Composite insulating layer with cavity structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Shougang steelmaking RH furnace superheated steam pipe insulation renovation project, pipe diameter DN325, length 906m, medium temperature 285 ℃, the experimental implementation steps are as follows:

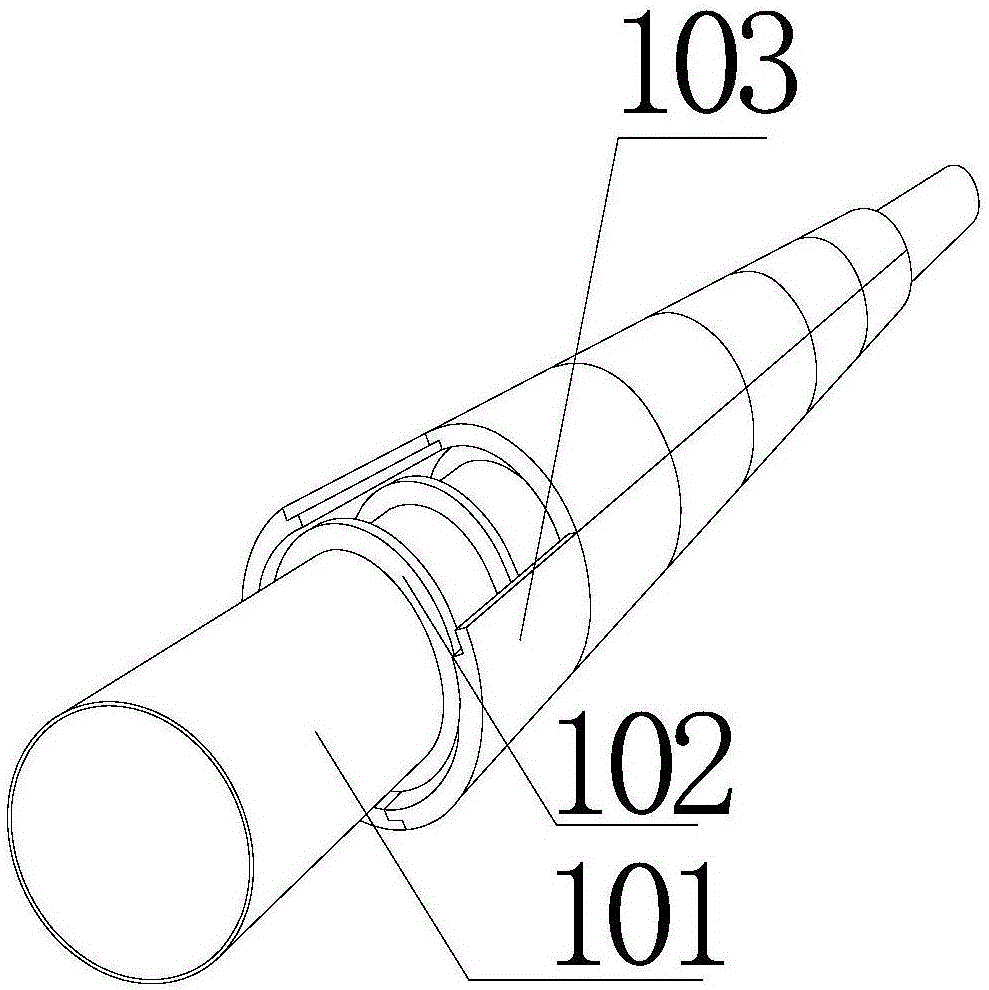

[0045] 1. Install a layer of thermal insulation layer 103 containing fiber material close to the pipeline or equipment substrate 101, and the thickness of the thermal insulation layer 103 is controlled at 12mm;

[0046] 2. A ring-shaped barrier 102 is arranged between the pipeline or equipment base 101 and the insulation layer 103 to form a cavity structure, and the barriers are arranged equidistantly along the surface of the pipeline or equipment base;

[0047] 3. The outer side of the thermal insulation layer 103 is installed with a full normal emissivity. The emission layer of the thermal barrier emission glass is selected, and the thickness is 50mm. According to the surface shape of the thermal equipment and the pipeline, it is cut into a plurality of thermal insulatio...

