Hole-forming construction process for slope-protecting pile in complex geologic environment

A technology with complex geology and construction technology, applied in infrastructure engineering, drilling equipment and methods, excavation, etc., and can solve problems such as hole wall collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

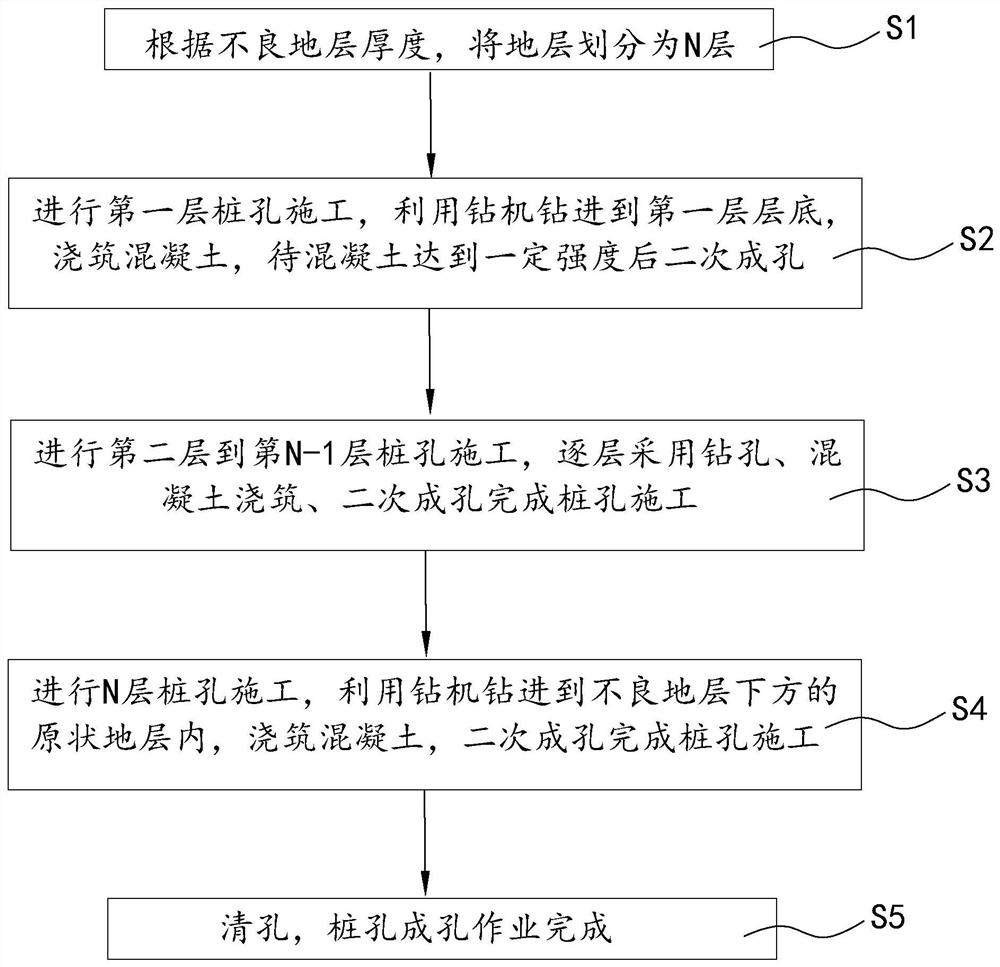

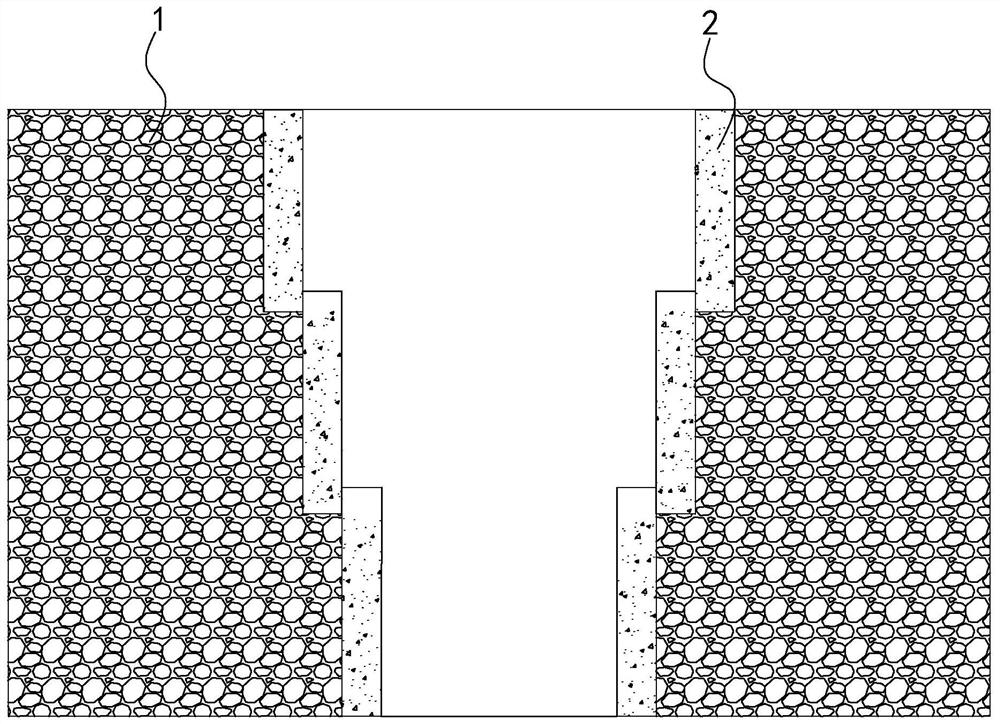

[0054] refer to figure 1 , figure 2 , the complex geological environment slope protection pile hole-forming construction technology includes the following steps;

[0055] S1. Layer division of soil layers to be formed by slope protection piles

[0056] According to the thickness of the miscellaneous fill layer 1, the layers are divided, and the 10m thick miscellaneous fill layer 1 is divided into N layers according to the thickness of each layer of 1.5m from top to bottom. In this embodiment, the value of N is 7, 1-6 The thickness of each layer is 1.5m, and the thickness of the bottom layer is 1m.

