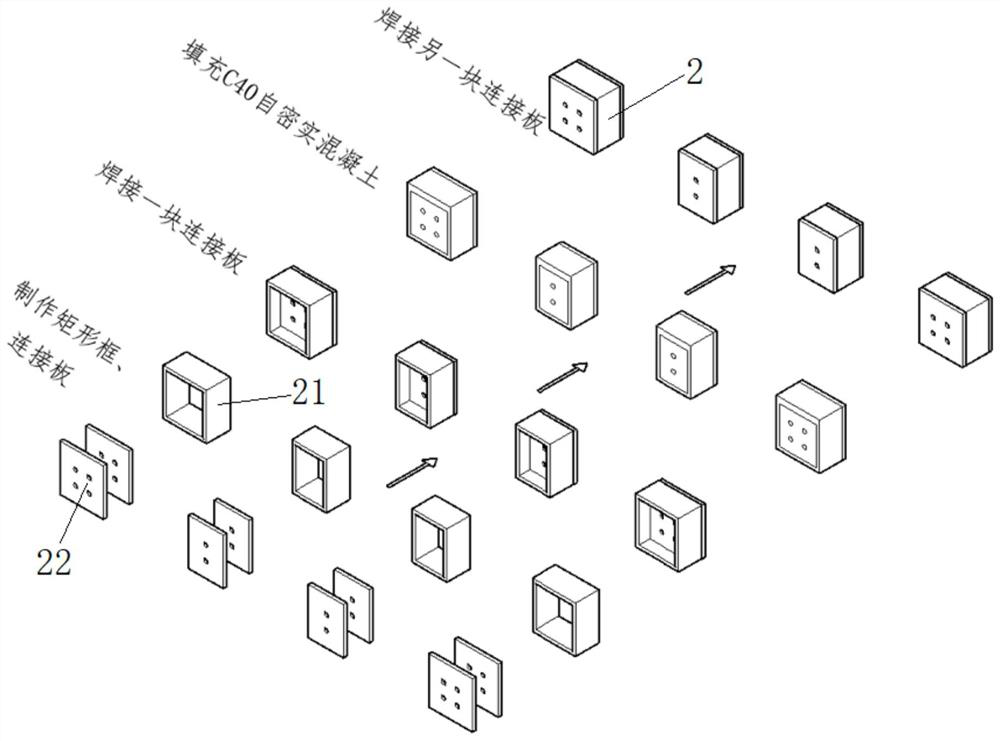

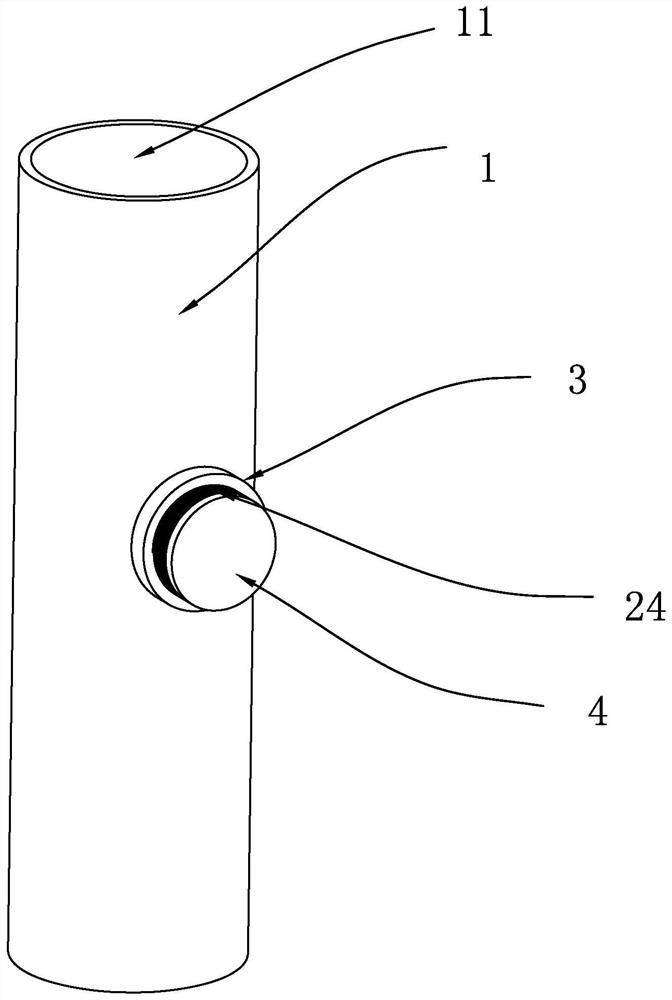

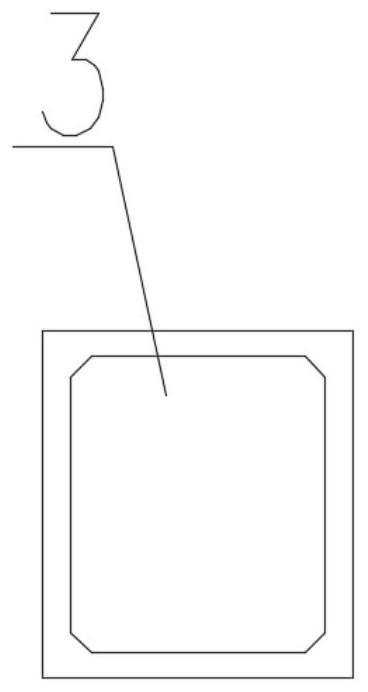

Semi-grouting sleeve assembly for fabricated building and construction method thereof

InactiveCN111255162ASmall sizeReduced sleeve outer diameterBuilding reinforcementsBuilding material handlingArchitectural engineeringReducer

The invention discloses a semi-grouting sleeve assembly for prefabricated building. The semi-grouting sleeve assembly comprises a first steel bar provided with a first external thread, a second steelbar provided with a second external thread, an integrated nut bolt, a straight thread sleeve provided with a grout discharging hole, a semi-grouting sleeve and a square nut. The semi-grouting sleeve comprises a rectangular pipe, a square-round reducer pipe, a round pipe, an outer-round inner-square pipe and a grouting hole formed in the square-round reducer pipe; one end of the rectangular pipe istransitionally enlarged and gradually changed to one end of the round pipe through the square-round reducer pipe, the outer diameter of the round pipe is the same as that of the outer-round inner-square pipe, and fourth external threads are arranged on the outer surfaces of the round pipe and the outer-round inner-square pipe; and a rectangular hole allowing the first steel bar to penetrate through and allowing the square nut not to penetrate through is formed in the outer-round inner-square pipe, and first internal threads matched with the first external threads and third external threads are formed in the straight thread sleeve. The semi-grouting sleeve assembly is simple in structure and low in application cost, and the overall quality of the semi-grouting sleeve assembly can be guaranteed when the sleeve is not fully grouted.

