Patents

Literature

47results about How to "No need for manual positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

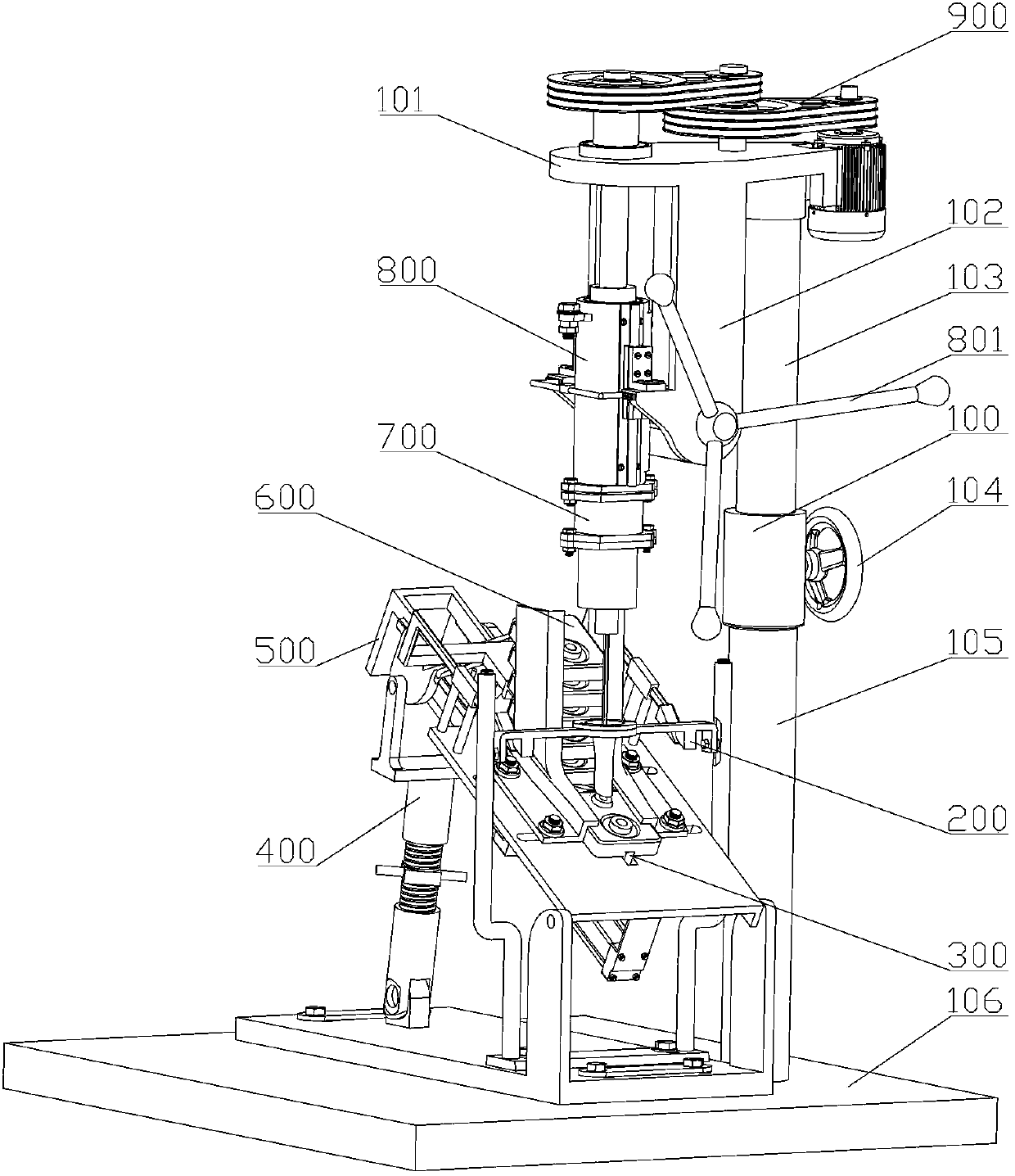

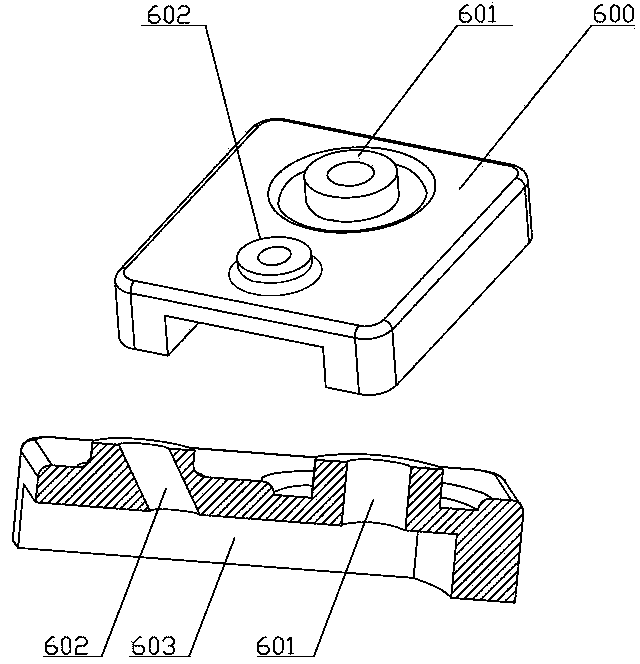

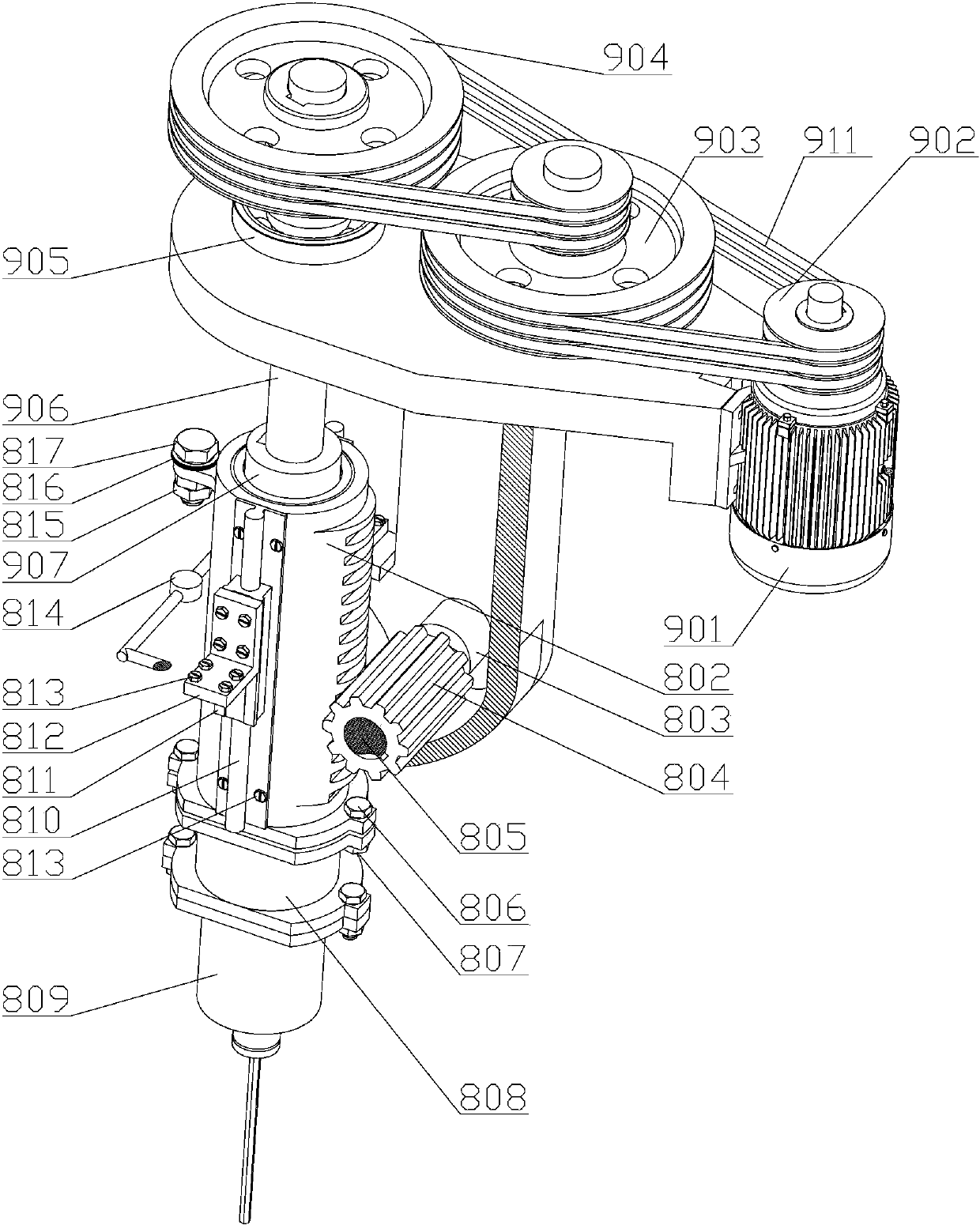

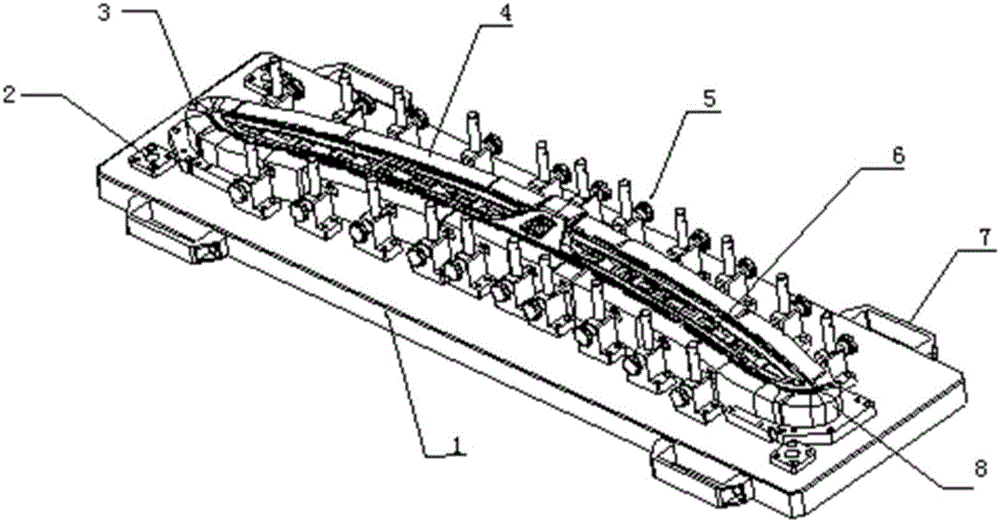

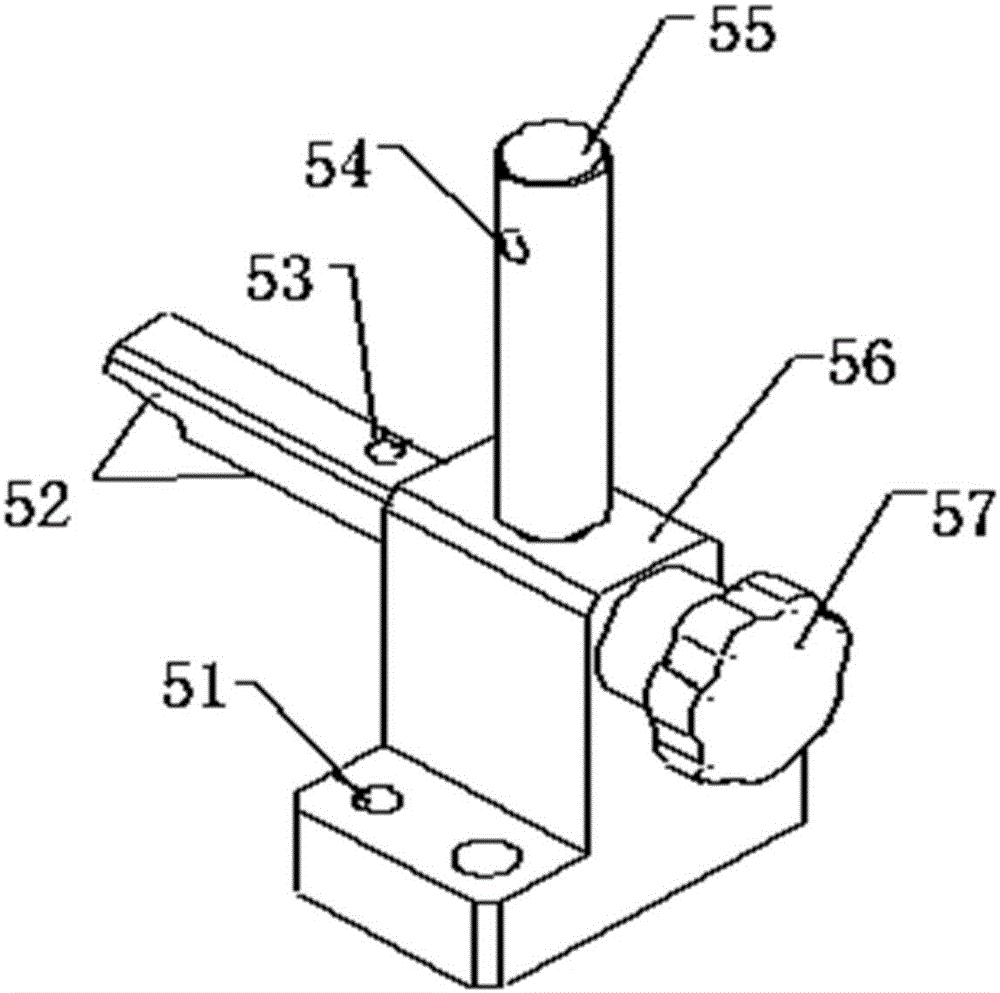

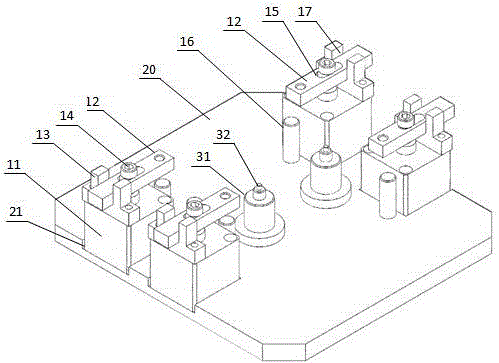

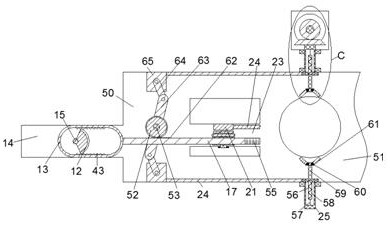

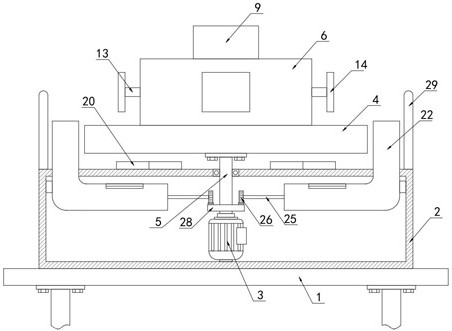

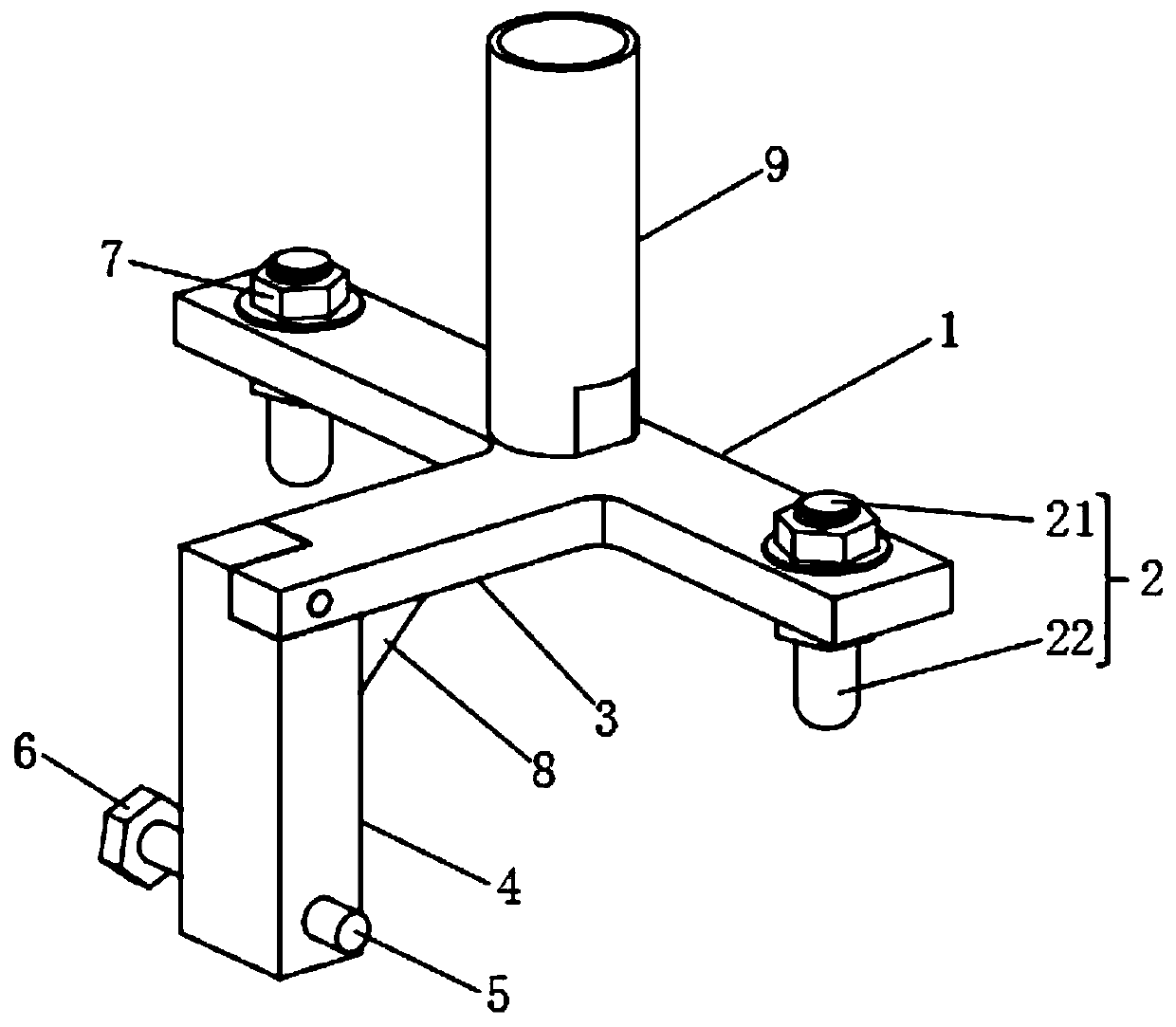

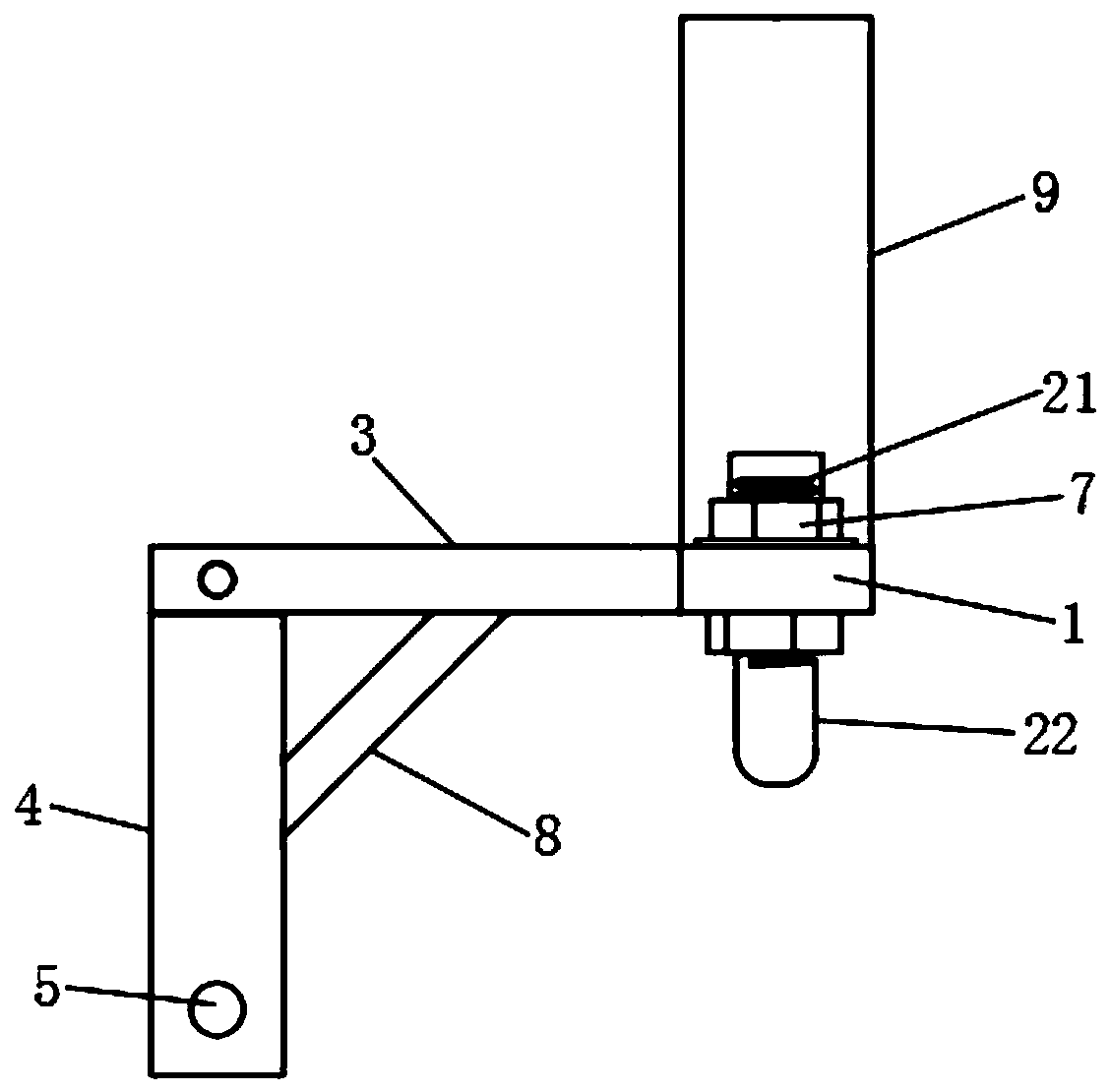

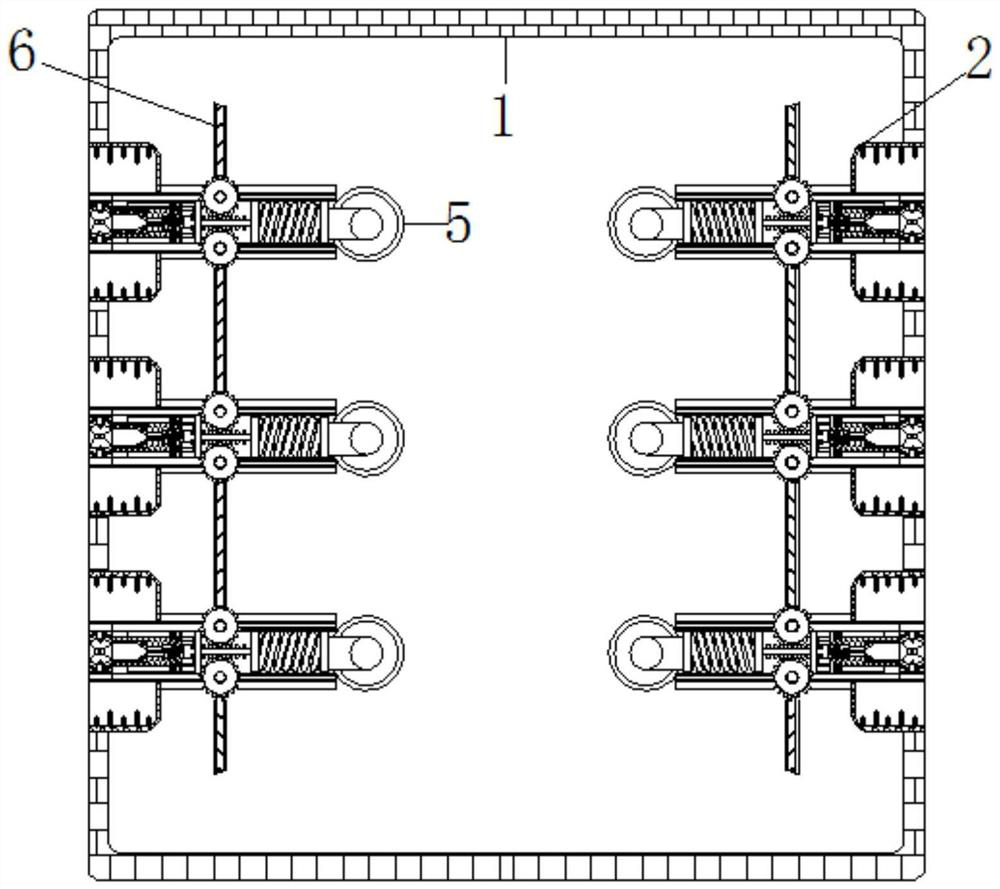

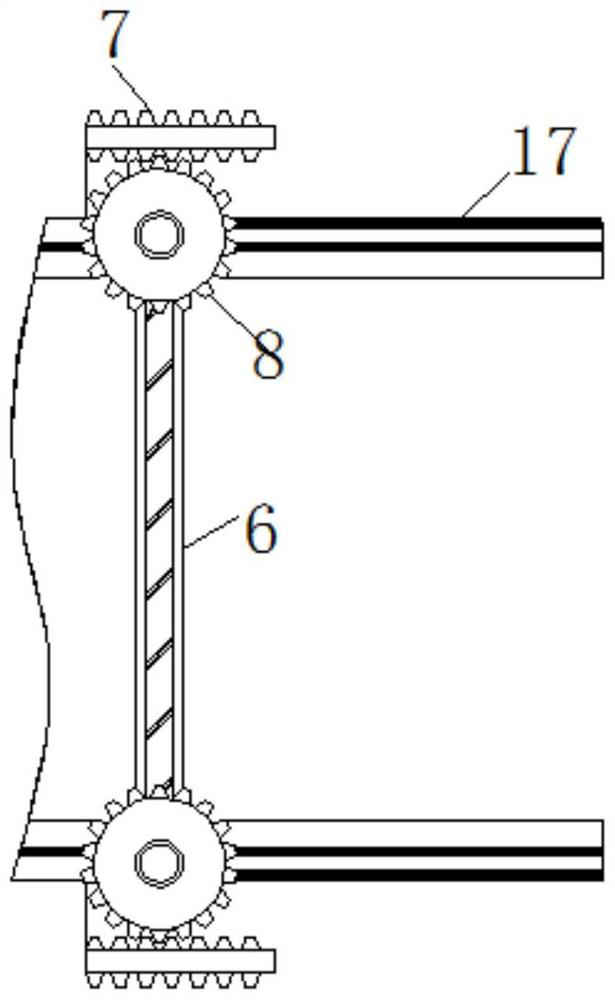

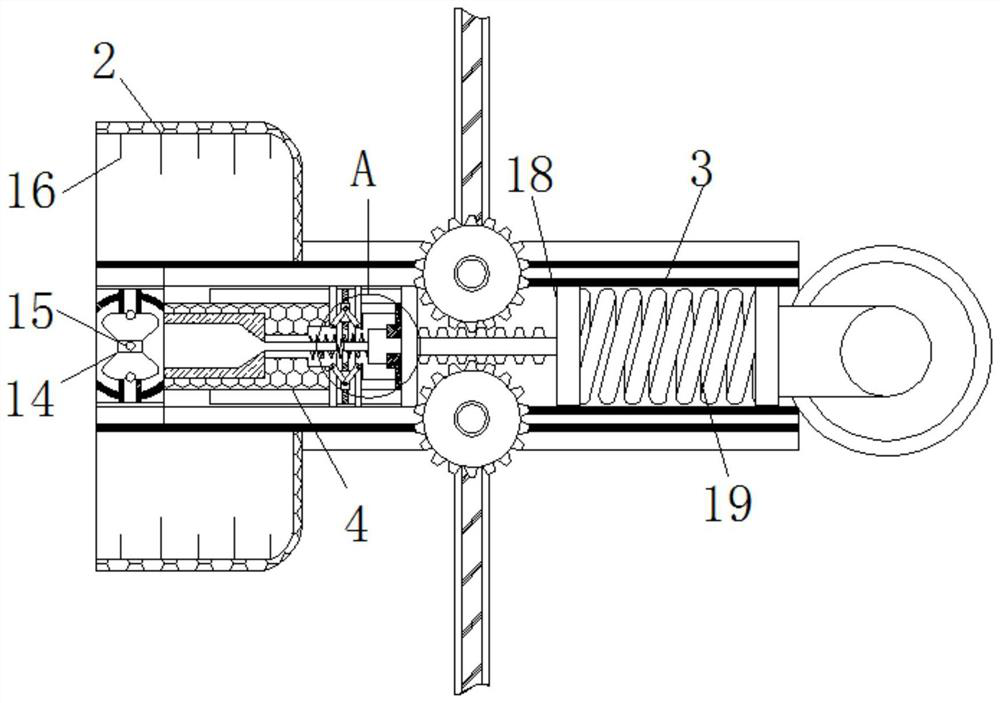

Safe screw assembling device capable of automatically feeding and synchronously assembling and disassembling workpieces

