A kind of prestressed anchor cable and prestressed anchor cable one-time forming construction method

A technology of prestressed anchor cable and construction method, which is applied in the directions of earthwork drilling, installation of anchor rods, infrastructure engineering, etc., to save time, reduce construction steps, and avoid easy-to-collapse holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

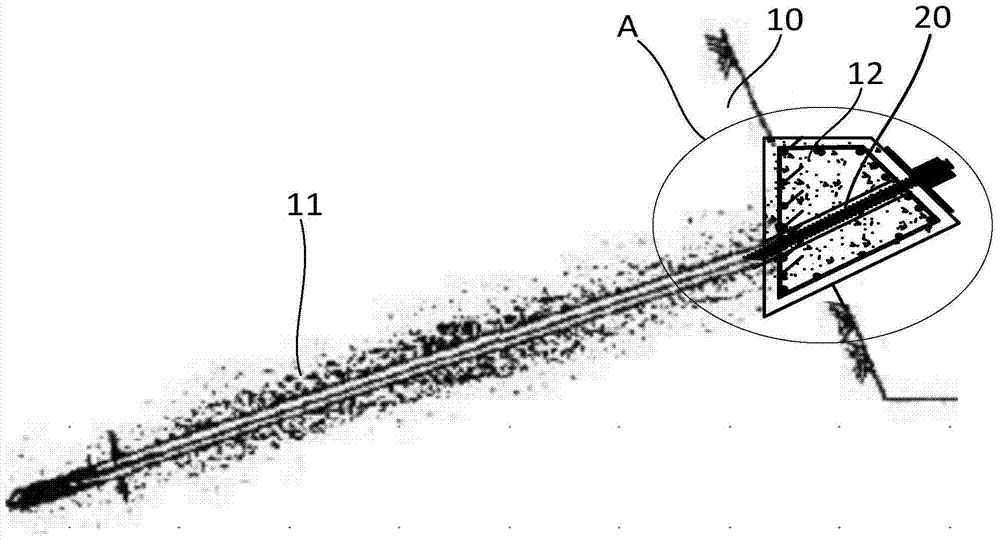

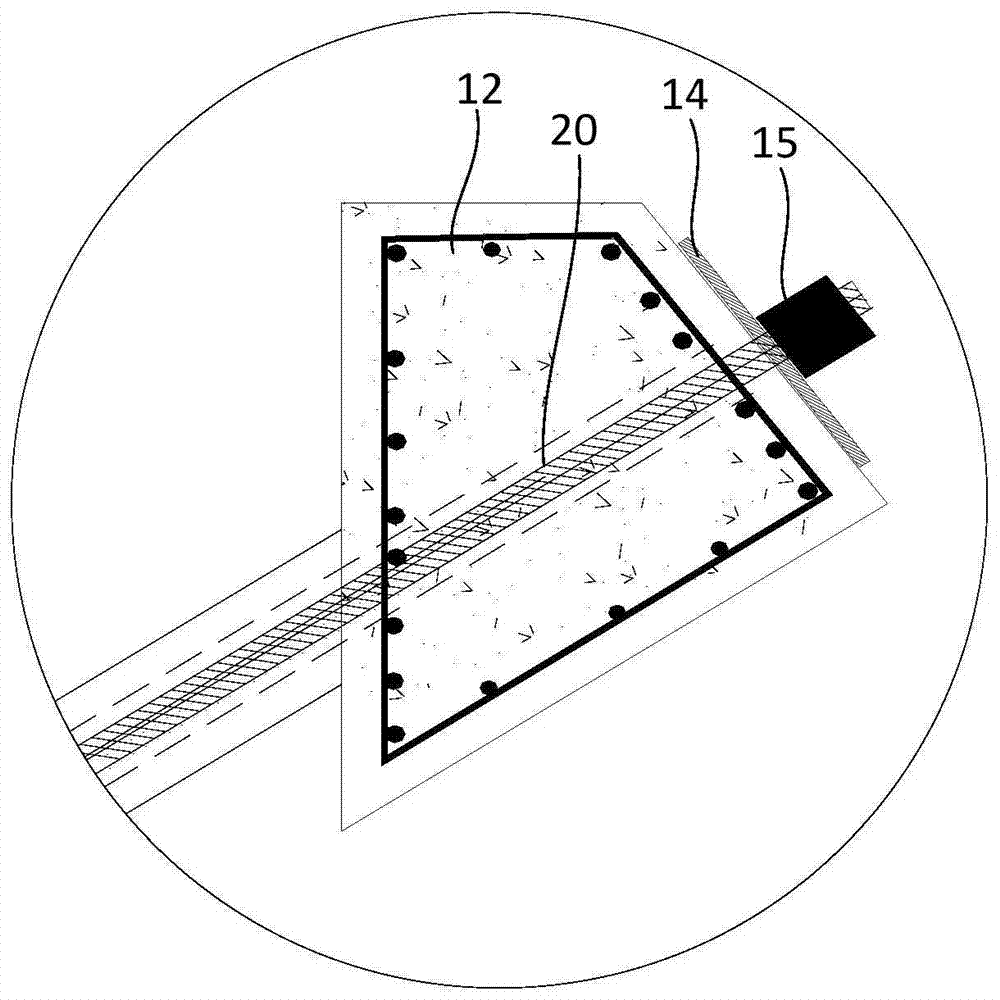

[0026] refer to figure 1 with figure 2 As shown, the prestressed anchor cable of the present invention includes: an anchoring body 11 arranged inside the soil layer 10 . The anchor body 11 is formed by the cement slurry sprayed out by the rotary jet drilling machine. An anchor cable 20 is buried inside the anchor body 11 , and the tail of the anchor cable 20 protrudes from the soil layer 10 and is connected to the waist beam 12 on the surface of the soil layer 10 .

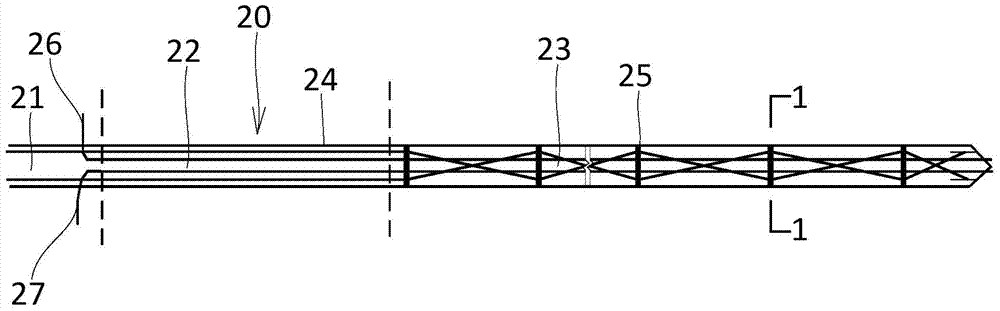

[0027] Such as figure 1 with image 3 As shown, the anchor cable 20 is sequentially divided into a tension section 21 , a free section 22 and an anchor section 23 from the tail to the front. The free section 22 and the anchor section 23 are buried inside the anchor body. The anchor cable 20 is a wire bundle composed of a plurality of steel strands 24 . In the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com