Embodiment 2

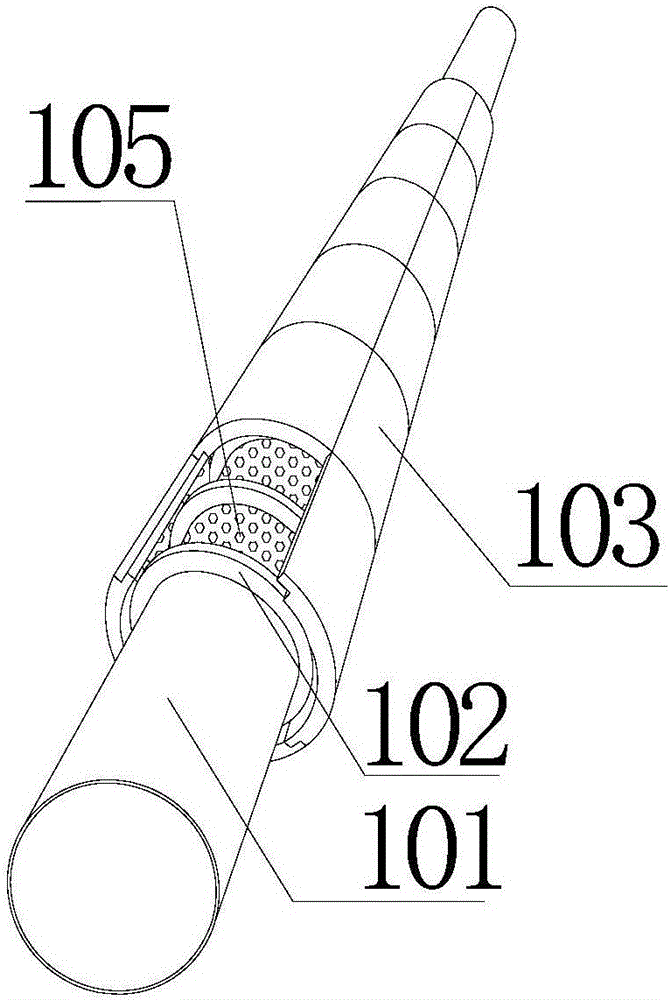

[0054] The other operation steps are basically the same as in Embodiment 1, except that in step 2, the cavity structure is filled with fillers 105, and the fillers 105 are one or more of insulating particles, vacuum materials, and emission materials.

[0055] See attached for specific structure figure 2 , with figure 2 In the middle, only the cavity structure and the connection relationship between the two related layers are highlighted, and other structures such as the emission layer and the inner protection layer are not reflected.

Embodiment 3

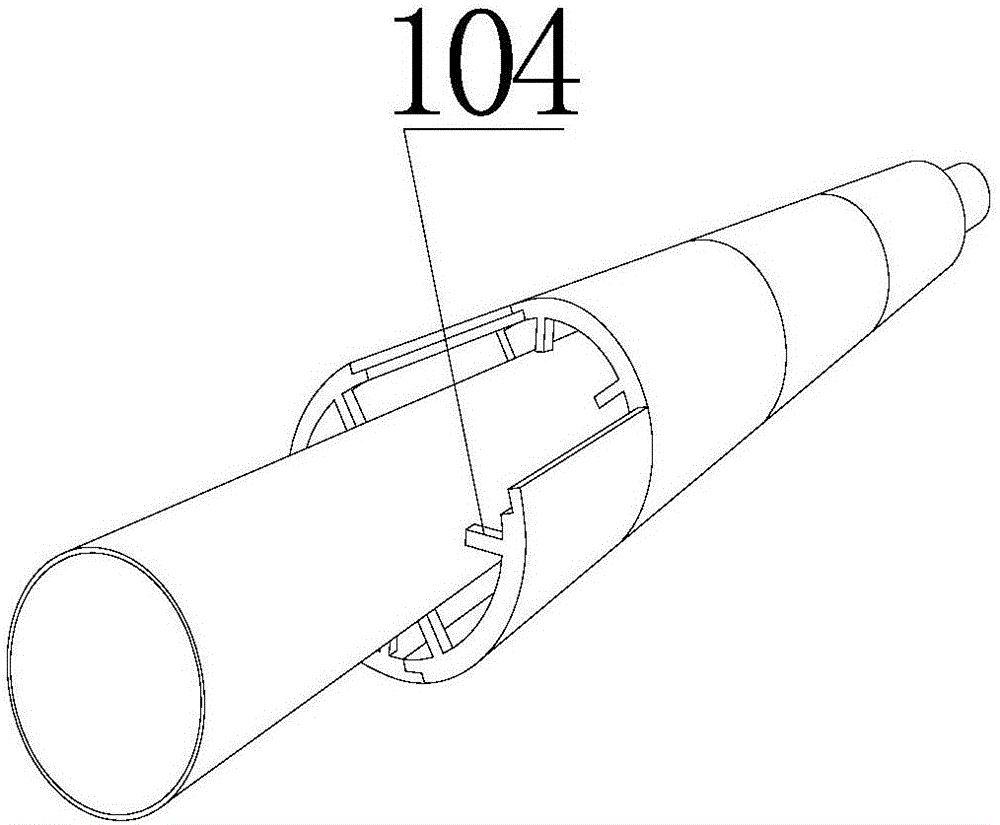

[0057] Other operating steps are basically the same as in Embodiment 1, except that in Step 2, a bracket 104 is provided between the pipeline or equipment base 101 and the insulation layer 103 to form a cavity structure.

[0058] See attached for specific structure image 3 , with image 3 In the middle, only the cavity structure and the connection relationship between the two related layers are highlighted, and other structures such as the emission layer and the inner protection layer are not reflected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com