ActiveCN103386606AIncrease productivityPrevent screw holes or screw slippage from being damagedMetal working apparatusEngineeringPulley

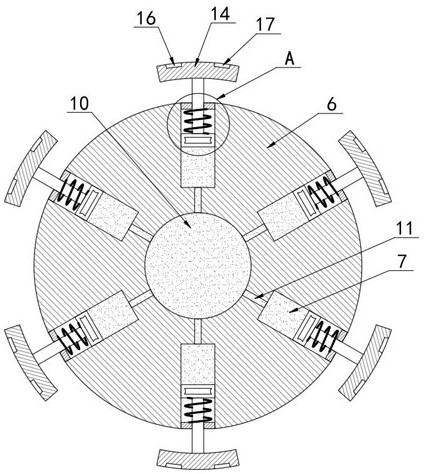

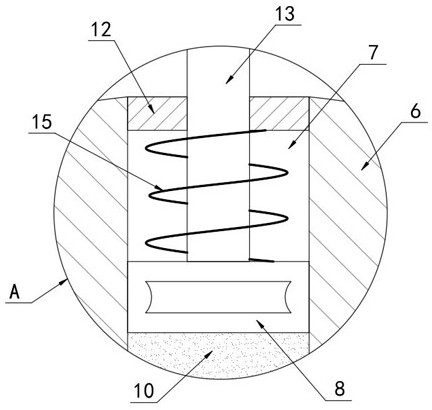

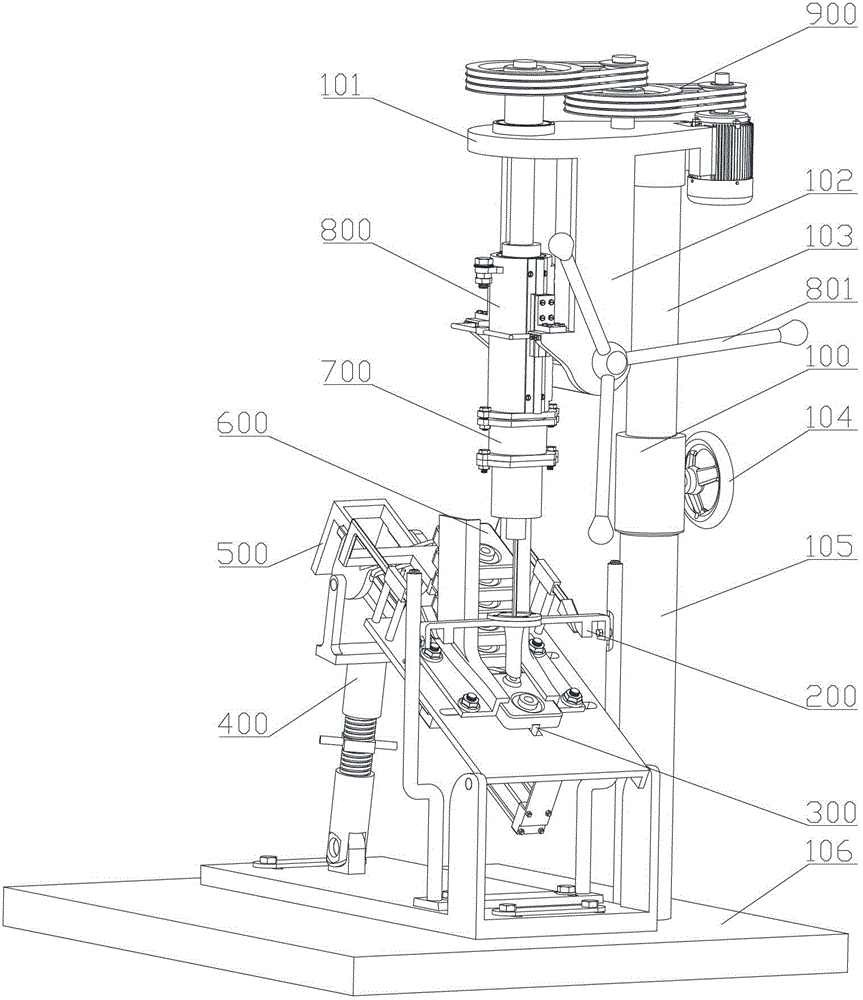

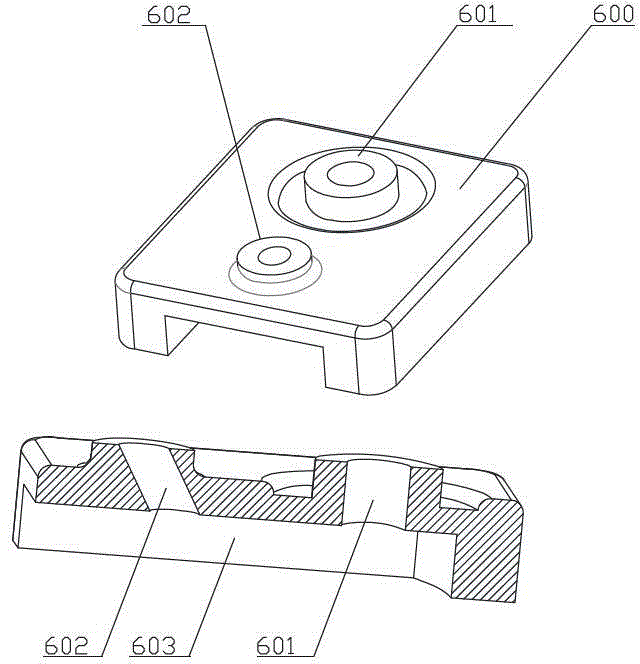

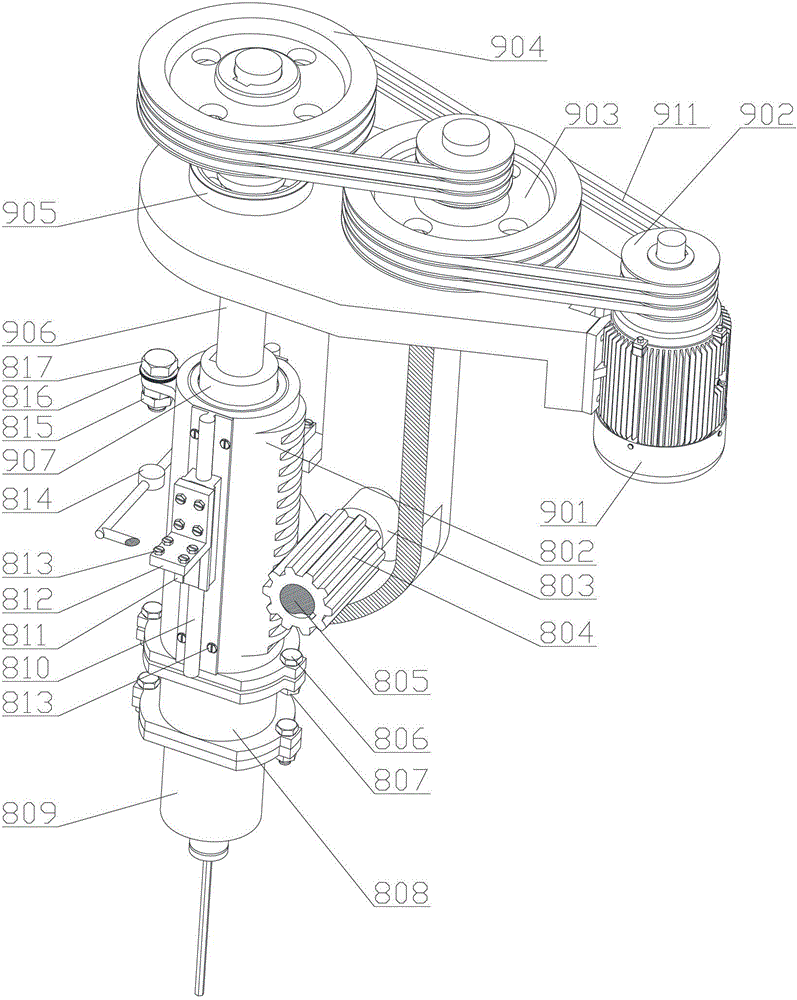

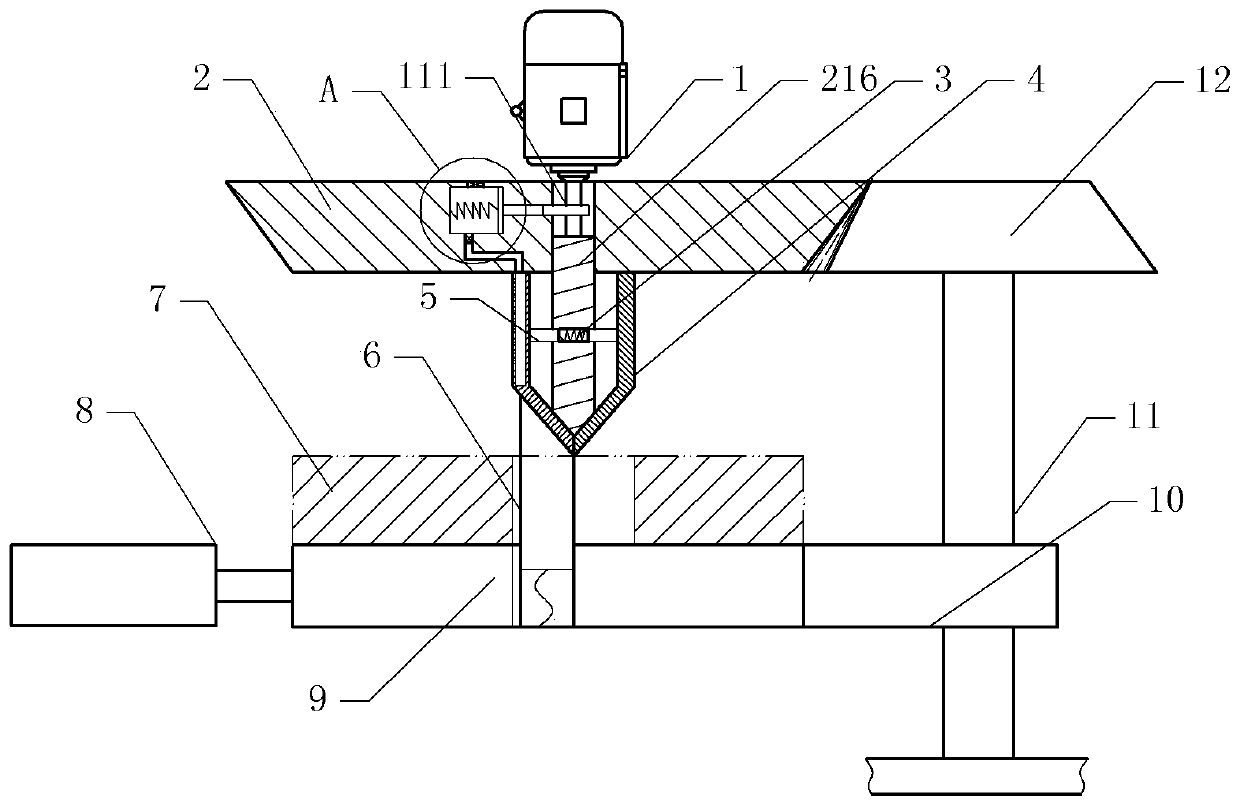

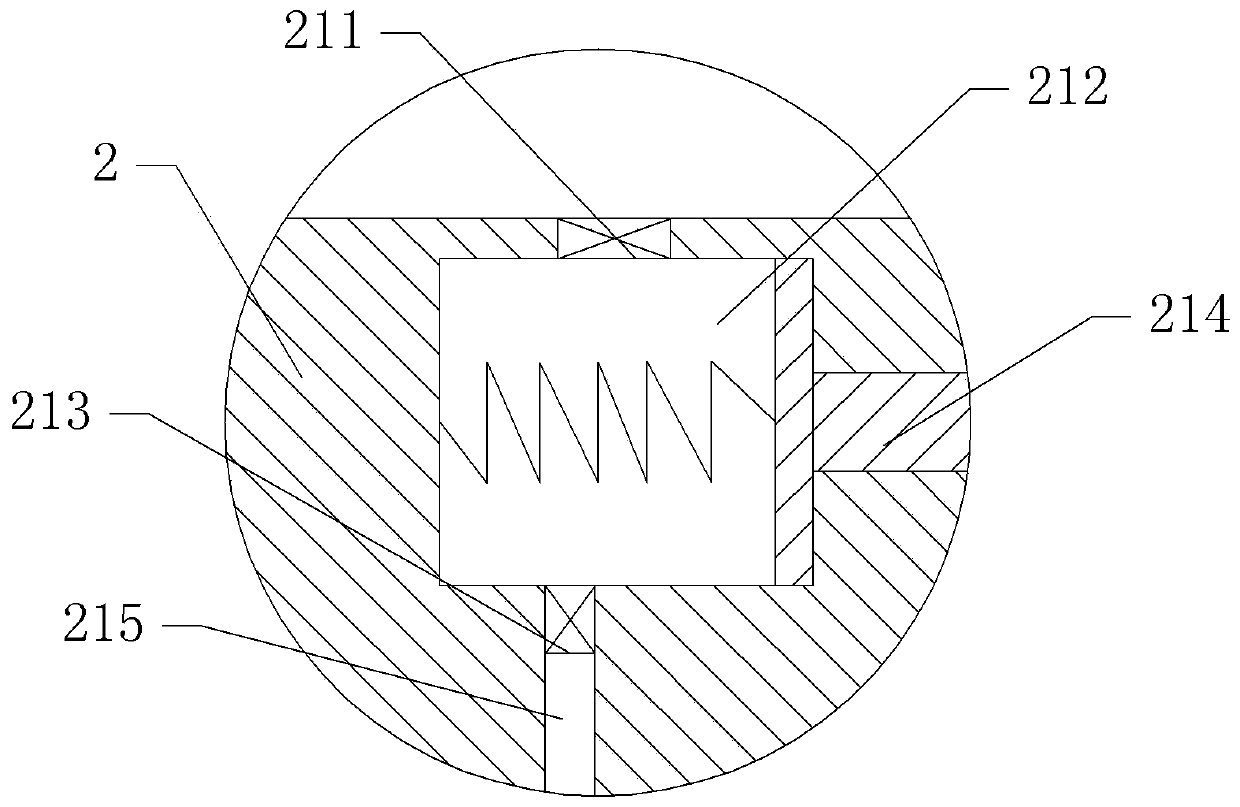

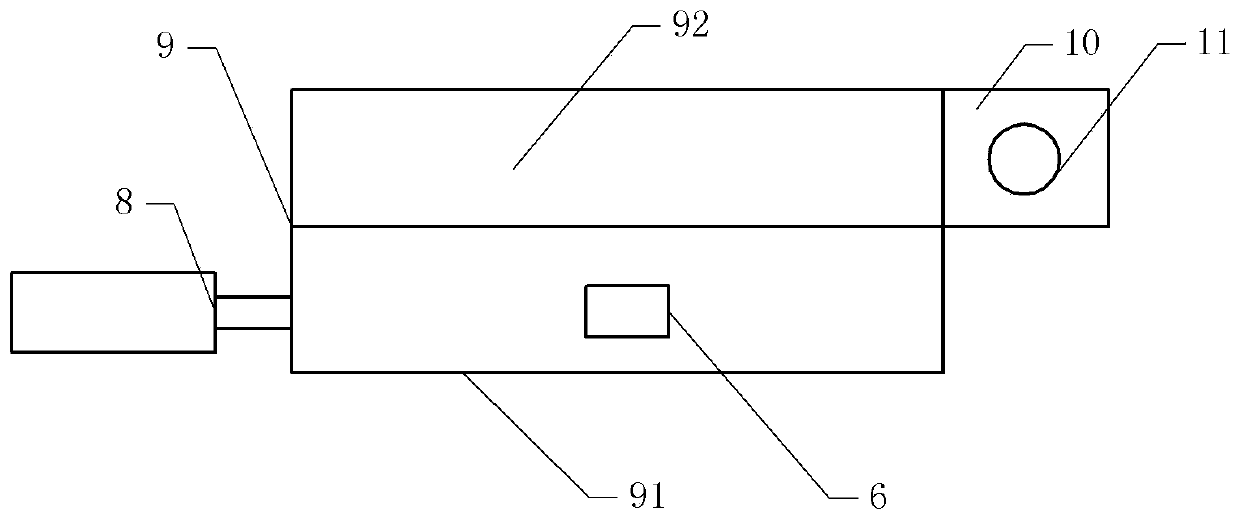

The invention discloses a safe screw assembling device capable of automatically feeding and synchronously assembling and disassembling workpieces, comprising a stand, a power device, a spinning tool feed unit, a spinning tool engaging and disengaging mechanism, a fastening screw guide device, an angle adjusting workbench, an automatic base feed unit and a synchronous base assembling and disassembling device. A mode that the piston rod of an air cylinder drives a push rod to enter and exit is adopted, an interior mirror base is automatically fed into a station, manual operation steps are saved, and the production efficiency is greatly increased; due to the adoption of the spinning tool engaging and disengaging mechanism, the required thread spinning length can be precisely realized, and meanwhile, screw holes are effectively prevented from being damaged by screwing or screws are effectively prevented from sliding; the rotating speed of a spinning tool can be changed along with the replacement of a speed reducing belt pulley, and the applicable range is wide; a fastening screw needs not to be positioned manually and can be precisely positioned by an operator through throwing the fastening screw in the fastening screw guide device along the approximate direction, and the labor intensity of the operator is effectively reduced; the assembled interior mirror base can be automatically detached, the production efficiency is further improved, and the labor intensity is further reduced.

Owner:GUANGXI UNIV

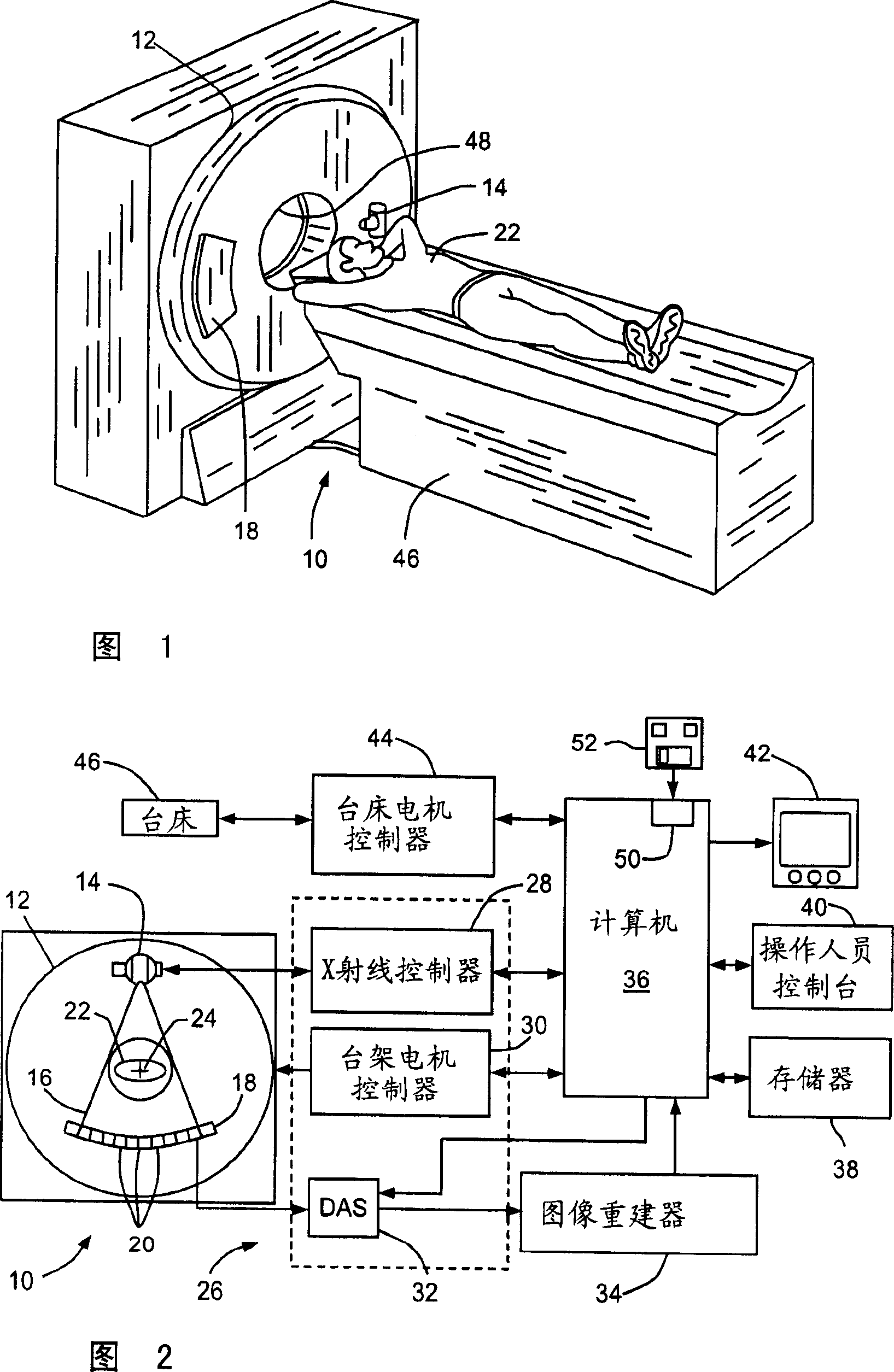

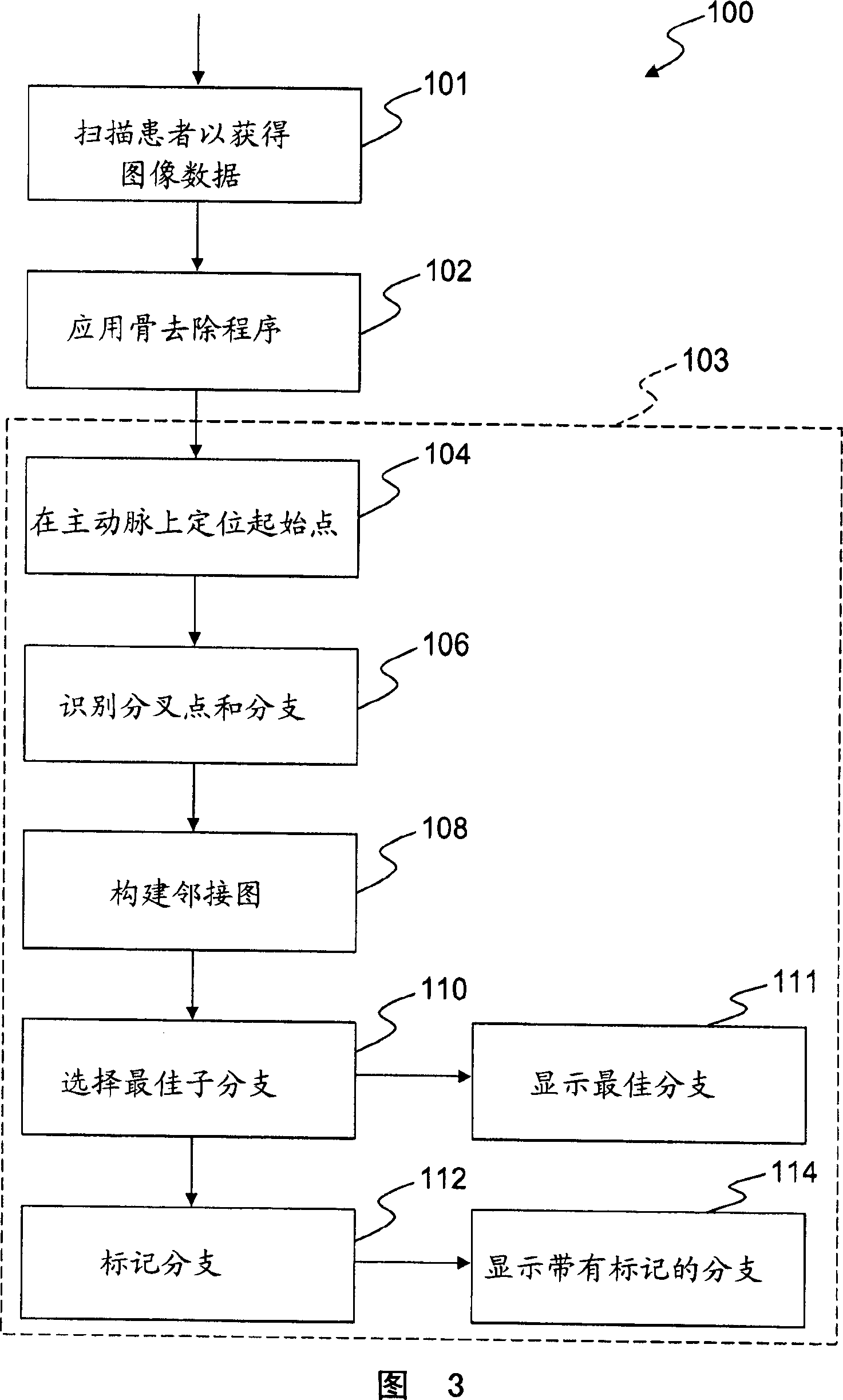

Methods and apparatus for selecting and/or labeling vessel branches

InactiveCN1983333AAvoid slow recognitionQuick tagImage enhancementImage analysisComputer graphics (images)Image system

A method for selecting and / or labeling a vessel image includes operating an imaging system to obtain reconstructed image data including a volume having vessels therein. A bone removal routine is then applied to the reconstructed image data to produce a bone-free image. An initial point on a main vessel in the bone-free image is located, and bifurcation points and branches departing from the main vessel are identified. An adjacency graph of each branch coming from the main vessel is built. The method includes either or both of selecting and displaying a best or at least a favorable path through the vessels in accordance with predetermined criteria using the adjacency branch, or labeling and displaying branches of the main vessel.

