Straddle type monorail steel-concrete combined track beam and erecting method

A straddle-type monorail and track beam technology, which is applied in the field of rail transit, can solve problems such as cumbersome solutions, and achieve the effect of reducing the difficulty of pouring, reducing steel bars, and reducing possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

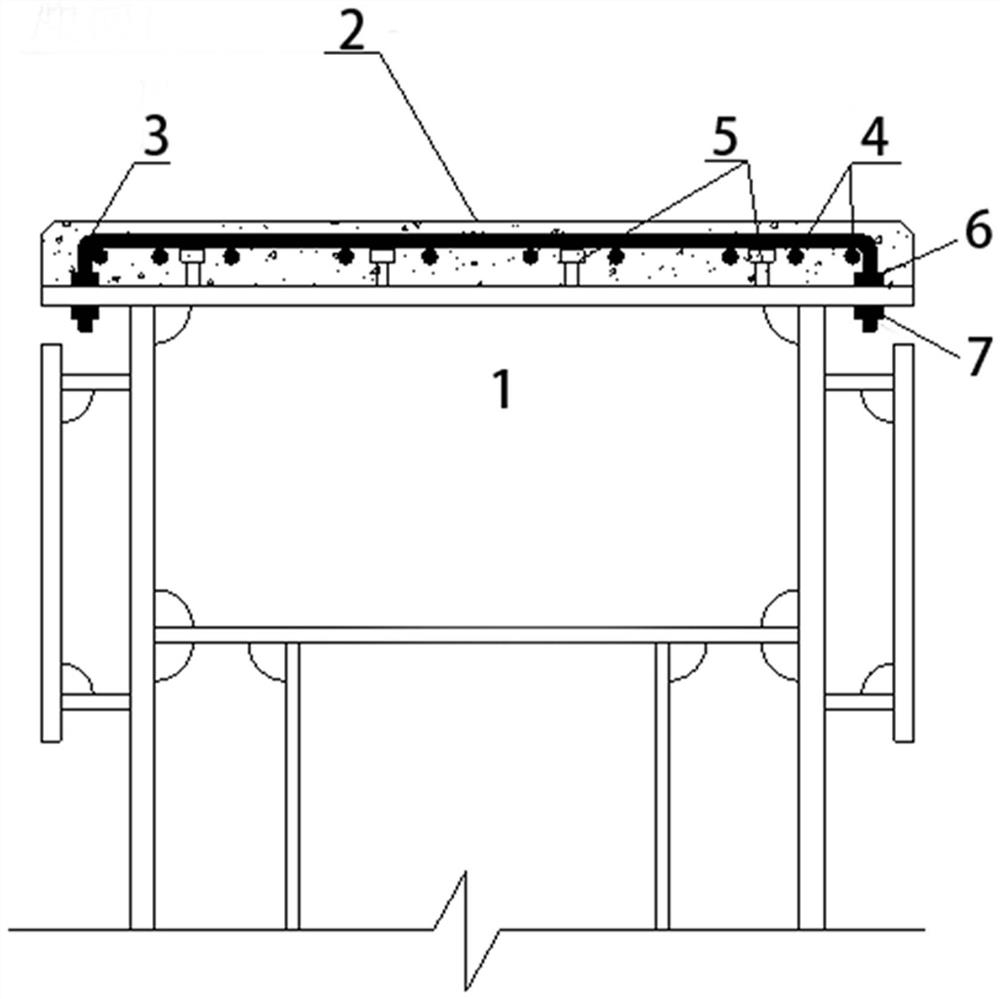

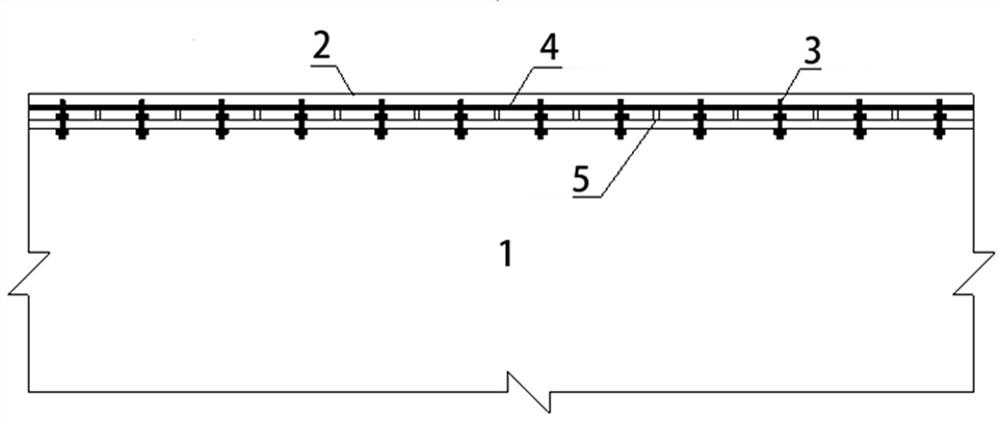

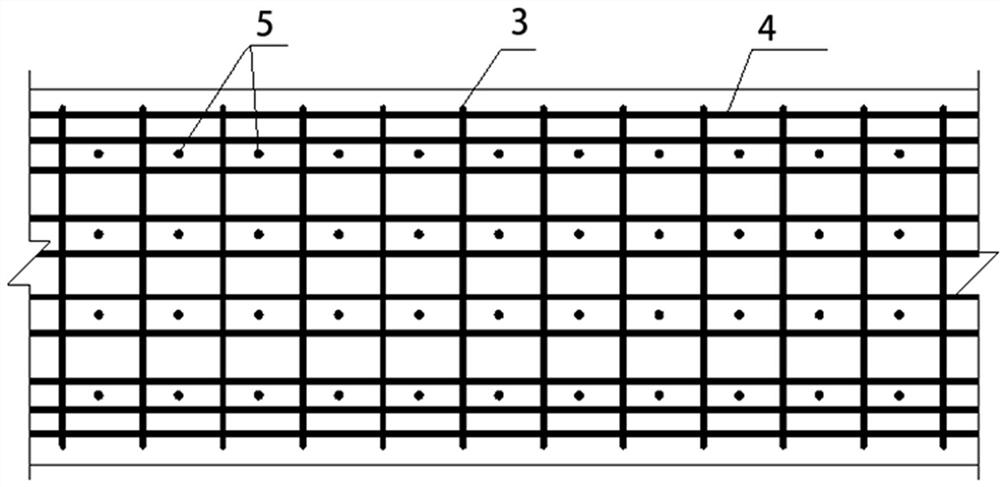

[0031] This implementation provides a method for erecting the straddle type monorail steel-concrete combined track beam of Embodiment 1, using the straddled type monorail steel-concrete combined track beam of Embodiment 1.

[0032] In the prior art, the construction process of conventional steel-concrete composite beams is as follows:

[0033] ①Steel girder 1 in the factory is processed and manufactured in sections; ②The positive bending moment part of the concrete is prefabricated in the factory; ③Steel beam 1 is transported to the bridge site in sections and then erected and assembled; ④The middle fulcrum is lifted by 20cm; ⑥Pouring the concrete of the cast-in-place section; ⑦Vibrating the concrete of the cast-in-place section;

[0034] In this application, however, the construction process is as follows:

[0035] Inside the factory:

[0036] S1, welding steel plate to prepare steel beam 1 section;

[0037] S2, punching holes on the edge of the top surface of the steel be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com