Owner:梁雪芽

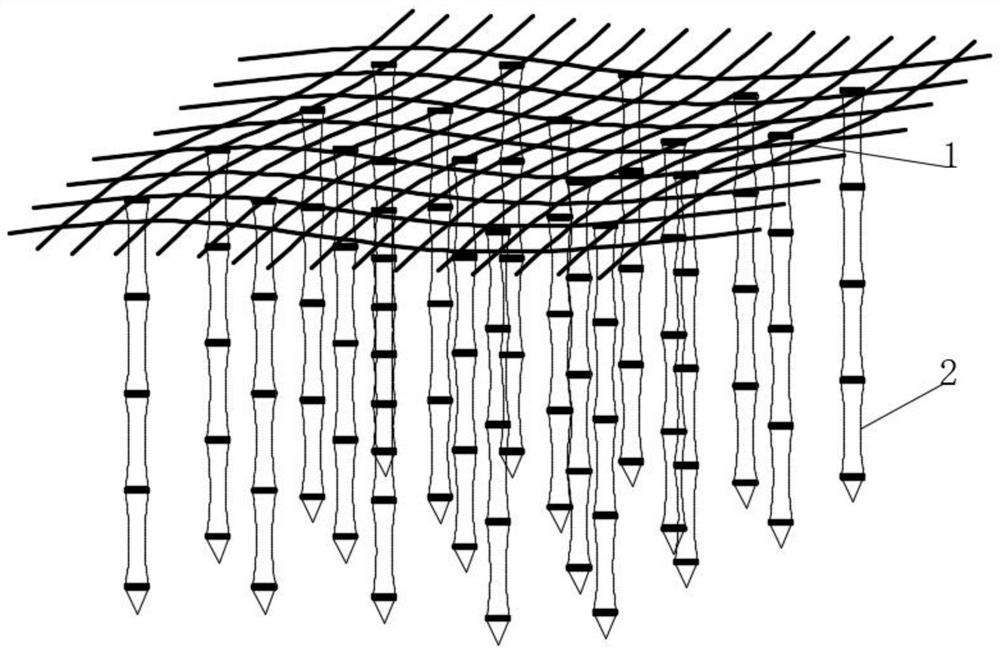

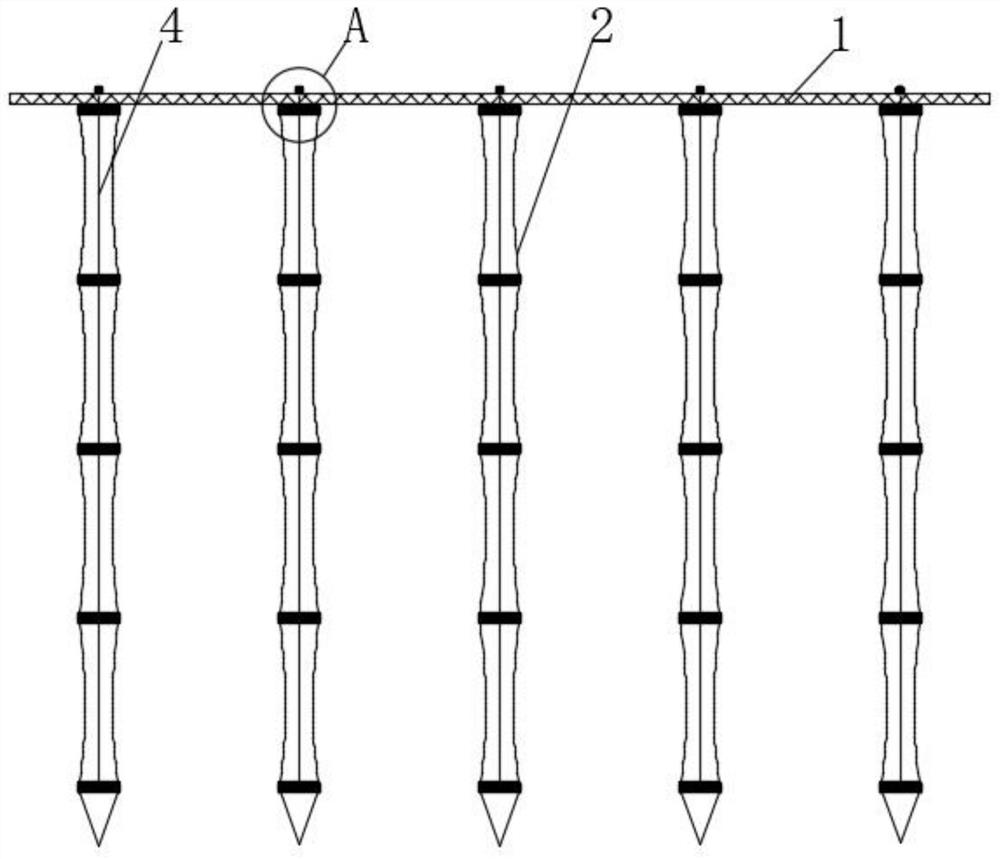

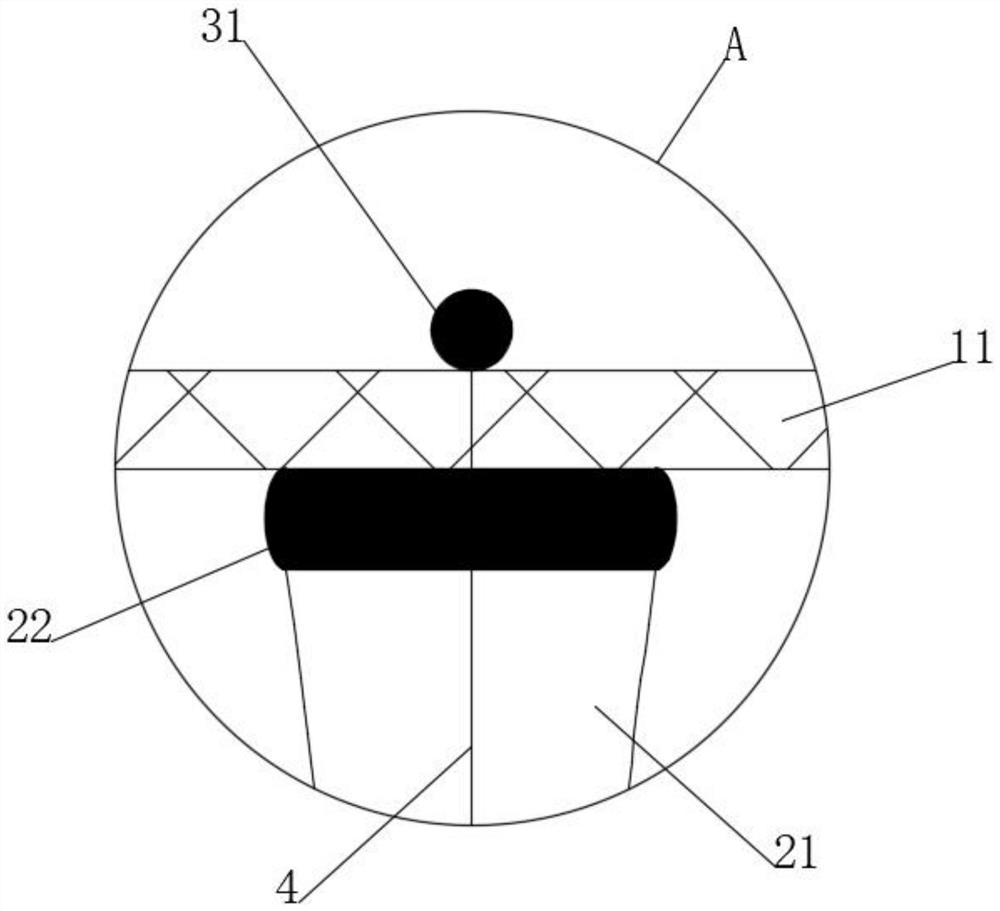

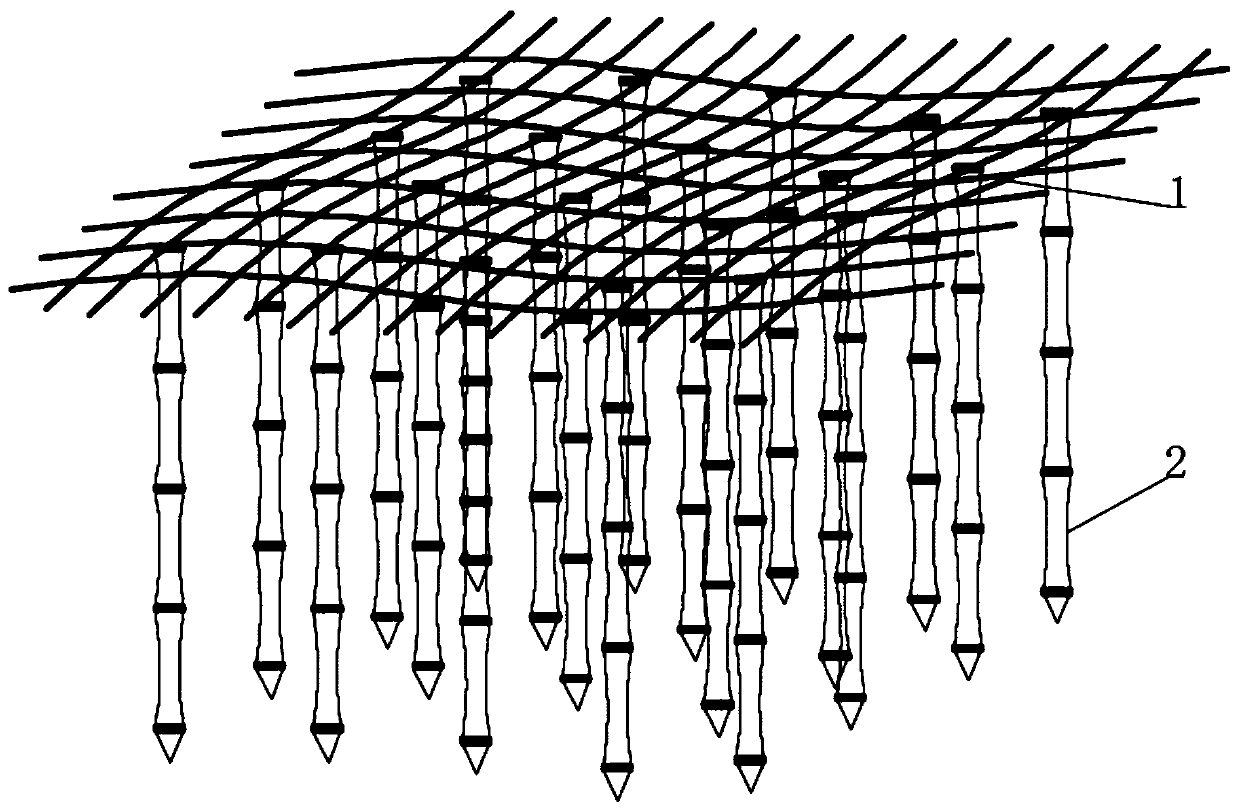

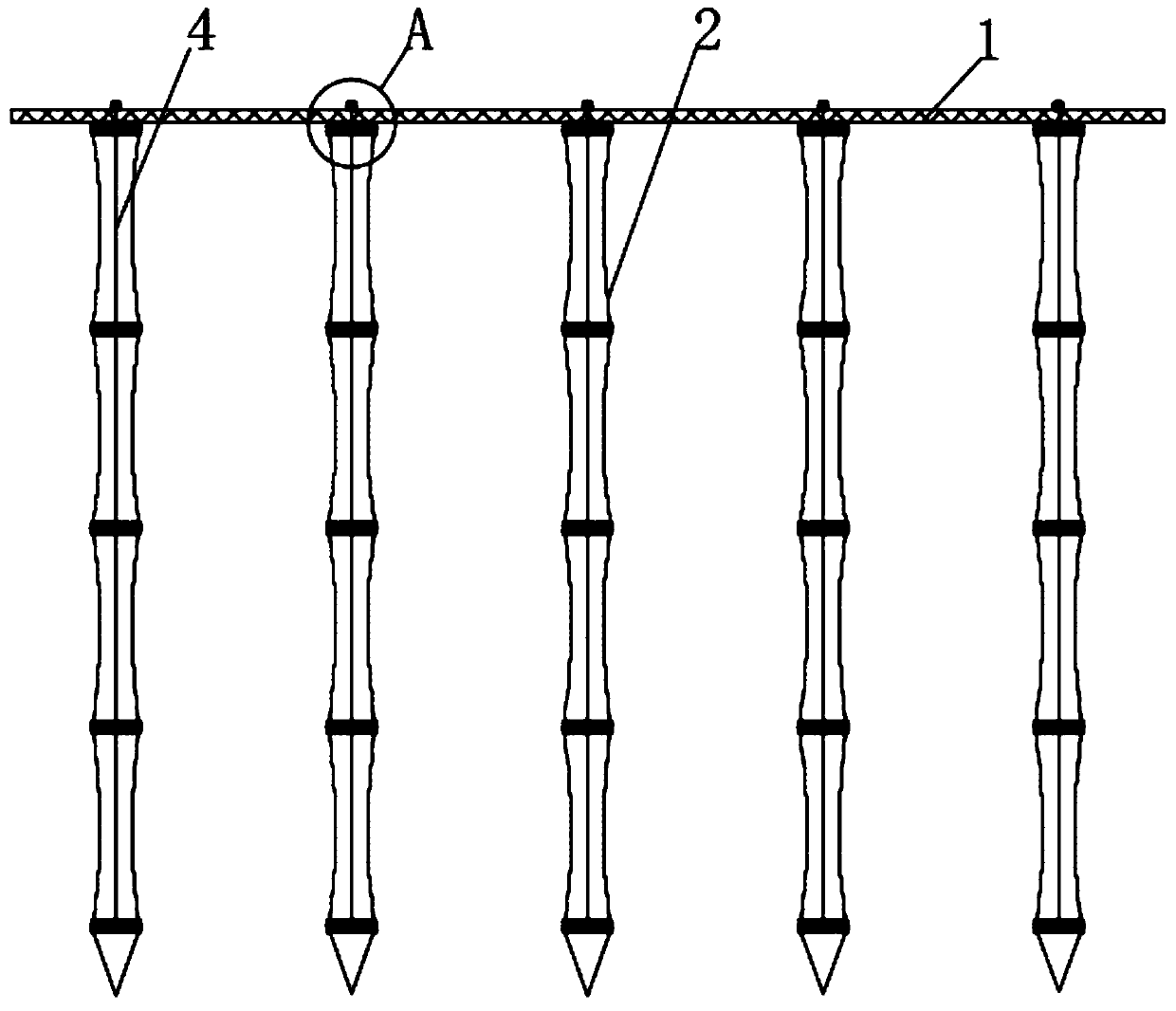

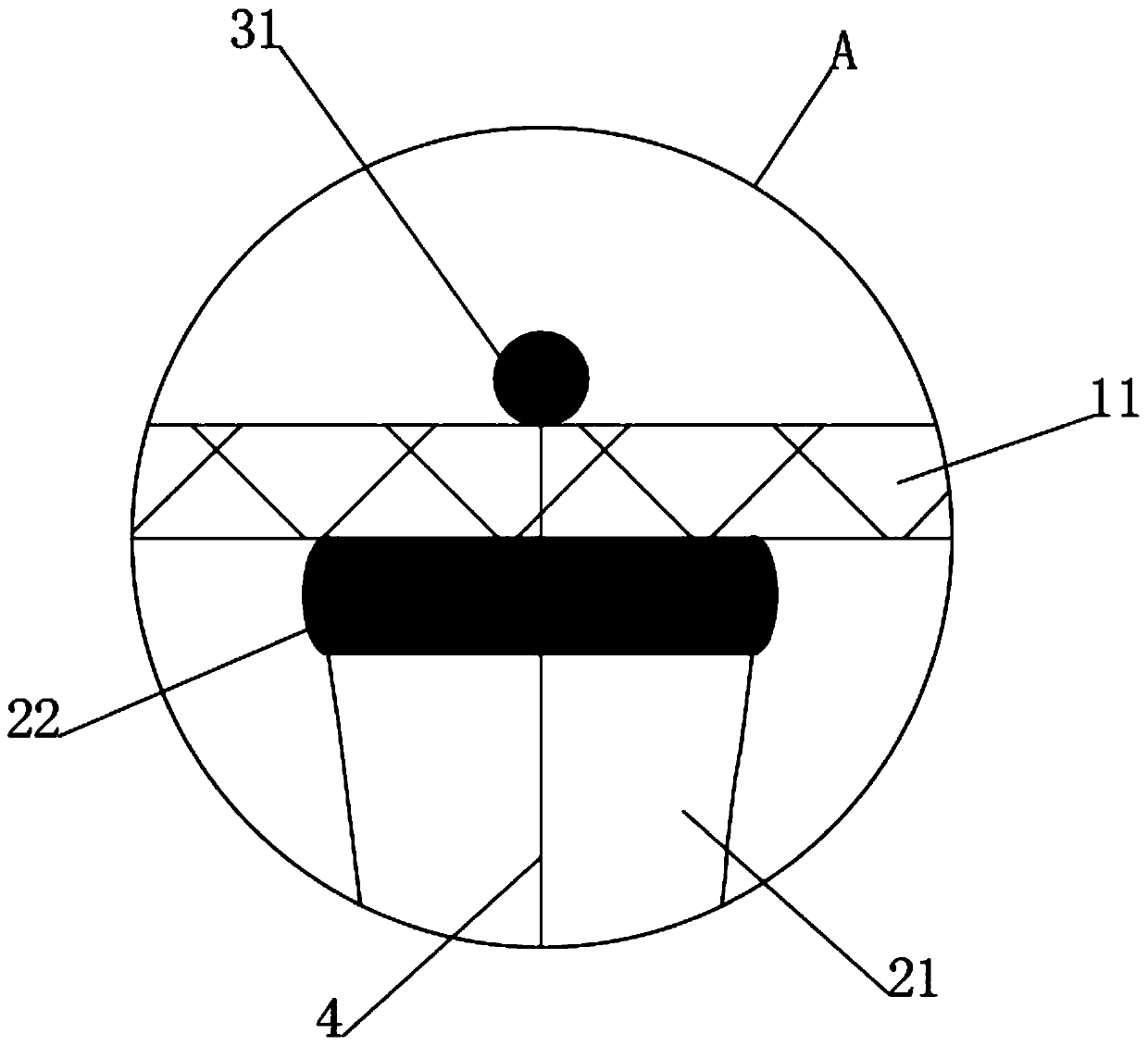

A bamboo-like plastic soil-buried auxiliary degradation net

ActiveCN111530881BEasy accessIncrease the number ofSolid waste disposalTransportation and packagingMicroorganismSoil science

The invention discloses a bamboo-like plastic soil-buried auxiliary degradation net, which belongs to the field of plastic degradation. An imitation bamboo-shaped plastic soil-buried auxiliary degradation net includes a screen body, and multiple nodes on the screen body are There are multiple pre-embedded bamboo rods evenly distributed. In the case of setting this auxiliary degradable net, under the action of the upward heat conduction mechanism, on the one hand, the heat in the plastic pile can be transferred to the discoloration ball, thereby reminding the work Personnel add microorganisms to the bamboo pre-embedded rod, and on the other hand, the heat is transferred to the pre-passed fried ball, so that the pre-passed fried ball is heated, expanded and burst, and the two sides of the pre-passed ball groove are connected. At this time, the bamboo joint embedded rod is connected inside and outside. , it is convenient for the added microorganisms to enter the plastic pile through the pre-pass ball groove, thereby increasing the number and types of microorganisms inside the plastic pile, and at the same time, the bursting of the pre-pass fried balls can have the effect of turning and loosening the nearby plastic, compared with the existing technology, which significantly increases the degradation rate of degradable plastics in soil burial.