Owner:GENERAL ELECTRIC CO

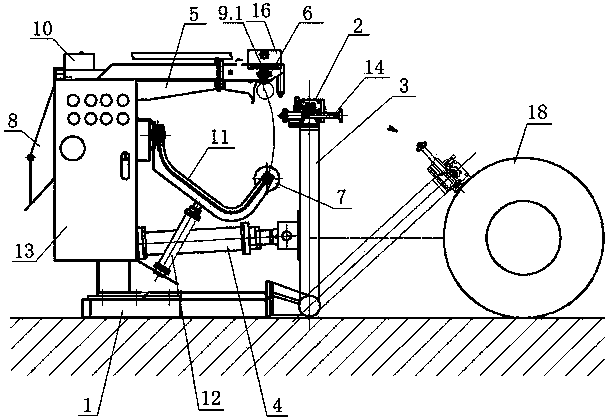

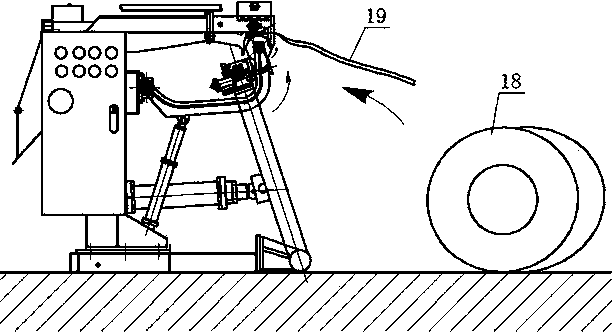

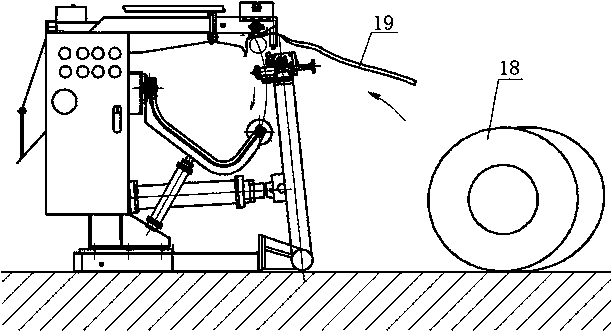

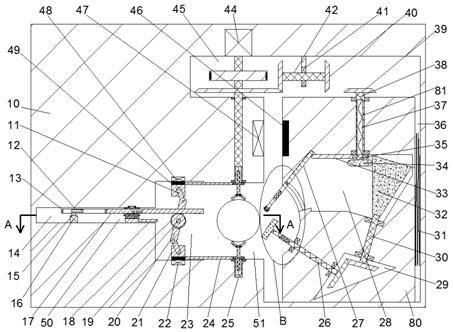

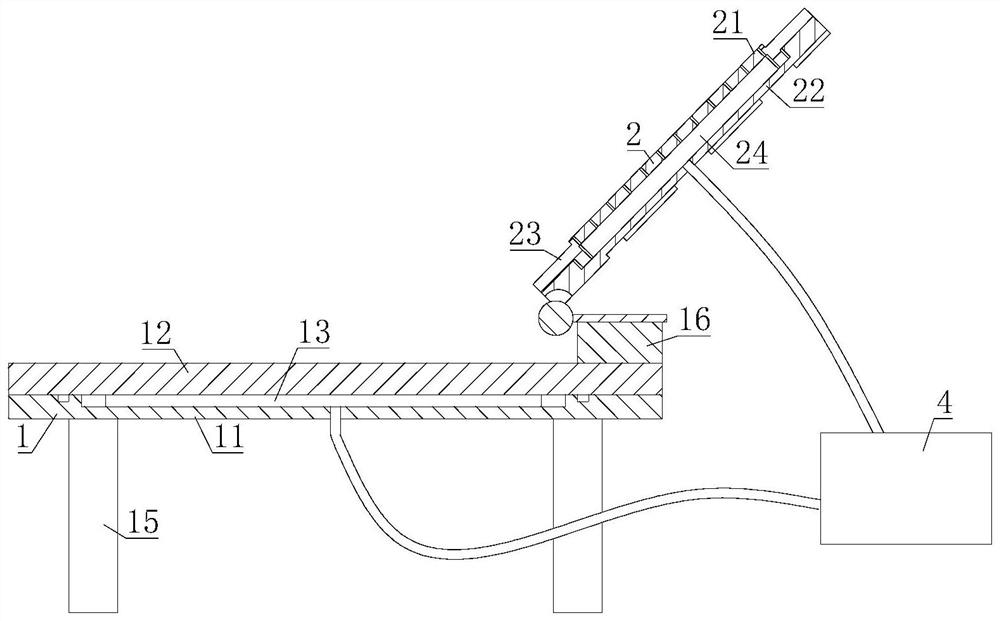

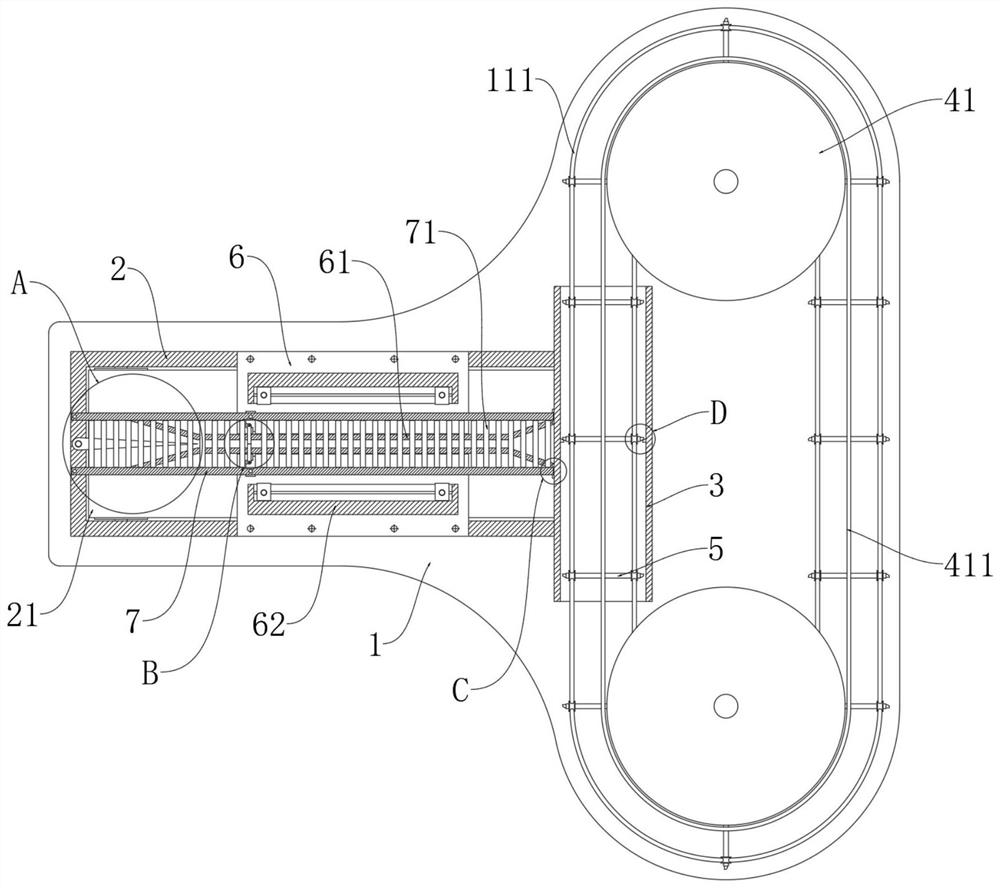

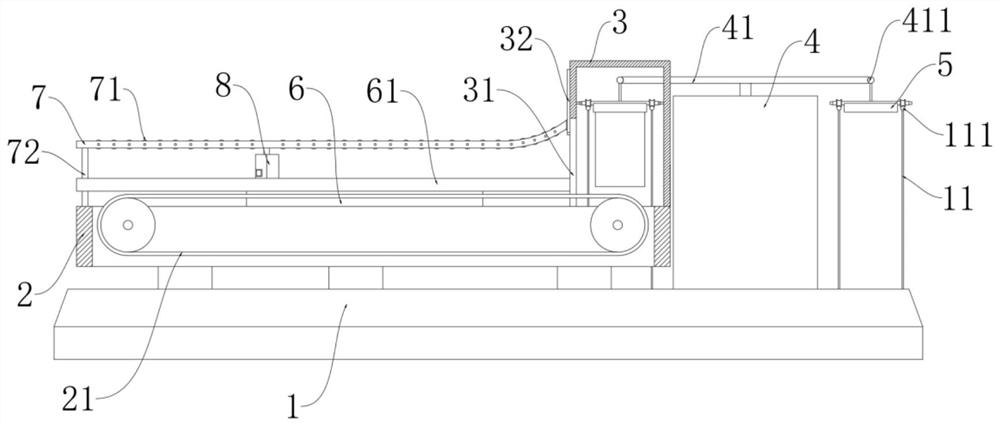

Steel band bale breaker

InactiveCN103770991ANo need for manual positioningHigh mechanical precisionArticle unpackingPapermakingEngineering

The invention relates to the field of binding band detaching equipment in the industries of steel, metallurgy, papermaking, package and the like, in particular to a steel band bale breaker which comprises a rack provided with a shearing mechanism, wherein the shearing mechanism is arranged on one end of a rotary arm, and the other end of the rotary arm is hinged to the bottom of the rack; one end of a rotary arm cylinder is connected with the rotary arm, and the other end o f the rotary arm cylinder is connected with the waist of the rack; the upper part of the rack is provided with a band feeding hopper; the inlet of the band feeding hopper is provided with an attaching clamp band roll; the tail end of the band feeding hopper is communicated with a discharge bin; a band feeding mechanism is arranged between the inlet of the band feeding hopper and the attaching clamp band roll; a band winding mechanism is arranged between the band feeding hopper and the discharge bin; the waist of the rack is hinged to a reeling crank arm; the tail end of the reeling crank arm is provided with a floating reeling crank roll matched with the attaching clamp band roll, and the reeling crank arm is connected with the reeling crank cylinder with the other end connected to the waist of the rack or the bottom of the rack. The steel band bale breaker is free from manual locating, high in mechanical precision, low in speed, simple and rapid in length regulation and high in efficiency.

Owner:武汉华翰液动机械有限责任公司

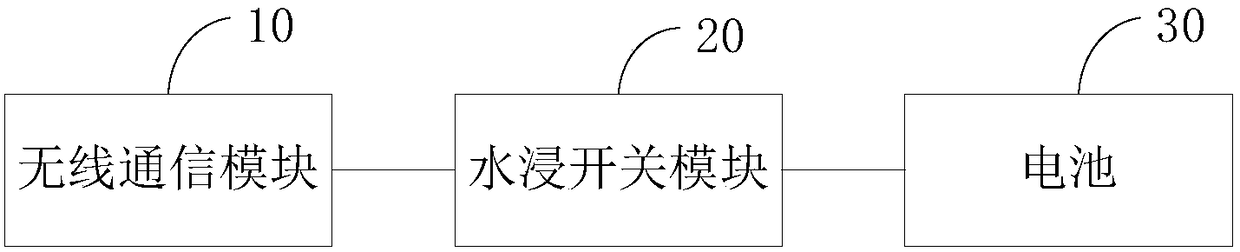

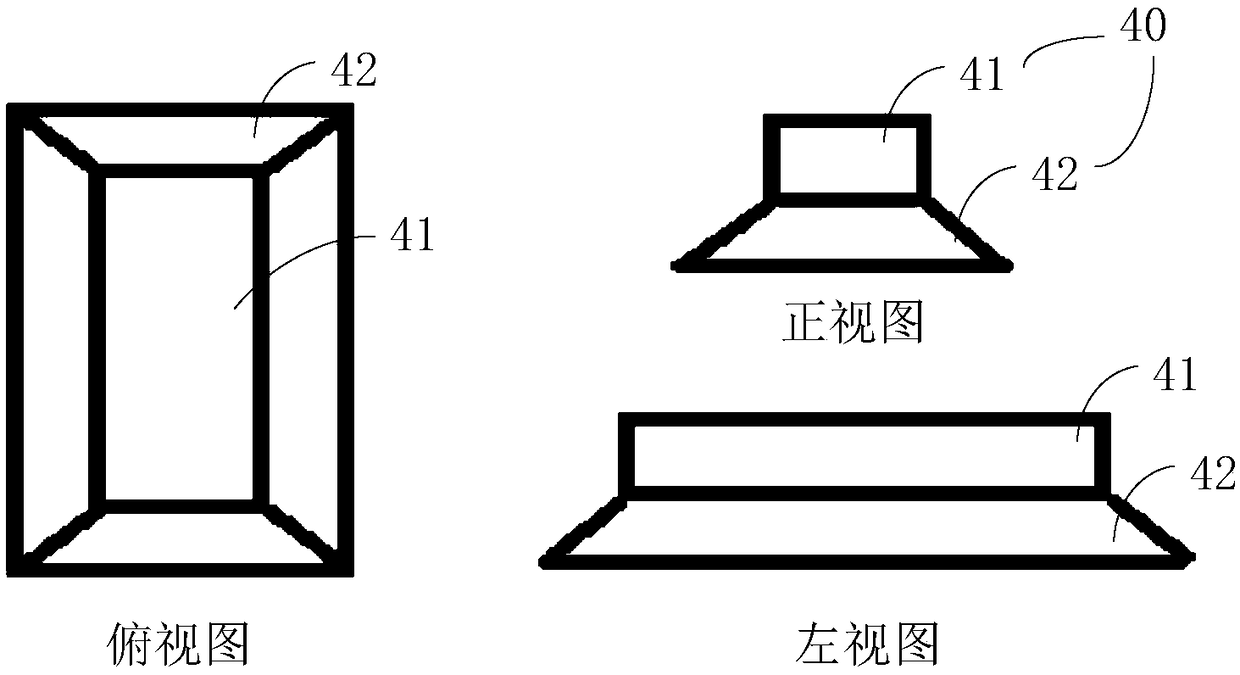

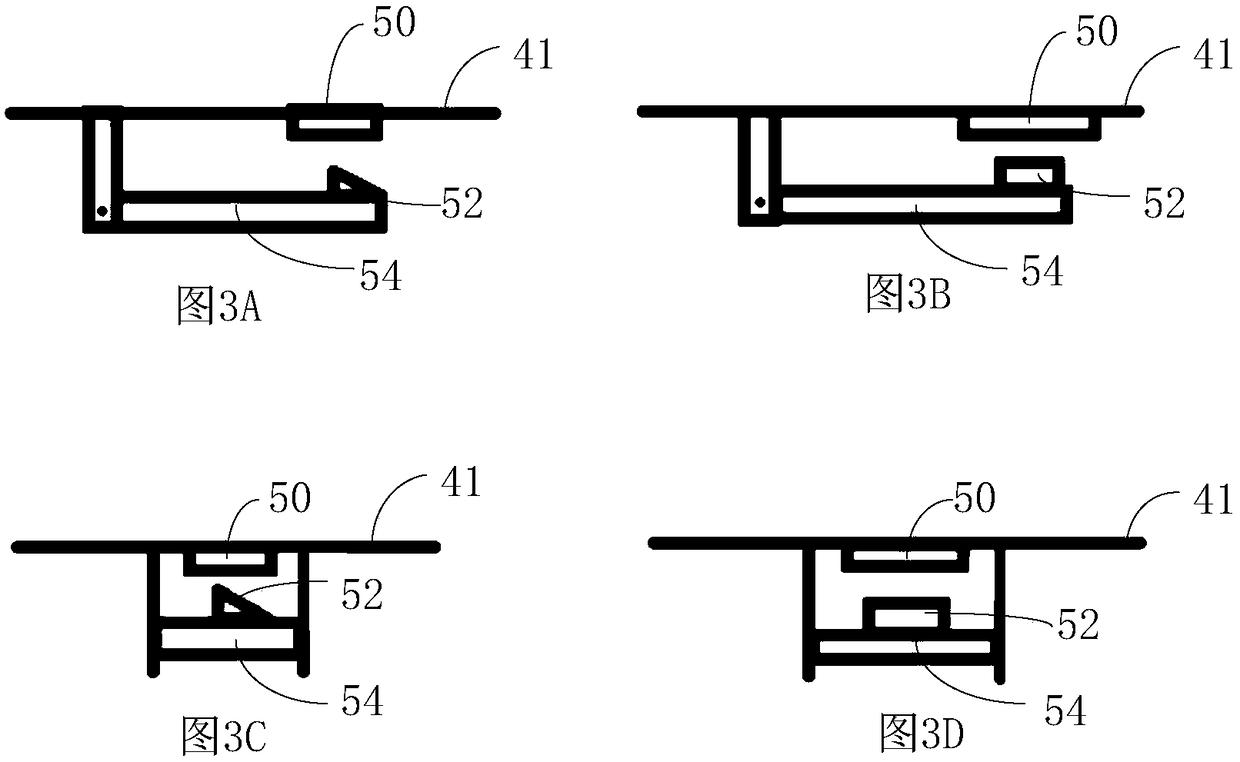

Detection device and system applied to blockage detection of drainage channel

InactiveCN109084860APrecise positioningHigh cleaning and dredging efficiencyMeasurement of fluid loss/gain rateMachines/enginesData centerControl signal

The invention relates to a detection device and system applied to blockage detection of a drainage channel. The detection device comprises a battery, a wireless communication module and a water logging switch module; the wireless communication module is used for sending water level detection information to a data center through a network signal; position information of all to-be-detected drainagechannels and corresponding detecting devices of all the to-be-detected drainage channels are stored in the data center; one end of the water logging switch module is connected with the battery, the other end of the water logging switch module is connected with the wireless communication module, and the water logging switch module is used for detecting the water level of the drainage channel in real time; when it is detected that the water level of the drainage channel is larger than or equal to the preset water level threshold value, a control signal for controlling the battery to communicatewith the wireless communication module is output; and when it is detected that the water level of the drainage channel is smaller than the preset water level threshold value, a control signal for controlling the battery to be disconnected with the wireless communication module is output. Therefore, the water logging switch module can accurately judge the magnitude of the water level of the drainage channel, manual positioning is not needed, the positioning efficiency is improved, and thus the clearing and dredge efficiency of the blocked drainage channel is improved.

Owner:FIBOCOM WIRELESS SOFTWARE INC

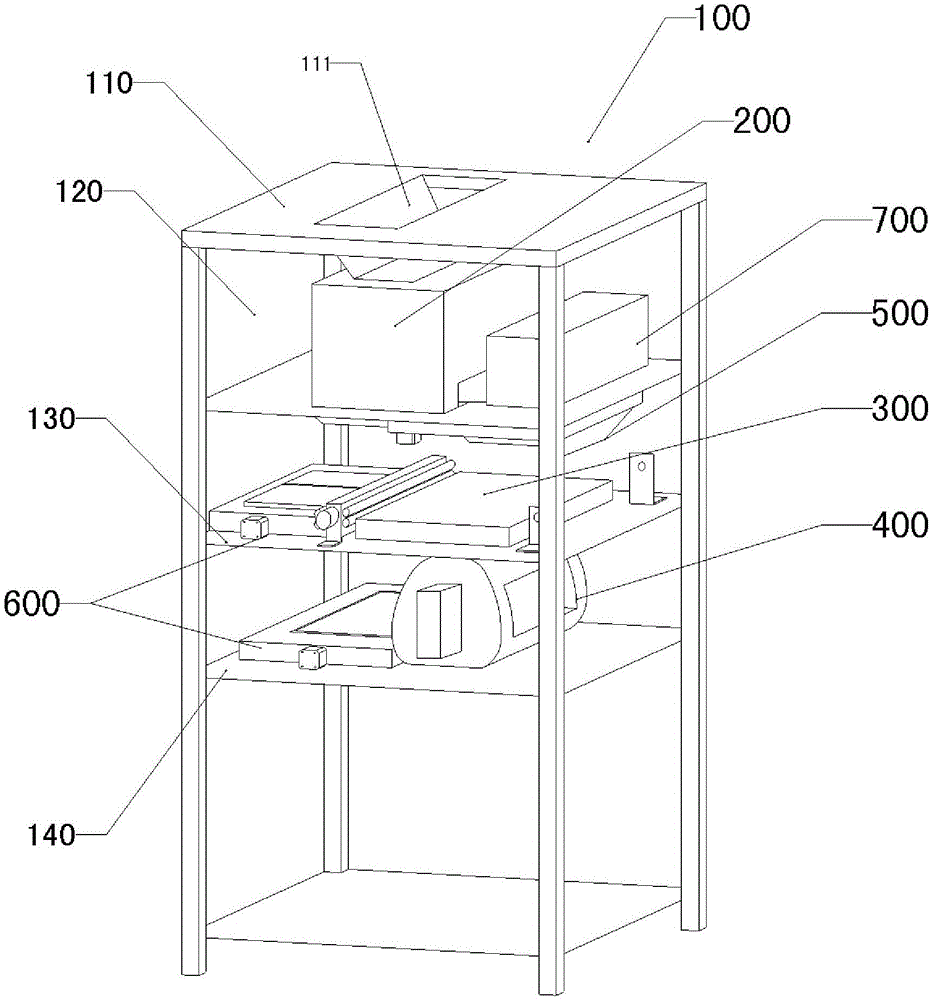

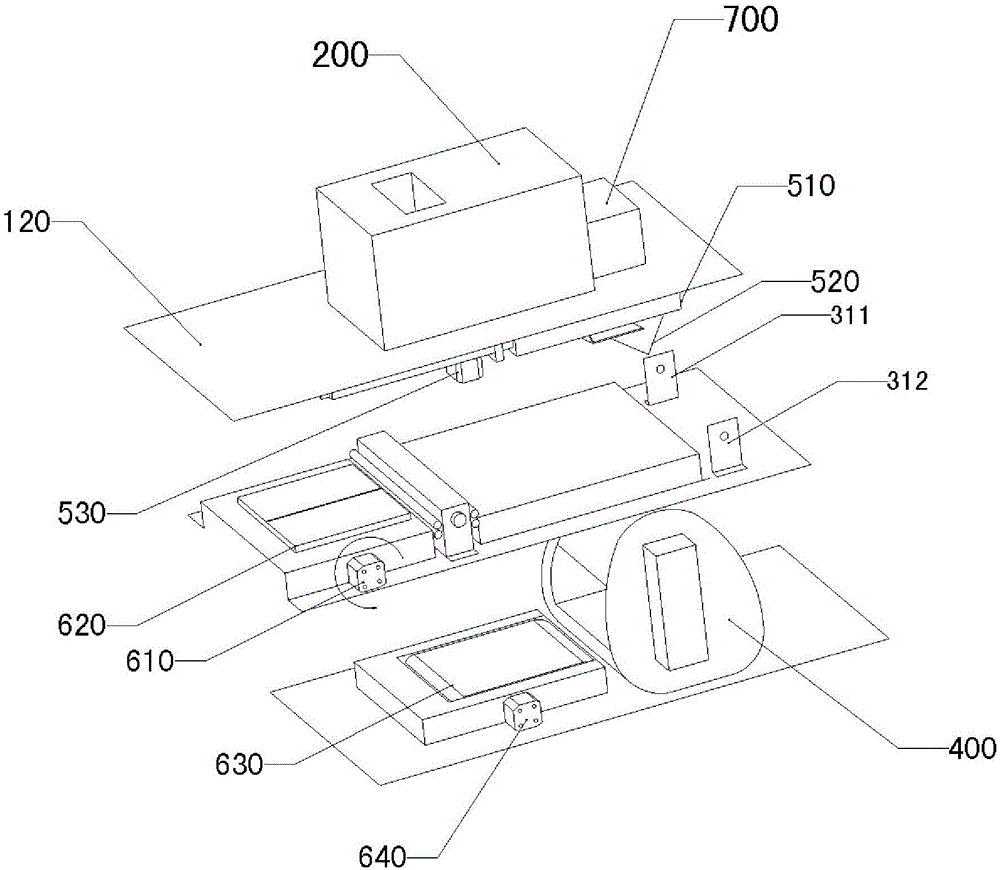

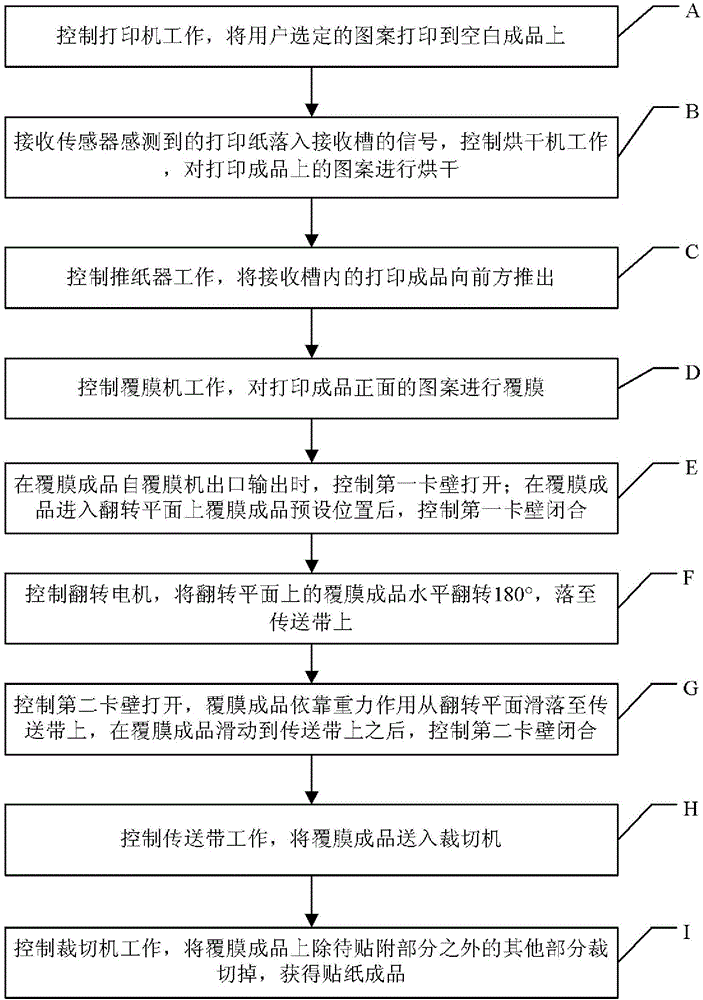

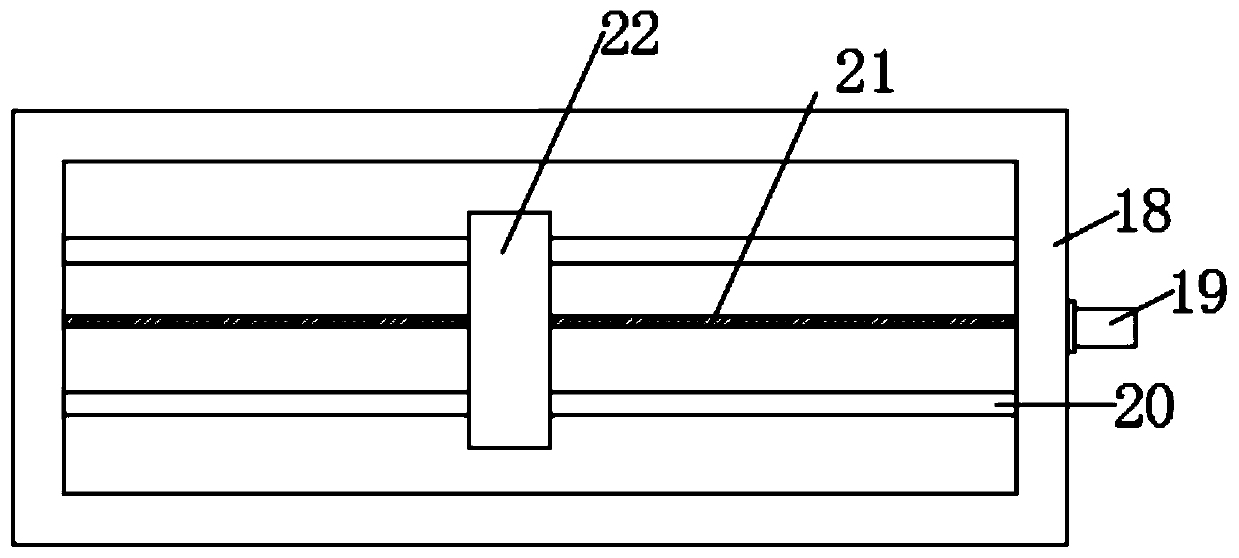

Automatic manufacturing all-in-one machine of paster for mobile terminal decoration and control method of all-in-one machine

ActiveCN106274083ASmall footprintShorten the timeTypewritersOther printing apparatusAssembly lineComputer terminal

The invention provides an automatic manufacturing all-in-one machine of paster for mobile terminal decoration and a control method of the machine. The automatic manufacturing all-in-one machine of the paster for mobile terminal decoration comprises a printer, a laminating machine and a cropping machine which are sequentially arranged from top to bottom and further comprises a first forwarding mechanism and a second forwarding mechanism; the first forwarding mechanism is arranged between the printer and the laminating machine and used for forwarding printed finished products output by the printer to a laminating part on a laminating plane of the laminating machine; the second forwarding mechanism is arranged between the laminating machine and the cropping machine and forwarding laminated finished products output by the laminating machine to the cropping machine; the whole automatic manufacturing all-in-one machine is of a layered structure, all machines are sequentially placed from top to bottom, the occupation space is reduced, meanwhile, the effect of the gravity of middle products of the paster is used for enabling the middle products of the paster to circulate among the printer, the laminating machine and the cropping machine, assembly line finishing of printing, heating, laminating and cutting is achieved, time is shortened, efficiency is improved, and the product quality is improved.

