Pouring mold for process nozzle protective material and pouring method thereof

A technology for pouring molds and process burners, which is applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., and can solve the problem of poor coordination of gasifier burner chambers, poor molding of front and rear end faces, and poor cylindricity and concentricity And other problems, to achieve the effect of improving surface finish, avoiding material loss, and good shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

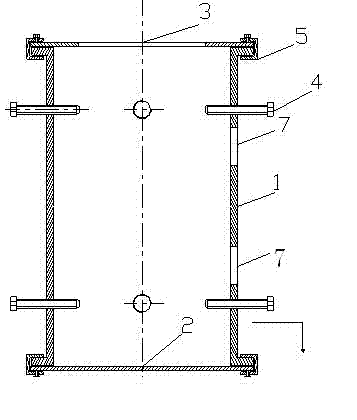

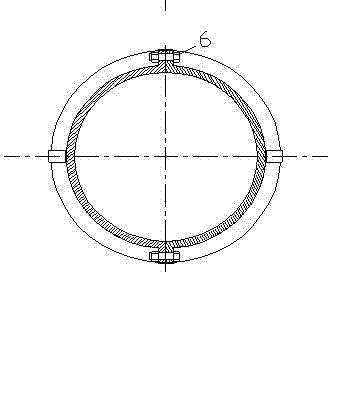

[0032] Casting mold for process burner of four-nozzle opposed coal-water slurry pressurized gasification furnace:

[0033] The above-mentioned pouring mold is made of cast iron, and the diameter of the cylindrical mold shell is 40-80 mm smaller than that of the burner chamber. The cylindrical formwork is spliced by two semi-circular arc-shaped plates, and the split surfaces are connected by studs. The front and rear baffles, and the back baffle are composed of two semicircular plates, which are fixed on the cylindrical formwork with clips, and the upper part of the cylindrical formwork is provided with a sprue for easy feeding.

[0034] When pouring: fix the pouring mold on the outside of the cooling water coil of the process burner, adjust the concentricity between the pouring mold and the burner with the adjusting bolt, install the front and rear baffles, pour the refractory material from the gate, and The outer wall of the mold is knocked to ensure that the pouring mater...

Embodiment 2

[0036] With embodiment 1, difference is: pull down pouring mold after drying 6 hours during pouring.

Embodiment 3

[0038] Casting molds for process burners of Texaco coal-water slurry pressurized gasifier:

[0039] The pouring mold is made of cast iron, and the diameter of the cylindrical mold shell is 40-100 mm smaller than that of the burner chamber. The cylindrical formwork is spliced by two semi-circular arc-shaped plates, and the split surfaces are connected by studs. The front and rear baffles, and the back baffle are composed of two semicircular plates, which are fixed on the cylindrical formwork with clips, and the upper part of the cylindrical formwork is provided with a sprue for easy feeding.

[0040] When pouring: fix the pouring mold on the outside of the cooling water coil of the process burner, adjust the concentricity between the pouring mold and the burner with the adjusting bolt, install the front and rear baffles, pour the refractory material from the gate, and The outer wall of the mold is knocked to ensure that the pouring material is poured evenly; steam is passed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com