Owner:深圳市恒得源环保新材料科技有限公司

Full-grouting sleeve for steel bar connection of assembly-type building, and construction method for full-grouting sleeve

InactiveCN111236540ASmall sizeIncrease the gapBuilding reinforcementsBuilding material handlingArchitectural engineeringReducer

The invention discloses a full-grouting sleeve for steel bar connection of an assembly-type building. The sleeve is characterized by comprising a rectangular pipe orifice (10), a first reducer pipe body (3), a second reducer pipe body (7), a round pipe orifice (13), a transition pipe body used for communicating between the first reducer pipe body and the second reducer pipe body, a pulp dischargehole (11) and a grouting hole (12), wherein axial cross sections of two ends of the transition pipe body are square; the upper end of the transition pipe body gradually changes to the rectangular pipeorifice through transition and shrinking of the first reducer pipe body; and the lower end gradually changes to the round pipe orifice through transition and shrinking of the second reducer pipe body. The sleeve disclosed by the invention has the beneficial effects that the structure is simple; application cost is low; the length of the full-grouting sleeve and cross sections of corresponding beam columns can be greatly reduced; and tensile strength of the full-grouting sleeve is further enhanced, and application cost of the assembly-type building is further reduced.

Owner:吴祖荣

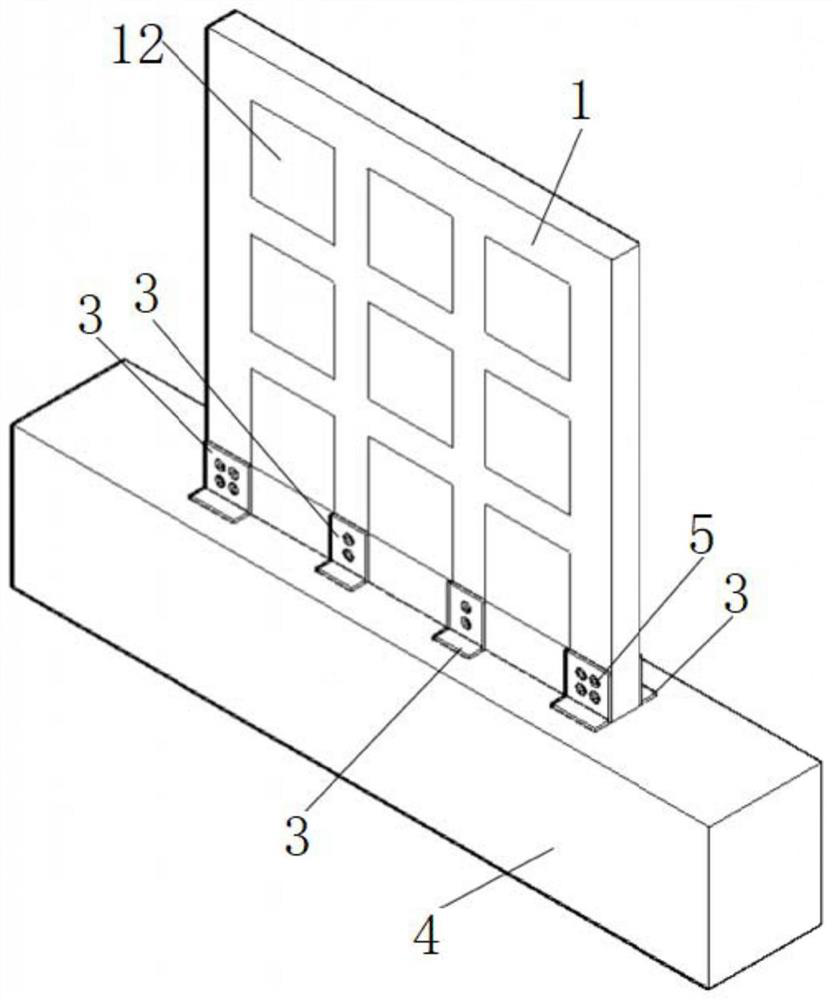

Fabricated composite wall based on steel pipes and construction method thereof

PendingCN111749366AImprove tensile propertiesImprove stress resistanceWallsHeat proofingEarthquake resistancePipe

The invention discloses a fabricated composite wall based on steel pipes and a construction method thereof. The fabricated composite wall comprises a prefabricated wallboard which is arranged on a foundation beam, the prefabricated wallboard comprises a steel pipe composite wall framework, building blocks and a concrete outer cladding layer, the steel pipe composite wall framework is of a rib lattice structure formed by splicing a plurality of steel pipes, and the rib lattice structure is filled with building blocks; wall connecting pieces are evenly arranged at the bottom end of the prefabricated wallboard and arranged at the joints of rib columns and rib beams of the prefabricated wallboard; and a foundation embedded part is embedded in the top end of the foundation beam, and the wall connecting part is connected with the foundation embedded part through a high-strength bolt. According to the fabricated composite wall, through the synergistic effect of the steel pipe composite wall framework and the concrete, the advantages of good tensile and compressive properties of the steel pipe and high compressive capacity of the concrete are fully utilized, and the bearing capacity and seismic performance of the fabricated composite wall are effectively improved; and the wall connecting pieces and the foundation embedded part are connected through high-strength bolts, dry connection of the foundation horizontal joint of the prefabricated wallboard is achieved, and stability is high.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Bamboo-joint-like auxiliary degradation net for soil burial for plastic

ActiveCN111530881AShorten the timeFast degradationTransportation and packagingSolid waste disposalMicroorganismSoil science

The invention discloses a bamboo-joint-like auxiliary degradation net for soil burial for plastic, and belongs to the field of plastic degradation. The bamboo-joint-like auxiliary degradation net forsoil burial for the plastic comprises a net plate body, wherein a plurality of uniformly-distributed bamboo-joint pre-buried rods are arranged at a plurality of joints on the net plate body. In the case that the auxiliary degradation net is arranged, under the action of an upwards-moving heat guide mechanism, on one hand, heat in a plastic pile is transferred to a color-change ball, and then working personnel are reminded of adding microorganisms into the bamboo-joint pre-buried rods; on the other hand, the heat is conducted to a pre-passing explosion ball, so that the pre-passing explosion ball is expanded with heat to be exploded; the two sides of a pre-passing ball groove are connected, at this moment, the inside and the outside of each bamboo-joint pre-buried rod are connected, and theadded microorganisms are facilitated to penetrate through the pre-passing ball groove and enter into the plastic pile, so that the number and the type of the microorganisms in the plastic pile are increased; and meanwhile, due to the explosion of the pre-passing explosion ball, the effects of overturning and loosening can be generated on the plastic in the vicinity, and compared with the prior art, the degradation speed for the degradable plastic in a soil burial manner is remarkably increased.

Owner:深圳市恒得源环保新材料科技有限公司

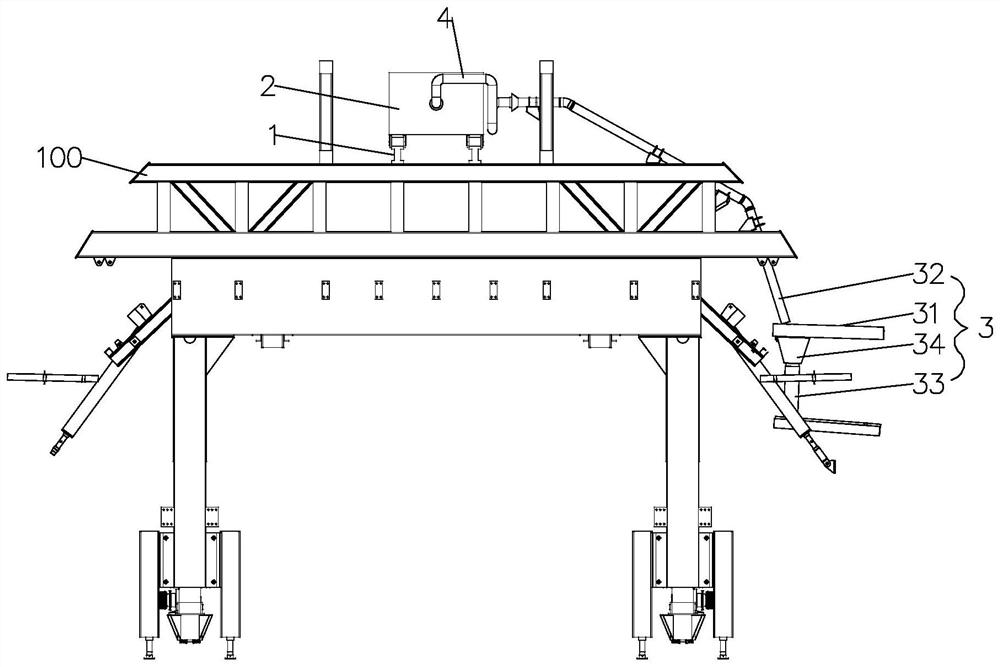

Mould grouting device for automatic lining trolley

PendingCN114215552ASimple structureRealize lining pouringUnderground chambersTunnel liningStructural engineeringTruck

The invention relates to the technical field of lining trolleys, in particular to a grouting device with a mold for an automatic lining trolley. Comprising a transportation track arranged on the top of a trolley rack, a transportation pump truck arranged on the transportation track in a sliding mode, a plurality of sets of grouting pipelines arranged downwards along a trolley formwork and a transfer bent pipe connected between the transportation pump truck and the grouting pipelines, and the grouting pipelines are arranged along the two sides of the transportation track; the lower ends of the grouting pipelines are provided with chutes penetrating through the trolley formwork to the outer side, the transfer bent pipes comprise a plurality of bent pipes connected end to end, the adjacent bent pipes are rotationally connected, and the transfer bent pipes are rotationally communicated with the grouting pipelines respectively. The grouting device of the lining trolley is simple in structure and convenient to use, and the grouting difficulty of a lining structure is reduced.