Owner:北京大秦新天下电子有限公司

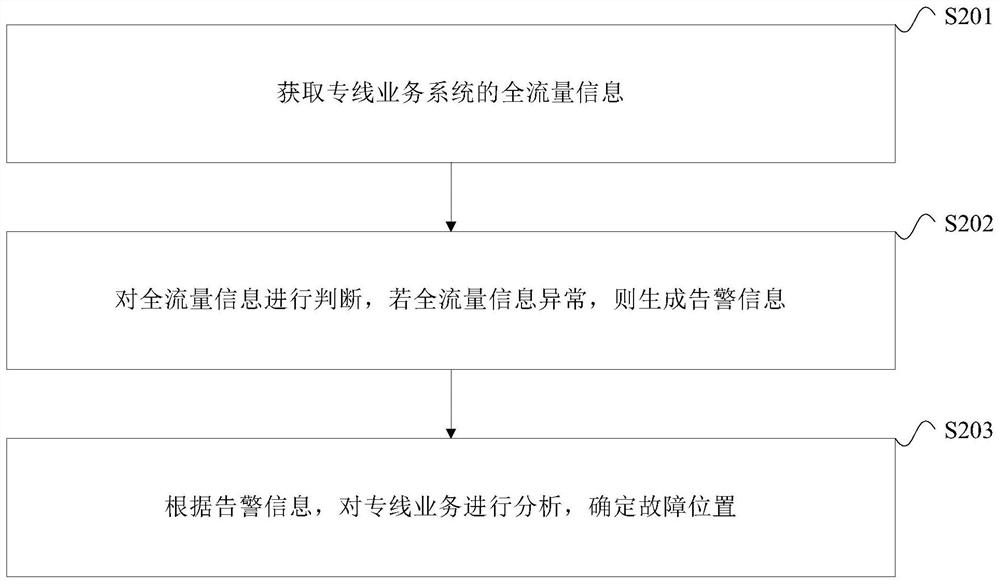

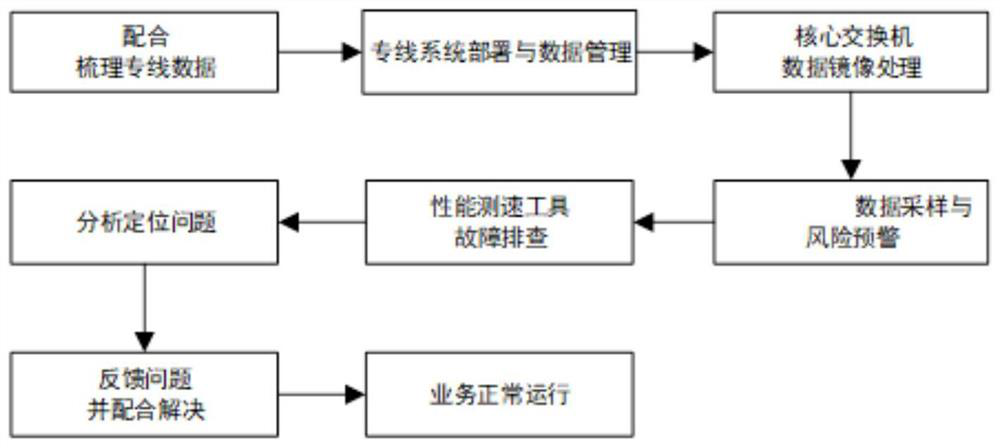

Network supervision method and device, equipment and storage medium

ActiveCN113179182AImprove accuracyImprove regulatory efficiencyData switching networksEngineeringReal-time computing

The invention provides a network supervision method and device, equipment and a storage medium. The method comprises the steps of: acquiring full-traffic information of a private line service system, wherein the full-traffic information comprises the traffic information of a user side and the traffic information of an operator side; performing abnormity judgment on the full-traffic information, and if the full-traffic information is abnormal, generating alarm information; and according to the alarm information, analyzing the private line service system and determining the fault position. By adopting he network supervision method and device, the fault position can be effectively and accurately positioned, manual positioning is not needed, the network supervision efficiency is improved, and the stability of the private line service system is improved.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

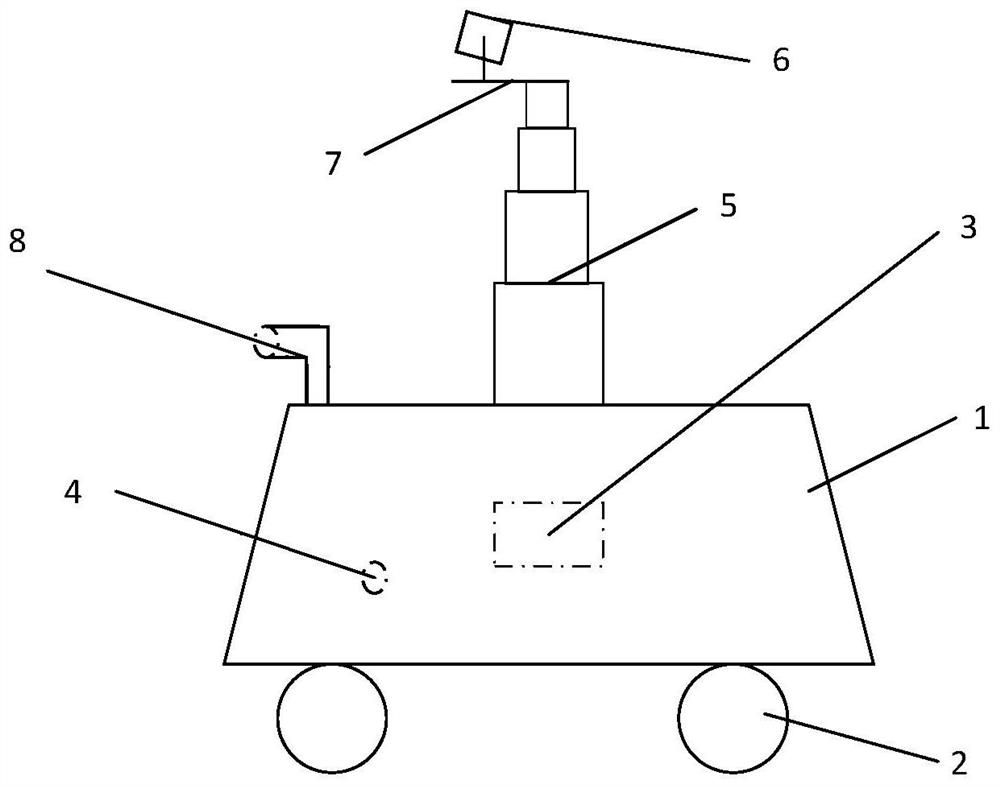

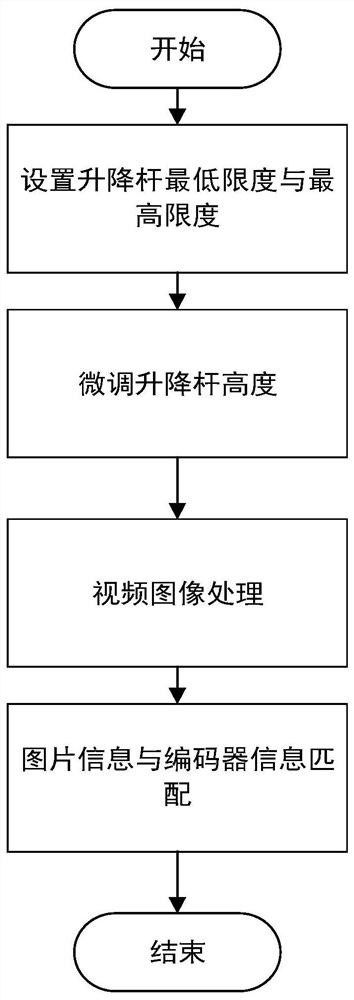

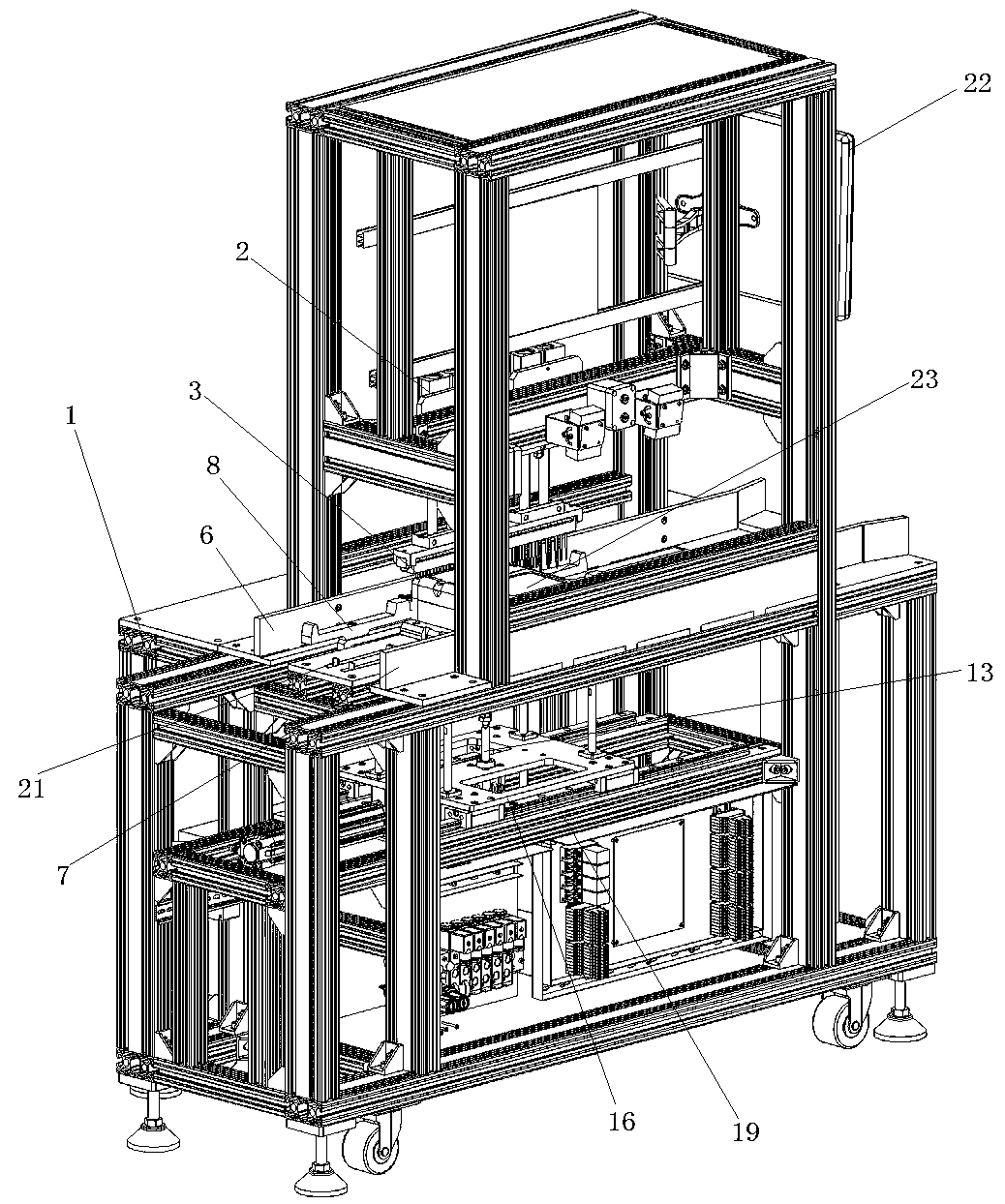

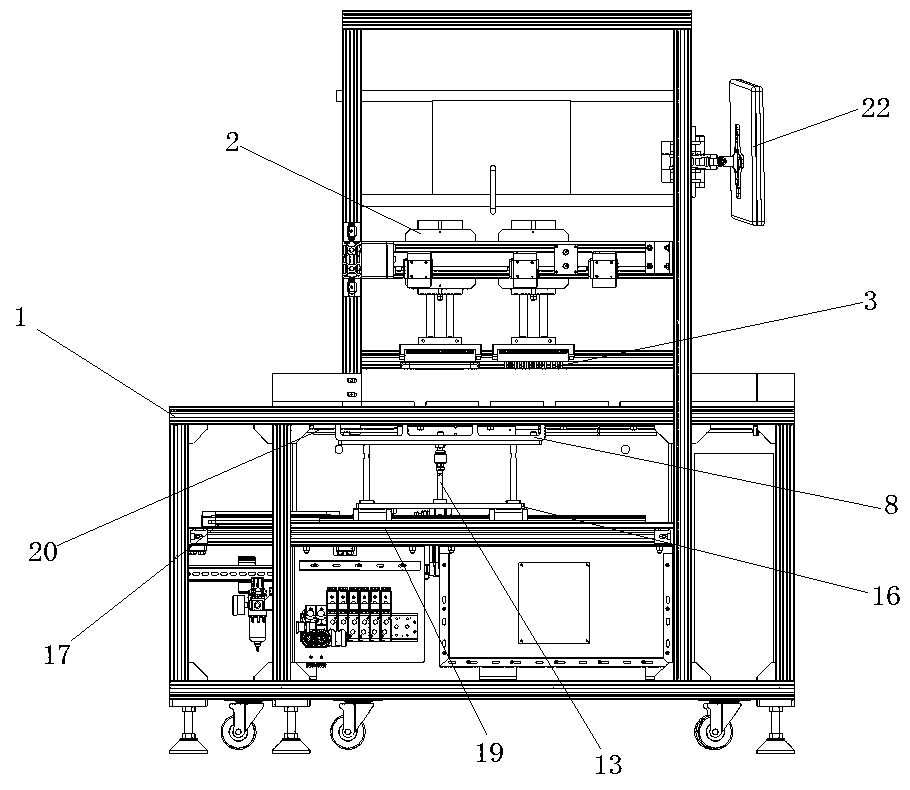

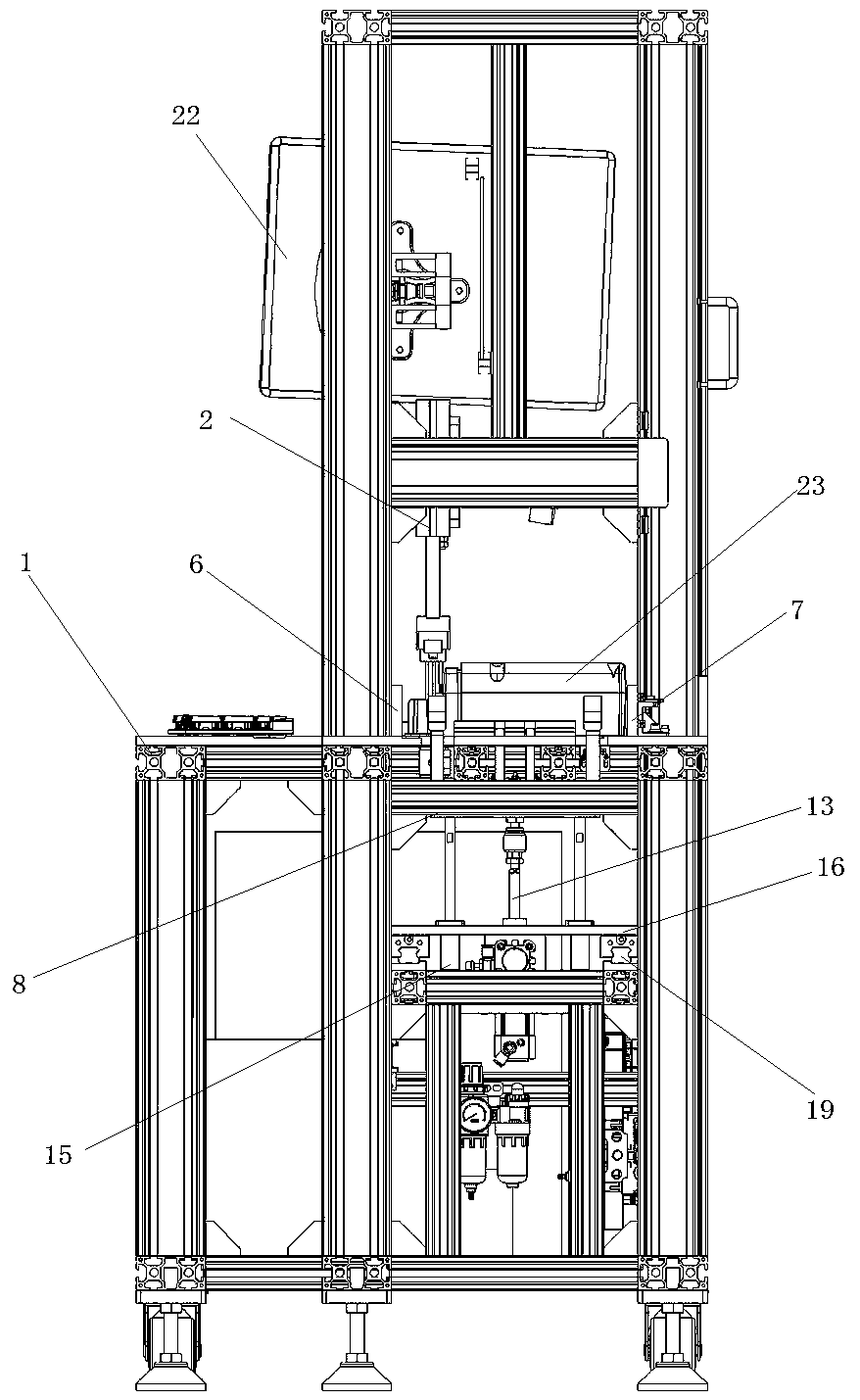

Unmanned inspection robot for power distribution room

ActiveCN112157642AImprove the level of intelligenceSave manpower and timeTelevision system detailsProgramme-controlled manipulatorControl engineeringCamera module

The invention relates to an unmanned inspection robot for a power distribution room. The unmanned inspection robot comprises a vehicle body, wheels, a vehicle body driving mechanism and a core controlboard, and further comprises a lifting holder, a camera holder, a camera module, a direct current motor with an encoder and a magnetic conduction sensor which are correspondingly connected with the core control board; and a magnetic circuit is laid in front of a power distribution cabinet in the power distribution room. The power distribution room inspection process comprises the steps of 1), controlling the lifting holder to be at the lowest height; 2), performing uniform inspection along the magnetic circuit according to the magnetic conduction sensor, and acquiring an inspection image in real time through the camera module until one round of inspection is completed; and 3), controlling the lifting holder to ascend, and repeatedly executing the steps 2) and 3). The core control board identifies an electric energy meter detecting device arranged on the power distribution cabinet from the inspection image so as to acquire the position of the power distribution cabinet and the height of the electric energy meter detecting device. According to the unmanned inspection robot for the power distribution room, compared with the prior art, manual time can be greatly saved, meanwhile, manual positioning is not needed, efficiency is greatly improved, and potential safety hazards can be reduced to the minimum.

