Semi-grouting sleeve assembly for fabricated building and construction method thereof

A semi-grouting sleeve and construction technology, which is applied in the direction of building components, building reinforcements, buildings, etc., can solve the problems of high application cost of semi-grouting sleeves, difficulty in guaranteeing grouting quality, and difficulty in pouring, so as to reduce compactness Hidden danger, not easy to grout dissatisfaction, reduce the effect of inner cavity size and sleeve outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

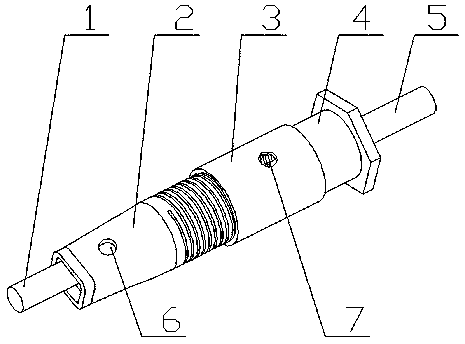

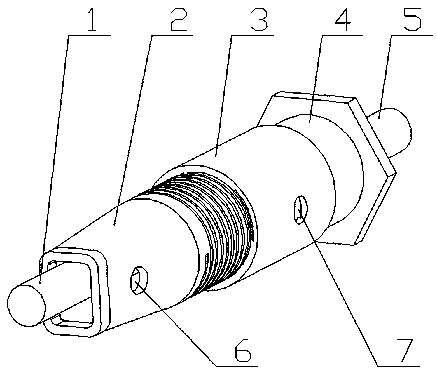

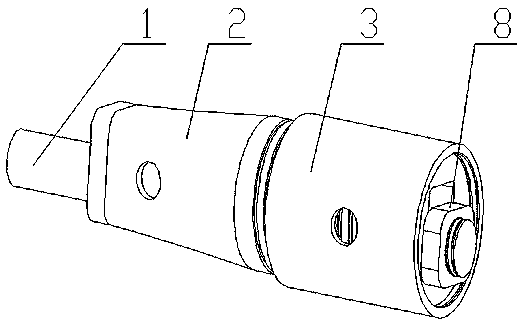

[0043] see Figure 1 to Figure 15, this embodiment provides a semi-grouting sleeve assembly for prefabricated buildings, including a first steel bar 1 provided with a first external thread 18, a second steel bar 5 provided with a second external thread 21, and an integrated nut and bolt 4 , a straight thread sleeve 3, a semi-grouting sleeve 2 and a square nut 8 provided with a grouting hole 7, the position of the grouting hole 7 can be determined according to the length of the straight threaded sleeve and the distance between the straight threaded sleeve and the third external thread The connection length design determines that the one-piece nut and bolt 4 is provided with a third internal thread 19 matching the second external th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com