Owner:CHINA RAILWAY 16TH BUREAU GRP BEIJING JIANGONG MASCH CO LTD

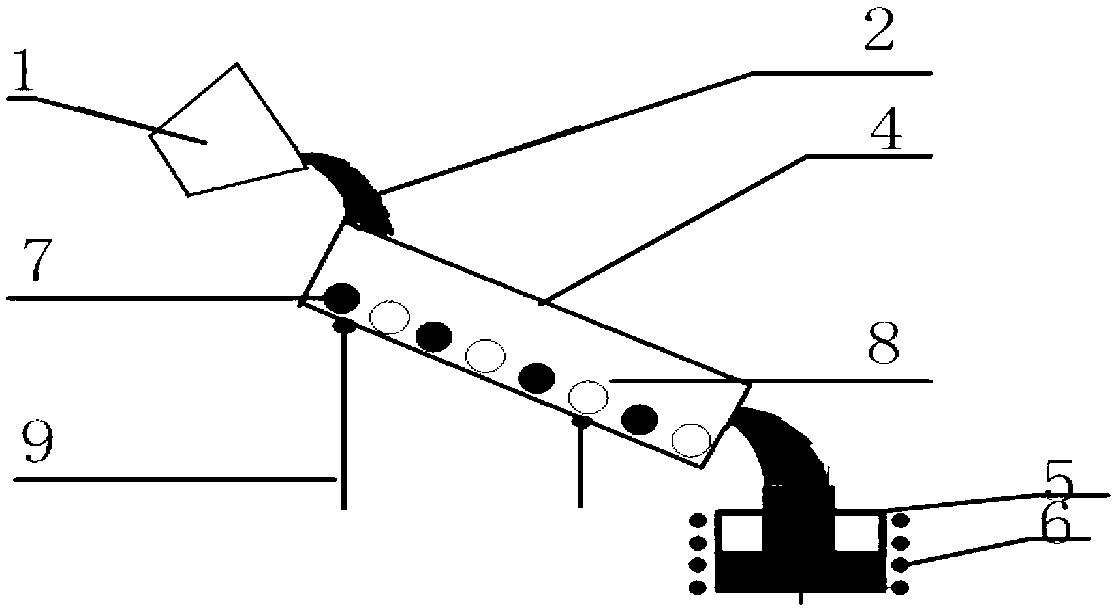

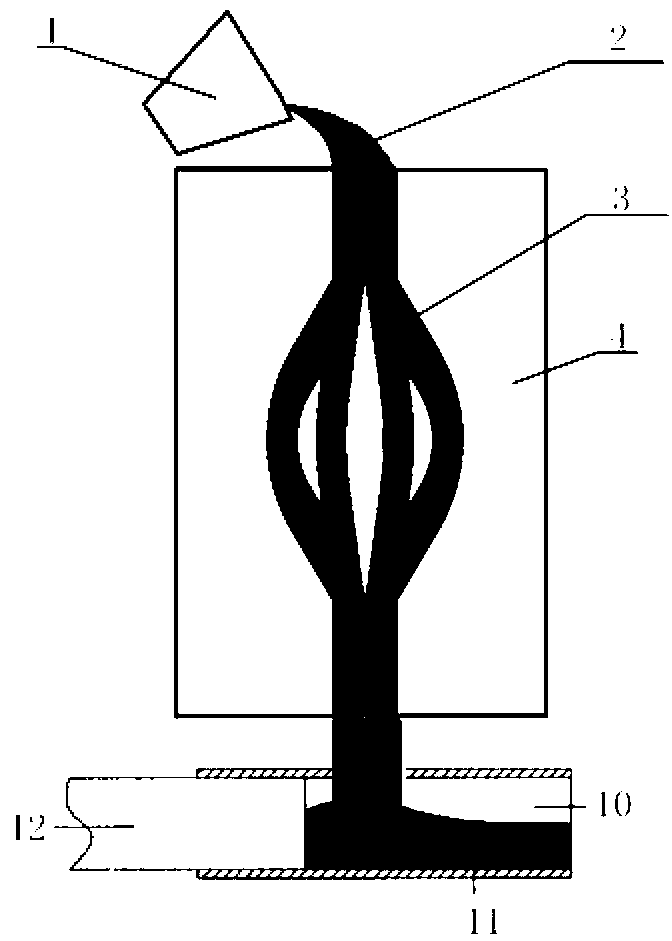

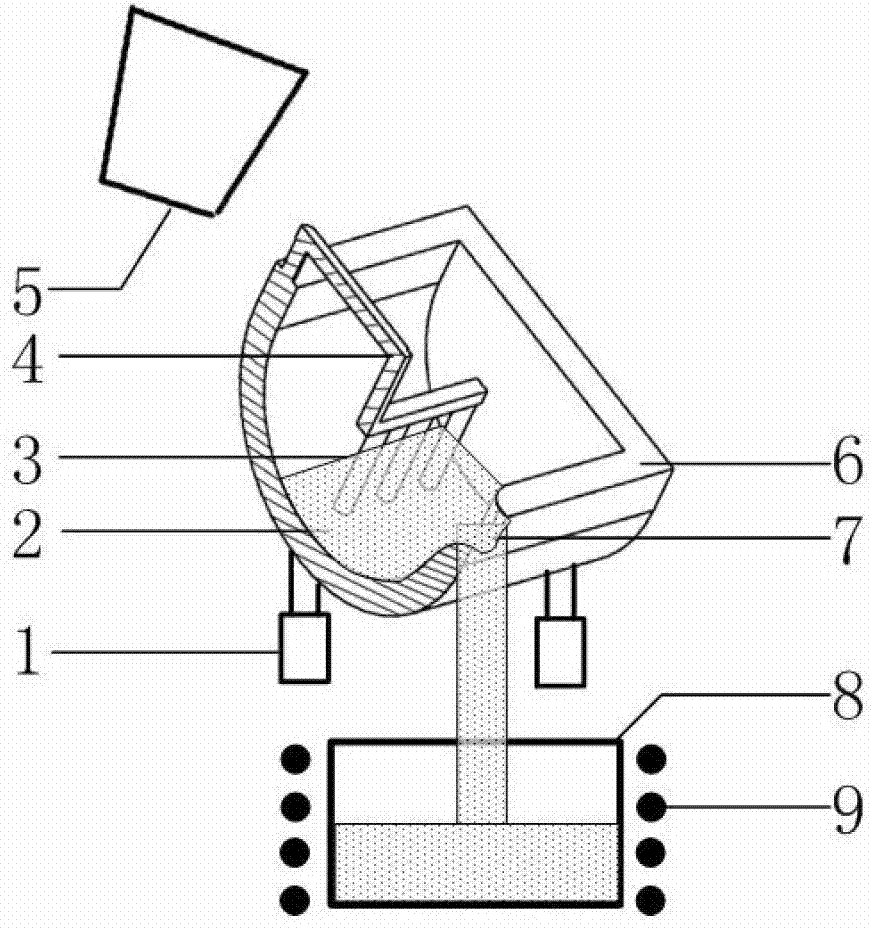

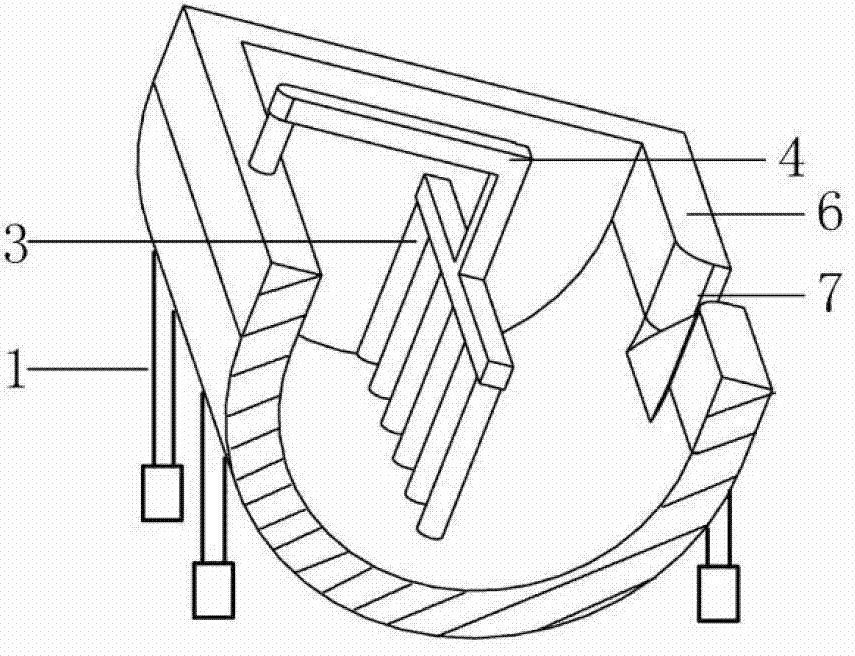

Swing stirring device for preparing semisolid slurry and rheoforming equipment

InactiveCN103341612BReduce manufacturing costReduce the difficulty of pouringShaking/oscillating/vibrating mixersMetal machiningSemi solid