Owner:SHANGHAI DIANJI UNIV

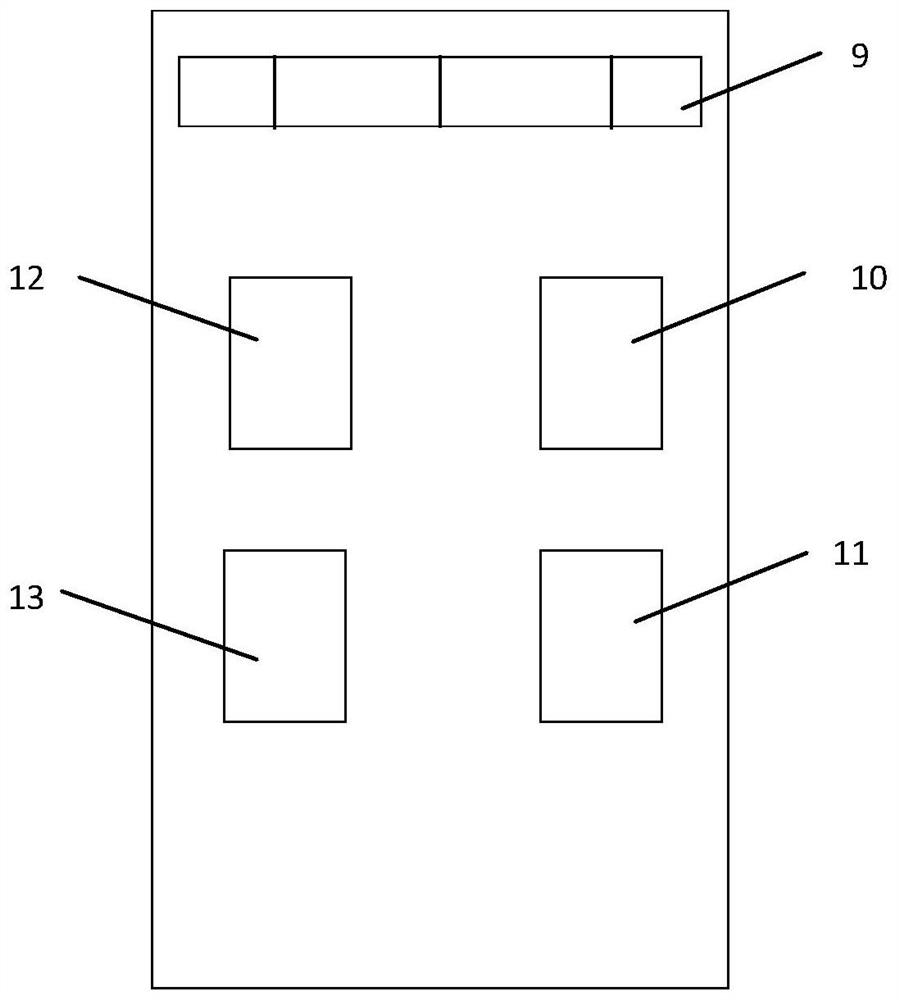

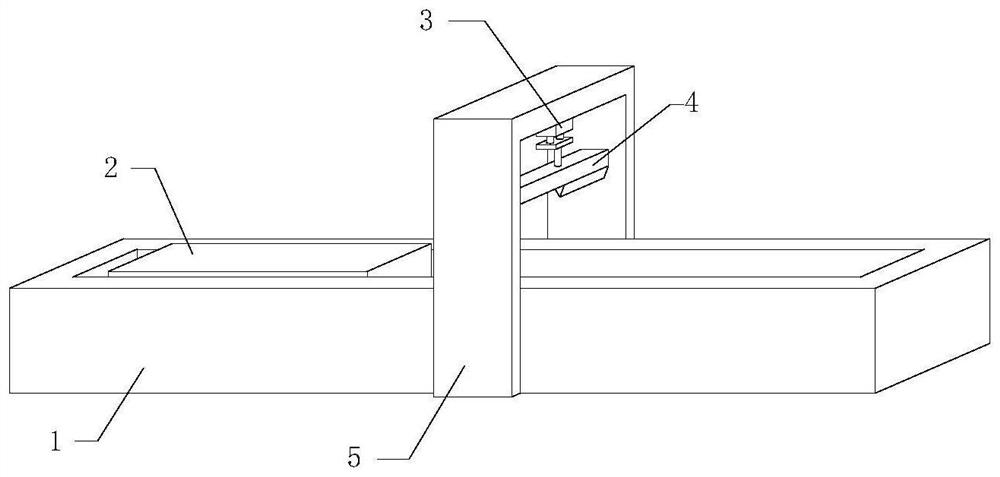

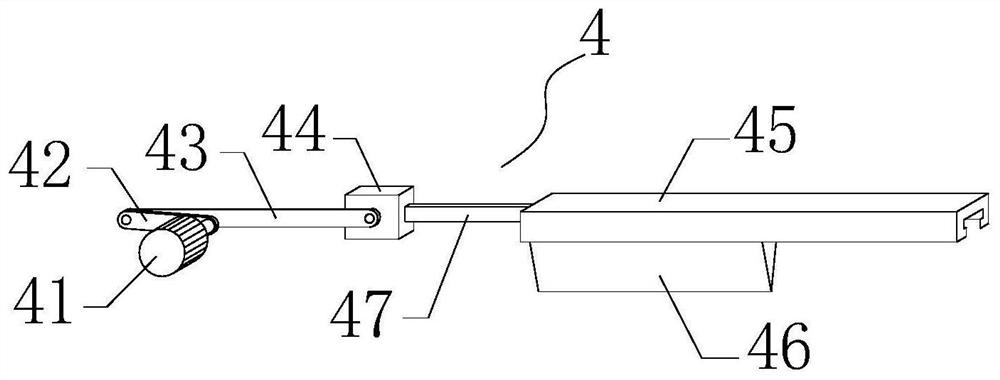

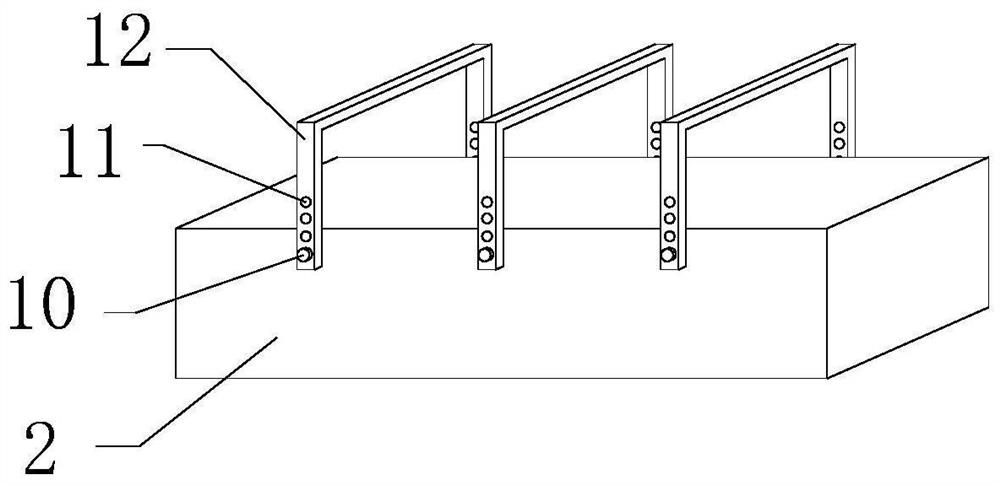

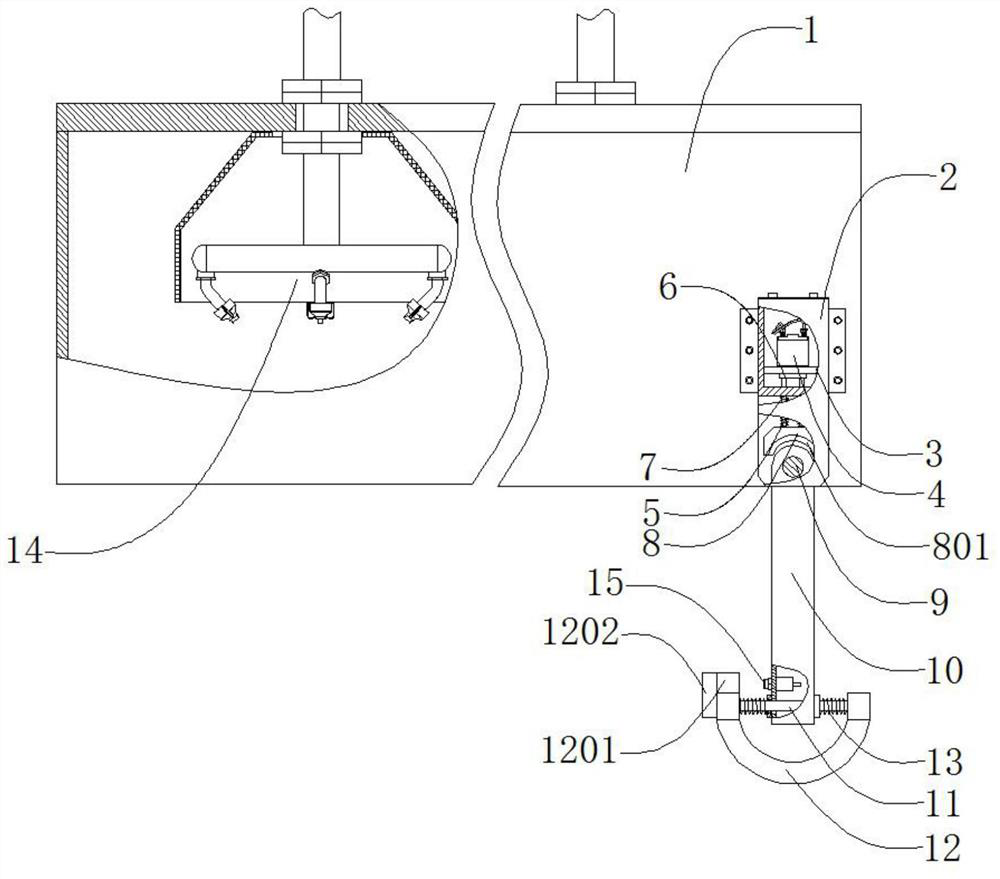

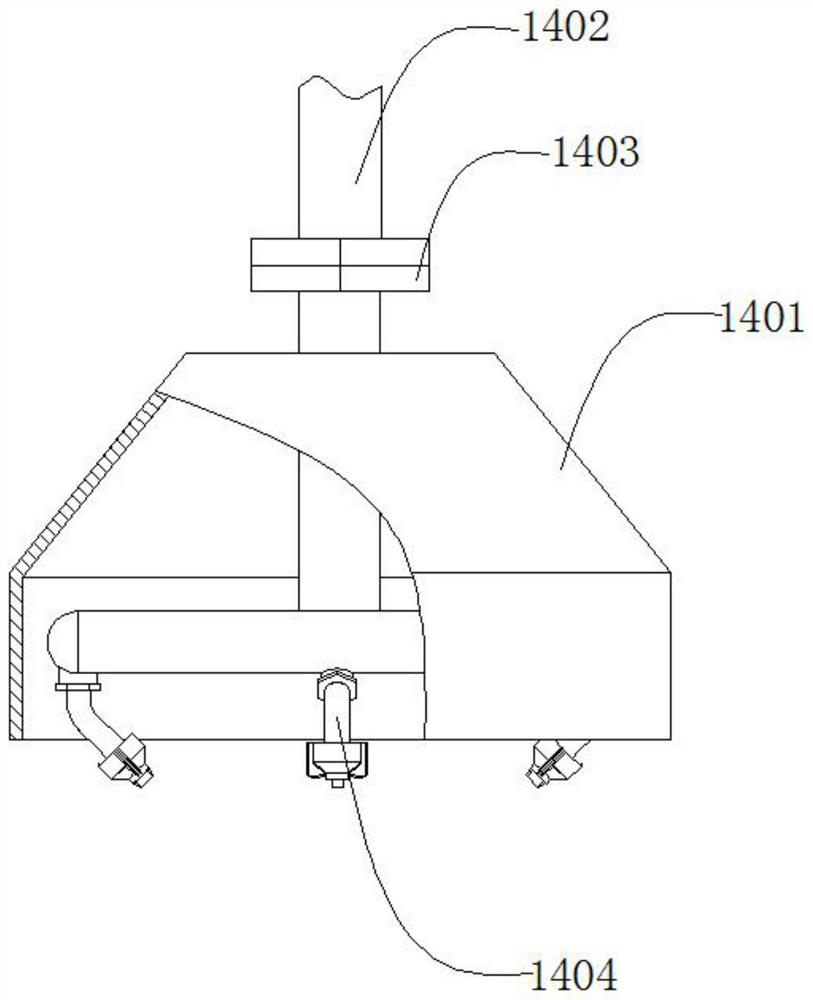

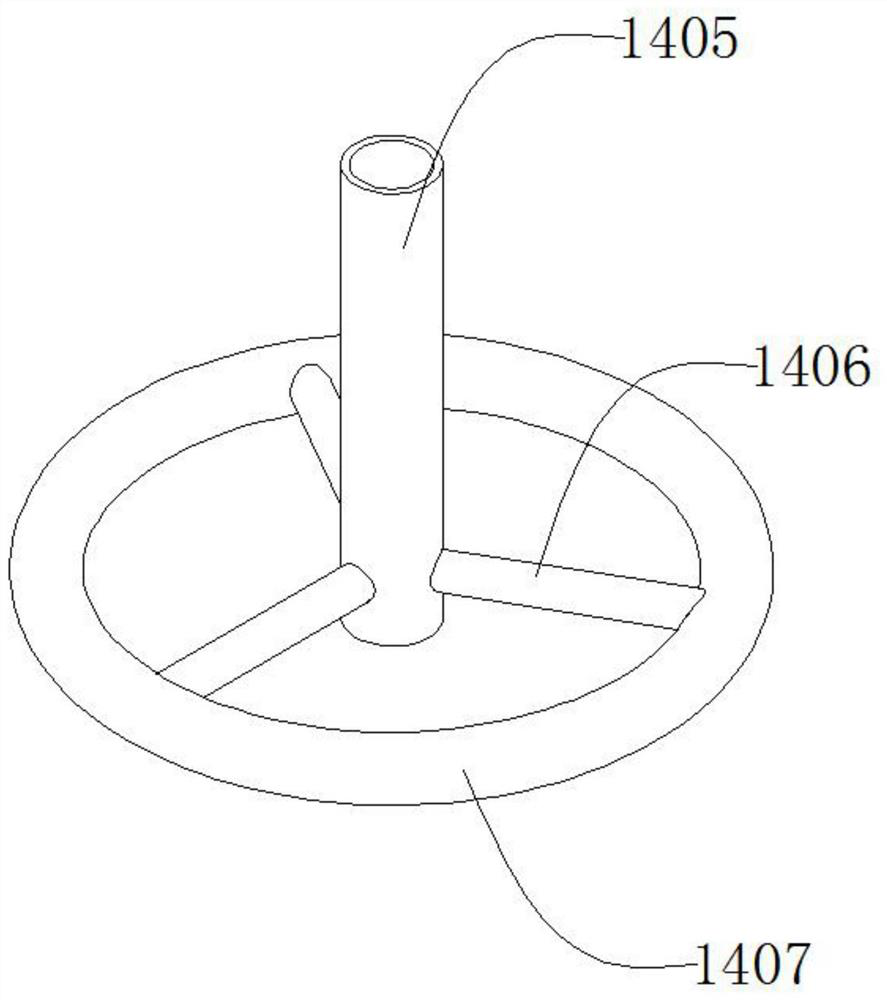

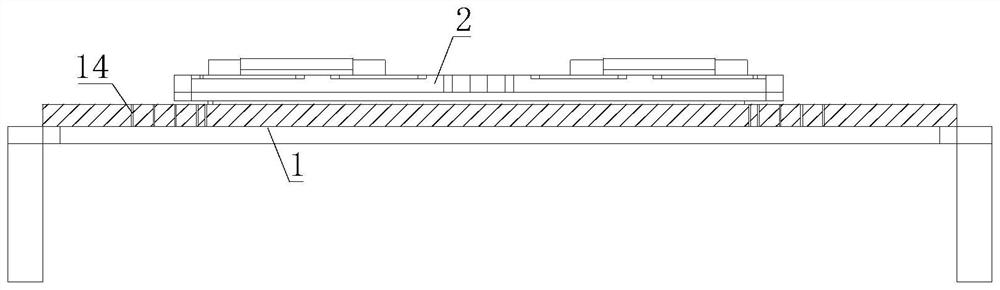

Electric energy meter testing device

InactiveCN111308410AAvoid manual electric shockSave human effortElectrical measurementsElectric energyTest bench

The invention relates to an electric energy meter testing device. The electric energy meter testing device comprises a testing platform, an electric energy meter testing mechanism, an electric energymeter transferring mechanism and a controller. The testing platform is provided with an electric energy meter positioning structure used for supporting and positioning an electric energy meter to be tested; the electric energy meter testing mechanism is provided with a testing probe which can be lifted up and down and is used for realizing contact and separation with a contact terminal of a to-be-tested electric energy meter; the electric energy meter transferring mechanism is used for transferring the tested electric energy meter from the positioning structure to a set position; the electricenergy meter transferring mechanism comprises a lifting part and a moving part; the lifting part is installed on the moving part; a lifting path and a moving path of the electric energy meter transferring mechanism avoid the testing platform; and the controller is used for controlling the lifting part and the moving part to move. The electric energy meter testing device is high in automation degree, can save a large amount of manpower, and improves the detection efficiency of the electric energy meter.

Owner:XUJI GRP +2

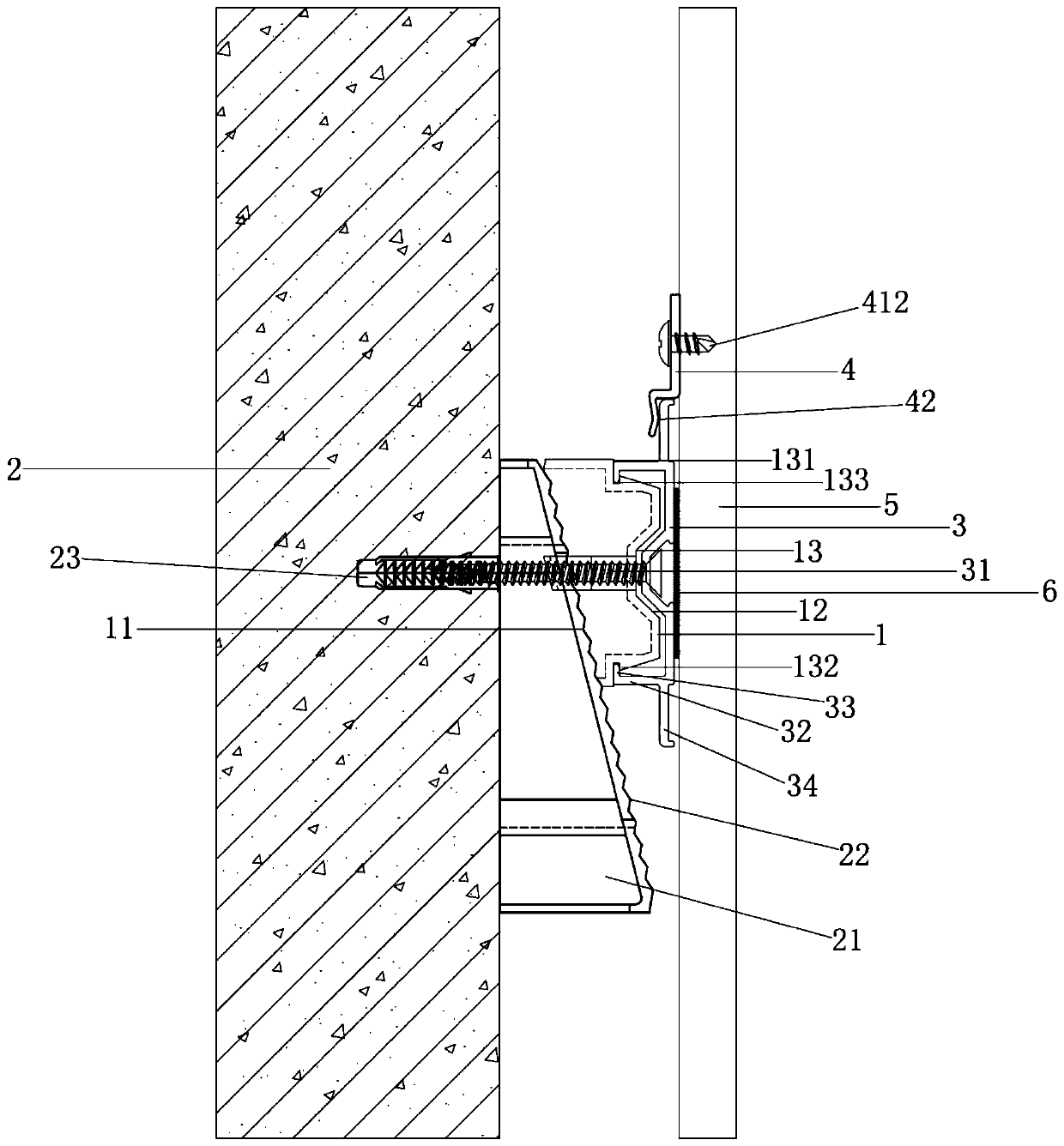

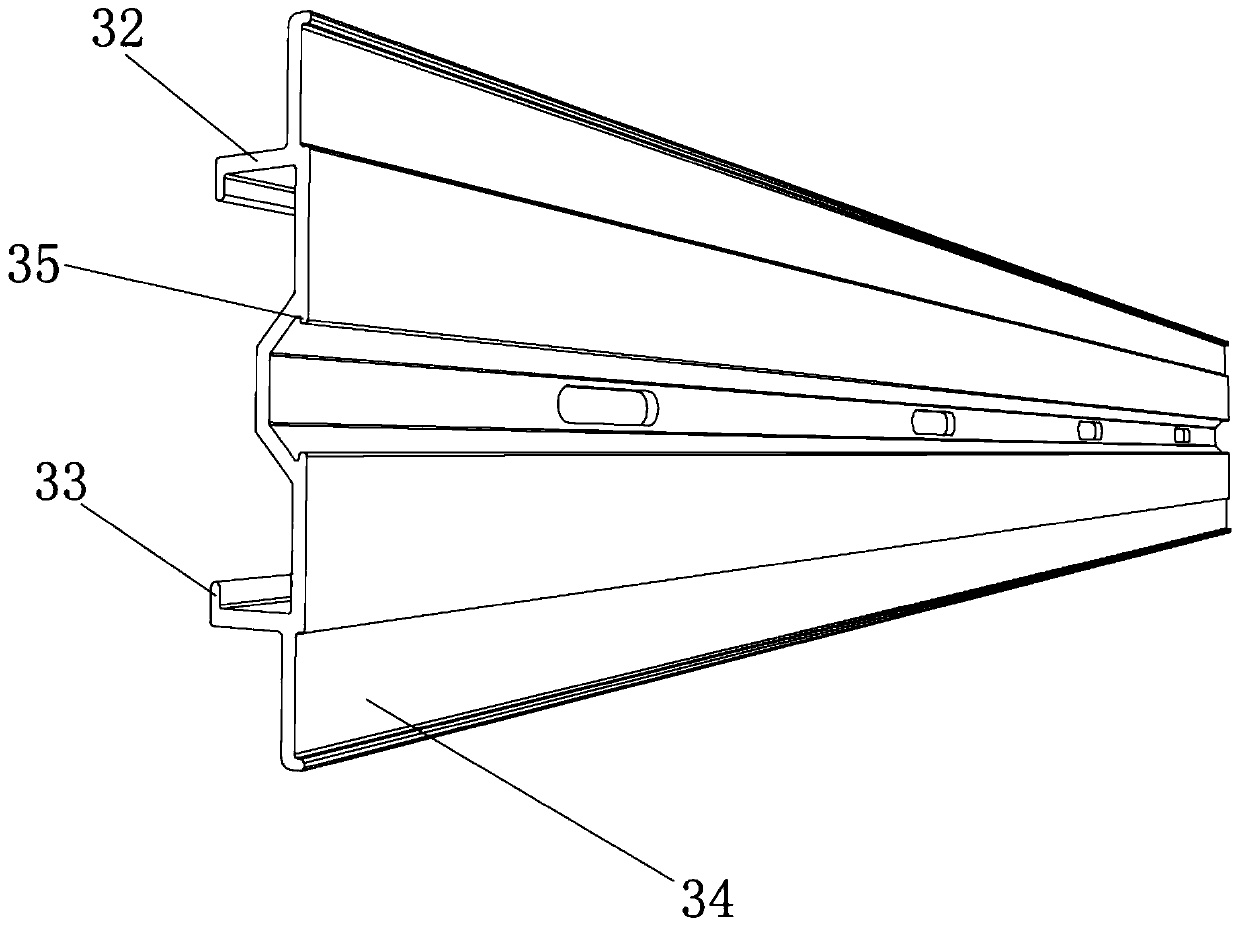

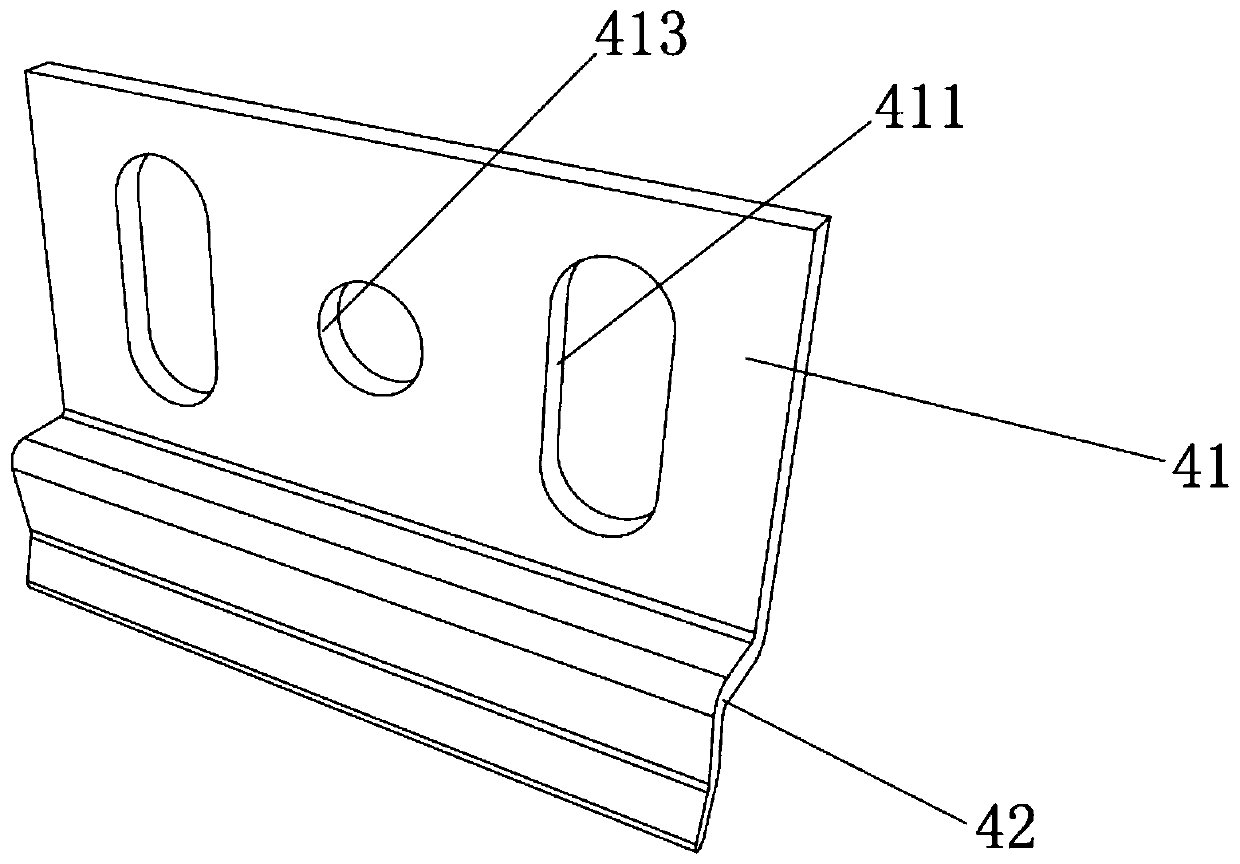

Convenient wall panel dry hanging installation structure and method

PendingCN110761515AReduce construction stepsReduce construction costsCovering/liningsKeelScrew joint

The invention provides a convenient wall panel dry hanging installation structure. The convenient wall panel dry hanging installation structure includes a first transverse keel, a second transverse keel, an adjustable dry hanging piece and a wall panel, wherein the first transverse keel is connected to a wall, the first transverse keel is provided with a W-shaped bending surface, the two oppositesides of the W-shaped bending surface are correspondingly connected with the edges of second connecting surfaces through a step, the edges of the W-shaped bending surface form chamfered surfaces extending outwards at the step, and clamping grooves are formed between the end parts of the chamfered surfaces and the step; the second transverse keel is bent into a W shape, the center part of the second transverse keel is connected to the center part of the first transverse keel through screws in a screw joint mode, and two right angle bending hooks are correspondingly arranged on the two oppositesides of the second transverse keel and are clamped into the clamping grooves; the adjustable dry hanging piece includes a dry hanging piece body and an elastic plate, the side of the dry hanging piece body is in an L shape, and the elastic plate is fixedly connected to the bottom end of the dry hanging piece body; and the wall panel is fixedly connected to the dry hanging piece body. The invention further provides an installation method. According to the convenient wall panel dry hanging installation structure and method, the construction cost can be reduced, manual positioning is not required, the construction is more convenient, and the loosening phenomenon is reduced.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Method and device for testing automobile plastic part

PendingCN106767264AEasy to operateShort timeMechanical counters/curvatures measurementsMechanical solid deformation measurementsComputer moduleEngineering

Owner:SHANGHAI YONGXING PLASTICS

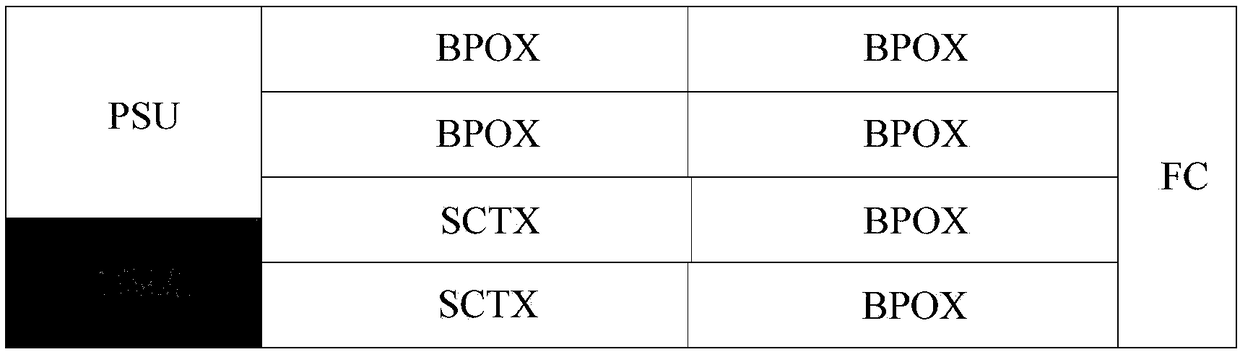

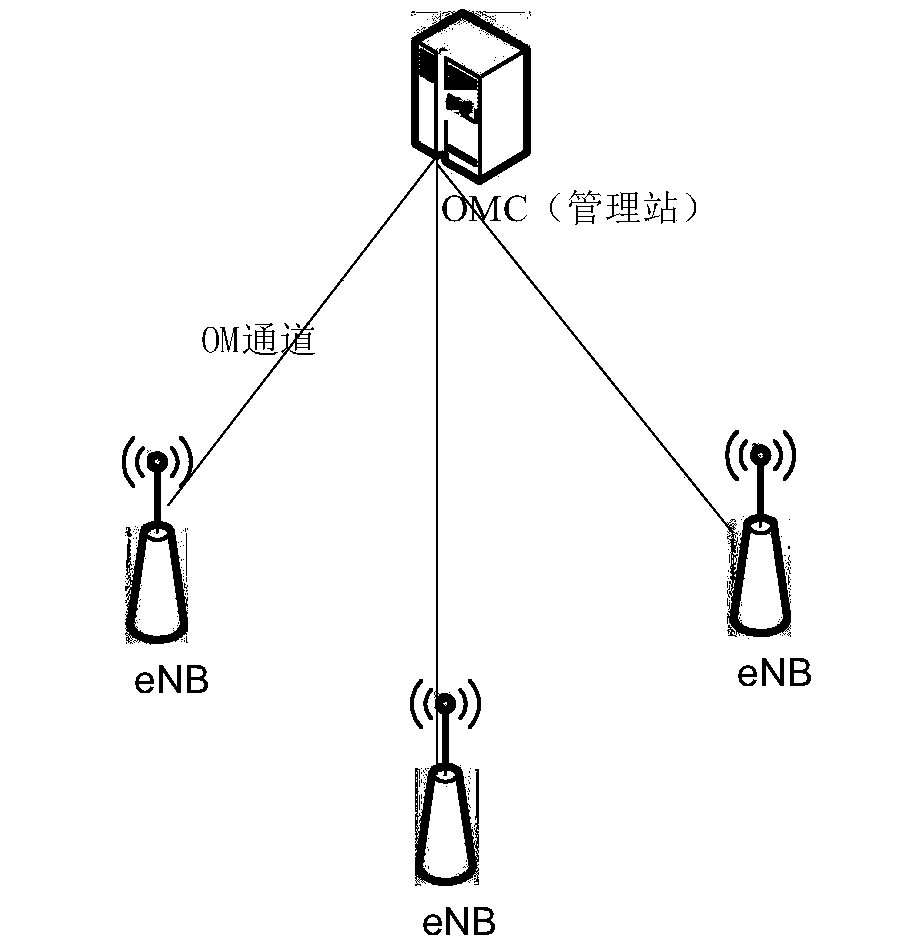

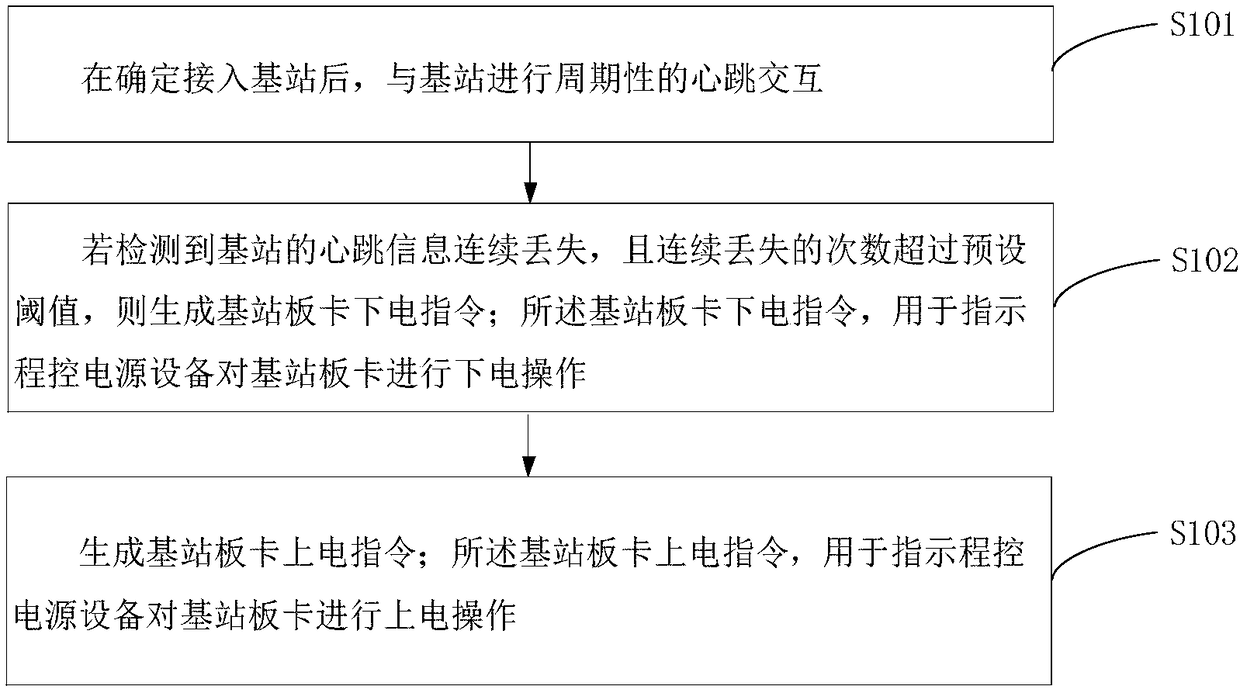

Automatic power-off recovery method and device after base station fault

InactiveCN109391987ANo need for manual positioningSave human resourcesSubstation remote connection/disconnectionHigh level techniquesRecovery methodElectricity

The embodiment of the invention provides an automatic power-off recovery method and device after a base station fault. In the method, a programmable power supply device performs the periodic heartbeatinteraction with a base station, and it is considered that the base station has a fault of software death when the number of continuous loss times of the heartbeat of the base station is judged to exceed a preset threshold value, and a base station board card power-off instruction is instantly generated so as to enable all board cards of the base station to be electrically disconnected. After a preset time period, the board card of the base station is considered to complete the power-off operation, and at this moment, a base station board card power-on instruction is generated to enable the base station to restore the power-on start. Therefore, the method can timely find out the fault of the base station after the death of the software of the base station, and there is no need of manual positioning. Moreover, the method can achieve the automatic power-off and restart of the base station when there is a fault, so as to enable the base station to return to a normal state. The method reduces the adverse effect to maximum degree, saves time, is efficient, and effectively saves the manpower resources.

