Heat insulation structure prefabricated integrated assembly wall panel and overall building forming method

A technology of wallboard and thermal insulation slurry, which is applied in the direction of building components, building structures, construction, etc., can solve the problems of many additional construction equipment, inconvenient transportation and use, and long construction period, and achieve the feasibility of preparation and construction methods, transportation and use Convenience and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

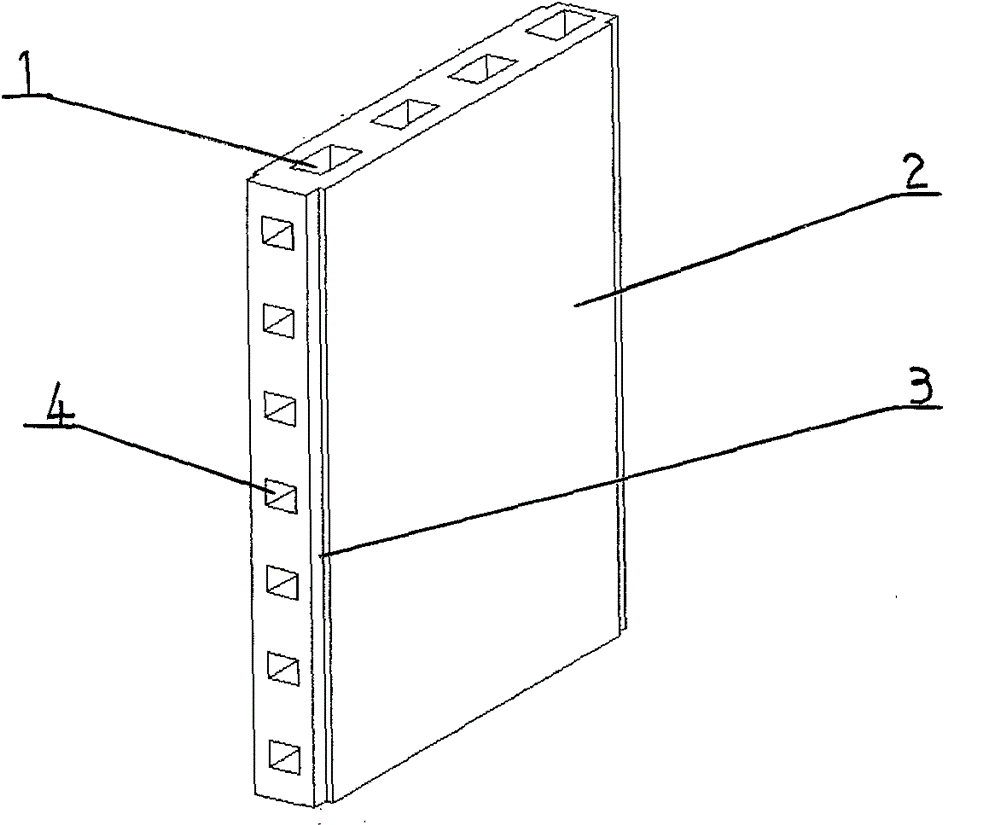

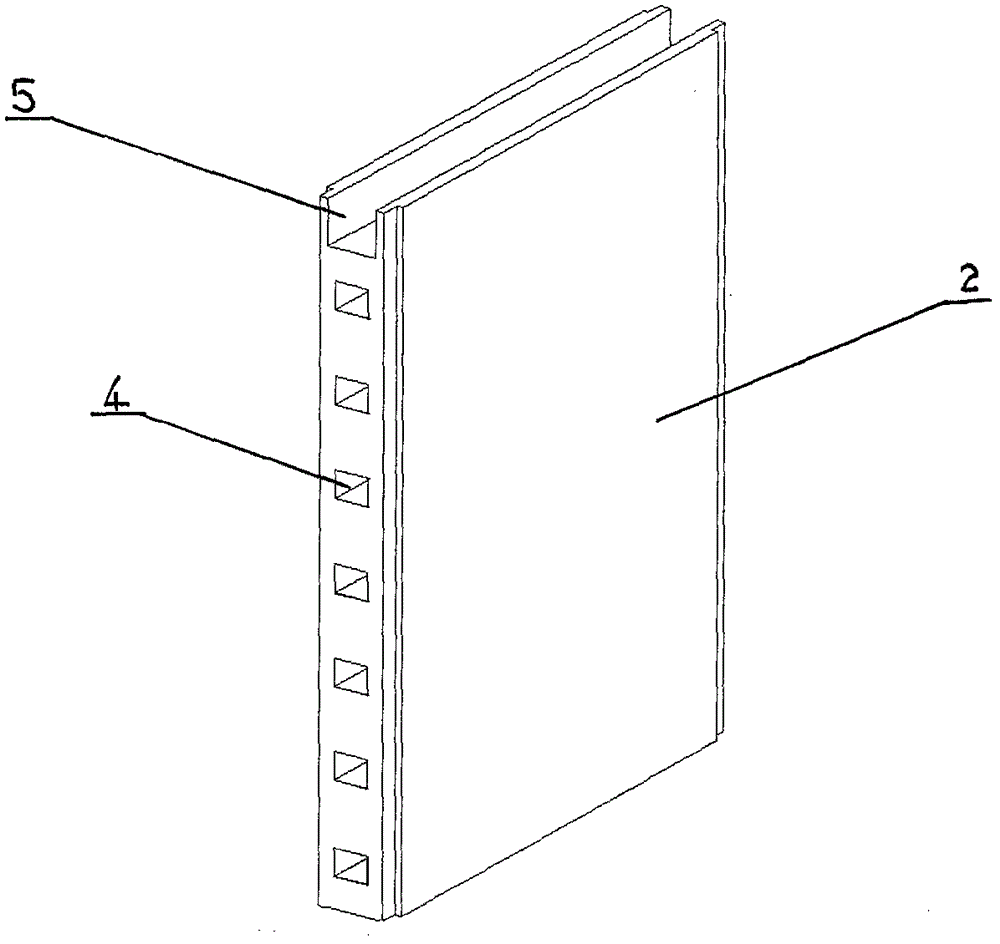

[0032] like Figure 1 to Figure 11 As shown, a prefabricated integrated assembled wall panel with thermal insulation structure is mainly composed of a panel body 2 .

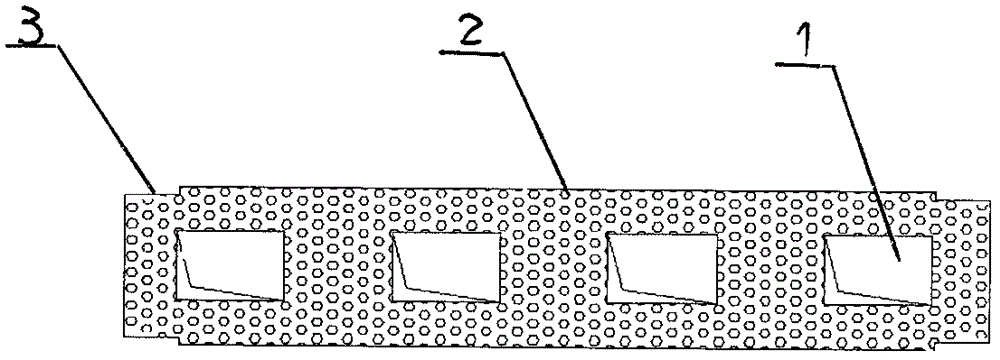

[0033] like figure 1 , image 3 As shown, the board body is made by mixing cement, polystyrene particles, admixture and water into a thermal insulation slurry, pouring it into the mold, waiting for drying, and removing the film. The plate body is a rectangular plate. Board seam connection grooves 3 are respectively provided on the sides of the board body and around the periphery. Longitudinal through-holes 1 parallel to the connecting grooves of the plate seams are provided at intervals in the longitudinal direction of the plate body. Horizontal through-holes 4 are arranged at intervals in the lateral direction of the plate body. The longitudinal through-holes communicate with the transverse through-holes, and one side of several panels is respectively provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com