Steel pipe piece device for freezing soil around tail of shield tunneling machine and construction method of steel pipe piece device

A technology for the surrounding soil and shield machines, which is applied in the direction of measuring devices, earth drilling, shaft equipment, etc., and can solve problems such as poor uniformity in the circumferential direction of the frozen soil curtain, penetrating damaged segments, and hidden dangers of permanent leakage. , to improve cooling efficiency, reduce heat convection, and increase contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0033] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

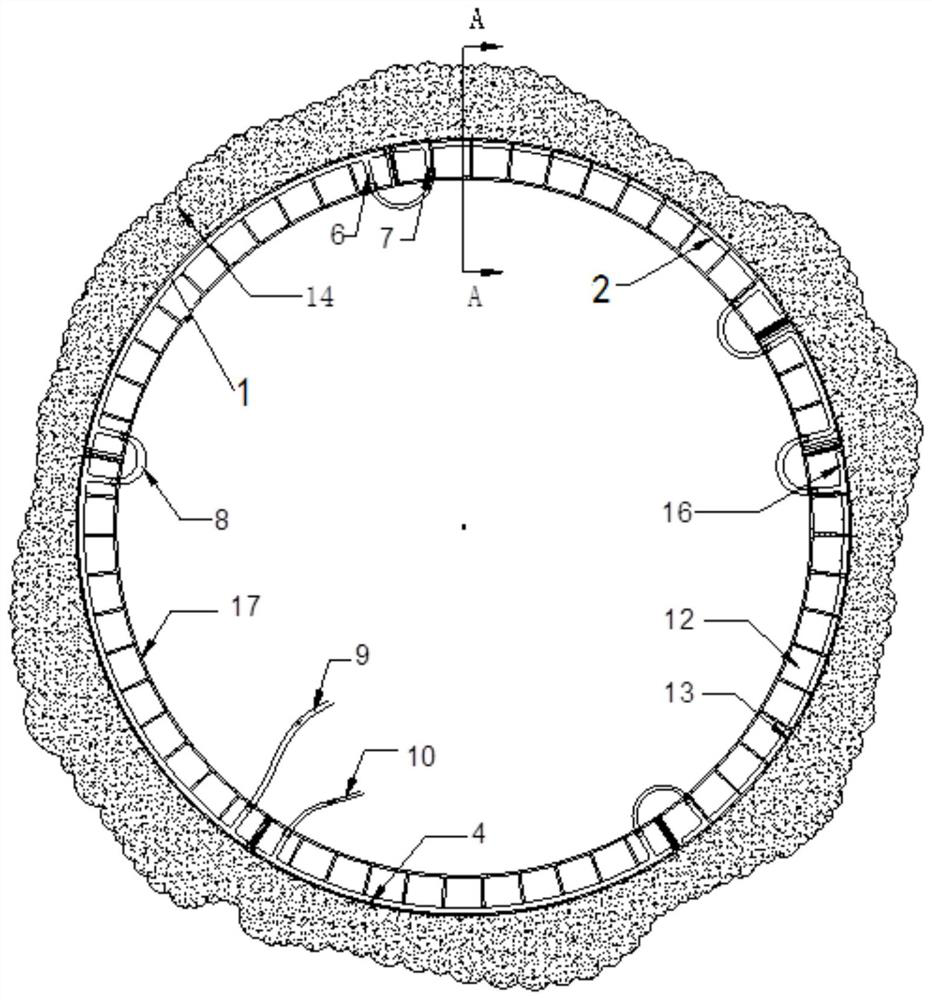

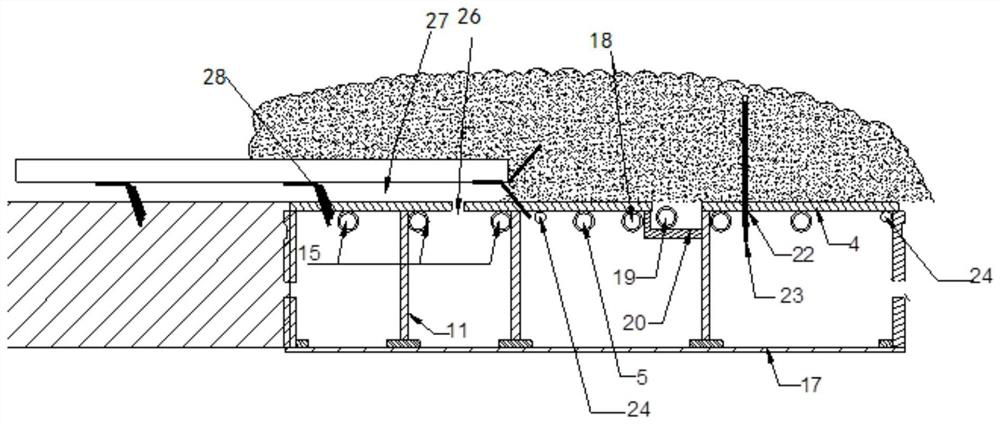

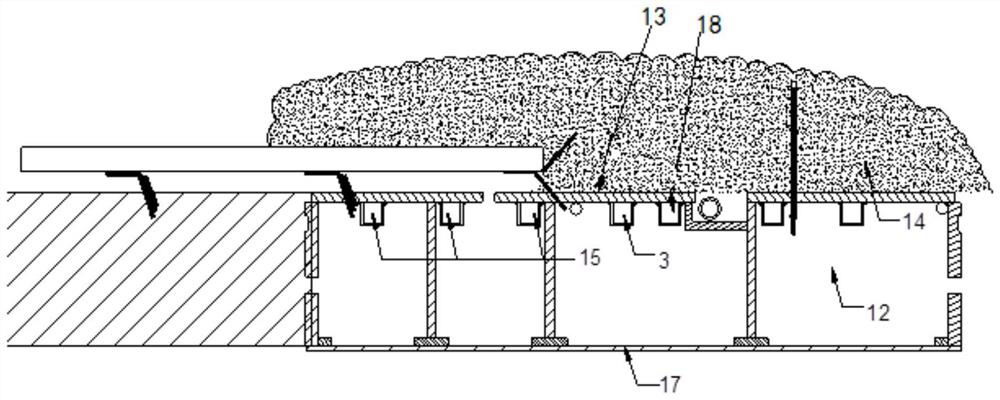

[0034] Such as Figure 1~4 As shown, the steel pipe sheet device for freezing the soil around the tail of the shield machine provided by the embodiment of the present invention includes: a plurality of arc-shaped steel pipe sheets 4, which are connected in sequence to form an annular steel pipe sheet 1; freezing pipeline 2, On the inner surface of each arc-shaped steel pipe sheet 4, multiple rows of freezing pipelines 2 are arranged along the arc, and the same row of freezing pipelines 2 on adjacent arc-shaped steel pipe sheets 4 are connected by a first pipe 8 to form multiple r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com