Convenient wall panel dry hanging installation structure and method

A kind of installation structure, convenient technology, applied in the direction of building structure, covering/lining, construction, etc., can solve the problems of uneven inclination of hanging wall panels, increase of process, cost, instability of dry hanging system, etc., and achieve less Construction steps, convenient construction, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

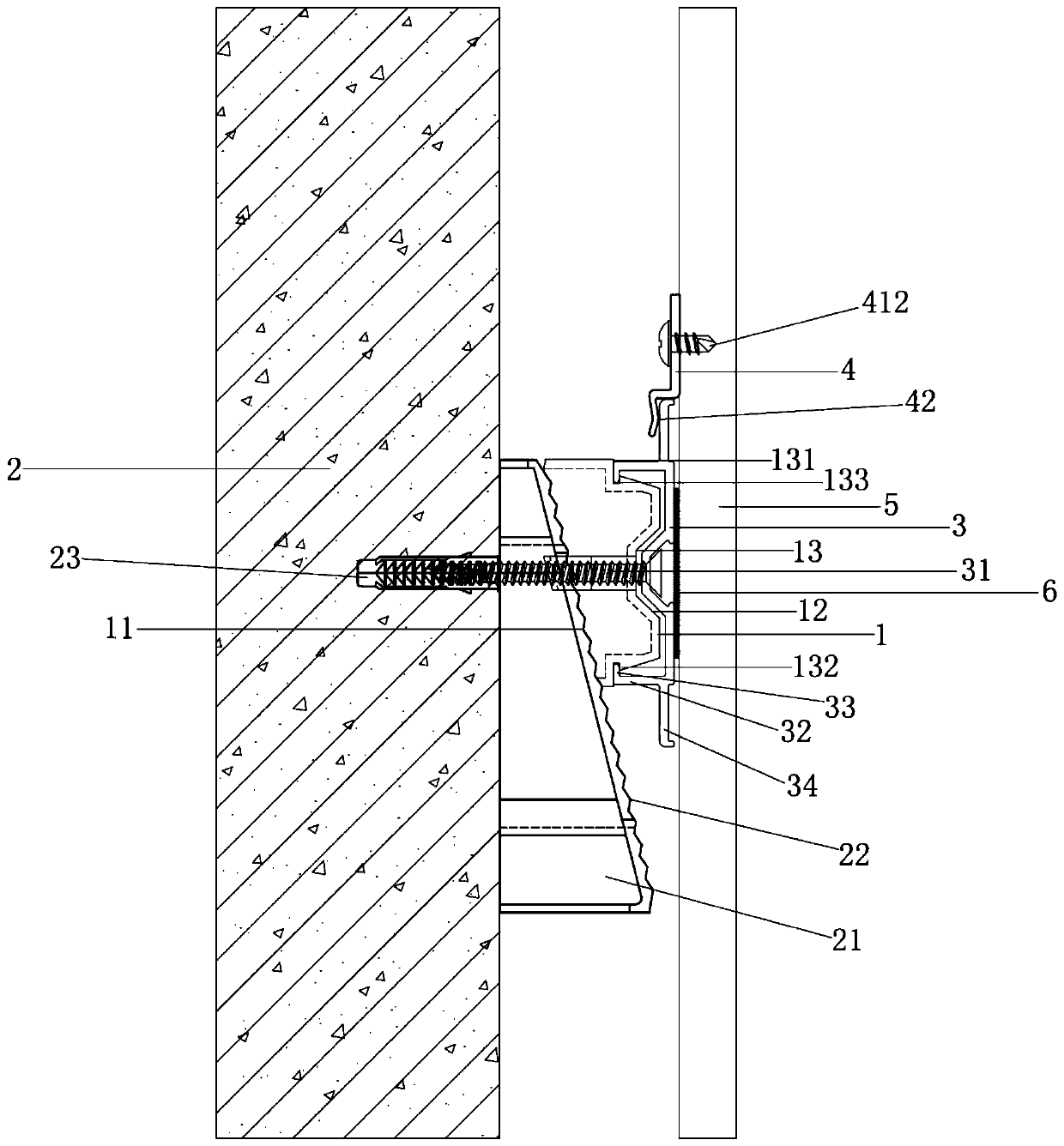

[0036] see Figure 1 to Figure 3 , the figure shows a portable wallboard dry-hanging installation structure provided by Embodiment 1 of the present invention, which mainly includes a first transverse keel 1 , a second transverse keel 3 , an adjustable dry-hanging member 4 and a wallboard 5 .