The invention provides a swing stirring device for preparing semisolid slurry and rheoforming equipment, and belongs to the field of semisolid metal processing technology. The swing stirring device for preparing the semisolid slurry is composed of swing lifting rods, a swing power device, an alloy melt, fixed stirring rods, a supporting frame, a pony ladle, a stirring chamber, a small sprue, a crucible, heating elements, a die-casting machine, a pressing chamber of the die-casting machine, the semisolid slurry, an injection punch, an extruding machine, a pressing chamber of the extruding machine, an extruding punch and the like. Based on the principles of cooling and stirring, the alloy melt flows in the stirring chamber under the action of the swing stirring rods, the nucleation of the alloy melt is promoted to prepare the semisolid slurry under the stirring action of the fixed stirring rods, and the rheoforming equipment achieves rheoforming easily when matched with forming equipment, such as the die-casting machine, the extruding machine or a forging machine. The swing stirring device for preparing the semisolid slurry and the rheoforming equipment are simple in structure, small in investment, low in production cost, stable and reliable in continuous preparation work, and quite suitable for preparation and forming production of the semisolid metal slurry or blank.

Owner:UNIV OF SCI & TECH BEIJING

Construction method of structural column structure with concealed beam floor slab

The present invention relates to the construction field of structural columns, in particular to the structural column structure of the concealed beam floor slab and the construction method. The structural column structure comprises: a reinforcement cage, a number of steel bars are arranged vertically in the reinforcement cage, and the upper and lower ends of the reinforcement bars are connected to the concealed beams. Floor; columnar structure, the columnar structure is made of concrete pouring, the steel bars are placed inside the columnar structure, the upper and lower ends of the columnar structure are connected to the floor; the structural column runs through two adjacent floors, and the steel bars in the structural columns of the two floors respectively It is connected as a whole, and a columnar structure is arranged around the steel bars at the junction of the two floors. The purpose of the invention of this application is to save steel bars, firmly connect with the main body, avoid steel bar displacement, reduce pouring difficulty, and reduce cost. A related construction method is also disclosed.

Owner:CHENGDU NO 4 CONSTR ENG

Concrete pouring structure of super high-rise steel pipe column

ActiveCN114673303ASolve the cumbersomeSolve difficultyStrutsHydro energy generationClassical mechanicsSteel columns

The concrete pouring structure of the super high-rise steel pipe column comprises a steel column, a pouring cavity is formed in the steel column in the height direction of the steel column in a hollow mode, a clamping hole allowing an external operator to pour concrete fluid into the pouring cavity is formed in the outer wall of the steel column, and the clamping hole communicates with the pouring cavity; a drainage assembly used for guiding the flowing direction of external concrete fluid is arranged on the clamping hole. The problems that in the prior art, the concrete pouring process of the super high-rise steel column is tedious, and the construction difficulty is increased are solved.

Owner:HUADONG BUILDING CO LTD OF CHINA CONSTR FIFTH ENG BUREAU +2

A solid-sealed pole of a vacuum circuit breaker

ActiveCN104124099BAvoid mutual contraction effectsImprove pouring qualityHigh-tension/heavy-dress switchesAir-break switchesEpoxyEngineering

The invention discloses a solid-sealed polar pole of a vacuum breaker. The solid-sealed polar pole of the vacuum breaker comprises a vacuum arc extinguishing chamber I, a vacuum arc extinguishing chamber II and a vacuum arc extinguishing chamber III which are sequentially and horizontally arranged. The three vacuum arc extinguishing chambers are vertically mounted, and the upper end of every vacuum arc extinguishing chamber is a movable end; the lower ends of the vacuum arc extinguishing chamber II and the vacuum arc extinguishing chamber III are connected with a copper bus bar I, and the lower end of the vacuum arc extinguishing chamber I is connected with a copper bus bar II; the movable ends of the vacuum arc extinguishing chamber I and the vacuum arc extinguishing chamber II are mounted inside the same cavity through separation of an epoxy baffle, and the movable end of the vacuum arc extinguishing chamber III is arranged inside a independent cavity through separation; a mounting surface is arranged above the epoxy baffle. The solid-sealed polar pole of the vacuum breaker is easy to mould by casting, avoids the problems existing in the prior art such as concealed cracks, cracking, local amplification, low strength and radiating difficulty and fully meets requirements on power supply.

Owner:ZHUHAI XJ ELECTRIC +1

Assembling-type building prefabricated reinforced concrete inner heat preservation wall body and inner-outer wallboard connecting reinforced steel bar

InactiveCN102425250BLower heat transfer coefficientLow costWallsHeat proofingPolyesterReinforced concrete

The invention relates to an assembling-type building prefabricated reinforced concrete inner heat preservation wall body and an inner-outer wallboard connecting reinforced steel bar, aims at improving the present prefabricated reinforced concrete inner heat preservation wall body, and is characterized in that: an axial connection reinforced steel bar in an alternate reinforced concrete short column is used for joining an H-shaped inner reinforced concrete wallboard and an H-shaped outer reinforced concrete wallboard, which are alternatively arranged, at least one section of the axial connection reinforced steel bar is wrapped by a heat insulation material with the heat conductivity being lower than that of the concrete, and the short concrete columns are separated from one another throughthe heat insulation material with the heat conductivity being lower than that of the concrete. On the premise that the overall structural strength of the inner heat preserving wall body is guaranteed, the cold-hot bridge phenomenon between the inner wallboard and the outer wallboard can be greatly reduced, and a heat conduction coefficient of each wall body is less than or equal to 0.45W / m<2> K; the cost of the connection short columns between the inner and the outer wallboards is greatly reduced, the cost of the connection short columns is slightly higher than that of the reinforced concreteshort column, and the cost of the connection short column is only one fourth of that of a fiberglass reinforced polyester (FRP) connection column. At least one section of the short-column connection reinforced steel bar in the axial direction is wrapped by the heat insulation material with low heat conductivity, the heat insulation material is simple to produce, a low-heat bridge connection reinforced steel bar is formed, a mold injection or immersion production way can be adopted, and the industrialized low-cost mass production can be realized. The axial connection reinforced steel bar in the connection concrete short column adopts an annular loop structure, the steel reinforced steel bar is greatly convenient to place, and the inner and the outer wallboard reinforced steel bars can be greatly conveniently connected with each other, the setting difficulty is not increased, and the mass production can be realized.

