Horizontal well supercritical CO2 fracture development enhanced geothermal method and system

A horizontal well and supercritical technology, applied in geothermal energy, geothermal power generation, geothermal collectors, etc., can solve problems such as thermal reservoir pollution, dry hot rock leakage, and increased operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

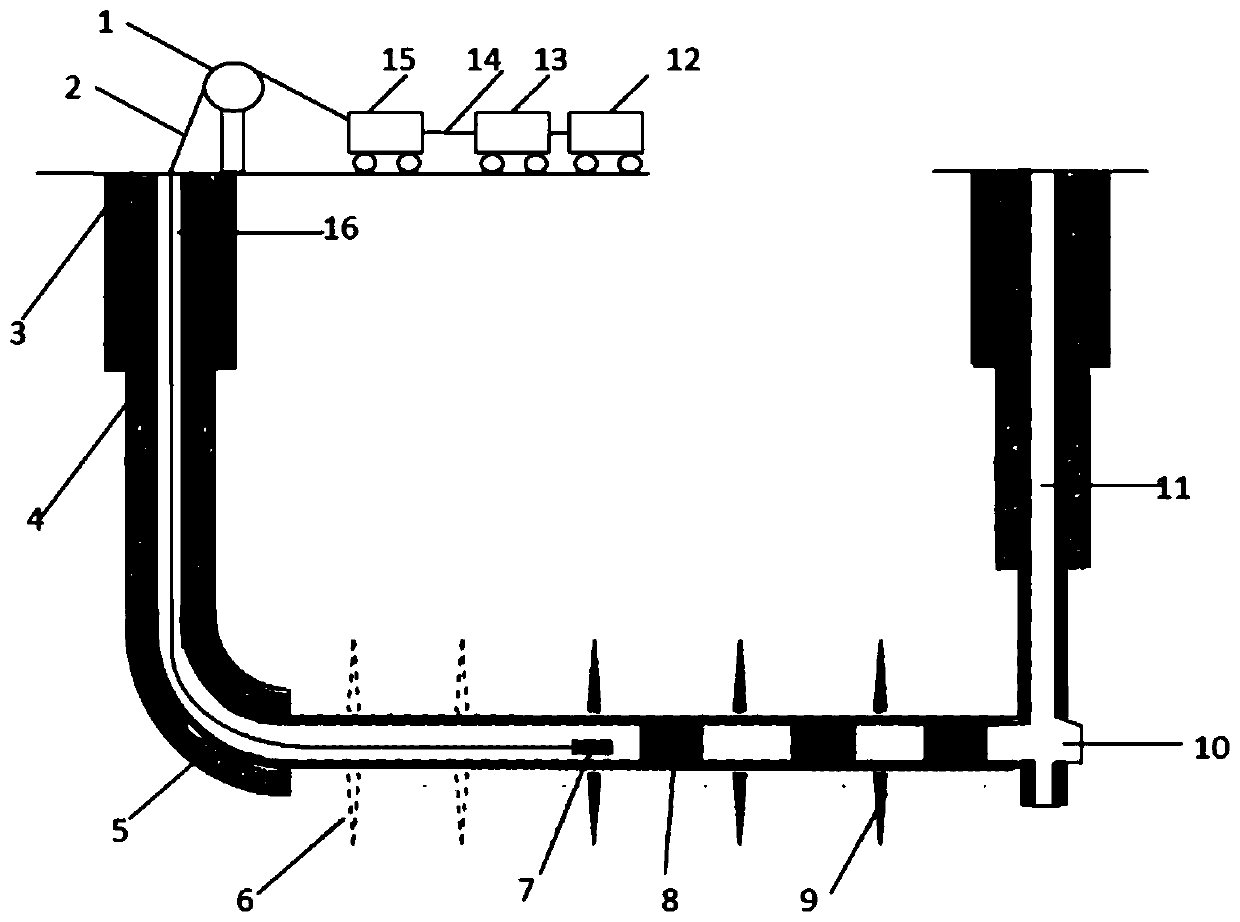

[0068] This embodiment provides a horizontal well supercritical CO 2 Fracturing to develop enhanced geothermal systems, where the system includes:

[0069] Horizontal well 16 and cave vertical well 11, the horizontal well 16 and cave vertical well 11 are respectively used as supercritical CO 2 Injection well and supercritical CO 2 Production well; the horizontal well 16 and the cave vertical well 11 are all three-open well body structures, and the first open well, the second open well and the third open well of the horizontal well and the cave vertical well are respectively lowered into surface casings 3, Technical casing 4 and production casing 5;

[0070] The end of the second opening of the horizontal well 16 is a 90° angle structure, and the tail end of the angle structure is located in the hot dry rock 6;

[0071]The horizontal section of the third open well of the horizontal well 16 is located in the hot dry rock 6; The third open well of 11 is connected in the cave ...