Owner:DATANG MOBILE COMM EQUIP CO LTD

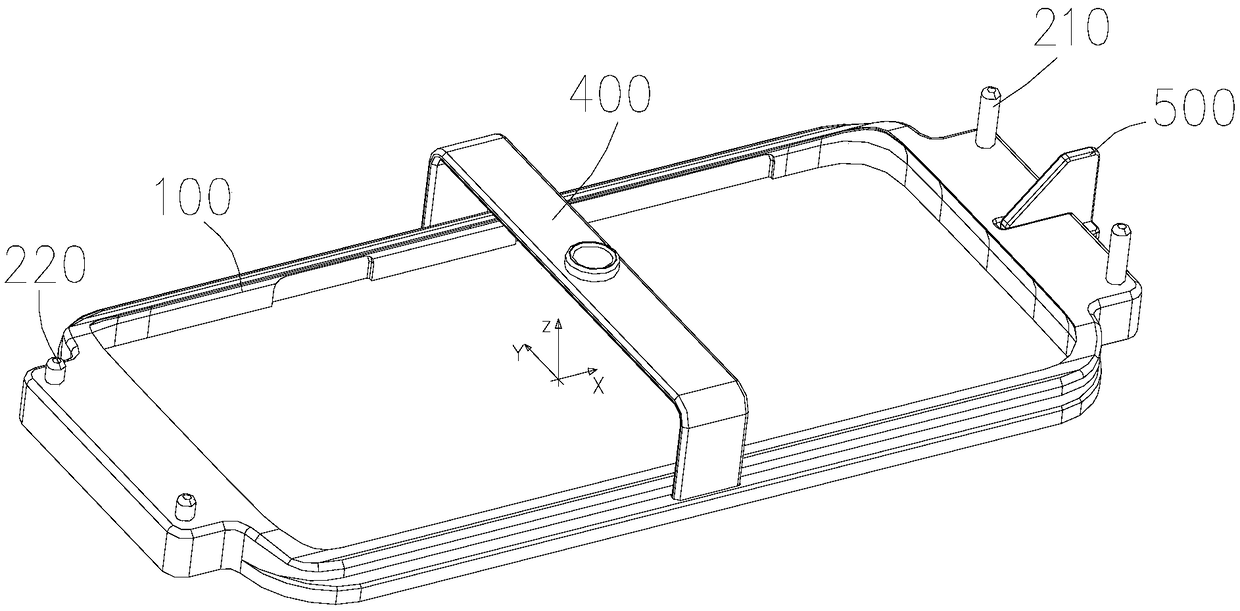

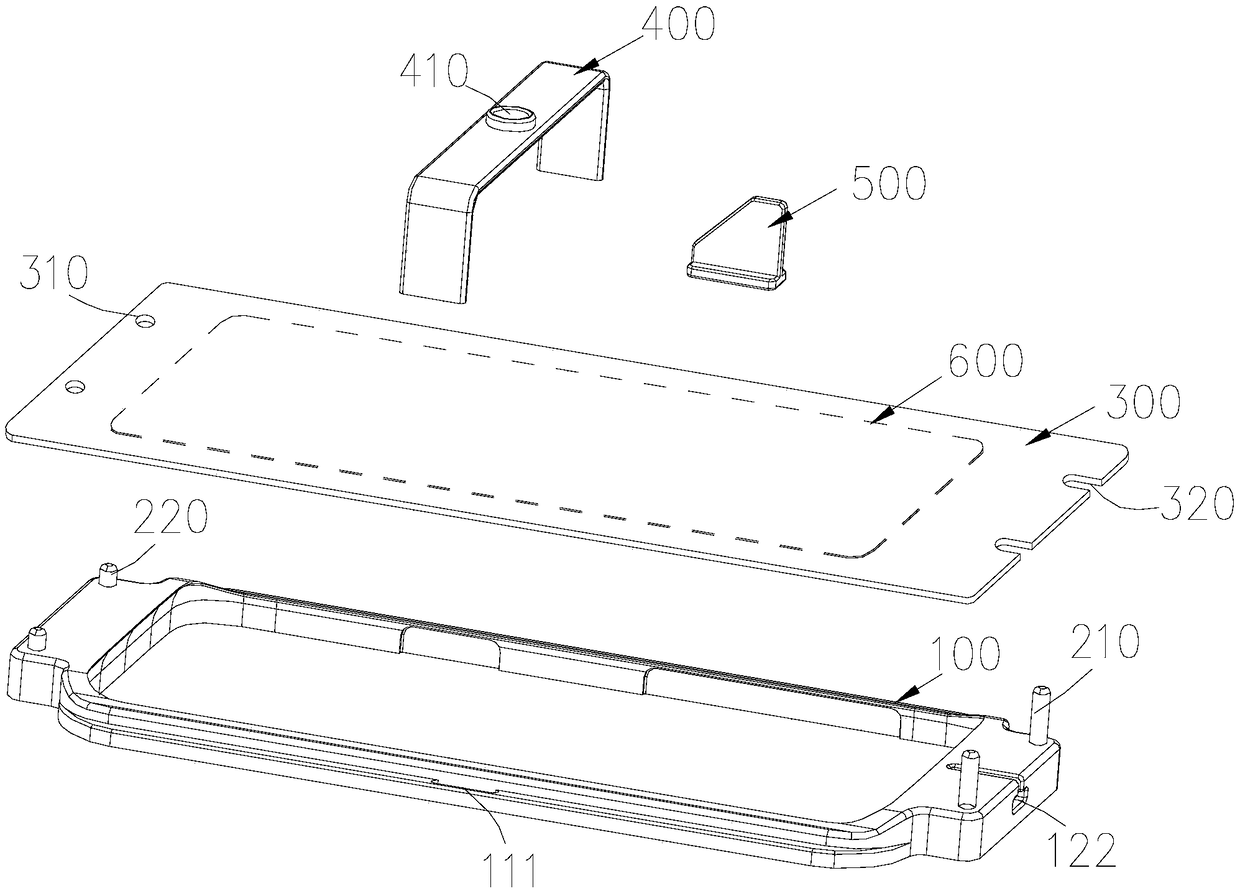

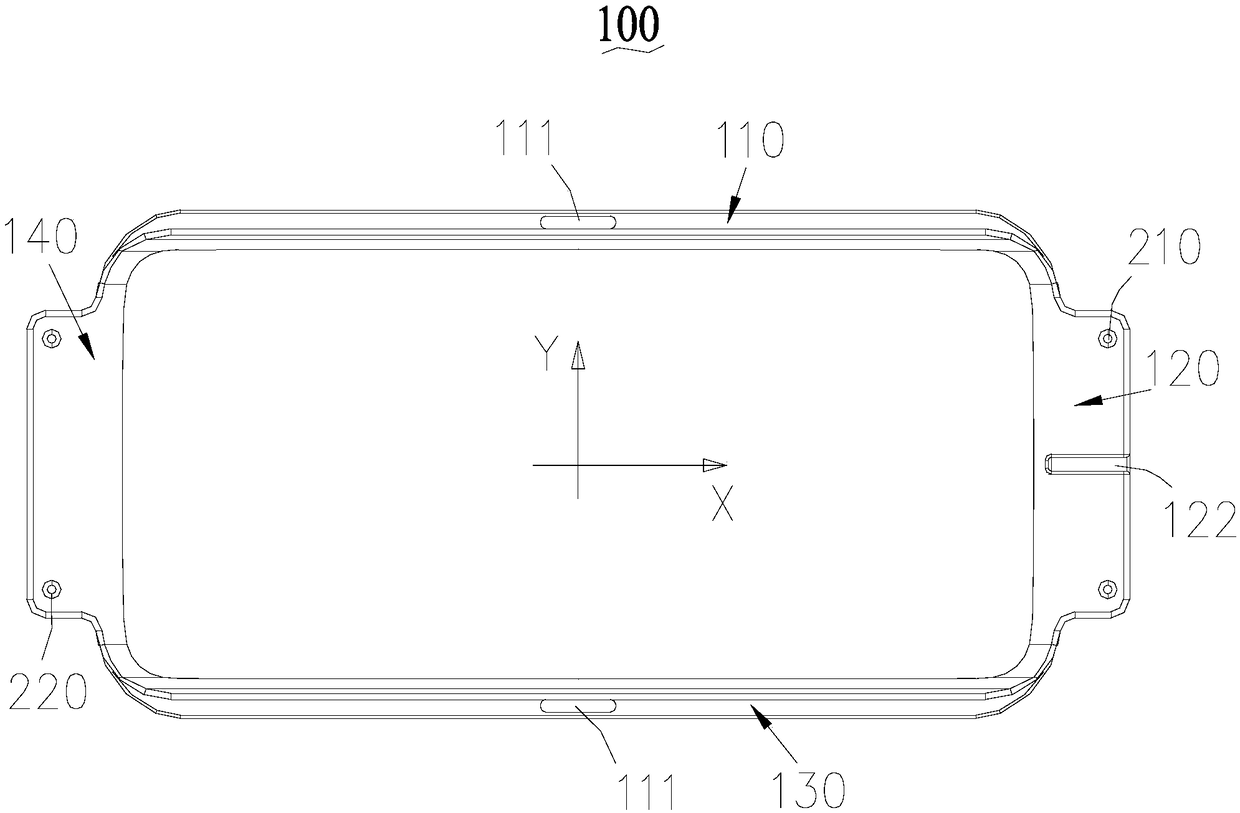

Electronic product membrane sticking device and membrane sticking method

The invention is suitable for the field of electronic product accessories, and particularly relates to an electronic product membrane sticking device and a membrane sticking method. The electronic product sticking device is used for sticking a protective membrane to an electronic product. The electronic product sticking device comprises: a retaining plate, which is provided with a retaining hole through up and down for fixing the electronic product, and the shape of the cavity of the fixing hole is matched with the shape of the electronic product when the operation face faces upwards; a positioning assembly, which comprises a right positioning column and a left positioning column; a hard flat plate having a preset area for detachably bonding the protective membrane in the plate surface towards the fixing plate; a left positioning through hole matched with the left positioning column is arranged on the plate surface of the hard flat plate towards the fixing plate, and a right positioning through groove is matched with the right positioning column and penetrates through the right positioning through groove. The electronic product membrane sticking device disclosed by the invention has the advantages of convenient operation, no need of manual positioning and rapid membrane sticking, so that the membrane sticking effect is good and stable.

Owner:SHENZHEN KANGCHENGTAI IND CO LTD

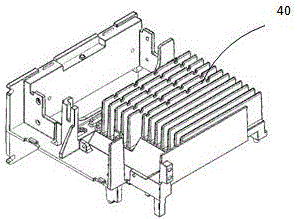

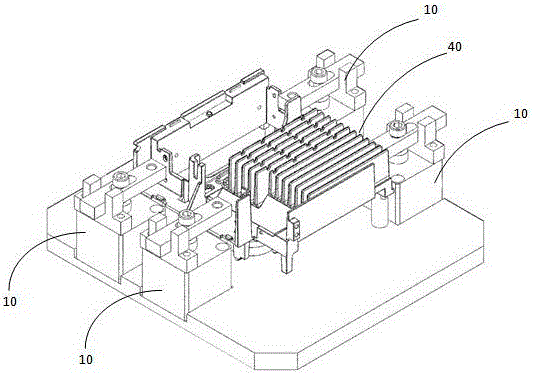

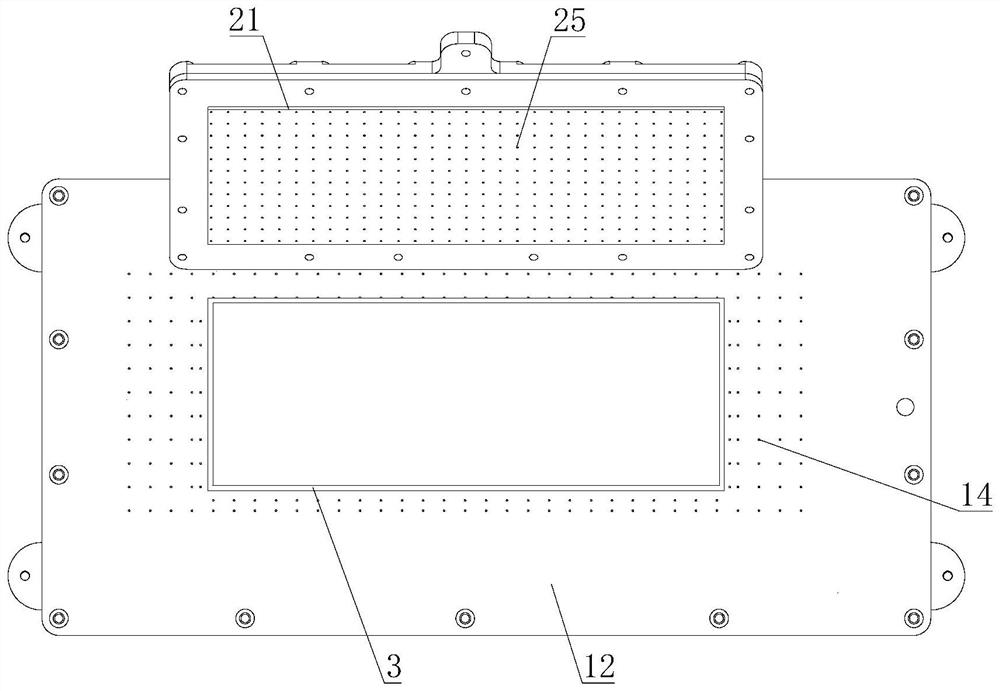

Back tool clamp of radiator

InactiveCN106425598AHas a guiding roleNo need for manual positioningWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention provides a back tool clamp of a radiator, and the back tool clamp can solve the technical problems that an existing clamp is relatively complex in use for clamping the radiator and is low in clamping efficiency. The back tool clamp comprises a bottom plate. The back tool clamp is characterized in that clamping mechanisms are separately arranged at the two sides of a bottom plate, wherein each clamping mechanism comprises an air cylinder, a pressure plate, a guide base and a fixed part; one end of each pressure plate is used for pressing the radiator, and the other end of each pressure plate is in sliding connection with a slide slot of the corresponding guide base; a strip-shaped through slot is formed each the pressure plate; one end of each fixed part passes through the strip-shaped through slot for fixing the corresponding pressure plate to the end part of the piston rod of the corresponding air cylinder; each fixed part is detachably connected with the piston rod of the corresponding air cylinder; each guide base is fixedly arranged on the bottom plate or the corresponding air cylinder; and a positioning mechanism which corresponds to the through hole in the bottom of the radiator is further arranged on the bottom plate.

Owner:WUXI TAICHANG PRECISION MACHINERY CO LTD

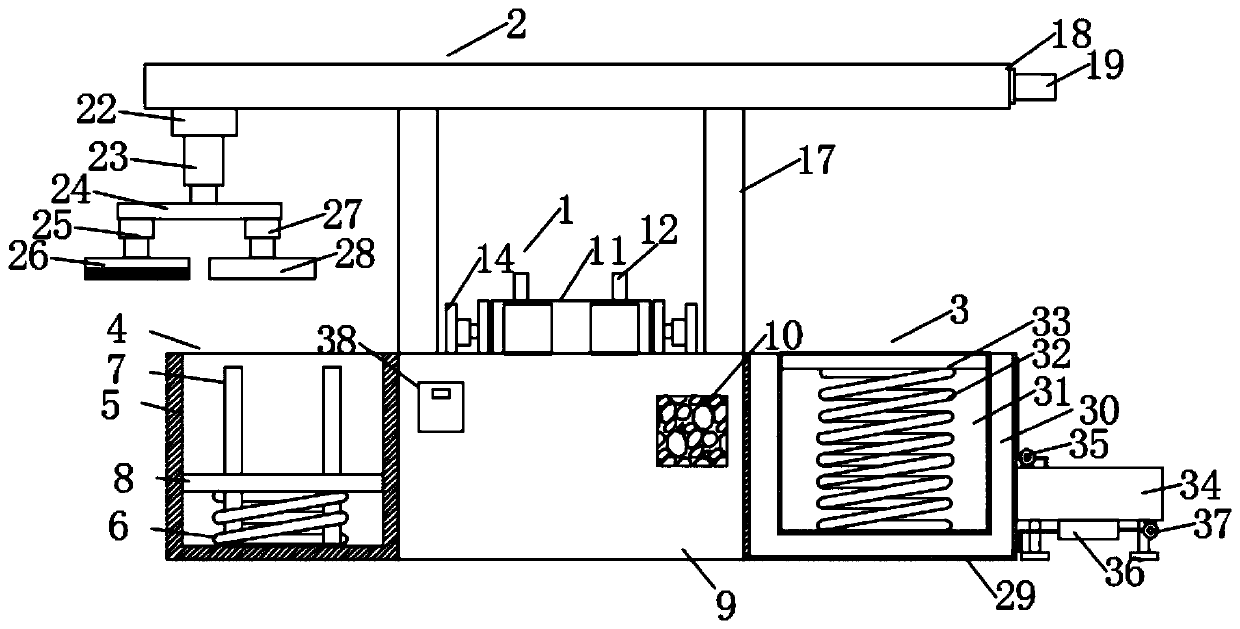

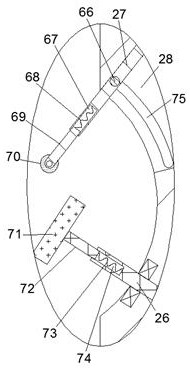

Rounding device for automobile spokes

ActiveCN110064683AEasy to storeEasy to limitShaping toolsMetal-working feeding devicesUltimate tensile strengthCooling time

The invention discloses a rounding device for automobile spokes. The rounding device comprises a rounding mechanism, a feeding mechanism, a cooling mechanism and a storing mechanism; and the feeding mechanism is arranged above the rounding mechanism, the cooling mechanism is arranged at one end of the rounding mechanism, the storing mechanism is arranged at the end, far away from the cooling mechanism, of the rounding mechanism, and the storing mechanism is composed of a storage tank, a reset spring positioning rod and a reset ejection plate. According to the rounding device, workpieces are conveniently stored and limited, the angles and positions of the spokes are conveniently determined, angle fixation of the spokes is conveniently achieved, the spoke fixing efficiency is greatly improved, the need for manual positioning is avoided, and the labor intensity of workers is reduced. A limit pressing plate is arranged, and therefore the spokes can be fixed, latches or bolts are avoided, the rounding device is convenient and quick, and the working efficiency of the rounding device for the spokes is improved; and a cooling water tank is arranged, cooling of the workpieces is facilitated, the cooling time is greatly shortened, and the cooling rate is increased.

Owner:瑞安市浙工大创新创业研究院

Polishing device for automobile parts

ActiveCN108406479AAchieve grindingPrecise penetrationEdge grinding machinesGrinding drivesGear wheelEngineering

The invention relates to the technical field of machining of automobile parts, and discloses a polishing device for automobile parts. The polishing device comprises a rack and a motor, and a main bevel gear is fixed to an output shaft of the motor; a supporting shaft is arranged at the bottom of the main bevel gear, friction plates slidably connected with the main bevel gear are arranged on the two sides of the supporting shaft, and protruding blocks are fixed to the friction plates correspondingly; a compressed spring is fixed between the protruding blocks, and the bottoms of the friction plates are both bevels inclined towards the supporting shaft; the lower portion of the main bevel gear is further provided with a telescopic air cylinder and a supporting seat; the supporting seat comprises a fixed seat body and a sliding seat body, a telescopic rod of the telescopic air cylinder is fixedly connected with the sliding seat body, the sliding seat body is slidably connected with a positioning rod matched with the friction plates, and the bottom of the positioning rod is provided with a reset spring; and the rack is rotatably connected with a secondary bevel gear which is engaged with the main bevel gear, the rack is provided with a lead screw, the secondary bevel gear drives the lead screw to rotate, and a nut seat of the lead screw is fixedly connected with the fixed seat body.According to the polishing device for the automobile parts, the structure is simple, and part holes and the bottom faces of the parts can be polished and deburred.

Owner:涟源市普东汽车配件铸造有限公司

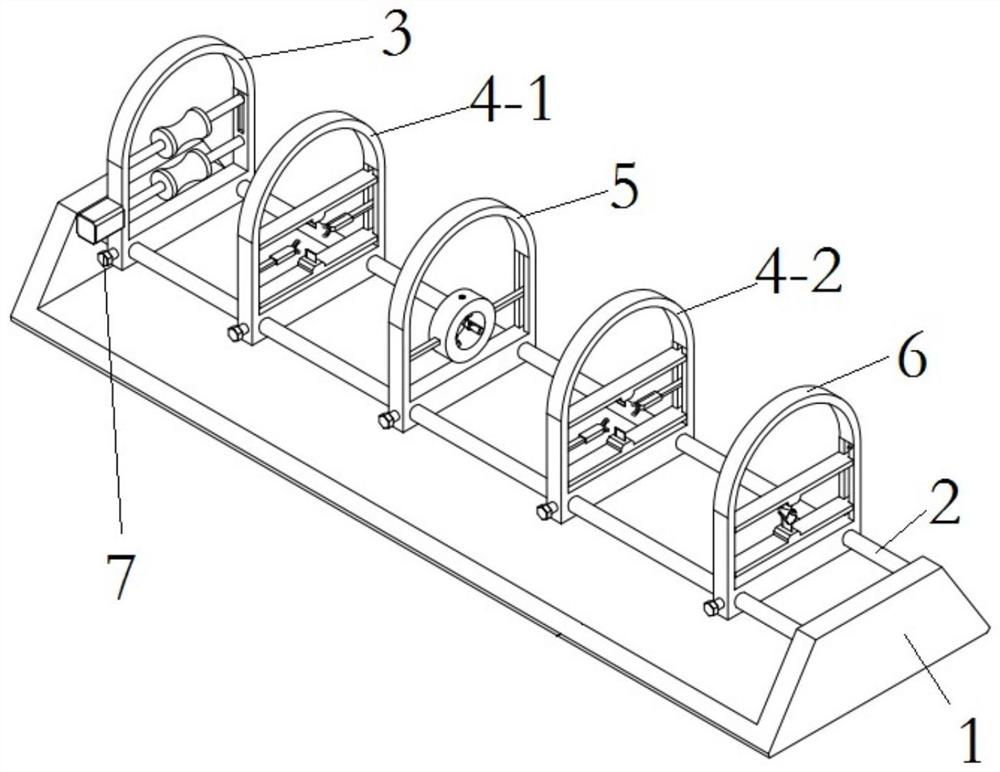

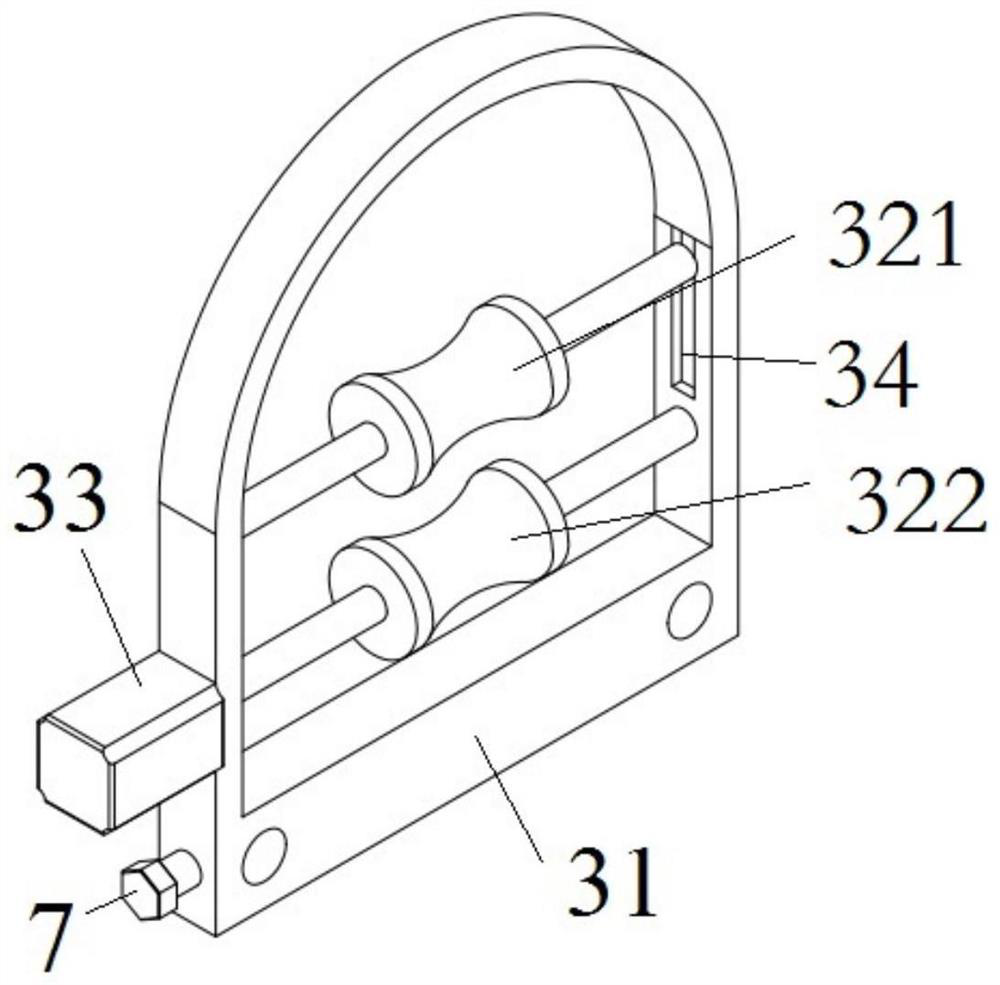

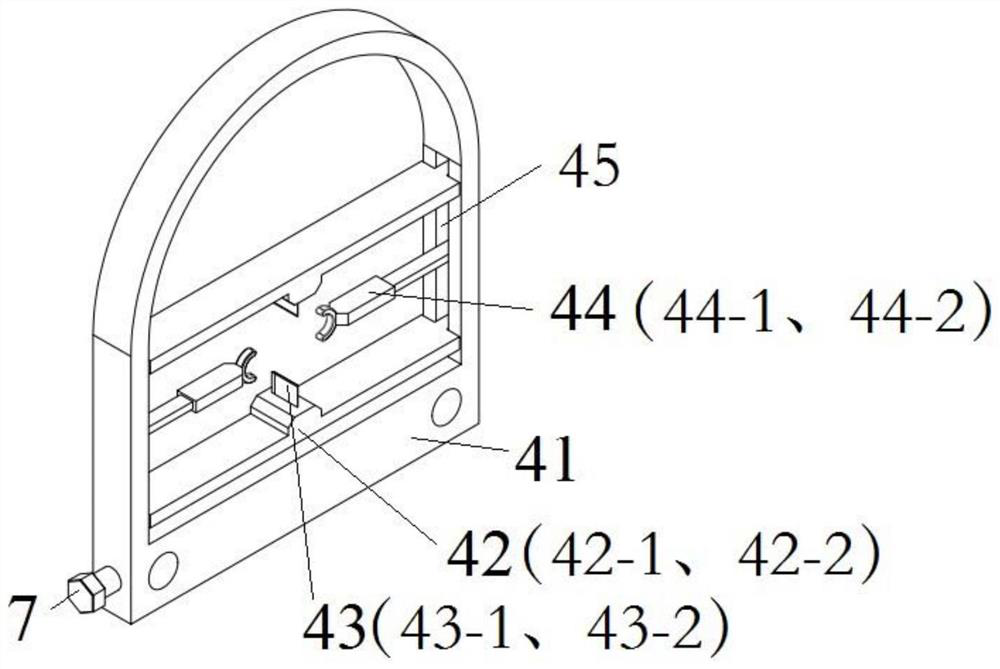

Large-diameter cable stripping machine and stripping method for power supply company

