Construction method for pouring constructional column concrete

A construction method and a technology of structural columns, which are applied in building construction, processing of building materials, preparation of building components on site, etc., can solve problems such as inconvenient pouring at the top opening, lack of formwork support for concrete, etc., and achieve lifting pouring quality and reduce the difficulty of pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

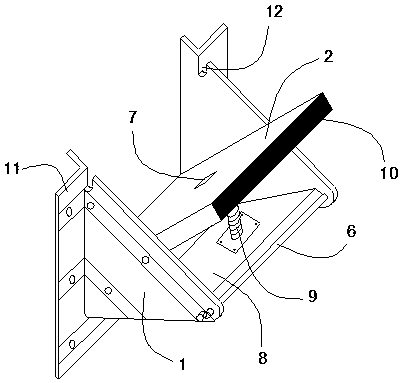

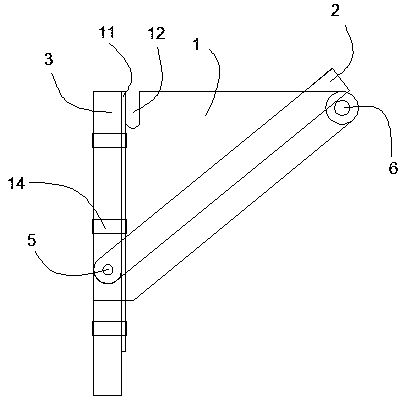

[0037] like Figure 1 to Figure 4 Shown, a kind of construction method of construction column concrete pouring, comprises the following steps:

[0038]1) Set a switchable pouring structure at the pouring port 4 at the upper end of the structural column formwork 3: the switchable pouring structure includes two side panels 1, a movable panel 2 and a positioning rod 6, and the two side panels 1 are respectively Located on both sides of the pouring port 4, one side of the side plate 1 is connected to the outside of the structural column formwork 3 (outside, referring to the side of the structural column formwork 3 away from the contact with the concrete), and the other The lateral direction is inclined away from the construction column formwork 3, and the distance between the side of the side plate 1 away from the construction column formwork 3 and the construction column formwork 3 gradually increases from top to bottom. Wherein, the side plate 1 is in the form of a right triang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com