Owner:张吉华 +1

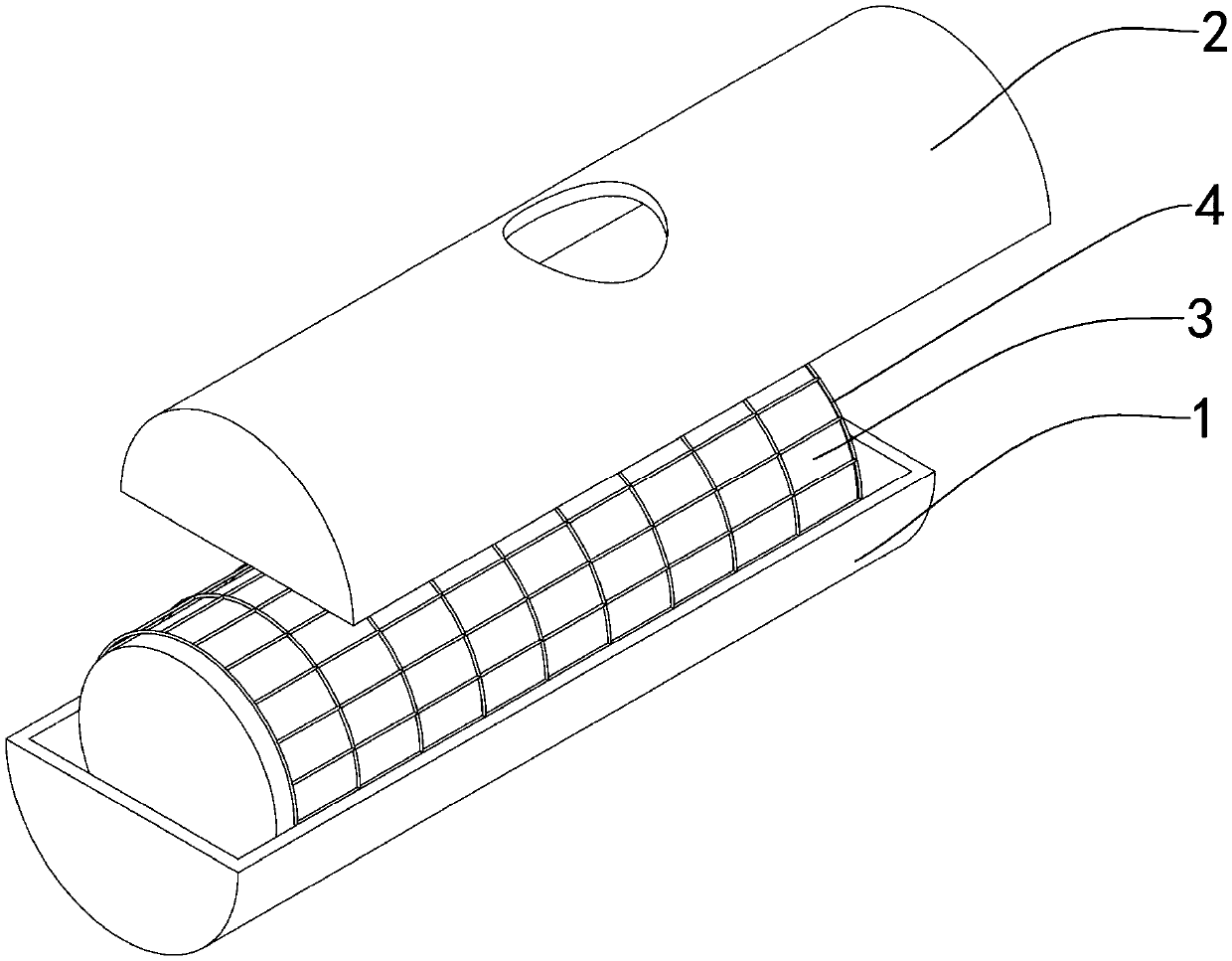

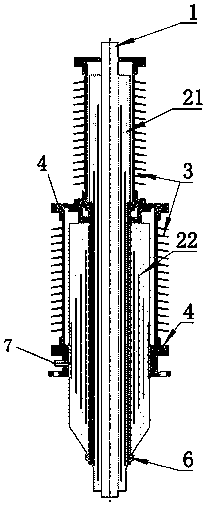

Straddle type monorail steel-concrete combined track beam and erecting method

PendingCN114508050AReduce construction stepsReduce crackingBridge structural detailsBridge materialsTrackwayArchitectural engineering

The invention provides a straddle type monorail steel-concrete combined track beam and an erecting method, and relates to the technical field of track traffic, the straddle type monorail steel-concrete combined track beam comprises a steel beam, a reinforcing mesh and a concrete body, the top face of the steel beam is parallel to the ground, at least one set of shear nails are arranged on the top face of the steel beam, and each set of shear nails are arranged in the length direction of the steel beam; the reinforcing mesh is located above the shear nails, and the end of the reinforcing mesh is connected with the steel beams. And the concrete body is connected with the steel beam through the shear nails and the reinforcing mesh. The mode that the reinforcing mesh and the steel beam are directly connected and the mode that the concrete body is directly poured on the framework formed by the reinforcing mesh are adopted, so that a concentric-square-shaped stirrup used in the prior art is replaced, and the connection stability of the concrete body and the steel beam is improved; the construction step that in the prior art, double steel bars with the diameter phi being 25 mm and the distance being 100 mm need to be arranged in a cast-in-place section is omitted, the pouring difficulty is lowered, and meanwhile the phenomenon that in the prior art, cracks are likely to occur in the cast-in-place section is avoided.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

Extra-high voltage resin impregnated paper alternate-current and direct-current capacitance sleeve tube

PendingCN109378185AReduce the difficulty of pouringImprove pass rateTransformers/inductances coils/windings/connectionsElectric component structural associationCapacitanceElectrical conductor

The invention discloses an extra-high voltage resin impregnated paper alternate-current and direct-current capacitance sleeve tube. The sleeve tube comprises a central conductive body, an inner capacitance core, an outer capacitance core, outer insulation members and installing flanges, the inner capacitance core and the outer capacitance core are installed on the middle conductive body, the lowerend of the inner capacitance core is inserted in the outer capacitance core, a zero screen of the outer capacitance core and a rear screen of the inner capacitance core are in equipotential bonding,the outer wall of the inner capacitance core and the outer wall of the outer capacitance core are sleeved with the outer insulation members and the installing flanges, the end of the outer capacitancecore is fixedly connected with the installing flange of the inner capacitance core, a capacitance tap is arranged on the installing flange of the outer capacitance core, and the capacitance tap is connected with the rear screen of the outer capacitance core. By means of the sleeve tube, the pouring difficulty of the main insulation capacitance core can be effectively reduced to improve the qualification rate of the insulation capacitor core, the weight is reduced, and the cost is reduced.

Owner:NANJING ZHIDA ELECTRICAL EQUIP CO LTD

Wax mold of pouring system for large-scale hollow crowned blade casting and its manufacturing method

ActiveCN105364006BReduce stressReduce the difficulty of pouringFoundry mouldsFoundry coresWaxSpherical shaped

The invention provides a wax mold of a large-size hollow shrouded blade casting pouring system and a manufacturing method of the wax mold. The wax mold comprises a casting wax mold and a runner wax mold; a core is arranged in the casting wax mold; a shroud inner gate is formed in the top of the casting wax mold, while a tenon inner gate is formed in the bottom of the casting wax mold; the runner wax mold comprises a first spherical riser of which the bottom is bonded to the top of the shroud inner gate and the top is connected to one end of a first horizontal runner; the other end of the first horizontal runner is connected to a straight runner; the top of the straight runner is bonded to a gate cup, while the bottom of the straight runner is connected to a second spherical riser; the second spherical riser is bonded to the tenon inner gate; the second spherical riser is connected to one end of a second horizontal runner, and the other end of the second horizontal runner is connected to the casting wax mold. According to the wax mold of the large-size hollow shrouded blade casting pouring system, the spherical risers and the corresponding runners are designed reasonably, such that smooth filling and effective feeding to a casting can be realized and the stress can be reduced; hence, the wax mold is applicable to produce large-size, hollow shrouded and complex-structure blades; the pouring difficulty can be reduced, such defects as core breakage, looseness and cracks of the casting can be avoided, and the product qualification rate can be increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

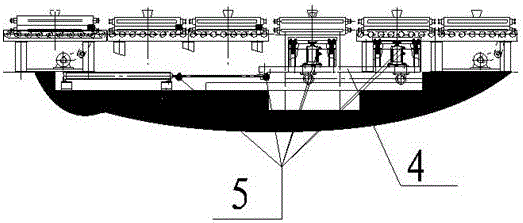

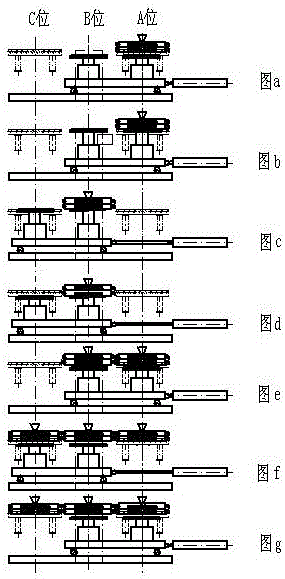

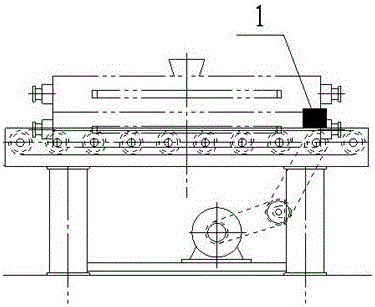

An orderly automatic movement and fixed-point pouring system of iron mold sand-covered casting

InactiveCN103962542BEliminates the case of splash stuck wheelsIncrease the level of automationCasting plantsWorking environmentCasting mold

The invention discloses an automatic ordered moving and fixed-point pouring system for sand coated iron mold casting molds, belonging to the field of casting. By installing a plurality of tracks, different types of products can enter corresponding motorized roller ways by virtue of a transfer trolley; a photoelectric switch detects whether the casting molds exist in a front roller way unit, so that automatic operation and ordered arrangement of the casting molds are realized; after reaching the front end of a pouring position, the casting molds are transferred to a pouring bracket without roller ways by virtue of a pouring trolley, and then are poured; after pouring, the poured casting molds are conveyed to automatic roller ways with a detection function to move forwards by virtue of the pouring trolley. Thus, automatic ordered operation and fixed-point pouring of the casting molds are realized; the labor of workers and the mismatch times caused by hitting of the casting molds are reduced, and the situation of wheel blocking caused by splashing of molten iron is eliminated; two products made of different materials can be independently poured; the pouring difficulty is lowered; a small amount of molten iron which is splashed into pits of the sand-coated pouring trolley can be removed regularly, so that an excellent working environment is ensured.

