Machine for constructing grouting gravel piles in tunnel and constructing method

A technology of construction machinery and construction methods, which is applied in drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., can solve the problems of large workload in construction space, solve the difficulties of one-time drilling and pile formation, overcome the Height limit and insufficient space, the effect of improving shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

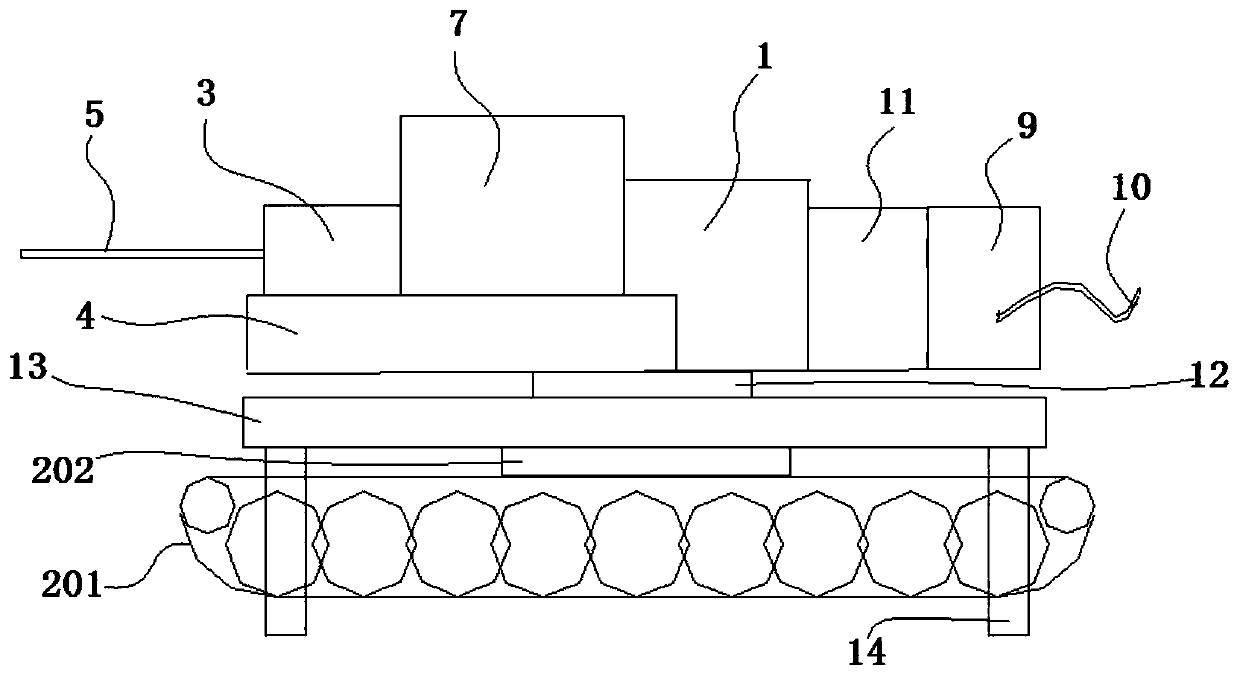

[0033] This embodiment discloses a construction machine for slurry-solidified gravel piles in tunnels, including a drilling system, a grouting system, a travel control room 1 and a crawler belt system 2 .