[0037] see Figure 1 to Figure 3 , the first transverse keel 1 has an opposite first connecting surface 11 and a second connecting surface 12, the first connecting surface 11 is connected to the wall 2, and the second connecting surface 12 has a The W-shaped bending surface 13, the opposite sides of the W-shaped bending surface 13 are respectively connected to the edge of the second connecting surface 12 through a step 131, and the edge of the W-shaped bending surface 13 forms an outwardly extending chamfer at the step 131 A locking groove 133 is formed between the surface 132 , the end of the chamfered surface 132 and the step 131 .

[0038] see Figure 1 to Figure 3 , the second tra...

Embodiment 2

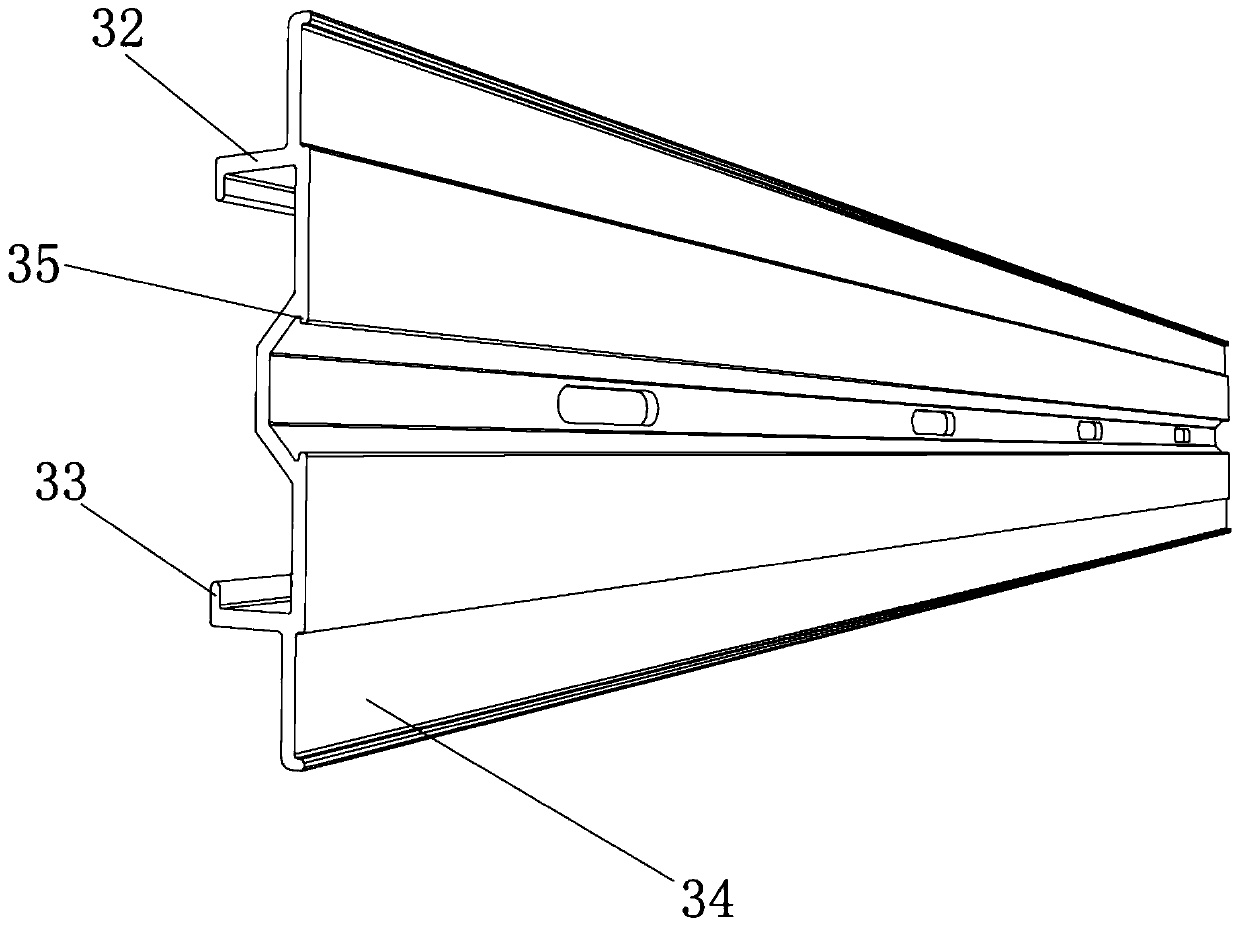

[0044] see Figure 1 to Figure 3 , the figure shows a portable wallboard dry-hanging installation structure provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: first The central part of the transverse keel 1 is a U-shaped bend extending toward the wall 2, and its opposite sides form a bell mouth structure. The central part of the second transverse keel 3 matches the shape of the central part of the first transverse keel 1, and the first There is a U-shaped gap between the central part of the transverse keel 1 and the central part of the second transverse keel 3, and the opposite sides of the central part of the second transverse keel 3 are respectively formed to extend into the central part of the second transverse keel 3. Convex edge 35. Through the setting of the above structure, the setting of the U-shaped gap can ensure that the screw will not be...