ActiveCN112217154AEat lessSmall cutting resistanceApparatus for removing/armouring cablesElectric cablesManufacturing engineering

The invention relates to a large-diameter cable stripping machine for a power supply company and a stripping method. According to the technical scheme, the large-diameter cable stripping machine for the power supply company comprises a base, a conveying mechanism and a cutter mechanism are installed on the base, and the cutter mechanism comprises a first cutter mechanism body and a second cutter mechanism body which is arranged behind the first cutter mechanism body and right faces the first cutter mechanism body. The cable sheath cutting device has the beneficial effects that the two stages of cutter mechanisms are arranged, thick cable sheaths are cut twice, the cutting depth during cutting of each stage is reduced, the cutting resistance is reduced, the cutting efficiency is improved, meanwhile, the stress of the cutters is reduced, the cutters are not prone to damage, the service life is prolonged, and the safety is improved. Meanwhile, the stripping method is convenient in cable installation, does not need manual positioning after installation, and reduces the labor cost.

Owner:国网山东省电力公司聊城市茌平区供电公司 +1

Leg fixing clamp for orthopedic surgery

ActiveCN111973289AGuaranteed positioningReduce fatigueOperating tablesDiagnosticsOrthopedics surgeryOrthopedic department

The invention discloses a leg fixing clamp for orthopedic surgery. The leg fixing clamp comprises a bottom plate, two adjusting devices, a lapping device, a sliding frame and a positioning device, wherein the two adjusting devices are installed at the left end and the right end of the bottom plate, and the lapping device is connected between the adjusting devices; and the sliding frame is arrangedabove the lapping device, and the positioning device is installed on the sliding frame. The situation that the pressing difficulty of medical staff is greatly increased due to the facts that the operation process is long and the wounded move disorderly due to tension and pain in the operation during manual pressing can be solved, the discomfort of the wounded due to excessive pressing can be avoided in the pressing process, and in the operation process, operation towels need to be laid on wounds of the legs of the wounded, and due to the fact that the legs are in a bent state or shake in theoperation process, the operation towels which are difficult to place for a long time can be straightened in time in the operation.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

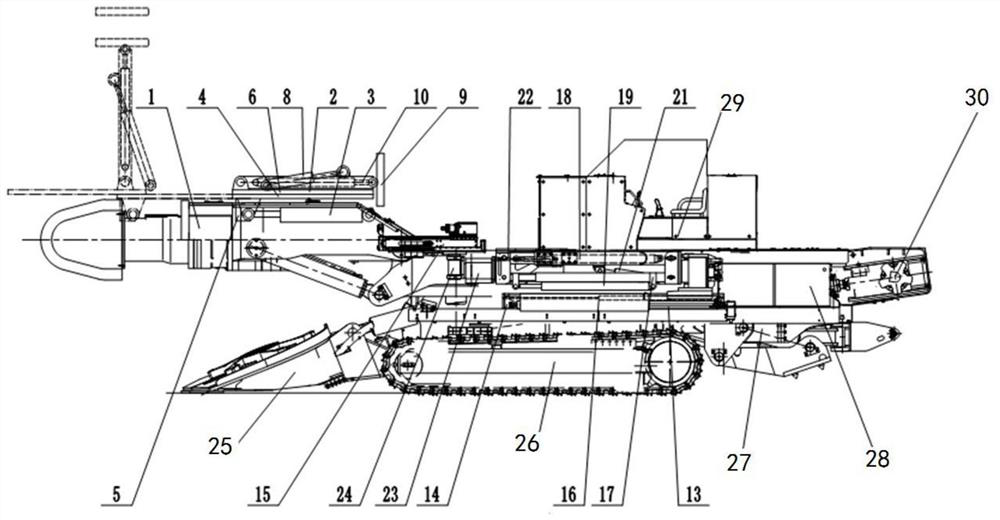

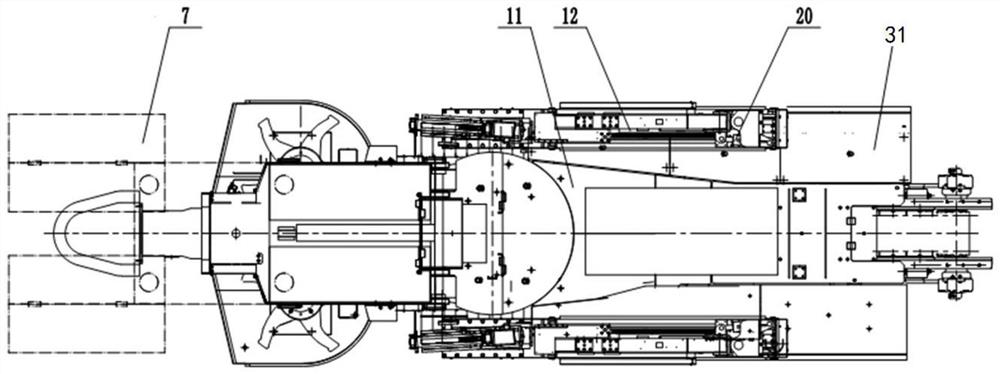

Excavation and anchoring all-in-one machine used for all-rock roadway and tunnel and control method thereof

ActiveCN111997642AImprove drilling abilityImprove drilling efficiencyReciprocating drilling machinesConstructionsMachine partsMachine

The invention belongs to the technical field of coal mine roadway tunneling and tunnel construction equipment, and discloses an excavation and anchoring all-in-one machine used for an all-rock roadwayand a tunnel and a control method of the excavation and anchoring all-in-one machine. A walking part is connected to the lower side of a body part, a rear supporting part is connected to the lower end of the rear side of the body part, a shovel plate part is connected to the front end of the body part, and a first conveyor part communicating with the shovel plate part is arranged in the middle ofthe body part. The front end of the upper side of the body part is connected with a cutting part. The upper portion of the cutting part is provided with a first platform supporting part and a secondplatform supporting part. The left side and the right side of the body part are connected with sliding rail type anchor rod machine parts. The front ends of the sliding rail type anchor rod machine parts are connected with impact type hydraulic anchor rod drilling machines. The impact type hydraulic anchor rod drilling machine is adopted to achieve the full-rock roadway or tunnel with the hardnessof more than or equal to 6, the ultra-strong drilling capability is achieved, and the drilling efficiency is improved. A cantilever type heading machine is integrated with the impact type hydraulic anchor rod drilling machines and an anchor rod supporting platform, so that the problem of single operation of roadway tunneling and anchor rod supporting is solved.

Owner:山西晟特恒采矿工程机械有限公司

Visual feeding manipulator

PendingCN111792365ANo need for manual positioningHigh degree of generalizationStorage devicesConveyor partsControl engineeringManipulator

The invention provides a visual feeding manipulator. The visual feeding manipulator comprises a mounting base, a feed table part, a blade turnover part and a material taking and discharging manipulator part, wherein the feed table part is mounted on one side of the mounting base, and comprises a material tray moving shaft and a material tray supplying box; the material tray supply box is mounted on the material tray moving shaft in a sliding manner; the blade turnover part is mounted on the top side of the mounting base and comprises a bracket base plate, a blade surface turning over part anda blade corner part; and the material taking and discharging manipulator part comprises a Z1 shaft, a C shaft, a vision part, an X1 shaft, a manipulator pressure head and a Y1 shaft. The visual feeding manipulator provided by the invention has the advantages that the visual feeding manipulator can place one thousand or more of processed products, can perform continuous operations all the day, is free from replacement of a material tray, is free from placing positioning on blades, and directly adopts visual positioning, the participation rate of staff can be greatly reduced, the production efficiency can be improved, and the production cost can be reduced.

Owner:东莞市卡丁精密机械有限公司

Spherical crystal polishing device capable of automatically adjusting rotating speed

InactiveCN112496949ASimple structureEasy to operateGrinding carriagesSpherical surface grinding machinesPhysicsEngineering

The invention discloses a spherical crystal polishing device capable of automatically adjusting the rotating speed. The spherical crystal polishing device comprises a main body, wherein a working cavity is formed in the main body, a polishing cavity is formed in the right side of the working cavity in a communicating mode, a polishing assembly is arranged in the polishing cavity, a first clamp cavity is formed in the left side of the working cavity in a communicating mode, a second clamp cavity is formed in the left side of the first clamp cavity in a communicating mode, and clamp assemblies are arranged in the first clamp cavity and the second clamp cavity. According to the spherical crystal polishing device, a crystal is clamped by clamps on the upper side and the lower side, a clamp motor is started, the crystal is alternately clamped by the clamps on the front side and the rear side and the clamps on the upper side and the lower side, the crystal is driven to rotate and be polishedwhen the crystal is clamped by the clamps on the front side and the rear side, the crystal is driven to reverse when the crystal is clamped by the clamps on the upper side and the lower side so thateach surface of the crystal can be polished, the surface roughness of the crystal is detected through a friction block during polishing, and the more rough the surface is, the higher the rotating speed of a polishing block is.

Owner:宿迁密香凌商贸有限公司

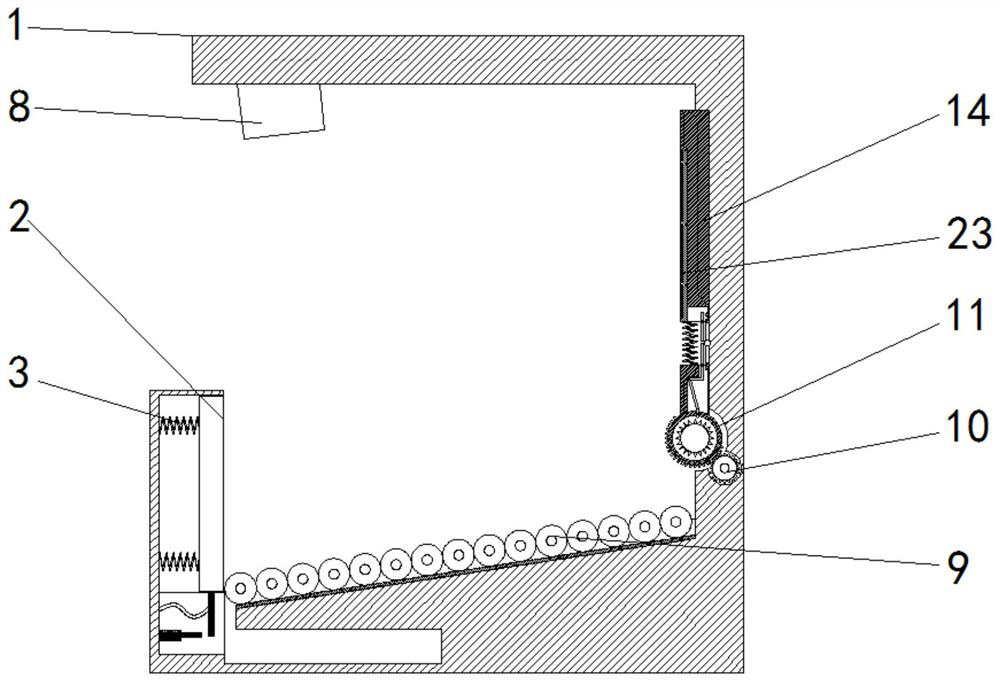

Continuous saw cutting device of cast ingot

InactiveCN111958044AGuaranteed frictionRealize the purpose of continuous feedingMetal sawing devicesStructural engineeringIngot

The invention provides a continuous saw cutting device of a cast ingot. The continuous saw cutting device comprises an underframe, a working table, a bracket, a lifting cylinder, an outer casing, an electric motor, a slide rail, a slider, a saw cutting blade, a driven connecting rod and a driving connecting rod, wherein the working table is connected into the underframe in a sliding manner, the bracket is arranged in the middle of the underframe, the cylinder is arranged on the inner top surface of the bracket, the outer casing is fixedly connected with an output shaft of the lifting cylinder,the electric motor is located in the outer casing, the slide rail is arranged at the top in the outer casing, the slider is connected into the outer casing in a sliding manner, the saw cutting bladeis connected into the slide rail through a slide seat in a sliding manner, the slide seat is fixedly connected with the slider, one end of the driven connecting rod is rotationally connected onto theslider, one end of the driving connecting rod is rotationally connected with the other end of the driven connecting rod, and besides, the other end of the driving connecting rod is fixedly arranged atthe output end of the electric motor; and the working table is connected to the interior of the underframe through a feeding mechanism in a sliding manner. The continuous saw cutting device of the cast ingot carries out continuous saw cutting on the cast ingot until sequential saw cutting operation is completed.

Owner:匠桥智谷科技(涡阳)有限公司

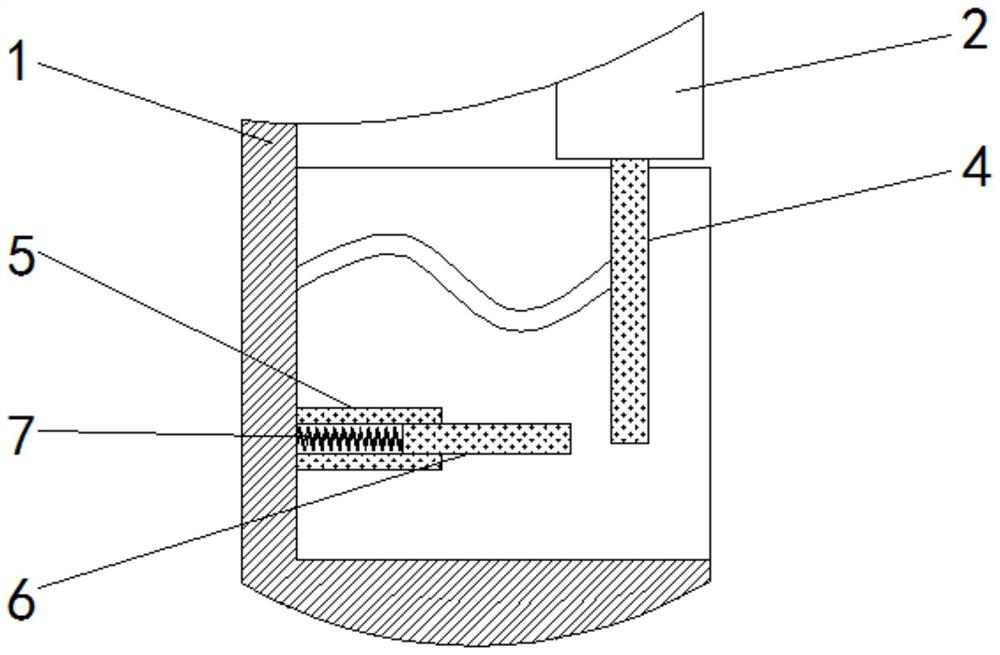

Contact detection type water spraying mechanism

InactiveCN112715334AReduce consumptionRapid positioningWatering devicesCultivating equipmentsWater resourcesEngineering

The invention discloses a contact detection type water spraying mechanism. The contact detection type water spraying mechanism comprises a box body, a detection box, a partition plate, an electromagnet, a first guide rod, an armature, a first spring, a clamping head, a rotating pin, a swing rod, a second guide rod, an arc-shaped contact head, second springs, water spraying mechanism bodies and a proximity switch. When a vehicle performs water replenishment operations, the arc-shaped contact head and a landscape guardrail are in contact to be stressed to push the second guide rod to slide along the swing rod, and when a detection block triggers the proximity switch, the electromagnet the armature are attracted to drive the clamping head fixedly connected with the first guide rod to move upwards to be separated from the swing rod, the swing rod rotates along the rotating pin, and at the moment, water is pumped into the water spraying mechanism. Water lines sprayed by a plurality of spray heads form an annular three-dimensional coating structure, and therefore, water supplementing operations are performed on green plants under the condition that the water consumption is reduced. The mechanism is simple in structure, through contact type detection and positioning, the landscape guardrail can be rapidly positioned, manual positioning is not needed, connection is improved, besides, annular three-dimensional water spraying is adopted, and consumption of water resources is reduced.

Owner:马鞍山盛凡智荣信息技术有限责任公司

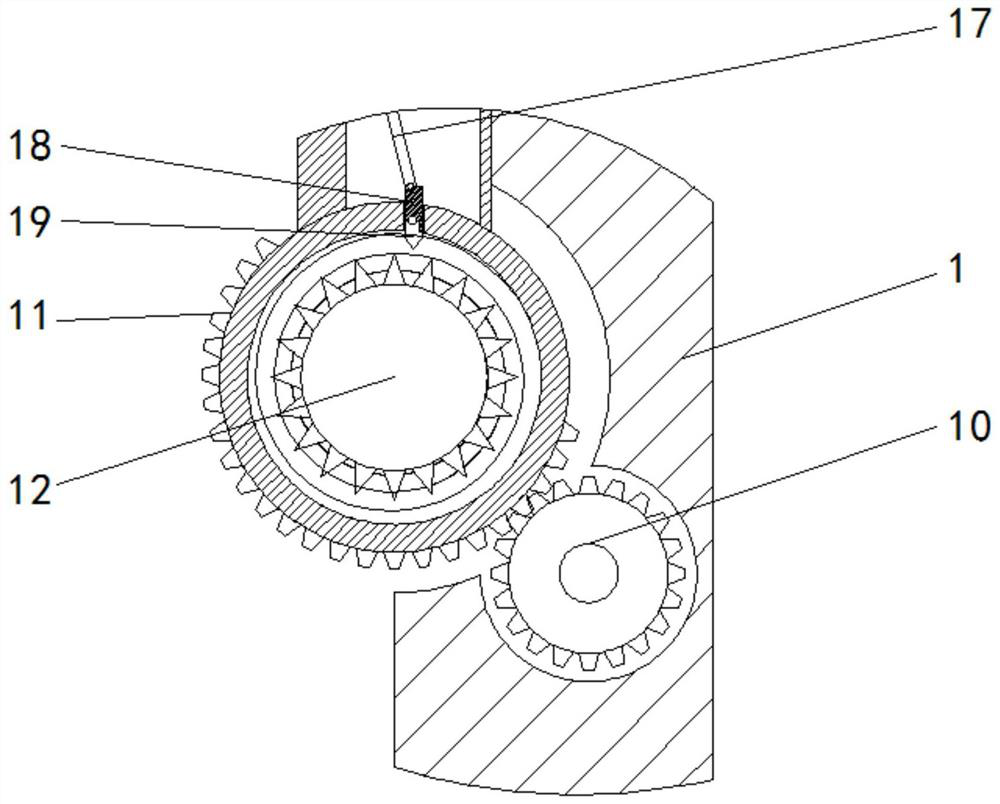

Express high-speed bar code scanning equipment capable of accurately scanning codes

PendingCN111814505AScan code automaticallyNo need for manual positioningSensing by electromagnetic radiationRatchetDrive wheel

The invention relates to the technical field of Internet of Things equipment. The invention further discloses express high-speed bar code scanning equipment capable of accurately scanning codes. Whichcomprises a machine frame, the inner wall of the rack is slidably connected with a sensing plate. A driving wheel is fixedly connected to the right side of the inner wall of the rack; a rotating wheel is meshed with the top of the driving wheel, a ratchet wheel is fixedly connected to the interior of the rotating wheel, a connecting spring is fixedly connected to the top of the rotating wheel, aswing rod is movably connected to the top of the rotating wheel, a connecting rod is movably connected to the left side of the swing rod, a pawl is movably connected to the bottom of the connecting rod, and a swing claw is movably connected to the bottom of the pawl. According to the high-speed bar code scanning equipment capable of accurately scanning the codes for the express delivery, the express delivery is guided into the leftmost side through the rolling wheels, the express delivery presses the sensing touch plate to move leftwards, the sensing touch plate drives the guide rod to move leftwards, and then the guide rod and the sliding rod are used in cooperation, so that the effects of automatic code scanning and no need of manual positioning are achieved.

Owner:章叔贞

Axial safety positioning device for hub machining

ActiveCN114248192AAvoid human errorReduce riskEdge grinding machinesPolishing machinesPhysicsElectric machinery

The invention belongs to the technical field of positioning and fixing for automobile hub machining, and particularly relates to a hub machining axial safety positioning device which comprises a workbench, a mounting seat is fixedly connected to the workbench, the mounting seat is of a hollow structure, a motor is fixedly mounted in the mounting seat, a rotating seat is arranged on the mounting seat, and the rotating seat is fixedly connected with the workbench. The output end of the motor is connected with a rotating shaft through a coupler, the upper end of the rotating shaft is fixedly connected with the bottom of a rotating seat, and a positioning mechanism used for positioning a hub is arranged on the rotating seat. The positioning mechanism comprises a rotating disc fixedly connected to the rotating base, and a plurality of sliding grooves distributed in an annular array are formed in the peripheral side wall of the rotating disc. The positioning plates can make contact with and abut against the inner wall of the hub through centrifugal force, adjustment is automatically conducted according to the inner diameter of the hub, positioning of the hub is achieved, the positions of the positioning plates are further stabilized through electrorheological fluid, and then the hub is fixed more stably and stably.

