Bamboo-joint-like auxiliary degradation net for soil burial for plastic

A kind of section, plastic technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of long time required for degradation, low degradation efficiency, slow degradation speed, etc., to reduce the time, The effect of increasing the number and species of microorganisms and increasing the rate of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

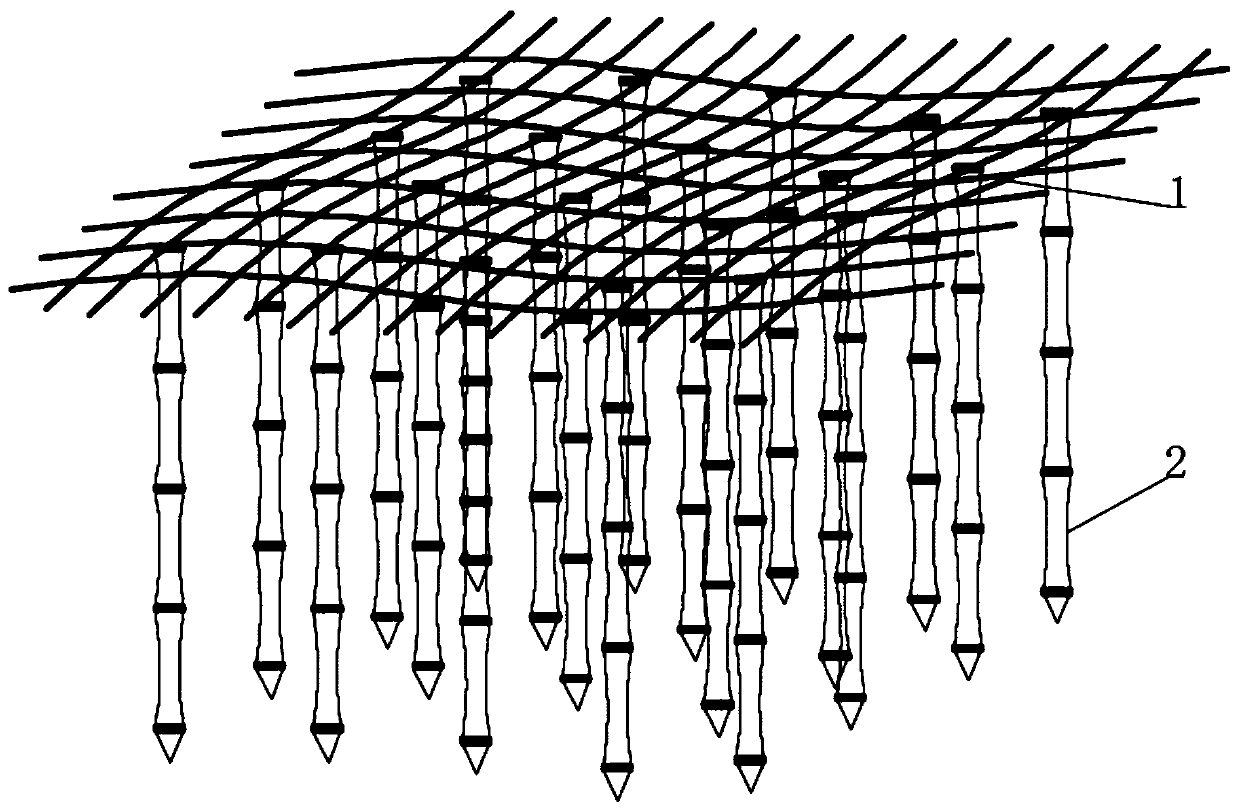

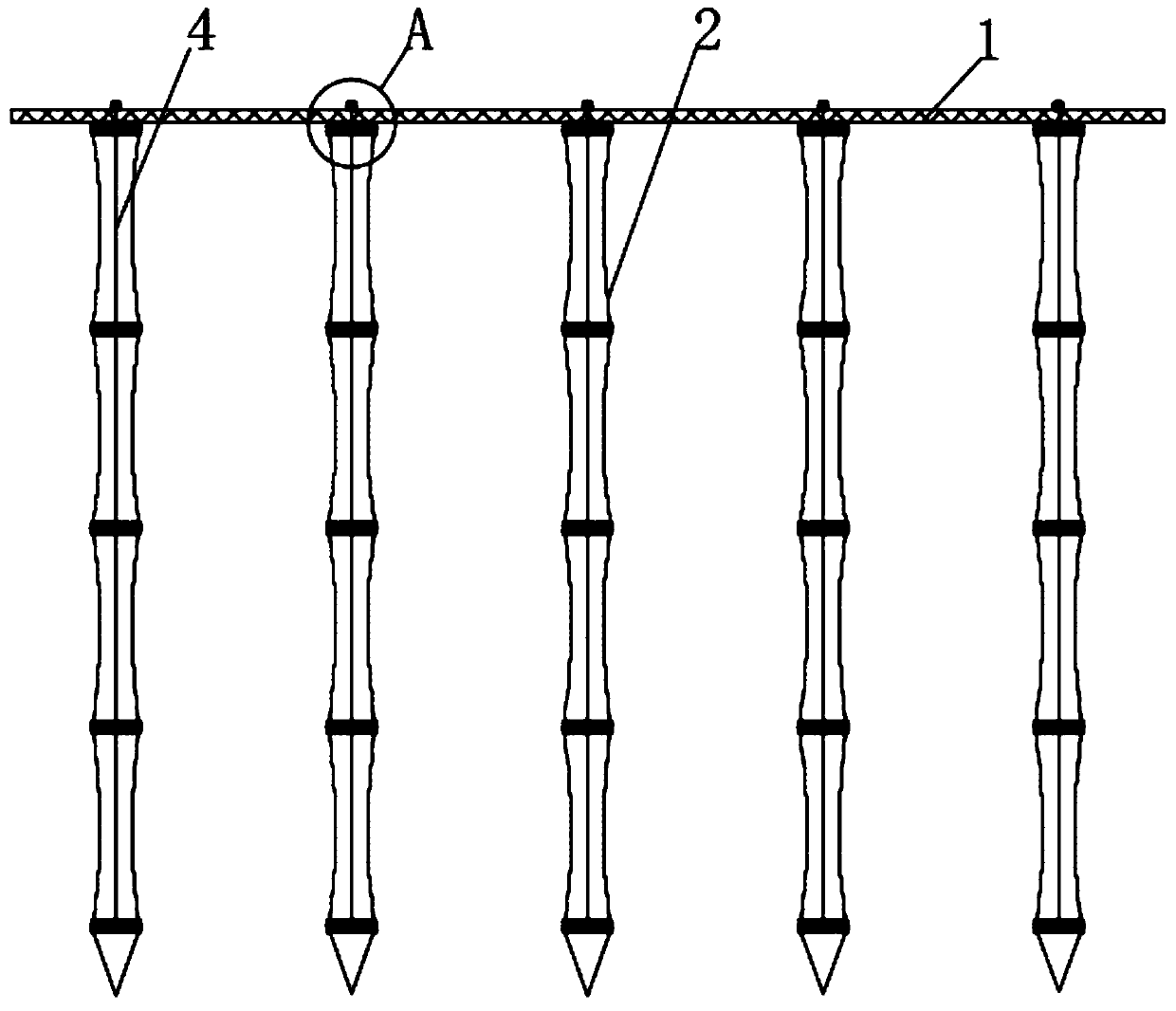

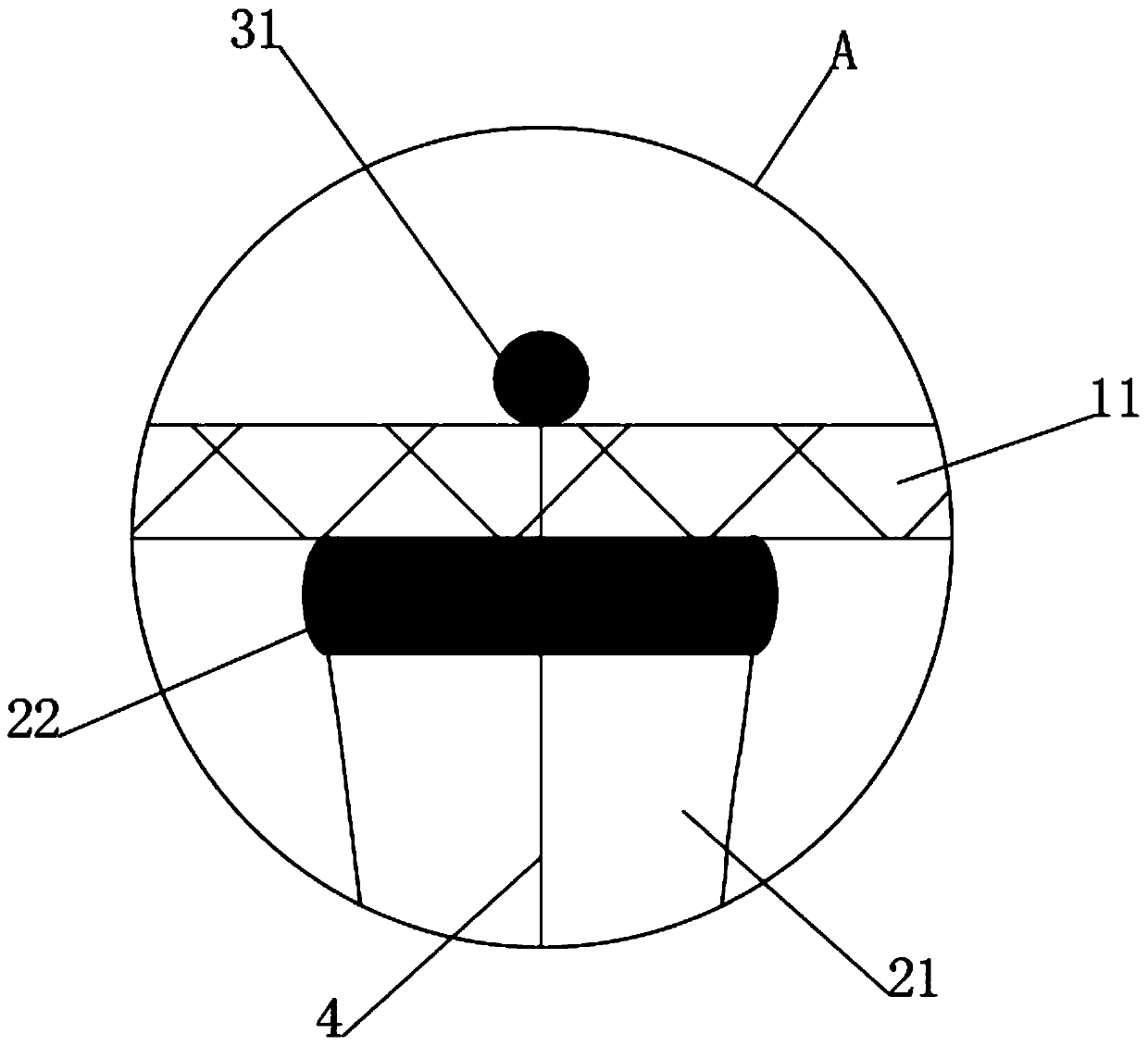

[0042] see Figure 1-2 , a bamboo-like plastic soil-buried auxiliary degradable net, comprising a screen body 1, a plurality of evenly distributed bamboo pre-embedded rods 2 are provided at multiple nodes on the screen body 1, please refer to Figure 3-4 , the upper end of bamboo pre-embedded rod 2 is fixedly connected with a plurality of evenly distributed connecting ropes 32 in a circumferential shape, and the upper ends of the plurality of connecting ropes 32 are fixedly connected with the same color-changing ball 31, and the color-changing ball 31 is coated with a thermally induced The spherical structure of the color-changing material coating, and the surface of the color-changing ball 31 is provided with multiple reflective cut surfaces. After the heat is generated in the plastic pile due to the respiration of microorganisms, when the heat is conducted upwards to the color-changing ball 31 under the action of the upward heat conduction mechanism 4, the color will change. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com