Embodiment 3

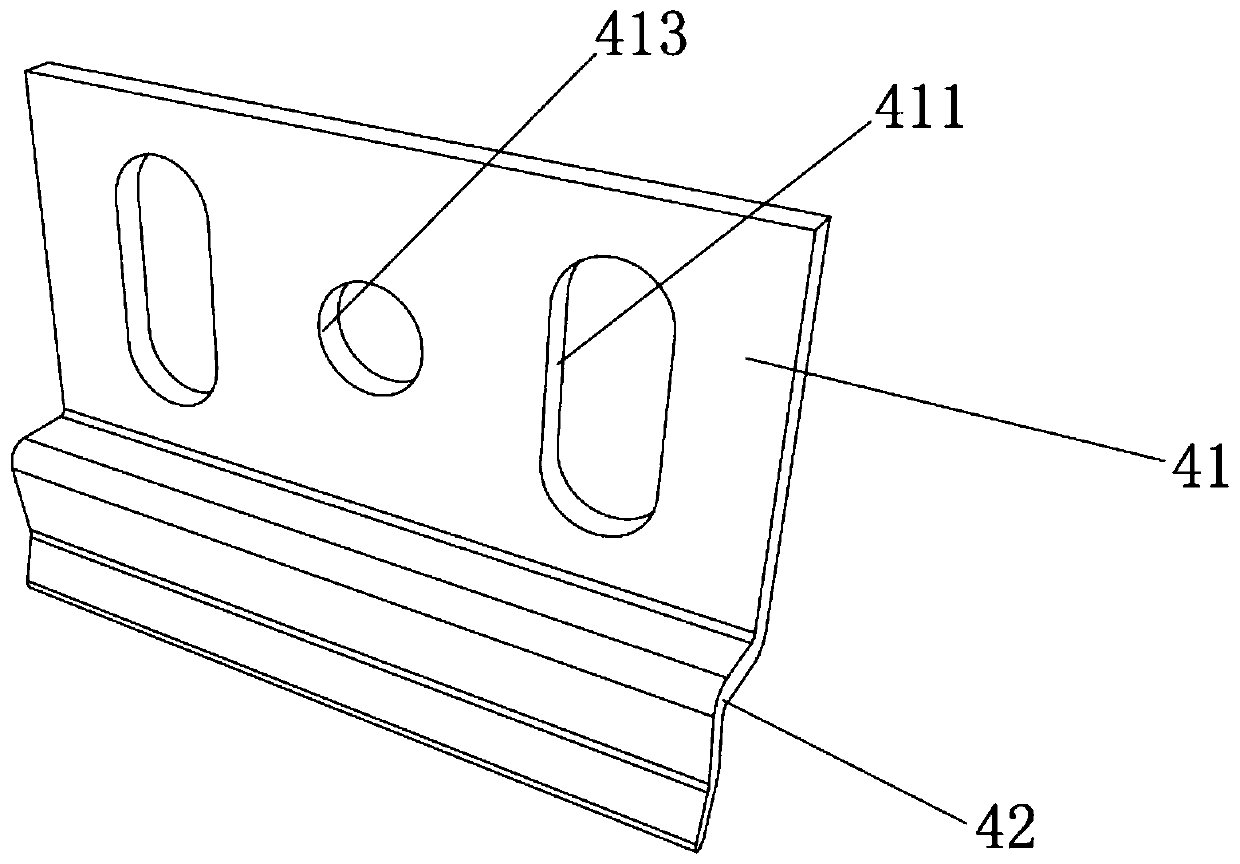

[0046] see Figure 1 to Figure 3, the figure shows a portable wallboard dry-hanging installation structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: dry-hanging The main body 41 is provided with two parallel waist-shaped holes 411, and the screw 412 penetrates into the waist-shaped holes 411 to fix the wallboard 5 on the main body 41 of the dry hanging piece, and a screw hole is arranged between the two adjacent waist-shaped holes 411 413. Through the setting of the above-mentioned structure, the installation height of the dry hanger can be adjusted conveniently through the waist-shaped hole, and the position of the dry hanger can be locked through the screw hole after adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com