Extra-high voltage resin impregnated paper alternate-current and direct-current capacitance sleeve tube

An AC-DC, capacitive technology, applied in transformer/inductor parts, transformer/inductor coil/winding/connection, circuit, etc., can solve the problems of difficult temperature control, low qualification rate, loss, etc., to reduce pouring Difficulty, improve the pass rate, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

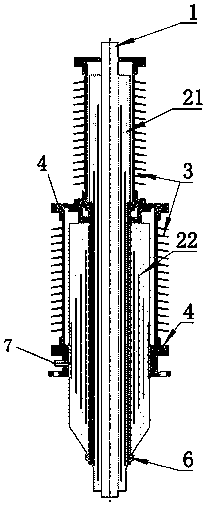

[0017] Such as figure 1 As shown, an UHV glue-impregnated paper AC / DC capacitive bushing of the present invention includes a central conductor 1, an inner capacitor core 21, an outer capacitor core 22, an outer insulation 3 and a mounting flange 4, and an inner capacitor core 21 Both the outer capacitor core 22 and the outer capacitor core 22 are installed on the central conductor 1, and the lower end of the inner capacitor core 21 is inserted into the outer capacitor core 22, the zero screen of the outer capacitor core 22 and the last screen of the inner capacitor core 21 equipotential bonding between them. The outer wall of the inner capacitor core 21 and the outer wall of the outer capacitor core 22 are sleeved with an outer insulation 3 and a mounting flange 4, and the end of the outer capacitor core 22 is connected to the mounting flange on the inner capacitor co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com