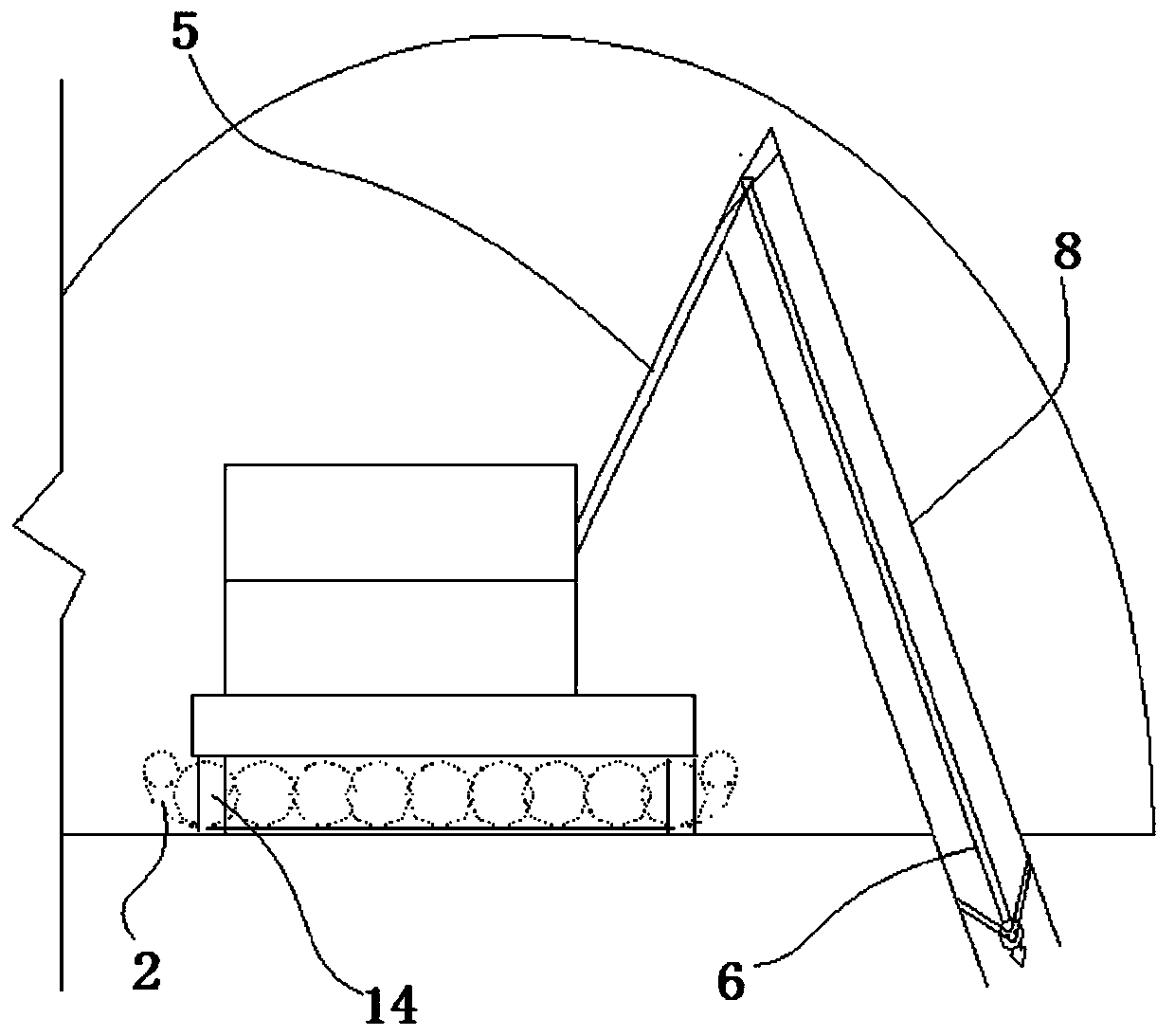

[0034] see figure 1 , the drilling system, the grouting system and the walking control room 1 are all set on the crawler system 2 .

