Assembling-type building prefabricated reinforced concrete inner heat preservation wall body and inner-outer wallboard connecting reinforced steel bar

A technology for thermal insulation walls and prefabricated walls, applied in thermal insulation, construction, building components, etc., can solve the problems of increased cost, difficulty in batch production of connectors, and large consumption, so as to reduce the phenomenon of cold and heat bridges and increase the difficulty of pouring , The effect of facilitating the placement of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

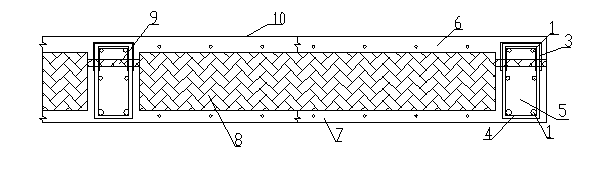

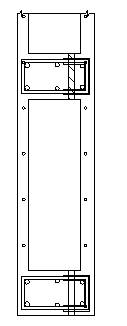

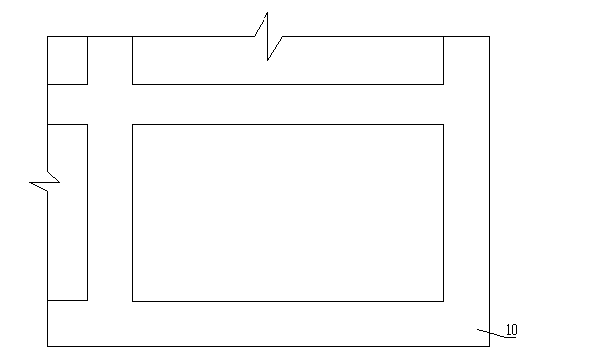

[0025] Embodiment 1: see figure 1 -5, the prefabricated reinforced concrete inner thermal insulation wall of the present invention has alternate inner reinforced concrete wall panels 7 and outer reinforced concrete wall panels 10 (each of which has a reinforced mesh 6 designed according to the strength requirements of the wall), and the two-phase concrete wall The boards are connected vertically and horizontally with alternate reinforced concrete short columns 5 to form an overall H-shaped structure. The hollow part between the inner and outer wall boards is filled with low thermal conductivity EPS polystyrene boards 8, and the overall thickness of the composition is 200mm. The thickness of the inner wall boards is 40mm. Prefabricated reinforced concrete inner insulation wall with slab thickness of 50mm and insulation layer thickness of 110mm.

[0026] Rectangular hoop steel bars 4 are used for the axial connection of the reinforced concrete short columns connecting the inner ...

Embodiment 2

[0027] Embodiment 2: As in Embodiment 1, there are horizontal and / or vertical hollow ventilation passages in the thickness of the prefabricated reinforced concrete inner insulation wall for natural ventilation of buildings.

Embodiment 3

[0028] Embodiment 3: As mentioned above, there are wiring pipes within the thickness of the prefabricated reinforced concrete inner insulation wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com