Embodiment 2

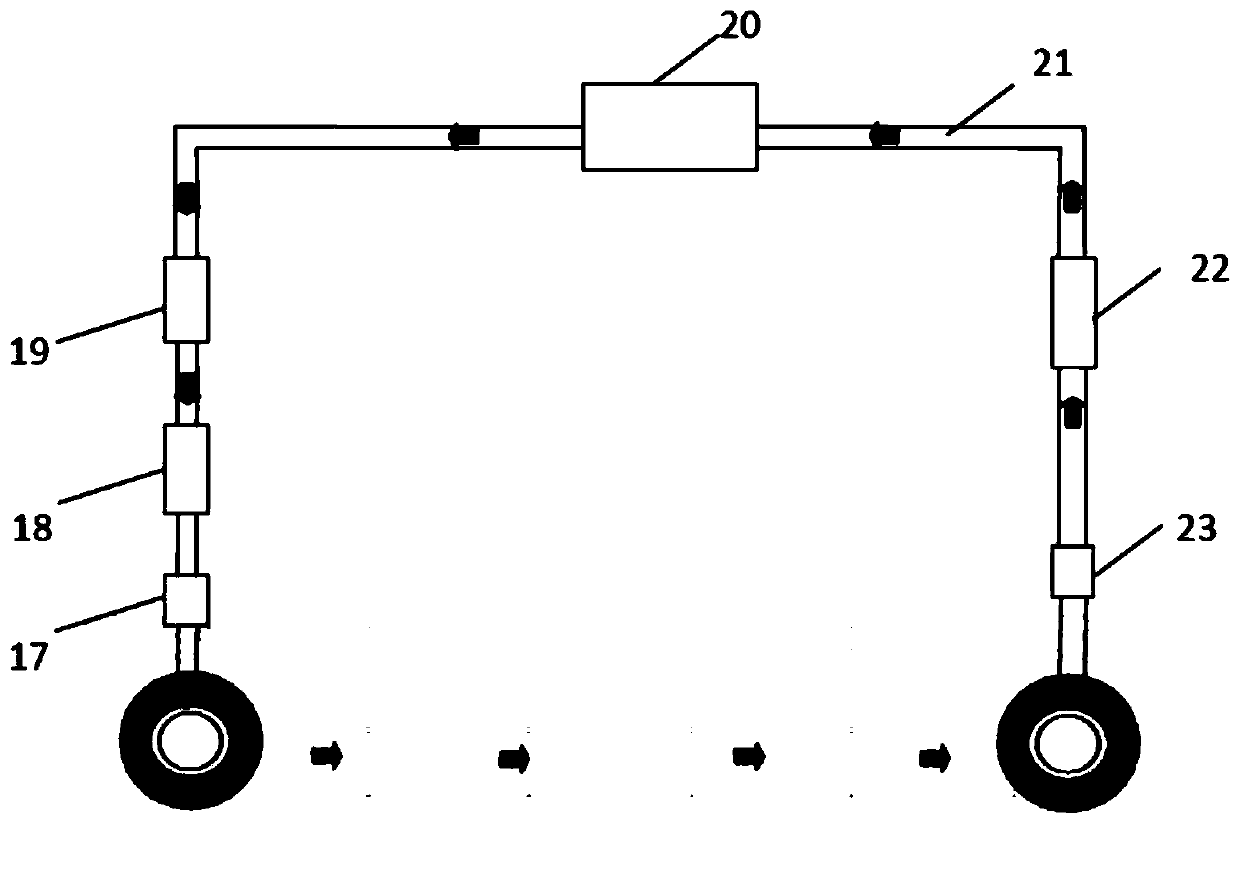

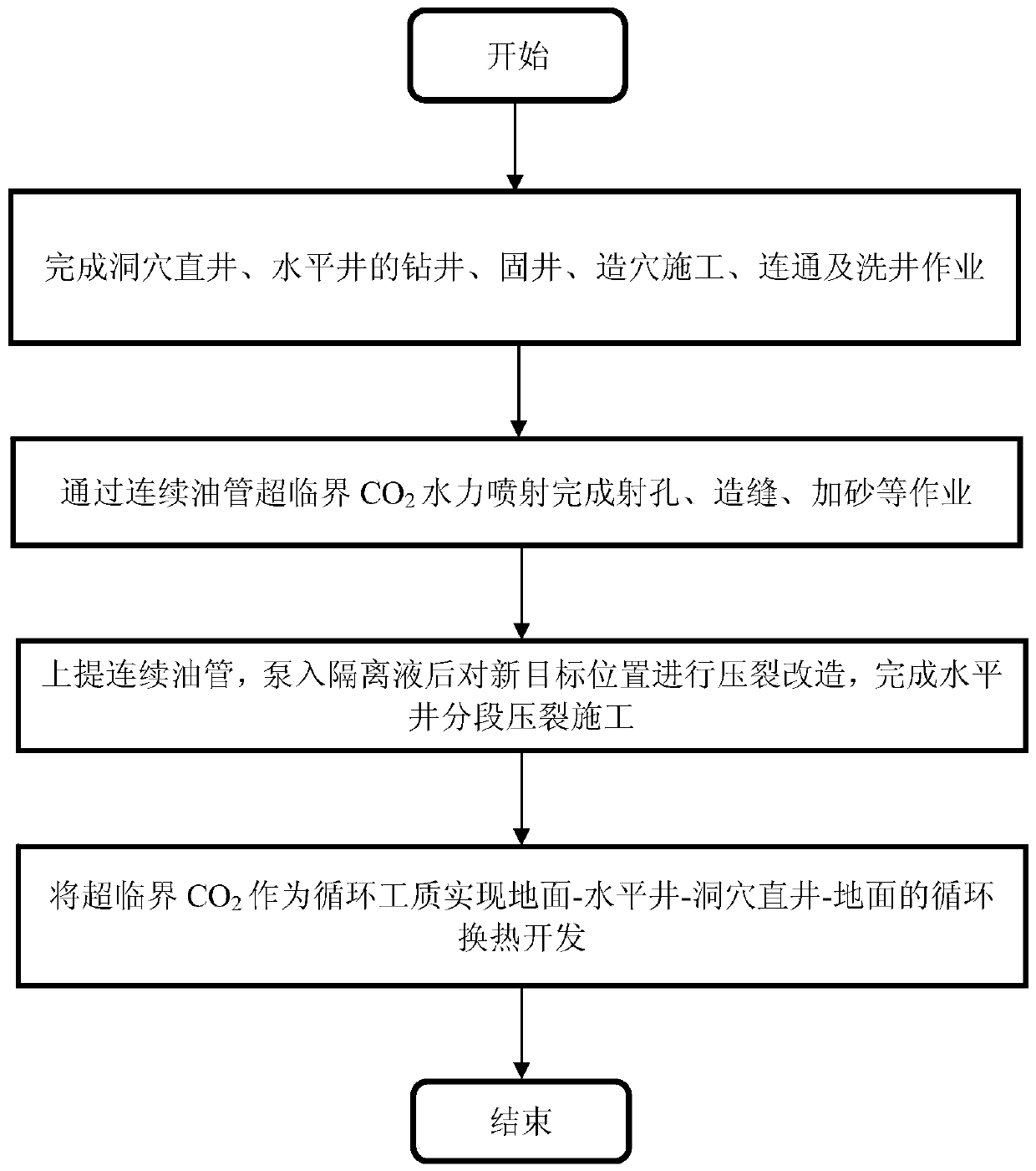

[0086] This embodiment provides a horizontal well supercritical CO 2 A method for developing enhanced geothermal energy by fracturing, which utilizes the horizontal well supercritical CO provided by Example 1 2 Fracturing Development Enhanced Geothermal System Realization in which the Horizontal Wells are Supercritical CO 2 The specific process flow chart of the method of fracturing to develop enhanced geothermal energy is as follows: image 3 As shown, the horizontal well supercritical CO 2 The schematic diagram of the transformation process in the method of fracturing to develop enhanced geothermal energy is shown in figure 1 As shown, the horizontal well supercritical CO 2 The schematic diagram of the wellhead production process in the method of fracturing to develop enhanced geothermal is as follows figure 2 shown, from Figure 1-Figure 3 As can be seen in , the method includes:

[0087] (1) In this embodiment, the buried depth of dry hot rock is 3000m, the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com