Concrete pouring structure of super high-rise steel pipe column

A technology for concrete and steel pipe columns, which is applied in the field of concrete pouring, and can solve problems such as tediousness and increased construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

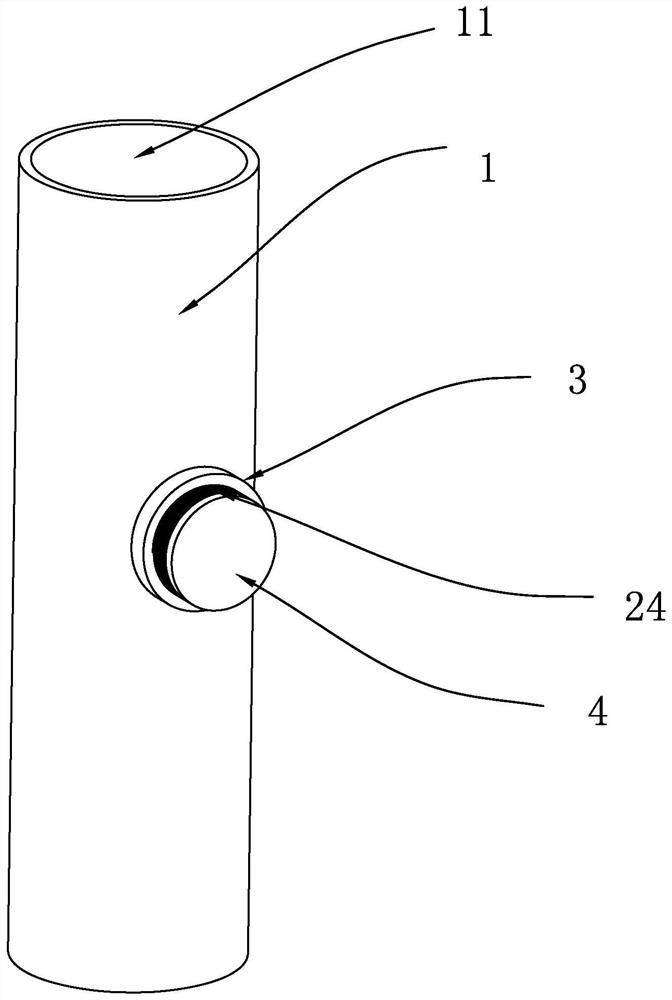

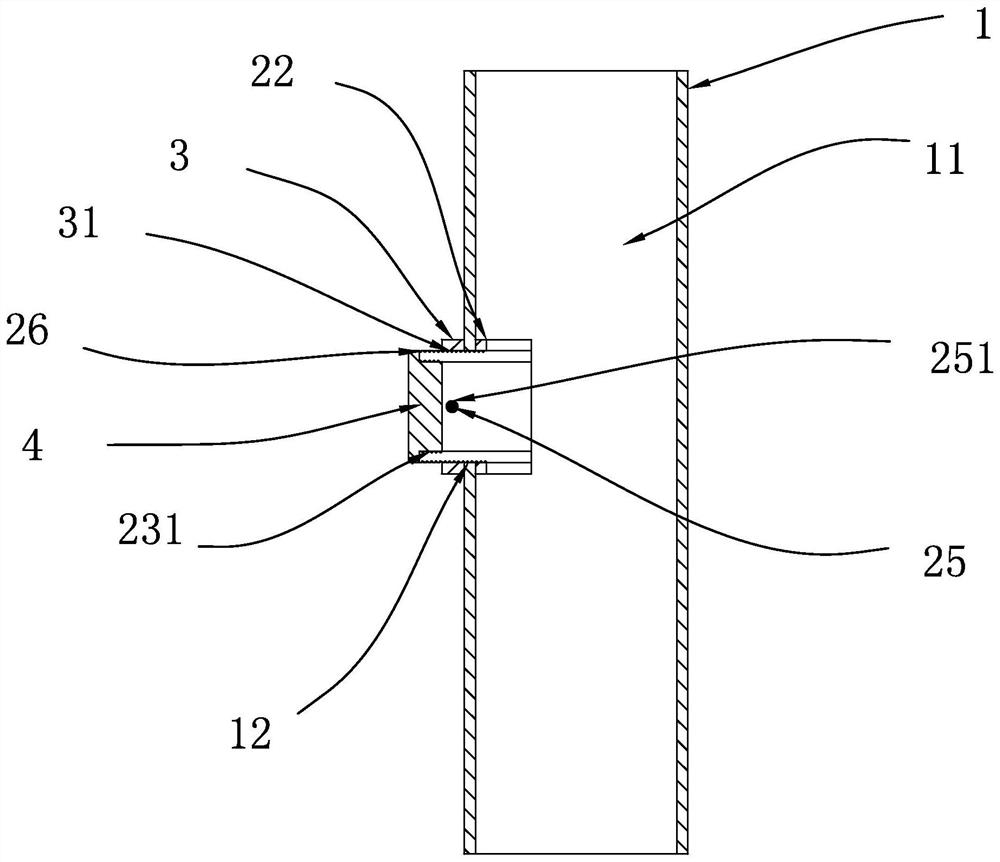

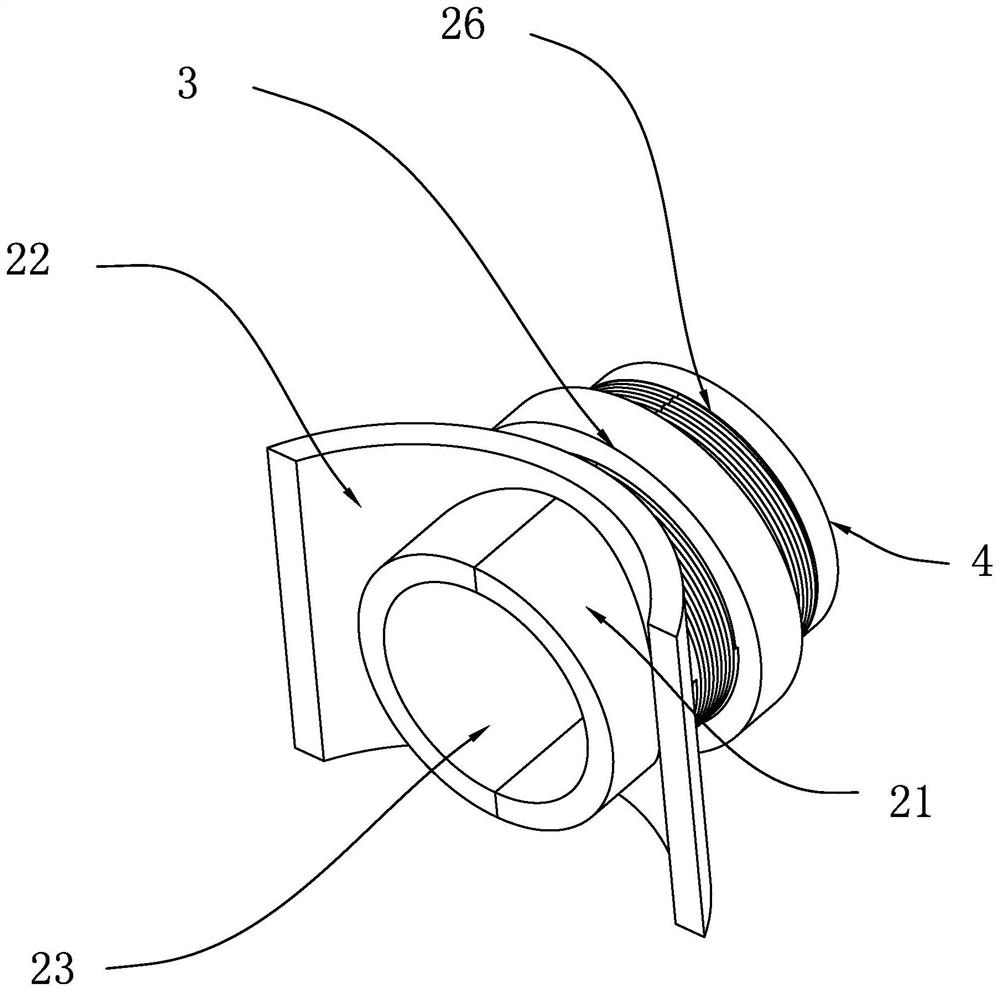

[0026] The present invention provides a concrete pouring structure of a super high-rise steel pipe column, including a steel column 1, a pouring cavity 11 is hollowed out along the height direction of the steel column 1, and an outer wall of the steel column 1 is provided for external operators to pour The clamping hole 12 for pouring concrete fluid in the cavity 11, the clamping hole 12 is arranged in communication with the pouring cavity 11, the clamping hole 12 is provided with a drainage assembly for guiding the flow of the external concrete fluid, and the drainage assembly includes two. There are two semi-cylindrical drainage columns 21, and two drainage columns 21 are arranged opposite to each other. One end of the drainage columns 21 is the insertion end for inserting into the casting cavity 11, and the other end is the drainage end located outside the steel column 1. The outer wall of the insertion end of the drainage column 21 is provided with an arc-shaped plate 22 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com