Owner:BINZHOU HEAD CRANKSHAFT

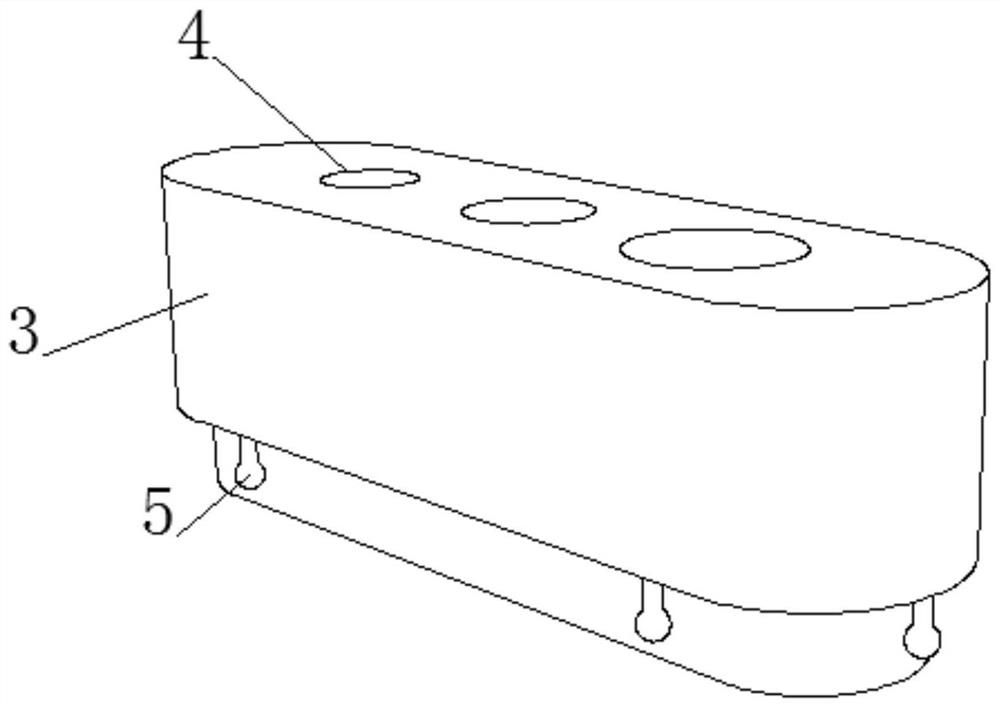

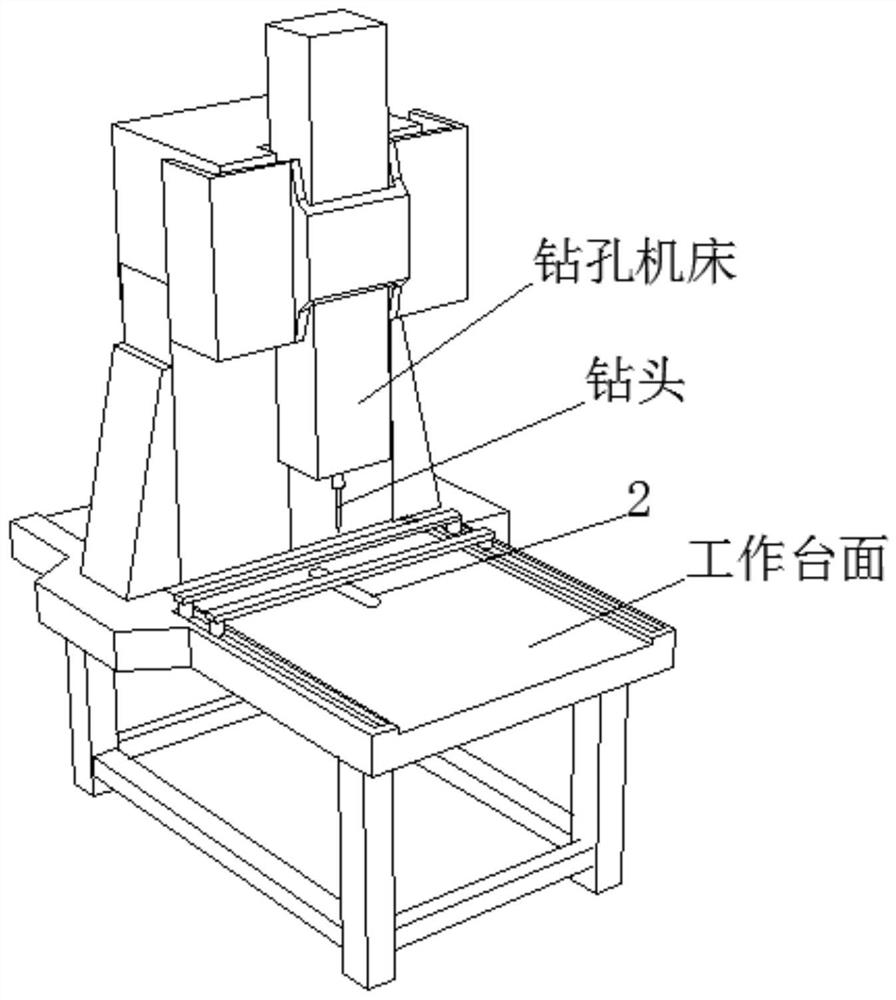

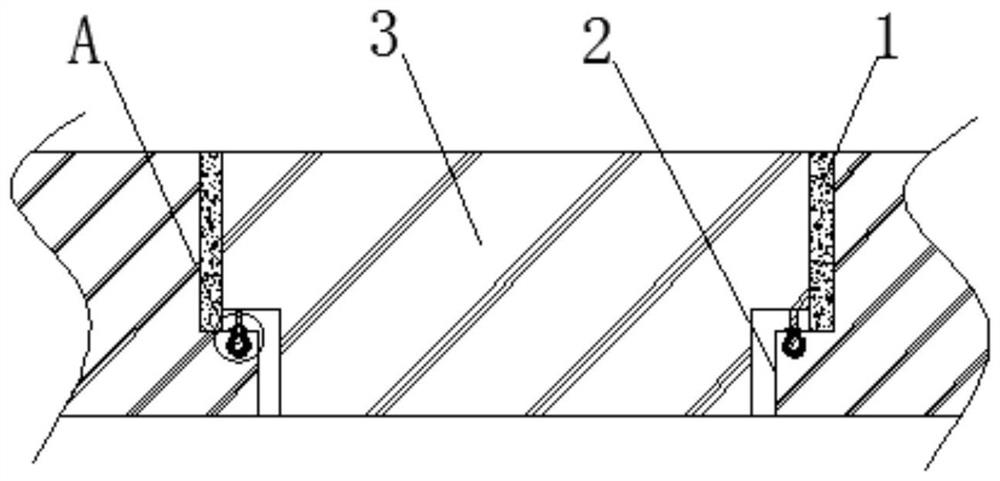

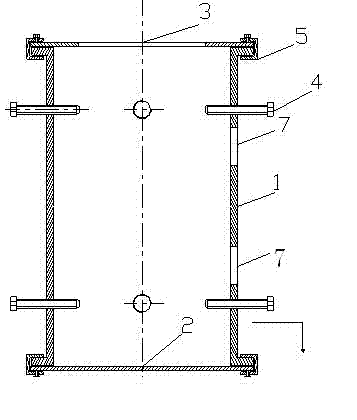

A circuit board drilling aid

ActiveCN110809369BReduce displacementReduce the probability of micro deformationPrinted circuit manufactureEngineeringMechanical engineering

The invention discloses a circuit board drilling aid and belongs to the technical field of circuit board drilling. The circuit board drilling aid can fill a drilling-assisting long hole on a drillingmachine with a long auxiliary drilling block such that the vacant area of a circuit board directly above the drilling-assisting long hole is reduced. Thus, during a drilling process, the area on the circuit board that is recessed downward from the drilling center can be effectively reduced, thereby reducing the workload of a worker for later leveling, reducing the area requiring leveling, loweringthe leveling difficult, and thus improving the overall efficiency of circuit board production. In addition, the use of an adaptive deformation hollow capsule and a sealing layer achieves the preliminary fixation of the inner layer of the aid and the secondary fixation of the upper side. The double fixation effectively reduces the displacement of the aid due to the vibration during drilling, reduces the probability of micro deformation of the circuit board, and improves the drilling quality.

Owner:徐州彤宇自动化科技有限公司

Pouring mold for process nozzle protective material and pouring method thereof

InactiveCN101869967BImprove pouring qualityAvoid damageFoundry mouldsFoundry coresStructural engineeringMechanical engineering

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

Separated ultra-wide prestressed concrete box girder structure and construction method thereof

PendingCN114855584AIncrease widthReduce the number of chambersBridge erection/assemblyBridge materialsConcrete beamsPre stress

The invention discloses a separated ultra-wide prestressed concrete box girder structure and a construction method thereof, and relates to the technical field of mixed cable-stayed bridge construction. The concrete box girder structure comprises a middle box girder, two side box girders and connecting girders, the middle box girder and the two side box girders are connected through a plurality of connecting girders, and the width of the concrete box girder structure is increased. The separated ultra-wide prestressed concrete box girder structure is decomposed into three box girders for construction, and in addition, the mode that all the separated box girders are constructed firstly, and then the connecting beam and the post-pouring section are constructed is adopted; the adverse effect of asynchronous longitudinal deformation, caused by factors such as self weight, prestress tension, shrinkage creep and temperature, of all the separation box girders on the connecting beam can be effectively reduced. In addition, the rigidity of the cast-in-place support can meet the requirement of each box girder, the pouring difficulty is reduced, maintenance is convenient, the risk that the concrete beam cracks in the construction process is effectively reduced, the construction safety is improved, and the construction quality is guaranteed.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com