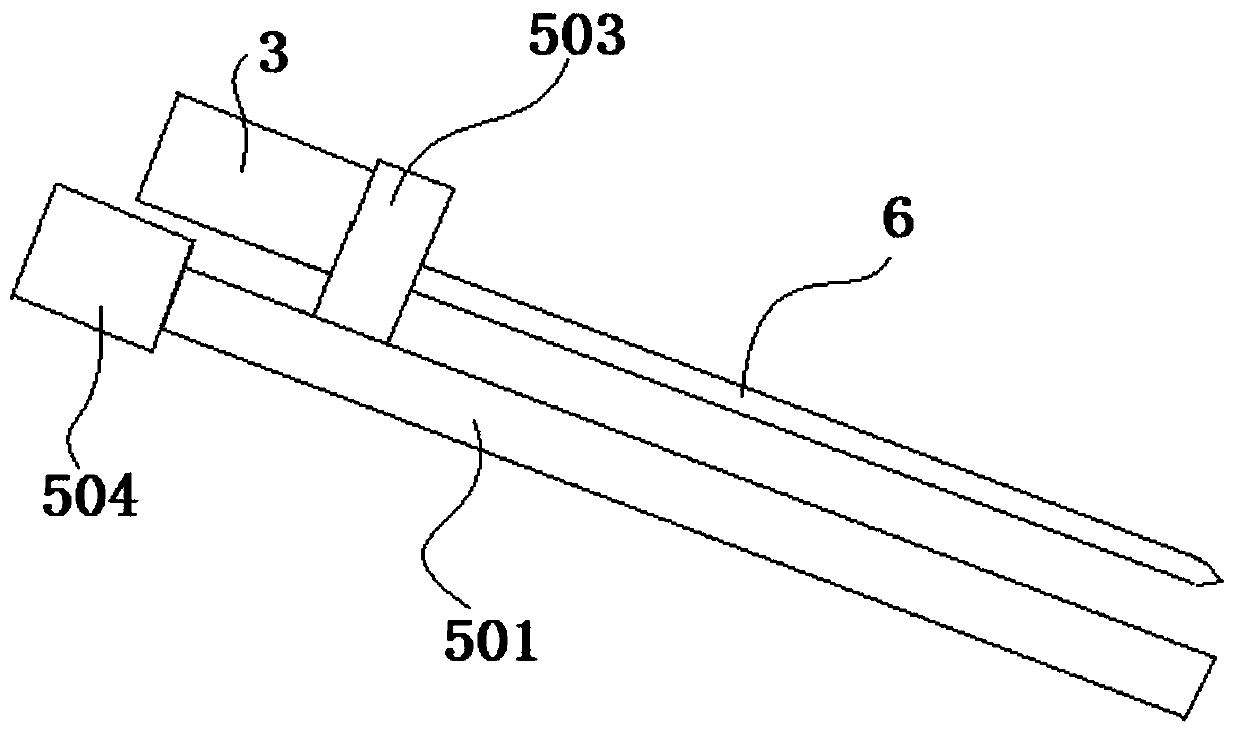

[0035] The drilling system includes a winch 3 , a main engine 4 , a construction frame 5 , a drilling rod 6 and a motor system 7 .

[0036] see figure 2 Or 3, the winch 3 is connected to the construction frame 5, and the drill pipe 6 is connected to the construction frame 5. The construction frame 5 includes an inclined sliding slot 501 , a hydraulic motor 504 is connected to the upper end of the sliding slot 501 , and a transmission chain is wound between the output end of the hydraulic motor 504 and the lower end of the sliding slot 501 .

[0037] A sliding block 503 is arranged on the transmission chain, and the sliding block 503 is in...

Embodiment 2

[0048] This embodiment discloses a construction method based on the construction machinery of slurry-solidified gravel piles in tunnels described in Embodiment 1, see Figure 4 , including the following steps:

[0049] 1) Construction positioning: the construction machine advances to the designed position, opens each of the corner supports 14, supports them to the ground, performs lofting at the designed position, and reviews and positions them.

[0050]2) Drilling construction: after the review is correct, use the drill rod 6 to carry out mechanical drilling. When drilling, drill in slow gear to ensure that the inclination angle of the drilling hole remains unchanged, and the maximum deviation does not exceed 1%.

[0051] 3) Connection construction: when the construction of the drill pipe of the Nth section is completed, the drill pipe 6 described in the N+1 section is connected with the drill pipe 6 of the Nth section with male and female buckles, and the thin-walled casing...

Embodiment 3

[0056] This embodiment discloses a construction machine for slurry-solidified gravel piles in tunnels, including a drilling system, a grouting system, a travel control room 1 and a crawler belt system 2 .

[0057] The drilling system, the grouting system and the walking control room 1 are all arranged on the crawler belt system 2 .

[0058] The drilling system includes a winch 3 , a main engine 4 , a construction frame 5 , a drilling rod 6 and a motor system 7 . The winch 3 is connected with a construction frame 5, on which a drill pipe 6 is connected. see figure 2 , the outer surface of the drill pipe 6 is provided with a thin-walled steel casing 8 .

[0059] see figure 1 , the grouting system includes a grouting pressure system 9 , a delivery hose 10 and a grout storage system 11 . The grout storage system 11 is connected to the grouting pressure system 9 . The grouting pressure system 9 is connected with a delivery hose 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com