Owner:宁波自由者汽车部件有限公司

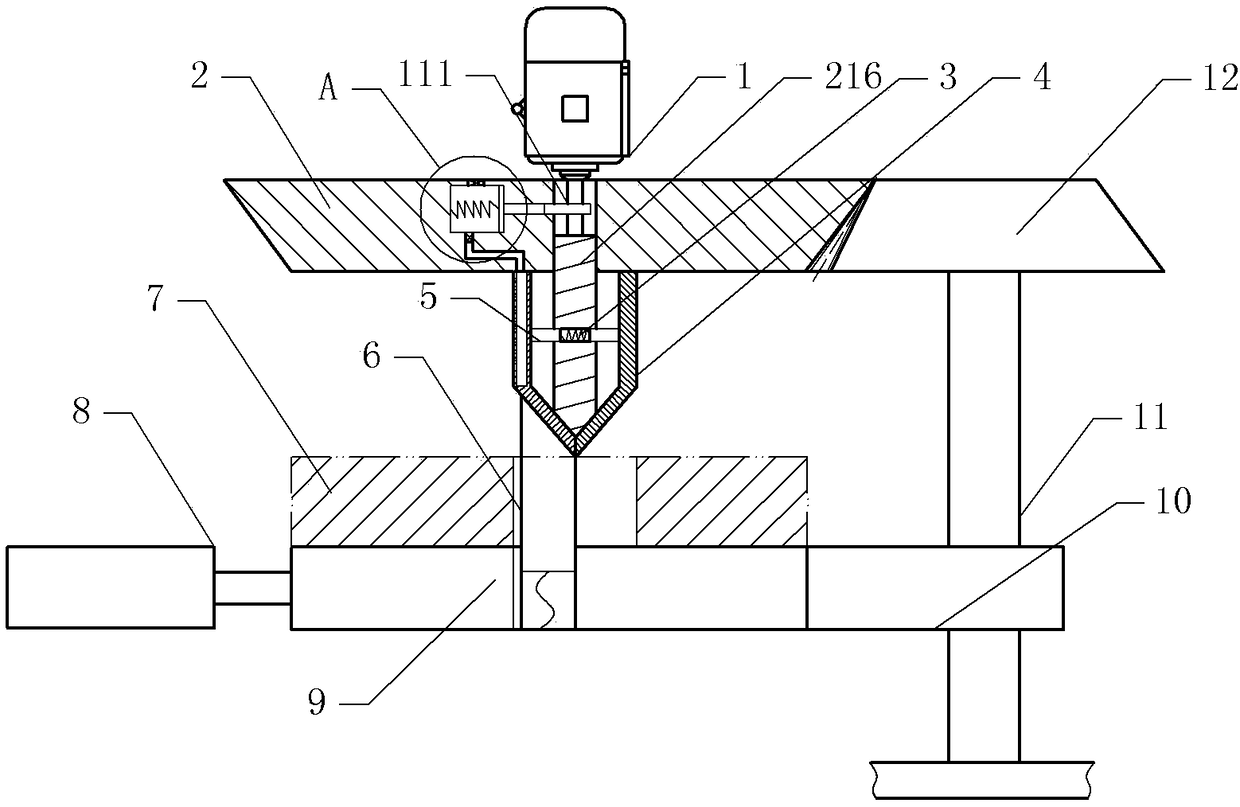

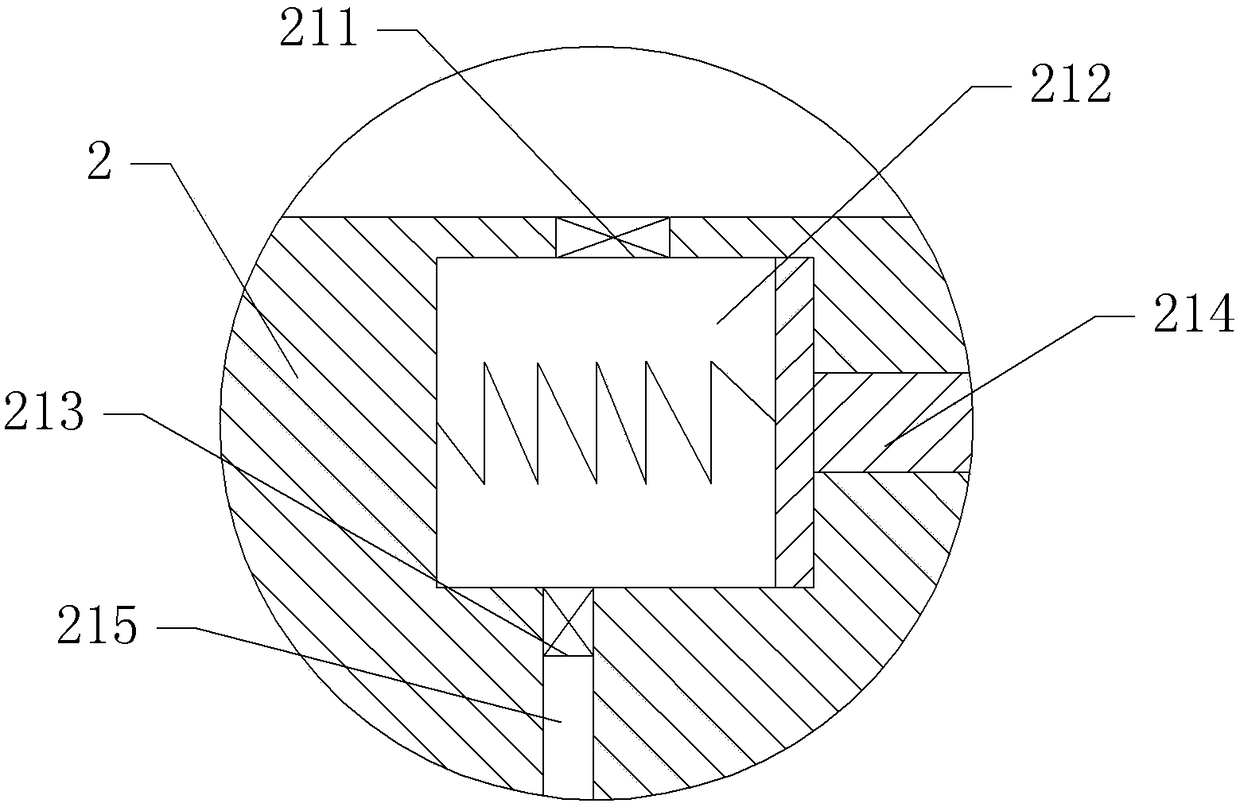

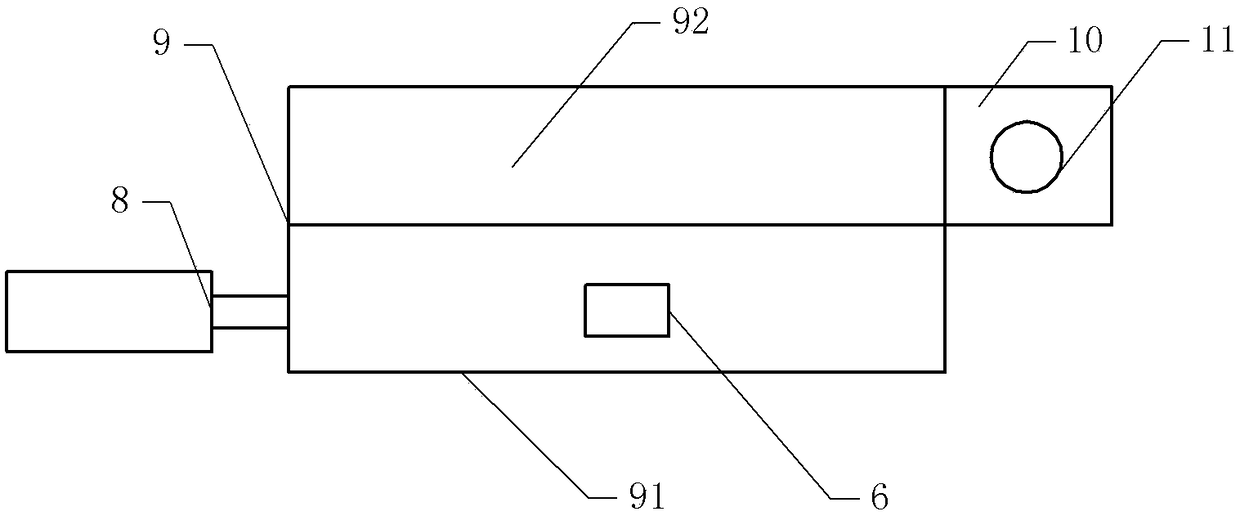

A screw safety assembly equipment capable of automatic feeding and synchronous loading and unloading of workpieces

ActiveCN103386606BReduce manual operationsIncrease productivityMetal working apparatusSet screwPower apparatus

The invention discloses a safe screw assembling device capable of automatically feeding and synchronously assembling and disassembling workpieces, comprising a stand, a power device, a spinning tool feed unit, a spinning tool engaging and disengaging mechanism, a fastening screw guide device, an angle adjusting workbench, an automatic base feed unit and a synchronous base assembling and disassembling device. A mode that the piston rod of an air cylinder drives a push rod to enter and exit is adopted, an interior mirror base is automatically fed into a station, manual operation steps are saved, and the production efficiency is greatly increased; due to the adoption of the spinning tool engaging and disengaging mechanism, the required thread spinning length can be precisely realized, and meanwhile, screw holes are effectively prevented from being damaged by screwing or screws are effectively prevented from sliding; the rotating speed of a spinning tool can be changed along with the replacement of a speed reducing belt pulley, and the applicable range is wide; a fastening screw needs not to be positioned manually and can be precisely positioned by an operator through throwing the fastening screw in the fastening screw guide device along the approximate direction, and the labor intensity of the operator is effectively reduced; the assembled interior mirror base can be automatically detached, the production efficiency is further improved, and the labor intensity is further reduced.

Owner:GUANGXI UNIV

Grinding device for auto parts

ActiveCN108406479BAchieve grindingPrecise penetrationEdge grinding machinesGrinding drivesElectric machineryStructural engineering

Owner:涟源市普东汽车配件铸造有限公司

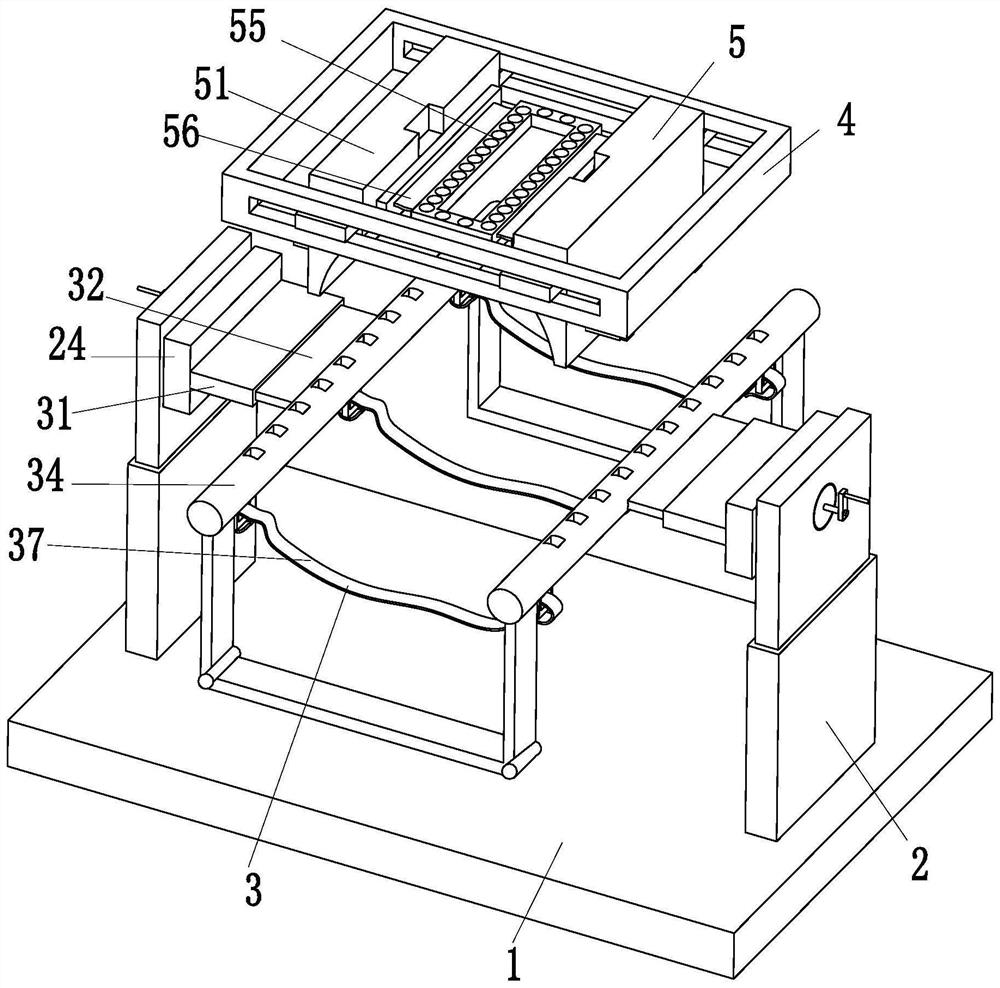

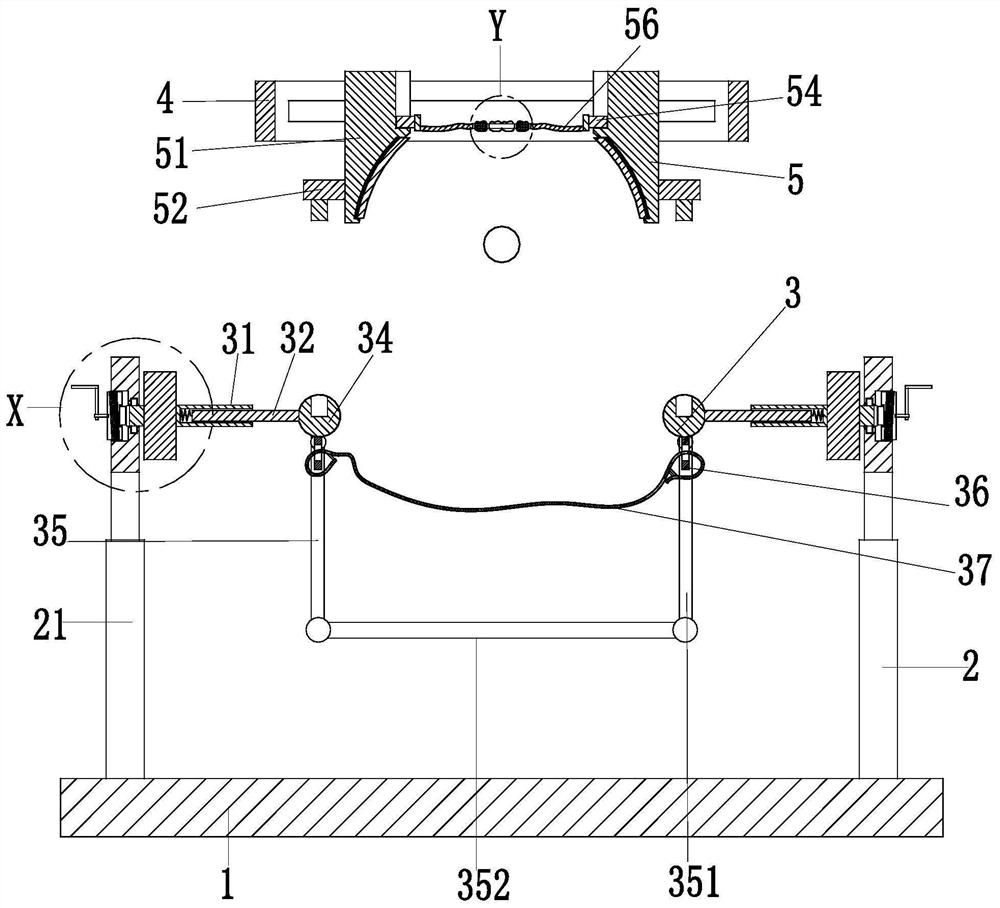

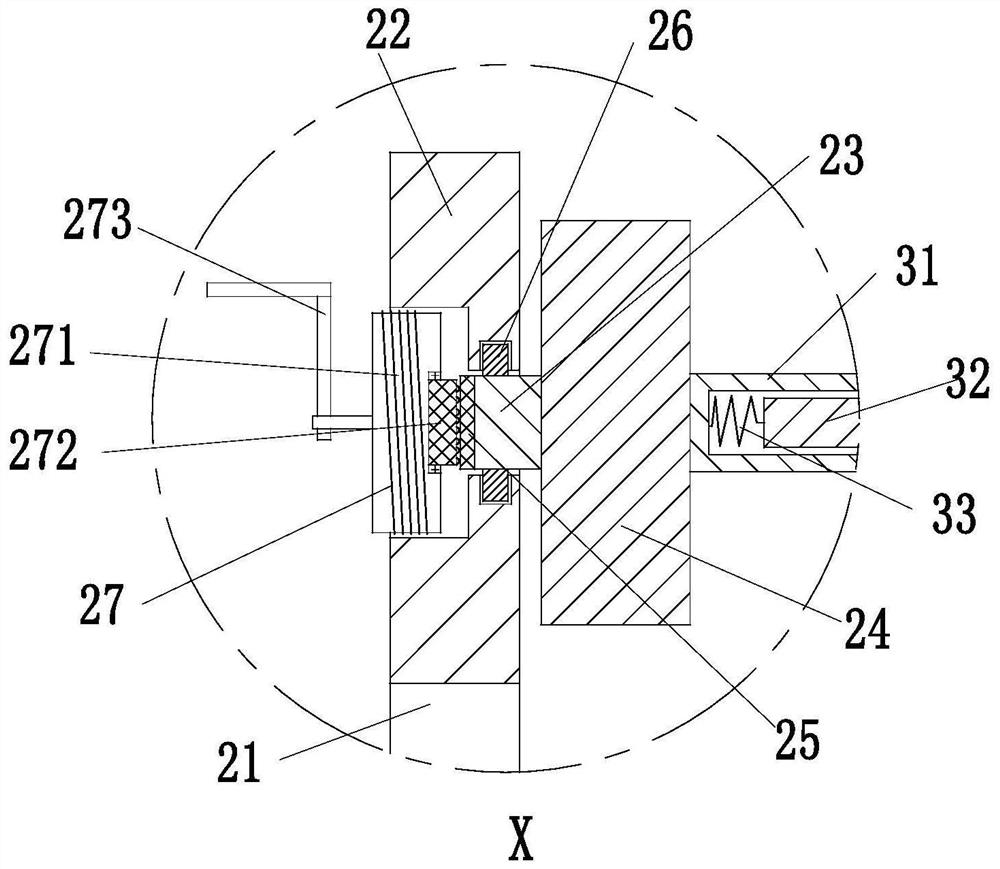

Fitting device and method for single-frame membrane electrode assembly of fuel cell

The invention belongs to the technical field of fuel cells, and particularly relates to a fuel cell single-frame membrane electrode assembly laminating device and method. The device comprises a frame positioning assembly and a proton exchange membrane positioning assembly, a bottom membrane is fixed on the frame positioning assembly, and a boundary structure is arranged on the proton exchange membrane positioning assembly. The method comprises the following steps: positioning a bottom film according to a boundary structure, and transferring and adhering the bottom film to a frame positioning assembly; a frame is taken and placed on the frame positioning assembly with the adhesive face of the pressure-sensitive adhesive facing upwards, and the pressure-sensitive adhesive on the frame is positioned through a bottom film; placing the proton exchange membrane on the proton exchange membrane positioning assembly, and positioning the proton exchange membrane by using the boundary structure; the proton exchange membrane positioning assembly and the frame positioning assembly are closed, and the frame is attached to the proton exchange membrane. The invention provides the fuel cell single-frame membrane electrode assembly laminating device and method which are accurate in positioning, better in sealing effect and simple in preparation process.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

Device for preventing oil injection pump from falling off

PendingCN111022229AAchieve positioningPrecise positioningMachines/enginesFuel injecting pumpsEngineeringInjection pump

The invention discloses a device for preventing an oil injection pump from falling off, relates to the technical field of engine assembly, and solves the technical problem of poor reliability of manual positioning. The device comprises a positioning rod, wherein the positioning rod is detachably provided with at least two positioning pins, one side of the positioning rod is provided with a first supporting connecting rod, the end part of the first supporting connecting rod is provided with a second supporting connecting rod, and the end part of the second supporting connecting rod is providedwith a front-back adjustable positioning assembly. The device is reasonable in structure, convenient to use and simple and rapid to operate, manual positioning is not needed, reliability is high, assembly efficiency is effectively improved, and production requirements are met.

Owner:GUANGXI YUCHAI MASCH CO LTD

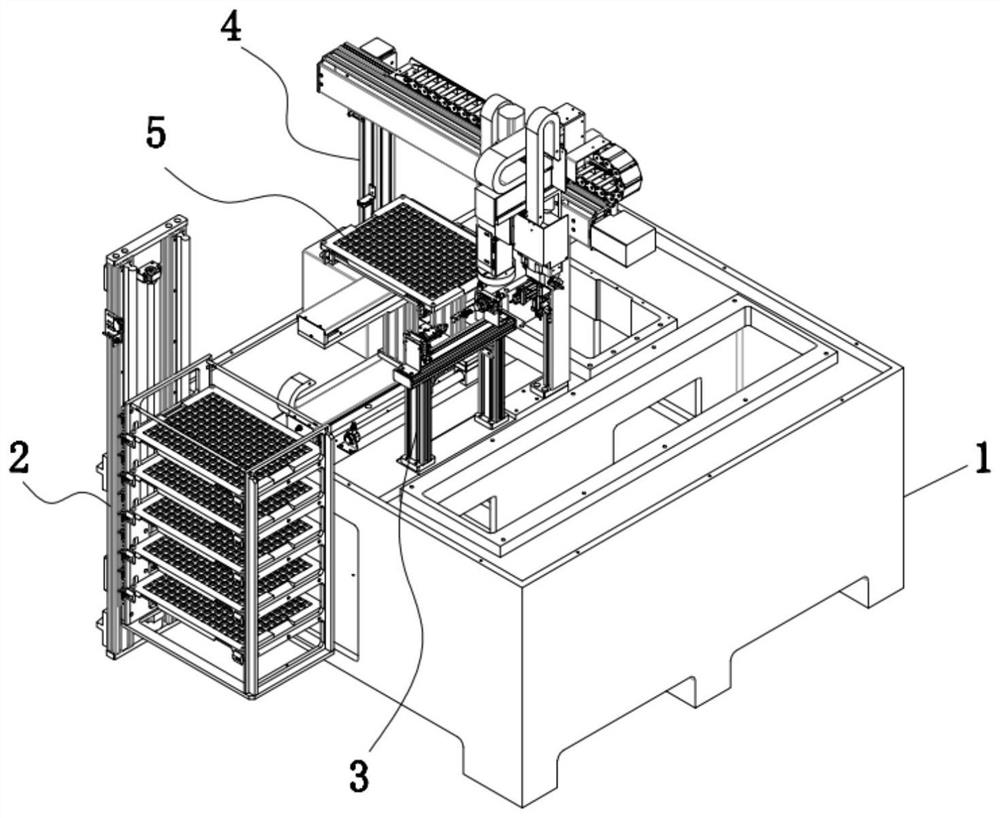

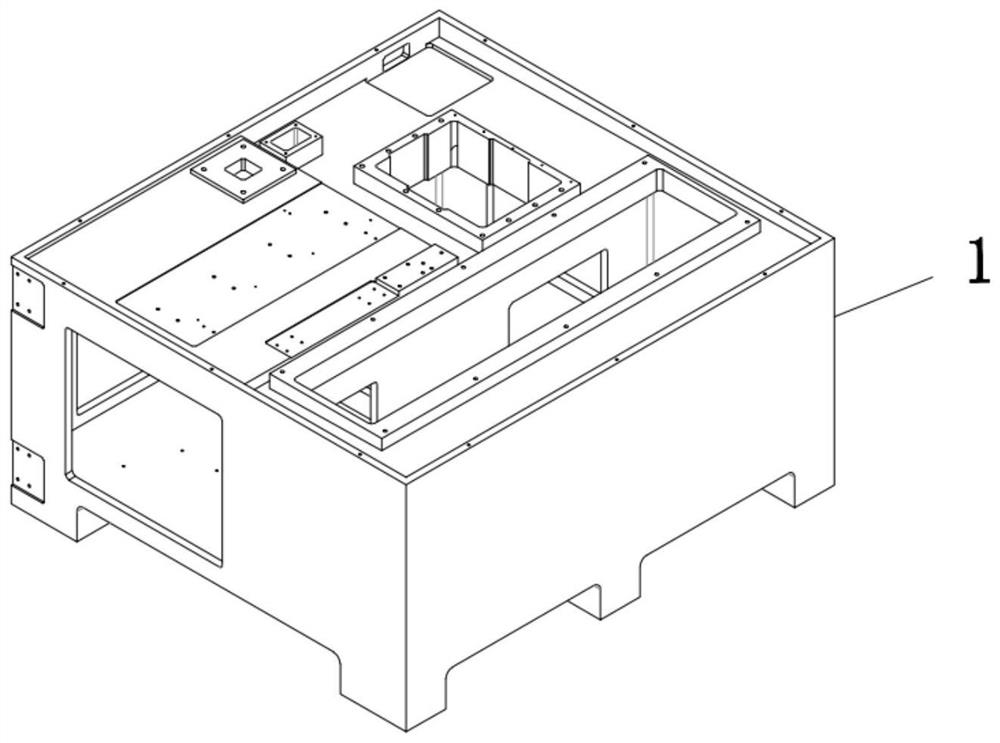

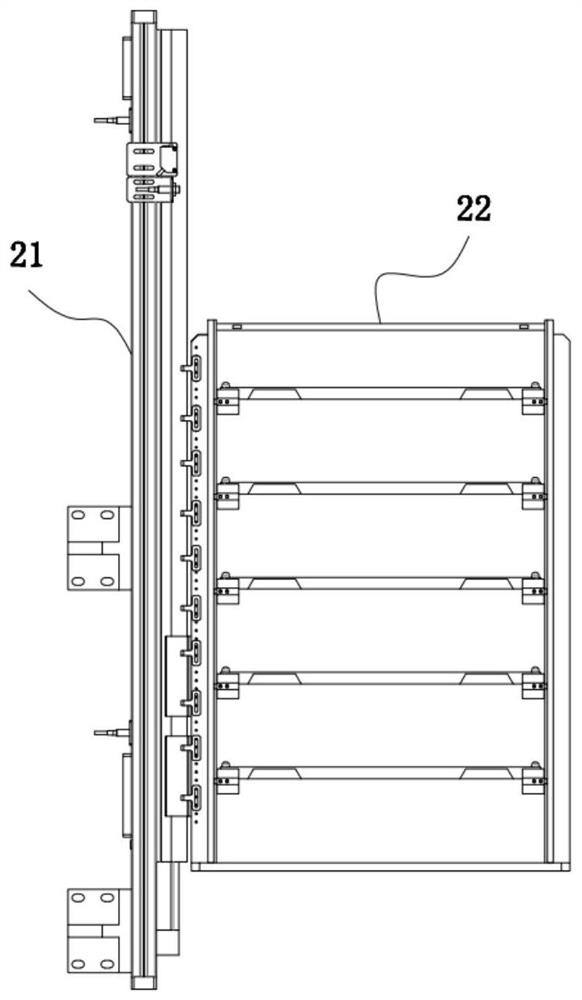

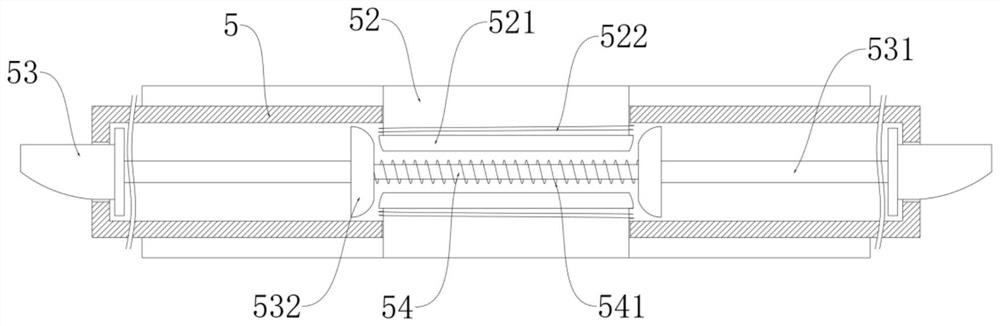

A flying probe testing machine and its flying probe module

ActiveCN113607984BFast loadingIncrease the feeding speedConveyorsElectrical testingStructural engineeringMachine

The invention discloses a flying probe testing machine, which includes a machine base, a plurality of support rods are equidistantly and symmetrically installed on one side of the support rod, and double surrounding rails are jointly installed on the upper ends of the plurality of support rods. A transport frame is installed on the base, and a belt conveyor is installed in the transport frame; the invention also discloses a flying probe module, which includes a driver installed on a screw rod, and a slide rail column is installed on one side of the driver , two square slide holes are symmetrically opened in the slide rail column. The present invention realizes the automatic cycle feeding through the cooperation of the double surrounding rails and the pinch pipe, the transmission disc and the transmission chain, realizes the functions of automatic straightening, automatic fixing and automatic positioning through the guide splint, the controllable baffle and the inner concave calibration roller, and through the separation Realize automatic sorting to the board, which is more efficient and reduces labor force. The half-split contact pin combined with conductive shrapnel and insulation realizes low-voltage and low-impact contact, reducing the possibility of damaging the circuit board.

Owner:昆山兢美电子科技有限公司

Frame edge flatness detection auxiliary equipment for furniture panel manufacturing

InactiveCN114353650ASmooth transmissionNo need for manual positioningMechanical roughness/irregularity measurementsGear wheelRack and pinion

The invention relates to the technical field of furniture panel manufacturing, and discloses a frame edge flatness detection auxiliary device for furniture panel manufacturing, which comprises a shell, a support frame is fixedly connected in the shell, an elastic piece is fixedly connected to the surface of the support frame, and a detection piece is movably connected to the joint of the elastic piece and the support frame. The end, away from the supporting frame, of the elastic piece is movably connected with a roller, and the upper and lower sides of the detection piece are movably connected with linkage shafts. The rollers are stressed to extrude the reset springs, the reset springs are pressed to push the racks to move, the racks move to be in meshed contact with the gears so as to push the gears to rotate, the gears rotate to drive the linkage shafts to rotate, and the rotating linkage shafts can keep the rollers at the two ends to rotate at the same speed. And the rotating speeds of the rollers are the same, so that the influence of uneven particles on the surface of the wood can be avoided, namely the wood can be stably conveyed, and the effect of stably conveying and cutting without manual positioning is achieved.

Owner:徐州申通木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com