[0057] Measure and set out the line, determine the position of the slope protection pile hole on the ground and mark the serial number, and carry out the drilling construction according to the sequence of the number when the hole is formed.

[0058] In this embodiment, a dry hole-forming construction method is adopted. The drilling rig is in place, and the drilling rig adopts ...

Embodiment 2

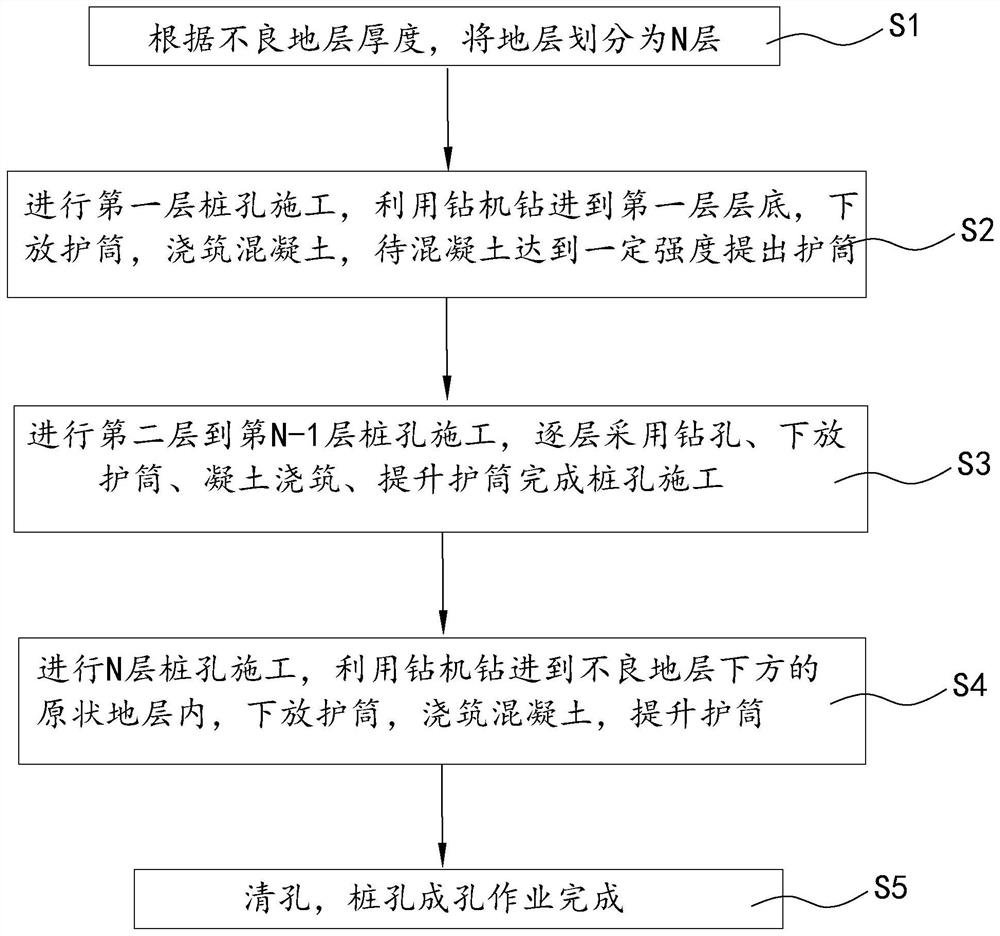

[0084] refer to figure 2 , image 3 , the complex geological environment slope protection pile hole-forming construction technology includes the following steps;

[0085] S1. Layer division of soil layers to be formed by slope protection piles

[0086] According to the thickness of the miscellaneous fill layer 1, the layers are divided. From top to bottom, the 10m thick miscellaneous fill layer 1 is divided into 7 layers according to the thickness of each layer of 1.5m. The thickness of one layer is 1m.

[0087] Measure and set out the line, determine the position of the slope protection pile hole on the ground and mark the serial number, and carry out the drilling construction according to the sequence of the number when the hole is formed.

[0088] In this embodiment, a dry hole-forming construction method is adopted. The drilling rig is in place, and the drilling rig adopts rotary drilling bits. The number of rotary drilling bits used is 8 and marked in the order of 1-...

Embodiment 3

[0119] refer to Figure 4 , Figure 5 , the complex geological environment slope protection pile hole-forming construction technology includes the following steps;

[0120] S1. Layer division of soil layers to be formed by slope protection piles

[0121] According to the thickness of the miscellaneous fill layer 1, the layers are divided, and the 10m thick miscellaneous fill layer 1 is divided into N layers according to the thickness of each layer of 1.5m from top to bottom. In this embodiment, the value of N is 7, 1-6 The thickness of each layer is 1.5m, and the thickness of the bottom layer is 1m.

[0122] Measure and set out the line, determine the position of the slope protection pile hole on the ground and mark the serial number, and carry out the drilling construction according to the sequence of the number when the hole is formed.

[0123] In this embodiment, a dry hole-forming construction method is adopted. The drilling rig is in place, and the drilling rig adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com